Professional Documents

Culture Documents

100%(1)100% found this document useful (1 vote)

543 viewsMaintenance Checklist For Extruder

Maintenance Checklist For Extruder

Uploaded by

minhvu378Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You might also like

- HC Hệ Thống Dầu EH Và Dầu Bảo Vệ Điều KhiểnDocument25 pagesHC Hệ Thống Dầu EH Và Dầu Bảo Vệ Điều KhiểnhuutinhNo ratings yet

- TH C Hành WordDocument7 pagesTH C Hành WordThanh Chầm VũNo ratings yet

- Checklist bảo dưỡng điều hòaDocument4 pagesChecklist bảo dưỡng điều hòaĐặng Ngọc HùngNo ratings yet

- Scope of Work RooftopDocument2 pagesScope of Work RooftopEurotech Tra TranNo ratings yet

- Bảo dưỡng xe nâng mitsubishiDocument18 pagesBảo dưỡng xe nâng mitsubishisơn forkliftNo ratings yet

- B o Trì, B o Dư NG MMTB Nhà MáyDocument8 pagesB o Trì, B o Dư NG MMTB Nhà MáyThanh Chầm VũNo ratings yet

- Pcn-Mi172 - CBB, KTCKDocument5 pagesPcn-Mi172 - CBB, KTCKDuy Khanh NguyễnNo ratings yet

- Quy trình thử tải máy phát điệnDocument8 pagesQuy trình thử tải máy phát điệnhuynhuanNo ratings yet

- Bao Duong Cham Soc Kta 19 M3Document82 pagesBao Duong Cham Soc Kta 19 M3ho hoNo ratings yet

- 179 Z183 (05) 01-Hướng dẫn vận hành và khởi động1Document23 pages179 Z183 (05) 01-Hướng dẫn vận hành và khởi động1Dương Hoàng ĐiệpNo ratings yet

- Kiem Tra Hieu Chinh Van Phan PhoiDocument67 pagesKiem Tra Hieu Chinh Van Phan PhoiDu TrầnNo ratings yet

- B ĐÁP Án XongDocument14 pagesB ĐÁP Án XongPhoenix ForceNo ratings yet

- B o Nam Dmxy-20a PM VFDDocument15 pagesB o Nam Dmxy-20a PM VFDBach NguyenNo ratings yet

- Brochure BTÐTDocument5 pagesBrochure BTÐTvanphuc1182No ratings yet

- Bảo Dưỡng D51EX-22Document53 pagesBảo Dưỡng D51EX-22chinhNo ratings yet

- Huong Dan Van Hanh May Bien ApDocument26 pagesHuong Dan Van Hanh May Bien Apdung110baclieuNo ratings yet

- Động cơ Cummin dòng QSB và quy trình kĩ thuật bảo dưỡng NEWDocument34 pagesĐộng cơ Cummin dòng QSB và quy trình kĩ thuật bảo dưỡng NEWBui Xuan DucNo ratings yet

- HM Máy - HD06Document6 pagesHM Máy - HD06ho van hatNo ratings yet

- HDSD Smartgen-MeetechDocument6 pagesHDSD Smartgen-MeetechTấn Dũng BùiNo ratings yet

- Hướng Dẫn Vận Hành Quạt GióDocument2 pagesHướng Dẫn Vận Hành Quạt GióĐông Tiền HảiNo ratings yet

- CFR F1 Engine Vietnamese Operation ManualDocument15 pagesCFR F1 Engine Vietnamese Operation ManualĐoàn Quang Việt100% (1)

- Bài giảng Công Nghệ Chế Tạo Máy Điện-Chương-5-MBADocument84 pagesBài giảng Công Nghệ Chế Tạo Máy Điện-Chương-5-MBAKhánh TrọngNo ratings yet

- Maintenance MacGregorDocument11 pagesMaintenance MacGregorVõ Quang LânNo ratings yet

- HDSD COMAP-meetechDocument6 pagesHDSD COMAP-meetechTấn Dũng BùiNo ratings yet

- Manual Guide For ColdroomDocument6 pagesManual Guide For Coldroomhoa.thelonggroupNo ratings yet

- 4. Quy trình vận hànhDocument65 pages4. Quy trình vận hànhDuong HoangNo ratings yet

- 5. Bảo Dưỡng Điều Hòa CơDocument1 page5. Bảo Dưỡng Điều Hòa Cơdtuan161002No ratings yet

- CÂU HỎI KIỂM TRA KIẾN THỨC VẬN HÀNH TURBINEDocument4 pagesCÂU HỎI KIỂM TRA KIẾN THỨC VẬN HÀNH TURBINEThangNo ratings yet

- Huong Dan Bao Tri AHUDocument5 pagesHuong Dan Bao Tri AHUhungstampNo ratings yet

- Chuong Trinh Trung Tu Co Khi M3Document10 pagesChuong Trinh Trung Tu Co Khi M3Nguyen Duc NhaNo ratings yet

- Đào T o Máy Phay S A NgàyDocument6 pagesĐào T o Máy Phay S A Ngàynguyentuanthang000No ratings yet

- Tai Lieu Thiet Bi Phu TuabinDocument115 pagesTai Lieu Thiet Bi Phu TuabinThanh SonNo ratings yet

- VẬN HÀNH MÁY PHÁT ĐIỆN DIESELDocument11 pagesVẬN HÀNH MÁY PHÁT ĐIỆN DIESELMạnh HoàngNo ratings yet

- Tap 6.1 - Chi Dan Ky Thuat Phan TBA - 14.10.2022Document219 pagesTap 6.1 - Chi Dan Ky Thuat Phan TBA - 14.10.2022Bình Minh LêNo ratings yet

- Yêu cầu kỹ thuậtDocument3 pagesYêu cầu kỹ thuậtQuyền Đức NguyễnNo ratings yet

- HANDBOOK 소모품 .JUNJIN - VN (ver4.4) PDFDocument80 pagesHANDBOOK 소모품 .JUNJIN - VN (ver4.4) PDFThienNo ratings yet

- 5-An Toan Lao Dong Khi Van Hanh May Nen KhiDocument3 pages5-An Toan Lao Dong Khi Van Hanh May Nen KhiLoc NguyenNo ratings yet

- Xử Lý Sự Cố Mba t1Document5 pagesXử Lý Sự Cố Mba t1Cuong VanNo ratings yet

- 07. QUY TRÌNH TẠM THỜI DẦU BÔI TRƠN - DẦU KÍCH (OK)Document13 pages07. QUY TRÌNH TẠM THỜI DẦU BÔI TRƠN - DẦU KÍCH (OK)nguyen xuan DongNo ratings yet

- TIỂU LUẬN MÁY LẠNH VÀ ĐHKK-THIỆPDocument6 pagesTIỂU LUẬN MÁY LẠNH VÀ ĐHKK-THIỆPĐặng ThiệpNo ratings yet

- Hướng dẫn bảo dưỡng khắc phục sự cố hệ thống khí nénDocument13 pagesHướng dẫn bảo dưỡng khắc phục sự cố hệ thống khí nénNguyễn Đình KhảngNo ratings yet

- Chương 2 Các Thiết Bị Chuẩn Đoán Kỹ Thuật Động Cơ ÔtôDocument77 pagesChương 2 Các Thiết Bị Chuẩn Đoán Kỹ Thuật Động Cơ ÔtôTrinh Phi HoangNo ratings yet

- Thí nghiệm động cơDocument50 pagesThí nghiệm động cơHiếu MinhNo ratings yet

- HVAC - Thi nâng bậc 2018 - KS 2-5 - Đề 1Document5 pagesHVAC - Thi nâng bậc 2018 - KS 2-5 - Đề 1VoldyNo ratings yet

- MVAC07 - Thu Nghiem PDFDocument9 pagesMVAC07 - Thu Nghiem PDFTrườngThànhLêNo ratings yet

- Chuong V - Yeu Cau Ve Ky Thuat - MPD BDDocument108 pagesChuong V - Yeu Cau Ve Ky Thuat - MPD BDtems BkNo ratings yet

- kiemdinhDocument13 pageskiemdinhthanhkhanh2109No ratings yet

- TDH TH y Khí Trong Máy Chương 6-2021Document111 pagesTDH TH y Khí Trong Máy Chương 6-2021Nguyễn ĐạtNo ratings yet

- Bảng Chào Giá: I. Nội dung: STT Nội dung Mã hàng Hãng SX ĐVT Số lượngDocument9 pagesBảng Chào Giá: I. Nội dung: STT Nội dung Mã hàng Hãng SX ĐVT Số lượngLong NguyễnNo ratings yet

- KhinenDocument131 pagesKhinenDuoc NguyenNo ratings yet

- tcvn 7144 -3-2007 - Động cơ đốt trong - CÁC PHÉP ĐO THỬDocument5 pagestcvn 7144 -3-2007 - Động cơ đốt trong - CÁC PHÉP ĐO THỬnguyenvantrucNo ratings yet

- Chilled Water Proportional BalanceDocument10 pagesChilled Water Proportional BalanceSinh NguyenNo ratings yet

- Bảo dưỡng PC200-8Document98 pagesBảo dưỡng PC200-8chinhNo ratings yet

- Huong Dan Dat AP Suat Khoan Ham Boomer L2DDocument5 pagesHuong Dan Dat AP Suat Khoan Ham Boomer L2DHai VanNo ratings yet

- Hướng dẫn vận hành và bảo dưỡng máy xúc lậtDocument4 pagesHướng dẫn vận hành và bảo dưỡng máy xúc lậtKomatsu Perkins HitachiNo ratings yet

- QPF-020AY Rev.02 公用工程日常检查报告 Biểu kiểm tra hằng ngàyDocument86 pagesQPF-020AY Rev.02 公用工程日常检查报告 Biểu kiểm tra hằng ngàyVo Chi TaiNo ratings yet

- Maintenance ScheduleDocument4 pagesMaintenance ScheduleLong NguyễnNo ratings yet

Maintenance Checklist For Extruder

Maintenance Checklist For Extruder

Uploaded by

minhvu378100%(1)100% found this document useful (1 vote)

543 views2 pagesOriginal Title

Maintenance Checklist for Extruder

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

100%(1)100% found this document useful (1 vote)

543 views2 pagesMaintenance Checklist For Extruder

Maintenance Checklist For Extruder

Uploaded by

minhvu378Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 2

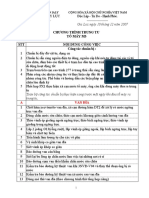

MAINTENANCE CHECKLIST FOR EXTRUDER AND ASSOCIATED ACCESSORIES

SERVICE DATE: _______________________________________ SERVICED BY: _________________________________________

CHECKS BEFORE EVERY RUN

Routines Check for the tool temperature and set the temperature to 190c to 200c Chec k Remarks

Kim tra nhit khun v thit lp nhit 190C n 200C

Check for working condition of heating zone cooling fans

Kim tra cc iu kin lm vic ca ngi hm m lm mt khu vc nng

Tank to be cooled before starting the extruder.

B cha c lm lnh trc khi bt u my n.

Check to make sure that the thermo couplings are in tool.

Kim tra m bo rng cc u d nhit khun c kt ni chc chn.

Check to make sure that the extruders head is in place.

Kim tra chc chn rng ngi vn hnh chnh my n c mt khi my hot ng .

CHECKS EVERY MONTH or TWO(depends on the production)

Routines Check for Motor brushes of the commutator length replacement

Kim tra chiu than chi qut ng c v thay th nu cn .

Chec k

Remarks

Cleaning of Motor brushes of the commutator

Lm sch bn chi ng c ca c gp

Cleaning of the filter of the air duct or to be replaced with open cell foam if necessary

Lm sch b lc ca ng dn khng kh hoc c thay th bng btdi ng m nu cn thit

Check gearbox oil level top up to required level if necessary.

Kim tra mc du hp s trn ln n mc cn thit nu cn thit.

Check fan motors for bearings and electric operations

Kim tra ng c qut hm m cho cc vng bi v cc hot ngin

Check electric heating elements and control gear Grease bearing at motors

Bi trn trc mt

Grease bearing conveyor

Bi trn trc bng ti

Clean chiller

sch thit b lm lnh

Clean the tank and refill with water and 6% of 425 if necessary.

Lm sch h v y nc v 6% ca 425 nu cn thit.

Check for any oil leaks

Kim tra cho bt k r r du

You might also like

- HC Hệ Thống Dầu EH Và Dầu Bảo Vệ Điều KhiểnDocument25 pagesHC Hệ Thống Dầu EH Và Dầu Bảo Vệ Điều KhiểnhuutinhNo ratings yet

- TH C Hành WordDocument7 pagesTH C Hành WordThanh Chầm VũNo ratings yet

- Checklist bảo dưỡng điều hòaDocument4 pagesChecklist bảo dưỡng điều hòaĐặng Ngọc HùngNo ratings yet

- Scope of Work RooftopDocument2 pagesScope of Work RooftopEurotech Tra TranNo ratings yet

- Bảo dưỡng xe nâng mitsubishiDocument18 pagesBảo dưỡng xe nâng mitsubishisơn forkliftNo ratings yet

- B o Trì, B o Dư NG MMTB Nhà MáyDocument8 pagesB o Trì, B o Dư NG MMTB Nhà MáyThanh Chầm VũNo ratings yet

- Pcn-Mi172 - CBB, KTCKDocument5 pagesPcn-Mi172 - CBB, KTCKDuy Khanh NguyễnNo ratings yet

- Quy trình thử tải máy phát điệnDocument8 pagesQuy trình thử tải máy phát điệnhuynhuanNo ratings yet

- Bao Duong Cham Soc Kta 19 M3Document82 pagesBao Duong Cham Soc Kta 19 M3ho hoNo ratings yet

- 179 Z183 (05) 01-Hướng dẫn vận hành và khởi động1Document23 pages179 Z183 (05) 01-Hướng dẫn vận hành và khởi động1Dương Hoàng ĐiệpNo ratings yet

- Kiem Tra Hieu Chinh Van Phan PhoiDocument67 pagesKiem Tra Hieu Chinh Van Phan PhoiDu TrầnNo ratings yet

- B ĐÁP Án XongDocument14 pagesB ĐÁP Án XongPhoenix ForceNo ratings yet

- B o Nam Dmxy-20a PM VFDDocument15 pagesB o Nam Dmxy-20a PM VFDBach NguyenNo ratings yet

- Brochure BTÐTDocument5 pagesBrochure BTÐTvanphuc1182No ratings yet

- Bảo Dưỡng D51EX-22Document53 pagesBảo Dưỡng D51EX-22chinhNo ratings yet

- Huong Dan Van Hanh May Bien ApDocument26 pagesHuong Dan Van Hanh May Bien Apdung110baclieuNo ratings yet

- Động cơ Cummin dòng QSB và quy trình kĩ thuật bảo dưỡng NEWDocument34 pagesĐộng cơ Cummin dòng QSB và quy trình kĩ thuật bảo dưỡng NEWBui Xuan DucNo ratings yet

- HM Máy - HD06Document6 pagesHM Máy - HD06ho van hatNo ratings yet

- HDSD Smartgen-MeetechDocument6 pagesHDSD Smartgen-MeetechTấn Dũng BùiNo ratings yet

- Hướng Dẫn Vận Hành Quạt GióDocument2 pagesHướng Dẫn Vận Hành Quạt GióĐông Tiền HảiNo ratings yet

- CFR F1 Engine Vietnamese Operation ManualDocument15 pagesCFR F1 Engine Vietnamese Operation ManualĐoàn Quang Việt100% (1)

- Bài giảng Công Nghệ Chế Tạo Máy Điện-Chương-5-MBADocument84 pagesBài giảng Công Nghệ Chế Tạo Máy Điện-Chương-5-MBAKhánh TrọngNo ratings yet

- Maintenance MacGregorDocument11 pagesMaintenance MacGregorVõ Quang LânNo ratings yet

- HDSD COMAP-meetechDocument6 pagesHDSD COMAP-meetechTấn Dũng BùiNo ratings yet

- Manual Guide For ColdroomDocument6 pagesManual Guide For Coldroomhoa.thelonggroupNo ratings yet

- 4. Quy trình vận hànhDocument65 pages4. Quy trình vận hànhDuong HoangNo ratings yet

- 5. Bảo Dưỡng Điều Hòa CơDocument1 page5. Bảo Dưỡng Điều Hòa Cơdtuan161002No ratings yet

- CÂU HỎI KIỂM TRA KIẾN THỨC VẬN HÀNH TURBINEDocument4 pagesCÂU HỎI KIỂM TRA KIẾN THỨC VẬN HÀNH TURBINEThangNo ratings yet

- Huong Dan Bao Tri AHUDocument5 pagesHuong Dan Bao Tri AHUhungstampNo ratings yet

- Chuong Trinh Trung Tu Co Khi M3Document10 pagesChuong Trinh Trung Tu Co Khi M3Nguyen Duc NhaNo ratings yet

- Đào T o Máy Phay S A NgàyDocument6 pagesĐào T o Máy Phay S A Ngàynguyentuanthang000No ratings yet

- Tai Lieu Thiet Bi Phu TuabinDocument115 pagesTai Lieu Thiet Bi Phu TuabinThanh SonNo ratings yet

- VẬN HÀNH MÁY PHÁT ĐIỆN DIESELDocument11 pagesVẬN HÀNH MÁY PHÁT ĐIỆN DIESELMạnh HoàngNo ratings yet

- Tap 6.1 - Chi Dan Ky Thuat Phan TBA - 14.10.2022Document219 pagesTap 6.1 - Chi Dan Ky Thuat Phan TBA - 14.10.2022Bình Minh LêNo ratings yet

- Yêu cầu kỹ thuậtDocument3 pagesYêu cầu kỹ thuậtQuyền Đức NguyễnNo ratings yet

- HANDBOOK 소모품 .JUNJIN - VN (ver4.4) PDFDocument80 pagesHANDBOOK 소모품 .JUNJIN - VN (ver4.4) PDFThienNo ratings yet

- 5-An Toan Lao Dong Khi Van Hanh May Nen KhiDocument3 pages5-An Toan Lao Dong Khi Van Hanh May Nen KhiLoc NguyenNo ratings yet

- Xử Lý Sự Cố Mba t1Document5 pagesXử Lý Sự Cố Mba t1Cuong VanNo ratings yet

- 07. QUY TRÌNH TẠM THỜI DẦU BÔI TRƠN - DẦU KÍCH (OK)Document13 pages07. QUY TRÌNH TẠM THỜI DẦU BÔI TRƠN - DẦU KÍCH (OK)nguyen xuan DongNo ratings yet

- TIỂU LUẬN MÁY LẠNH VÀ ĐHKK-THIỆPDocument6 pagesTIỂU LUẬN MÁY LẠNH VÀ ĐHKK-THIỆPĐặng ThiệpNo ratings yet

- Hướng dẫn bảo dưỡng khắc phục sự cố hệ thống khí nénDocument13 pagesHướng dẫn bảo dưỡng khắc phục sự cố hệ thống khí nénNguyễn Đình KhảngNo ratings yet

- Chương 2 Các Thiết Bị Chuẩn Đoán Kỹ Thuật Động Cơ ÔtôDocument77 pagesChương 2 Các Thiết Bị Chuẩn Đoán Kỹ Thuật Động Cơ ÔtôTrinh Phi HoangNo ratings yet

- Thí nghiệm động cơDocument50 pagesThí nghiệm động cơHiếu MinhNo ratings yet

- HVAC - Thi nâng bậc 2018 - KS 2-5 - Đề 1Document5 pagesHVAC - Thi nâng bậc 2018 - KS 2-5 - Đề 1VoldyNo ratings yet

- MVAC07 - Thu Nghiem PDFDocument9 pagesMVAC07 - Thu Nghiem PDFTrườngThànhLêNo ratings yet

- Chuong V - Yeu Cau Ve Ky Thuat - MPD BDDocument108 pagesChuong V - Yeu Cau Ve Ky Thuat - MPD BDtems BkNo ratings yet

- kiemdinhDocument13 pageskiemdinhthanhkhanh2109No ratings yet

- TDH TH y Khí Trong Máy Chương 6-2021Document111 pagesTDH TH y Khí Trong Máy Chương 6-2021Nguyễn ĐạtNo ratings yet

- Bảng Chào Giá: I. Nội dung: STT Nội dung Mã hàng Hãng SX ĐVT Số lượngDocument9 pagesBảng Chào Giá: I. Nội dung: STT Nội dung Mã hàng Hãng SX ĐVT Số lượngLong NguyễnNo ratings yet

- KhinenDocument131 pagesKhinenDuoc NguyenNo ratings yet

- tcvn 7144 -3-2007 - Động cơ đốt trong - CÁC PHÉP ĐO THỬDocument5 pagestcvn 7144 -3-2007 - Động cơ đốt trong - CÁC PHÉP ĐO THỬnguyenvantrucNo ratings yet

- Chilled Water Proportional BalanceDocument10 pagesChilled Water Proportional BalanceSinh NguyenNo ratings yet

- Bảo dưỡng PC200-8Document98 pagesBảo dưỡng PC200-8chinhNo ratings yet

- Huong Dan Dat AP Suat Khoan Ham Boomer L2DDocument5 pagesHuong Dan Dat AP Suat Khoan Ham Boomer L2DHai VanNo ratings yet

- Hướng dẫn vận hành và bảo dưỡng máy xúc lậtDocument4 pagesHướng dẫn vận hành và bảo dưỡng máy xúc lậtKomatsu Perkins HitachiNo ratings yet

- QPF-020AY Rev.02 公用工程日常检查报告 Biểu kiểm tra hằng ngàyDocument86 pagesQPF-020AY Rev.02 公用工程日常检查报告 Biểu kiểm tra hằng ngàyVo Chi TaiNo ratings yet

- Maintenance ScheduleDocument4 pagesMaintenance ScheduleLong NguyễnNo ratings yet