Professional Documents

Culture Documents

PB 52 File Slug Catcher

PB 52 File Slug Catcher

Uploaded by

Gonzalo Arabey SañezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PB 52 File Slug Catcher

PB 52 File Slug Catcher

Uploaded by

Gonzalo Arabey SañezCopyright:

Available Formats

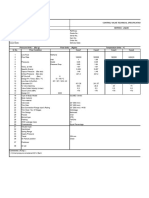

SLUG CATCHER

TECHNICAL BULLETIN

The scope of the slug catcher is the separation of a two-phase flow. The two-phase stream flow from the pipeline enters the slug catcher section at about 11.5 m elevation from ground. The last part of the pipeline is also flanged pieces of pipe slightly sloped downward to permit the liquid to accumulate and be separated. When the flow comes to the separator inlet, the first separation occurs between the gas that flows in the separator and the liquids that goes straight to the end section of the pipeline where it is discharged by a level control valve. The gas phase flows through the separator and the demisters where the remaining entrained liquids are separated to the bottom of the vessel and returned into the pipeline section (liquid section). Any excess gas retained in the liquid section is returned to the separator with the equalizer line.

The demister space can be divided into multi equivalent sections with separate gas outlets and washing devices. If salt or pipeline solids plug the demisters, it is possible to wash one section at a time, while the other sections continue to work. If the amount of liquid phase increases, it is possible to add a flanged piece of pipe at the end of the pipeline to accommodate the unexpected flow increase. To sum up the main features of our proprietary slug catcher are the following: If the liquid flow increases it is possible to handle the unexpected liquid stream simply by adding flanged pieces of pipe as needed; The plugging of the demister will not stop the operation.

GAS GAS GAS

1 - 1.5

parent company

Tozzi Sud S.p.A.

contacts

Headquarter: Via Zuccherificio, 10 48010 Mezzano RA Italy Tel. +39.0544.525050 Fax +39.0544.525099 World Offices: Houston USA Caracas VENEZUELA Cairo EGYPT Tripoli LYBIA Aksai KAZAKHSTAN Web site: www.tozzisud.com/comart E-mail: comart@tozzisud.com

You might also like

- ISO 9624 2019 Amd 1 2021Document7 pagesISO 9624 2019 Amd 1 2021Mayuresh GawadeNo ratings yet

- En 12220-1998 Ventilation For Buildings - Ductwork-Dimensions of Circular Flanges For General VentilationDocument10 pagesEn 12220-1998 Ventilation For Buildings - Ductwork-Dimensions of Circular Flanges For General Ventilationcostas matsangosNo ratings yet

- DRS - Operation & Control PhilosophyDocument5 pagesDRS - Operation & Control PhilosophyAnand GNo ratings yet

- Two Phase SeparatorDocument67 pagesTwo Phase SeparatorRaden MasNo ratings yet

- LiquidDocument2 pagesLiquidsiddhesh_guessNo ratings yet

- ASME VIII Div II - 2010 - InglésDocument4 pagesASME VIII Div II - 2010 - InglésAlex García ZamudioNo ratings yet

- API Specification 6D 24th Edition Errata 10 20210803Document1 pageAPI Specification 6D 24th Edition Errata 10 20210803ANANDNo ratings yet

- Stuewe 201708 Catalogue Type-HsdDocument25 pagesStuewe 201708 Catalogue Type-HsdJorge A VilalNo ratings yet

- Caesar Newsletter Timehistory AnalysisDocument16 pagesCaesar Newsletter Timehistory AnalysisNixonNo ratings yet

- Gear Box No Load Run Test ReportDocument1 pageGear Box No Load Run Test ReportPRABHUDAYAL SHARMANo ratings yet

- 800D SeriesDocument3 pages800D Seriesvkeie0206No ratings yet

- Iso 16904-2016Document78 pagesIso 16904-2016ejrfjxhjtntauuwtfcNo ratings yet

- ASME Section 1 and Pressure Equipment DirectiveDocument5 pagesASME Section 1 and Pressure Equipment DirectivealextentwentyNo ratings yet

- Jun 94Document16 pagesJun 94Ashok KumarNo ratings yet

- 2632 PL DS 001 Line PipeDocument3 pages2632 PL DS 001 Line PipeAdvisNo ratings yet

- PIPEMILL - Piping Engineering, Design and AnalysisDocument1 pagePIPEMILL - Piping Engineering, Design and Analysisfahid masoodNo ratings yet

- IMIOrton MV SeriesDocument4 pagesIMIOrton MV SeriesFelipe Gamboa GálvezNo ratings yet

- Reciprocating: CompressorDocument12 pagesReciprocating: CompressorAkbar HartawanNo ratings yet

- Ghibson GB015Document2 pagesGhibson GB015Jessicalba LouNo ratings yet

- Liquid Monopropellant CombustionDocument4 pagesLiquid Monopropellant Combustionherdi sutanto adigunaNo ratings yet

- Chapter 12 - Wave Forces On Slender CylinderDocument78 pagesChapter 12 - Wave Forces On Slender CylinderJuan Carlos GonzálezNo ratings yet

- Test Report Long-Term Ring Bending Strain (SB)Document4 pagesTest Report Long-Term Ring Bending Strain (SB)Diana QuinteroNo ratings yet

- Pipes FittingsDocument7 pagesPipes FittingsTushar ArekarNo ratings yet

- Composite Construction Works For CNG Station at Kovvur, West Godavari District, A.PDocument209 pagesComposite Construction Works For CNG Station at Kovvur, West Godavari District, A.Pvinay1999No ratings yet

- Importing Nozzle Loads From Autopipe Into Autopipe NozzleDocument3 pagesImporting Nozzle Loads From Autopipe Into Autopipe NozzlegchammaNo ratings yet

- CSP FlexDocument4 pagesCSP FlexBhoomaiah Sunkenapalli100% (1)

- Relief Valve: RVP Metal Seat Relief Valves Series RVPDocument4 pagesRelief Valve: RVP Metal Seat Relief Valves Series RVPsnipertombNo ratings yet

- DBB CatalogueDocument28 pagesDBB CatalogueHeri SetyantoNo ratings yet

- Mil C 16173Document28 pagesMil C 16173Lokesh Narasimhaiah100% (1)

- Pneumatic, Piston Type: Needle Valve ActuatorsDocument20 pagesPneumatic, Piston Type: Needle Valve Actuatorsarif fadhillahNo ratings yet

- BS 7491-3-1994Document18 pagesBS 7491-3-1994FathyNo ratings yet

- Vacuum PerliteDocument8 pagesVacuum PerlitePhilippe GhyselNo ratings yet

- Astm Material TableDocument1 pageAstm Material TableSatish Kumar MauryaNo ratings yet

- PETRO TCS Ops Manual 700-40 45Document52 pagesPETRO TCS Ops Manual 700-40 45paulm3565No ratings yet

- Hyundai Pump SUBMERGED C PUMP PDFDocument10 pagesHyundai Pump SUBMERGED C PUMP PDFZuzanna Kat-ToporskaNo ratings yet

- Side Mounted HandwheelDocument20 pagesSide Mounted HandwheelaaaNo ratings yet

- TEMA Eighth Edition - ClarificationsDocument13 pagesTEMA Eighth Edition - ClarificationsJerome100% (1)

- EJMA Bellows CalculatorDocument3 pagesEJMA Bellows CalculatorJulian MorantesNo ratings yet

- BS EN 12542 - 2010 LPG Equipment and Accessories. Static Welded Steel Cylindrical Tanks, Serially Produced For The Storage of Liqu - Libgen - LiDocument66 pagesBS EN 12542 - 2010 LPG Equipment and Accessories. Static Welded Steel Cylindrical Tanks, Serially Produced For The Storage of Liqu - Libgen - LiRinnoNo ratings yet

- Steam Tracing AppendixDocument13 pagesSteam Tracing AppendixAmin BagheriNo ratings yet

- Data Sheet QOCDocument1 pageData Sheet QOCAnonymous qUMJ27ITQsNo ratings yet

- Weldingguide ENG PDFDocument518 pagesWeldingguide ENG PDFkamals55No ratings yet

- Glassflake Lining Metal TanksDocument5 pagesGlassflake Lining Metal TanksSimbu ArasanNo ratings yet

- Dynamic Behavior of Closed-Loop Control SystemsDocument24 pagesDynamic Behavior of Closed-Loop Control SystemsBhowmickNo ratings yet

- Codap 2005 Division 1 Accueil SNCTDocument45 pagesCodap 2005 Division 1 Accueil SNCTbecemNo ratings yet

- Erection Tank MethodDocument1 pageErection Tank MethodAndre YosiNo ratings yet

- MS 01 168Document12 pagesMS 01 168Rawn BushNo ratings yet

- Example E4.3.1Document6 pagesExample E4.3.1Dario100% (1)

- CalcvesselDocument11 pagesCalcvesselHami Keserci100% (2)

- Pig Trap End Closure105671465 PDFDocument24 pagesPig Trap End Closure105671465 PDFashishNo ratings yet

- DeepWater Nu-Bolt OrderDocument1 pageDeepWater Nu-Bolt OrderPaulNo ratings yet

- Instruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Document8 pagesInstruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Ramon GarciaNo ratings yet

- Numerically Efficient Modified Runge-Kutta Solver For Fatigue Crack Growth AnalysisDocument8 pagesNumerically Efficient Modified Runge-Kutta Solver For Fatigue Crack Growth AnalysisMuhammad Ahsan SaleemNo ratings yet

- Flange Design: Welding UnitsDocument0 pagesFlange Design: Welding Unitsabhi1648665No ratings yet

- Specification and Requirements For Intelligent Pig Inspection of Pipelines Ver 3.2Document30 pagesSpecification and Requirements For Intelligent Pig Inspection of Pipelines Ver 3.2abomb1524No ratings yet

- IGEM - TD - 3 - Edition 5 - Introduction & ScopeDocument16 pagesIGEM - TD - 3 - Edition 5 - Introduction & ScopeMohamed alatrashNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Slug CatcherDocument3 pagesSlug Catcherwkhan_55No ratings yet