Professional Documents

Culture Documents

Operation Process Shee1

Operation Process Shee1

Uploaded by

bvbmanjunathprasadOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operation Process Shee1

Operation Process Shee1

Uploaded by

bvbmanjunathprasadCopyright:

Available Formats

Operation Process Sheet

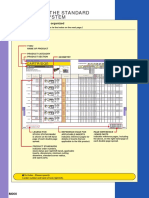

Operation No 1 Sequence of Operations Machine Tools Spindle RPM (N) Feed (F) (mm/rev) Depth of Cut (mm) Length of cut (L) (mm) No of cuts Formula (T) M/c ing Time (Min) Remarks

Checking of workpiece for the required dimension Facing operation on both ends to reduce the length of the workpiece from 130mm to 125mm. Single point cutting tool Single point cutting tool Counter drill X 2 (both sides) X 2 (both sides) X 2 (both sides)

Rough cut

Lathe

710

0.3

12.5

L / (N x F)

Smooth cut

Lathe

710

0.1

0.5

12.5

L / (N x F)

Counter drilling

Lathe

710

0.2

L / (N x F)

Plane turning operation dia reduces from 25 to 22mm. Single point cutting tool Single point cutting tool

Rough cut

Lathe

710

0.3

125

L / (N x F)

Smooth cut

Lathe

710

0.1

125

L / (N x F)

Step turning operation dia reduces 22 to 18mm for the total length X 5

Rough cut Smooth cut

Lathe Lathe

Parting tool Parting tool

710 710

0.3 0.1

1 1

X X

2 1

L / (N x F) L / (N x F)

Taper turning operation for the length X Single point cutting tool Single point cutting tool Knurling tool

Rough cut

Lathe

710

0.3

L / (N x F)

Smooth cut Knurling operation for the length X Thread cutting for the length X Chamfering

Lathe

710

0.1

L / (N x F)

Lathe

112

0.1

0.5

L / (N x F)

Lathe

Threading tool Single point cutting tool

112

2.5

0.2

10

L / (N x F) X 2 (both sides)

Lathe

710

0.033

Job No:

Figure:

Aim:

Specifications: Workpiece:

Cutting tool:

Machines:

Work holding & supporting devices:

Measuring instruments:

You might also like

- Sandvik Metal Cutting Technology Training HandbookDocument364 pagesSandvik Metal Cutting Technology Training HandbookITL200_U95% (21)

- Belin Tools PDFDocument40 pagesBelin Tools PDFdoc_nebulaNo ratings yet

- 4Document77 pages4Venkatamanikandan RajendranNo ratings yet

- NN 20 25 32yb - e PDFDocument4 pagesNN 20 25 32yb - e PDFAnonymous m6yoprE9zNo ratings yet

- 20100716172219667Document6 pages20100716172219667김두리No ratings yet

- 4.0 Results and Discussions 4.1 ResultsDocument11 pages4.0 Results and Discussions 4.1 ResultsKamlesh NathanNo ratings yet

- I Grades enDocument230 pagesI Grades enDougPabitonNo ratings yet

- Metal Machining and Automation (ME 3201)Document19 pagesMetal Machining and Automation (ME 3201)kasam santhosh prathikNo ratings yet

- Important Points With Regard To CNC Part Programming: CNC Parts Programs Cam Lab (Version Dated.23.03.2017)Document23 pagesImportant Points With Regard To CNC Part Programming: CNC Parts Programs Cam Lab (Version Dated.23.03.2017)CharyNo ratings yet

- Unit 2.1 Kinimatic Motion and Chip FormationDocument94 pagesUnit 2.1 Kinimatic Motion and Chip FormationHABTAMU FEKADUNo ratings yet

- 7 - Machining PART-2 (Chapter 18)Document70 pages7 - Machining PART-2 (Chapter 18)khaledfnaisNo ratings yet

- 15 Technical Catalog Casting Steel eDocument52 pages15 Technical Catalog Casting Steel elbo330% (1)

- I XmillDocument8 pagesI XmillVladimir Pereira MacielNo ratings yet

- Dibujos de Fresass!!!!Document19 pagesDibujos de Fresass!!!!Humberto AnguloNo ratings yet

- Chapter Two PDFDocument70 pagesChapter Two PDFberhaneNo ratings yet

- Milling 2003Document20 pagesMilling 2003ishanNo ratings yet

- Fraesen eDocument172 pagesFraesen eMarin Ionut-EduardNo ratings yet

- Welcome To International Journal of Engineering Research and Development (IJERD)Document8 pagesWelcome To International Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- Milling MachinesDocument48 pagesMilling MachinesAliah IzzahNo ratings yet

- 7 Machining Processes PDFDocument46 pages7 Machining Processes PDFOsama abdurahmanNo ratings yet

- Lecture 5Document11 pagesLecture 5Shakeel AhmadNo ratings yet

- Turning: ATMH1283 CNC and Workshop Technology Machining Operation Calculation (Turning)Document4 pagesTurning: ATMH1283 CNC and Workshop Technology Machining Operation Calculation (Turning)Shan PinNo ratings yet

- Chapter Twenty ThreeDocument11 pagesChapter Twenty Threeabdullaammar090No ratings yet

- 1 217 Milling WebsiteDocument44 pages1 217 Milling WebsiteJorge ZabalaNo ratings yet

- Demo PartDocument4 pagesDemo PartPeaceNo ratings yet

- Fundamentals of MachiningDocument39 pagesFundamentals of Machiningpassion481100% (1)

- Sumitomo MDFDocument2 pagesSumitomo MDFFabianoKovalechenNo ratings yet

- ManufProc2 1MaterialRemovalDocument48 pagesManufProc2 1MaterialRemovalJeff HardyNo ratings yet

- Lecture No. 7 Turning ParametersDocument29 pagesLecture No. 7 Turning ParametersMuhammad Irfan100% (1)

- ME - 32021 Chapter (I) Machining Processes and Machine Tools - PPTX (Repaired)Document23 pagesME - 32021 Chapter (I) Machining Processes and Machine Tools - PPTX (Repaired)WILYNo ratings yet

- Angular Velocity:: Production TechnologyDocument10 pagesAngular Velocity:: Production TechnologySean MINo ratings yet

- Spinner TC 65Document2 pagesSpinner TC 65Ibrahim KayaNo ratings yet

- Formulas For MillingDocument5 pagesFormulas For MillingArtūrs CeimersNo ratings yet

- Tech Mill FormulasDocument5 pagesTech Mill FormulaspchakkrapaniNo ratings yet

- Observations: General Data of The Required Work Piece For The MachiningDocument2 pagesObservations: General Data of The Required Work Piece For The MachiningGayan SameeraNo ratings yet

- c006b MDocument28 pagesc006b MVignesh WaranNo ratings yet

- 12mm Size Insulated Shaft TypeDocument5 pages12mm Size Insulated Shaft TypeshyhuNo ratings yet

- Summary Report: RitikDocument35 pagesSummary Report: Ritikshivam modanwalNo ratings yet

- Mechanics of Metal CuttingDocument33 pagesMechanics of Metal Cuttingnyilmaz72411No ratings yet

- Lathe 150826222523 Lva1 App6892Document75 pagesLathe 150826222523 Lva1 App6892jbcNo ratings yet

- 20J3XB - Programming - EN M80 VER00Document142 pages20J3XB - Programming - EN M80 VER00maxvelyrNo ratings yet

- Copia de Ballnose-CalcDocument3 pagesCopia de Ballnose-CalcOscar Corpus SalasNo ratings yet

- Metal Machining and Automation (ME 3201)Document11 pagesMetal Machining and Automation (ME 3201)kasam santhosh prathikNo ratings yet

- CH 7 MillingDocument54 pagesCH 7 MillingVirender RawalNo ratings yet

- High Productivity Vertical Machining CenterDocument16 pagesHigh Productivity Vertical Machining CenterCornelia Mihaela MNo ratings yet

- SR 20j-jn A4eDocument12 pagesSR 20j-jn A4ebjpulsarNo ratings yet

- 5.1 Operating Conditions - Turning, Milling & DrillingDocument31 pages5.1 Operating Conditions - Turning, Milling & DrillingjpmanikandanNo ratings yet

- Machining Operations EDocument15 pagesMachining Operations Ehadyzaky482No ratings yet

- Summary of Cutting Data For Ext. Cylindrical Surface: Material DetailsDocument4 pagesSummary of Cutting Data For Ext. Cylindrical Surface: Material DetailsAndrei MihaiNo ratings yet

- Manufacturing & ProductionDocument16 pagesManufacturing & ProductionMithun Raju0% (1)

- Modeling and Analysis of A Surface Milling Cutter Using Finite Element AnalysisDocument6 pagesModeling and Analysis of A Surface Milling Cutter Using Finite Element AnalysisIJERDNo ratings yet

- 3.1 Metal RemovalDocument40 pages3.1 Metal RemovalMichael Kearney50% (2)