Professional Documents

Culture Documents

Work Method Statement For Coring Works (A)

Work Method Statement For Coring Works (A)

Uploaded by

Ben LimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Method Statement For Coring Works (A)

Work Method Statement For Coring Works (A)

Uploaded by

Ben LimCopyright:

Available Formats

Work Method Statement For Coring Works Plan (Qualitative) Risk Assessment

Work Activity: CORING WORKS FAB LEVEL 3 Date Start: _____________________ No#:___________________ Date End: ___________________

Sequential Steps For Completion Of Work To inform and get approval from IFKM Owner,FMCS,Area Owner, EHS Personal and M+W GROUP Safety Officer. FMCS TEL: 8111 Explain job sequence and hazards to workers before start work To barricade the work area and provide sufficient signages

Potential Hazards Arise From The Work Communication breakdown

Risk Level 1

Safety Precautions/ Preventive Measures To Control The Hazards To arrange Site survey line work together with EHS personal and site management. To ensure that the SAVE WORK PERMIT, authorization related permits are completed before job initiation.

Controlled Risk Level 1

Sequential steps for work completion not followed may cause physical injuries or material damage

TOOL BOX MEETING to be conducted by work supervisor to all workers before work starts.

Mobilization of material, tools and equipment to site manually. (from lorry to work area) Hand Tools Ladder Electrical tools Scaffold Coaring drill

Unauthorized person in the work area Physical injuries to the workers Mobilization of material

Barricade the work area. Place relevant safety signs. Full PPE to be comply, Hardhat, safety shoe, safety glasses and cut resistant gloves &dust mask. Mobilization location to be confirmed with coordinator Temporary storages areas for material to be check with area owners.

ELECTRICAL TOOLS

Electrical hazards

All electrical tools must be check & tagging with prom serf before using. To check the extension wires and power tools condition before use. ELCB is compulsory for electrical usages Power supply points to be identified and get approval from system owners before using.

To wear proper hand glove. To be use scaffoldings & ladder as a temporary working platform Physical injury 2 Dust musk to be worn. To be comply safety glass [ transparent] To be comply buddy system. 2 Ladder safety Use at least one hand to grasp ladder. Top of ladder should never be used as a step. Ladders should never be moved, shifted or extended while occupied. Do not carry an object or load that could cause person to lose the balance. Scaffold Competency 2 The scaffolding erection should be done under the supervision of a competent person who has registered with DOSH. To wrap mobile scaffold Custer wheel with cloth tape before entering epoxy floor. Material for erection and dismantling should be secured with a nylon rope on the erectors safety harness or body. Falling from height 2 Full body harnesses with double lane yard to be wear while Working above 6ft. 1 1 1 1

Falling object

CORING WORKS Electrical Core Drilling Machine specially used at site for coring concrete wall penetration.Features include a side guard and a drainage water outlet. A clamp provided to firmly secure the material during the cutting cycle. Concrete Core drilling involves cutting circular holes and removing core to allow for service such as sprinkler pipe penetration. The procedure involves bolting a drill mast to the concrete surface to be core-drilled. During drilling with a circular drill diamond bit, water from a hose connected to a tap is flushed down the hole to capture dust, remove slurry and keep the drill bit Electrical tools to be checked and tagged. Electrical hazard Trip hazard 2 Electrical tools to comply with ELCB. Ensure work place is accessible and safe to work. Check the site condition of any obstruction, such as, debris and loose or flaking material. Barricade the work zone for maximum radius. Tool should be secured with a nylon rope on the erectors safety harness or body. Full body harnesses to be wear while Working above 6ft. Lane yard to be secured to the solid structure. 1

Falling object

Falling from height

cool. Preparation: . make sure all drill areas have been scanned for electric cable. . check all electrical equipment has current safety tags. . suspend all electric cables safely above floor or ground level. . check all mechanical parts for loose components. . ensure each power cable is fitted with a ELCB. . erect barricades and clear no-entry signs to area where drilling is in progress. To identify the actual location for coaring activity at existing wall and below high raised floor. To drill and coring adequate holes on existing wall by using electrical drill.

Housekeeping to be done throughout the work process.

Trip hazard 2

Keep the work area clear from loose material and debris.

Acknowledgement I understand this work plan requirements and agree that the above proposed work activities will always be accomplished in safe condition, in accordance with the Controlled Measures. All persons under my supervision have been informed. I have reviewed and endorsed that the proposed work will be completed in an effective safe practice and condition. I have been informed that these job activities and all the Preventive measures are appropriate, in place and will be followed. The safety requirements of this Permit have been explained to the Permit Holder and work may proceed with minimal risk. Accepted by IFKM EHS Name: Signature: Date:

Prepared by Project/safety Supervisor Name: Signature: Date:

Accepted by IFKM System Owner Name: Signature: Date:

Qualitative Risk Level: Very Low:1 Low:2 Medium:3 High:4 Very High:5 Risk Level at or above Medium Level requires Control measures (Hierarchy of Control) It shall be the Full Responsibility of Requestor to Explain the Work Plan (Qualitative) Risk Assessment to his worker before job is due to start

You might also like

- Renovations Method StatementDocument6 pagesRenovations Method StatementOfentse Ledwaba100% (2)

- Frameless Glass InstallationDocument4 pagesFrameless Glass InstallationNita Jamnu60% (5)

- Method of Statement For Coring WorkDocument1 pageMethod of Statement For Coring WorkSyazwan Zulkifli100% (2)

- Method of Statement For Pressure Testing ProceduresDocument3 pagesMethod of Statement For Pressure Testing ProceduresBen Lim82% (11)

- Method Statement For ScaffoldingDocument12 pagesMethod Statement For ScaffoldingChirag SharmaNo ratings yet

- Coring MethodologyDocument2 pagesCoring MethodologyOscar Ballarta58% (12)

- Unitech Metro - SAFE WORK METHOD STATEMENT - CARPENTRYDocument3 pagesUnitech Metro - SAFE WORK METHOD STATEMENT - CARPENTRY'David Tee100% (2)

- Method Statement & Risk Assessment For Roller ShutterDocument3 pagesMethod Statement & Risk Assessment For Roller Shutterchandanprakash30100% (1)

- MoveU Exercise Manual Phase 1 - Andrew Dettelbach PDFDocument33 pagesMoveU Exercise Manual Phase 1 - Andrew Dettelbach PDFlubietwixa donekvadorNo ratings yet

- Detailed Lesson Plan in Health (Final Demo)Document4 pagesDetailed Lesson Plan in Health (Final Demo)Maria Gizella Valencia Paa80% (71)

- Method Statement For Roof, Wall and Floor WorkDocument27 pagesMethod Statement For Roof, Wall and Floor WorkĐặng Quang HuyNo ratings yet

- Method Statement For Roller ShutterDocument2 pagesMethod Statement For Roller Shutterchandanprakash30100% (1)

- Sealant Method StatementDocument2 pagesSealant Method Statementamg00773% (11)

- Method Statement For Damp Proof MembraneDocument2 pagesMethod Statement For Damp Proof MembraneSuhaila Namaku100% (1)

- Method Statement For Installation of Wooden Flooring PDFDocument18 pagesMethod Statement For Installation of Wooden Flooring PDFChris EnyinnayaNo ratings yet

- Method Statement For Wall Panels InstallationDocument11 pagesMethod Statement For Wall Panels InstallationChristos LoutrakisNo ratings yet

- Method Statement For Pile BreakingDocument3 pagesMethod Statement For Pile BreakingAnonymous YxBTH8lhZ100% (4)

- Method Statement-Waterproofing System SubstructureDocument6 pagesMethod Statement-Waterproofing System Substructureramtsan33% (3)

- Method of Statement For Pressure Test PDFDocument2 pagesMethod of Statement For Pressure Test PDFBen Lim0% (1)

- Sugar Glider Care Guide PDFDocument2 pagesSugar Glider Care Guide PDFrizal0% (1)

- Hand Book of Poultry Farming and Feed FormulationsDocument3 pagesHand Book of Poultry Farming and Feed Formulationsေကာင္းကင္ တူးမဲ့သူNo ratings yet

- Method of Statement Plumbing WorksDocument3 pagesMethod of Statement Plumbing Workshasan_67648961650% (2)

- Doors Method StatementDocument5 pagesDoors Method StatementTAHER AMMAR100% (2)

- Method Statement Demolition MS 873 Non Load Bearing WallDocument6 pagesMethod Statement Demolition MS 873 Non Load Bearing WallShruti Sinha100% (1)

- Method Statement For Rebar InstallationDocument4 pagesMethod Statement For Rebar InstallationPaul Ladjar100% (2)

- Method Statement For Concreting WorksDocument1 pageMethod Statement For Concreting WorksEncik BadrulNo ratings yet

- Method of Statement For Core Drilling WorksDocument7 pagesMethod of Statement For Core Drilling WorksUgurNo ratings yet

- Metal Fire Door Installation Method StatementDocument1 pageMetal Fire Door Installation Method StatementTAHER AMMARNo ratings yet

- Method Statement For Slab On GradeDocument3 pagesMethod Statement For Slab On Grademustafa75% (4)

- Method Statement For PlasteringDocument14 pagesMethod Statement For Plasteringjameel100% (1)

- Fire Emergency Lights Requirement in Malaysia Write-UpDocument13 pagesFire Emergency Lights Requirement in Malaysia Write-UpBen Lim50% (2)

- Preparation of Pipe Tapping WorksDocument2 pagesPreparation of Pipe Tapping WorksBen Lim100% (1)

- Method Statement: Emergency Contact DetailsDocument9 pagesMethod Statement: Emergency Contact DetailsShazwaniNo ratings yet

- Method Statement CoringDocument1 pageMethod Statement Coringkkk82% (17)

- Method Statement For Conventional Formwork BlogDocument9 pagesMethod Statement For Conventional Formwork BlogMohasin Khan100% (1)

- 2.method Statement Excavation and TrenchingDocument4 pages2.method Statement Excavation and Trenchingشاز إياسNo ratings yet

- Method Statement - Plastering, Dated. Jan. 03. 2007Document5 pagesMethod Statement - Plastering, Dated. Jan. 03. 2007mohamed4879No ratings yet

- Method Statement: For Internal & External Plastering Works: Rev. Date Prepared by Checked & Approved byDocument9 pagesMethod Statement: For Internal & External Plastering Works: Rev. Date Prepared by Checked & Approved byEyutt Hghgh100% (1)

- MS For MasonryDocument23 pagesMS For MasonryThimira Bandara EkanayakeNo ratings yet

- Method Statement For Civil WorksDocument16 pagesMethod Statement For Civil WorksRICHARD FUNUENo ratings yet

- 4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1Document7 pages4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1ABHISHEKNo ratings yet

- AAC Block Masonary - Method StatementDocument2 pagesAAC Block Masonary - Method StatementdawoodnagnurNo ratings yet

- Method Statement For Substructural Waterproofing Works REV 00Document40 pagesMethod Statement For Substructural Waterproofing Works REV 00Bleep News100% (1)

- Method Statement TileDocument10 pagesMethod Statement Tilebeshnu garanaikNo ratings yet

- Method Statement-External Wall PlasteringDocument3 pagesMethod Statement-External Wall PlasteringkrishNo ratings yet

- METHOD STATEMENT Gypsum Board Ceiling Gypsum Partitions Ceiling TilesDocument10 pagesMETHOD STATEMENT Gypsum Board Ceiling Gypsum Partitions Ceiling TilesHARISH ROHANNo ratings yet

- Method of Statement For WaterproofingDocument10 pagesMethod of Statement For WaterproofingJoe PsNo ratings yet

- WMS (Method Statement For Formwork, Reinforcement and Concrete Works)Document9 pagesWMS (Method Statement For Formwork, Reinforcement and Concrete Works)PUI CHEE KHIAN100% (1)

- Method Statement For Cement PlasteringDocument6 pagesMethod Statement For Cement PlasteringYazhisai SelviNo ratings yet

- Method Statement For Hard Barrication InstallationDocument10 pagesMethod Statement For Hard Barrication Installationshamshad ahamedNo ratings yet

- Method Statement For False Ceiling WorkDocument5 pagesMethod Statement For False Ceiling Worktrija_mrNo ratings yet

- MOS of Installation Rise FloorDocument13 pagesMOS of Installation Rise FloorHussam WaleedNo ratings yet

- WMS-HAND EXCAVATION & BACKFILLING - Rev1Document10 pagesWMS-HAND EXCAVATION & BACKFILLING - Rev1nice hossainNo ratings yet

- Bauer - Method of Statement For Glass Wall PartitionDocument8 pagesBauer - Method of Statement For Glass Wall PartitionGeorge VitacionNo ratings yet

- MOS - Plumbing and Sanitary Services Rev. 2Document4 pagesMOS - Plumbing and Sanitary Services Rev. 2KAKANo ratings yet

- Sunken FillingDocument3 pagesSunken FillingASHOKKUMARNo ratings yet

- Method Statement for Formwork, Reinforcement bars and Ready Mix Concrete عامDocument20 pagesMethod Statement for Formwork, Reinforcement bars and Ready Mix Concrete عامM.ZEKEBA0% (1)

- Method Statement For Earth WorkDocument5 pagesMethod Statement For Earth Workgvs raoNo ratings yet

- Inspection & Test Plan (Itp) : Gypsum Board False CeilingDocument1 pageInspection & Test Plan (Itp) : Gypsum Board False CeilingLOPA THANDARNo ratings yet

- MS For Form - WorksDocument8 pagesMS For Form - WorksImho Tep100% (1)

- Method Statement For Tiles InstallationDocument4 pagesMethod Statement For Tiles InstallationVeronica De JesusNo ratings yet

- Method Statement For ScaffoldingDocument3 pagesMethod Statement For Scaffoldingamg007100% (6)

- Method Statement HoldingDocument4 pagesMethod Statement Holdingqoci5koNo ratings yet

- Work Method Statement For Block WorkDocument6 pagesWork Method Statement For Block Workronaldo aguirreNo ratings yet

- Facility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3Document8 pagesFacility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3AldrinNo ratings yet

- Method Statement For Installation-Mv MCC and MotorsDocument3 pagesMethod Statement For Installation-Mv MCC and MotorsAldrige Tatenda VengesaiNo ratings yet

- Method Statement - Installing Solar PV Roof PanelsDocument5 pagesMethod Statement - Installing Solar PV Roof PanelsregalelectricalNo ratings yet

- Directional Drill SafetyDocument7 pagesDirectional Drill SafetyMartahan ManurungNo ratings yet

- Fricton Loss in Valves & FittingsDocument3 pagesFricton Loss in Valves & FittingsBen LimNo ratings yet

- Addressable Fireman Intercom System Write UpDocument3 pagesAddressable Fireman Intercom System Write UpBen LimNo ratings yet

- Carbon Dioxide Fire Suppression SystemDocument9 pagesCarbon Dioxide Fire Suppression SystemBen Lim100% (1)

- Wet Riser Pump-Sets CalculationDocument3 pagesWet Riser Pump-Sets CalculationBen LimNo ratings yet

- 1.1.0 General Description of VESDA Aspirating Smoke Detection SystemDocument9 pages1.1.0 General Description of VESDA Aspirating Smoke Detection SystemBen Lim100% (1)

- Method of Statement For Hydrant Pipe Joining Revised (Collar Joint)Document5 pagesMethod of Statement For Hydrant Pipe Joining Revised (Collar Joint)Ben LimNo ratings yet

- Pyrogen - Design, Operation & Maintenance ManualDocument82 pagesPyrogen - Design, Operation & Maintenance ManualBen Lim100% (2)

- Budget Cost For Fire Protection SystemDocument1 pageBudget Cost For Fire Protection SystemBen LimNo ratings yet

- Description Downcomer SystemDocument1 pageDescription Downcomer SystemBen Lim100% (1)

- Servicing of Powder, Foam, Water and Wetchemical ExtinguishersDocument1 pageServicing of Powder, Foam, Water and Wetchemical ExtinguishersBen LimNo ratings yet

- VesdaDocument6 pagesVesdaBen LimNo ratings yet

- Method of Statement For Addressable Fire Alarm SystemDocument3 pagesMethod of Statement For Addressable Fire Alarm SystemBen Lim80% (5)

- RecycleDocument1 pageRecycleBen LimNo ratings yet

- MineralsDocument2 pagesMineralsgnana deepNo ratings yet

- Reliability and Validity of The Ocular Surface Disease IndexDocument7 pagesReliability and Validity of The Ocular Surface Disease Indexpompoo posmmspNo ratings yet

- Disaster RiskDocument20 pagesDisaster RiskMariane Orola CaduyacNo ratings yet

- Microsaw and Piezosurgery in Harvesting Mandibular Bone Blocks From The Retromolar Region: A Randomized Split-Mouth Prospective Clinical TrialDocument8 pagesMicrosaw and Piezosurgery in Harvesting Mandibular Bone Blocks From The Retromolar Region: A Randomized Split-Mouth Prospective Clinical TrialdivyaNo ratings yet

- Usman Pharmacy Nowshera VirkanDocument5 pagesUsman Pharmacy Nowshera VirkanShani ShaniNo ratings yet

- Ece 1101 - Engineering Lab I Course Outline Sem IiDocument6 pagesEce 1101 - Engineering Lab I Course Outline Sem Iibelkhair ahmedNo ratings yet

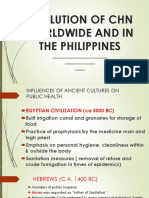

- Evolution of CHN Worldwide and in The PhilippinesDocument17 pagesEvolution of CHN Worldwide and in The PhilippinesBethrice MelegritoNo ratings yet

- Stock Up & Stock Out - SMU024-PDF-EnGDocument9 pagesStock Up & Stock Out - SMU024-PDF-EnGSathiyamoorthy DuraisankaranNo ratings yet

- Resume of S. Sawvik Mittra: Career ObjectivesDocument4 pagesResume of S. Sawvik Mittra: Career ObjectivesSawvik MittraNo ratings yet

- 266-File Utama Naskah-502-1-10-20220701Document9 pages266-File Utama Naskah-502-1-10-20220701cah bagusNo ratings yet

- FPCN Contract - 2017 COHN6Document36 pagesFPCN Contract - 2017 COHN6Teddy WilsonNo ratings yet

- IJHSS - A Study On - Md. Afzalur RahmanDocument10 pagesIJHSS - A Study On - Md. Afzalur Rahmaniaset123No ratings yet

- Pydah College of EngineeringDocument31 pagesPydah College of Engineeringkmp pssrNo ratings yet

- Paragraph Unity and Coherence: What Is A Paragraph?Document2 pagesParagraph Unity and Coherence: What Is A Paragraph?Moezi DamdustNo ratings yet

- Spatial Distribution of Some Macro and Micro Nutrients in Relation To Land Evaluation Classes in Undulating Bushland Valleys of Melbourne AreaDocument5 pagesSpatial Distribution of Some Macro and Micro Nutrients in Relation To Land Evaluation Classes in Undulating Bushland Valleys of Melbourne AreaKusay WheibNo ratings yet

- Family Life TodayDocument3 pagesFamily Life TodayRaphael de Carvalho PortoNo ratings yet

- APS Safety Plan UpdateDocument1 pageAPS Safety Plan UpdateWews WebStaffNo ratings yet

- Medical Device Distributor PhilippinesDocument2,732 pagesMedical Device Distributor Philippinesjairaj GanjiNo ratings yet

- RESEARCHDocument25 pagesRESEARCHjillianeNo ratings yet

- Lesson 3 Primary Health Care and The Philippine Health Care Delivery System 1Document40 pagesLesson 3 Primary Health Care and The Philippine Health Care Delivery System 1Ritter GamingNo ratings yet

- Fighting Against Agoraphobia in The Highly Illogical BehaviourDocument10 pagesFighting Against Agoraphobia in The Highly Illogical BehaviourabeelwalkerNo ratings yet

- Why Mom Was RightDocument14 pagesWhy Mom Was RightBellNo ratings yet

- (Ebook PDF) Dutton's Introductory Skills and Procedures For The Physical Therapist Assistant 1st Edition Mark Dutton - Ebook PDF All ChapterDocument69 pages(Ebook PDF) Dutton's Introductory Skills and Procedures For The Physical Therapist Assistant 1st Edition Mark Dutton - Ebook PDF All Chapterusatngock100% (8)

- PannaDocument72 pagesPannaMohit AgarwalNo ratings yet

- Tosto, Et Al. (2015) - A Systematic Review of ADHD and Mathematical AbilityDocument14 pagesTosto, Et Al. (2015) - A Systematic Review of ADHD and Mathematical AbilityjuanNo ratings yet

- Epidemiologic MeasurementsDocument34 pagesEpidemiologic MeasurementsalaineaNo ratings yet