Professional Documents

Culture Documents

17 4 Stainless Steel Technical Data

17 4 Stainless Steel Technical Data

Uploaded by

anil_stephenCopyright:

Available Formats

You might also like

- API RP 571 - Damage Mechanisms SpreadsheetDocument12 pagesAPI RP 571 - Damage Mechanisms SpreadsheetSoftware ManagerNo ratings yet

- A Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesFrom EverandA Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesRating: 4 out of 5 stars4/5 (1)

- Stainless Steel AL 17-4 Precipitation Hardening Alloy: General PropertiesDocument5 pagesStainless Steel AL 17-4 Precipitation Hardening Alloy: General PropertiesforuzzNo ratings yet

- Aalco Metals LTD Stainless Steel 155 PH 310Document3 pagesAalco Metals LTD Stainless Steel 155 PH 310Ria MustikaNo ratings yet

- Aisi 4130Document2 pagesAisi 4130Ravi Chaitanya VelamarthyNo ratings yet

- Aisi 4130Document2 pagesAisi 4130ravivelamarthyNo ratings yet

- Aalco Metals LTD Stainless Steel 14542 174 630 Bar 100Document5 pagesAalco Metals LTD Stainless Steel 14542 174 630 Bar 100LORENA GRIJALBA LEONNo ratings yet

- 15-5 PHDocument2 pages15-5 PHfedaquiNo ratings yet

- Electrode Dan Welding Wires 1646204294Document7 pagesElectrode Dan Welding Wires 1646204294Gibran RamadhanNo ratings yet

- Difference Between y Block and Other Xmas TreeDocument6 pagesDifference Between y Block and Other Xmas TreeMOHAMED FAISALKHANNo ratings yet

- Aalco Metals LTD Stainless Steel 1.4542 17 4 PH 100Document4 pagesAalco Metals LTD Stainless Steel 1.4542 17 4 PH 100Sergio CLNo ratings yet

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDocument2 pagesStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdNo ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)adil_farooq_6No ratings yet

- Detail-Material Science NotesDocument276 pagesDetail-Material Science Notessureshbabu7374No ratings yet

- Material - (1 4462)Document2 pagesMaterial - (1 4462)Ashutosh PathakNo ratings yet

- Alloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureDocument2 pagesAlloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureBharathi SrinivasanNo ratings yet

- Aalco Metals LTD Stainless Steel 14021 Bar 311Document2 pagesAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaNo ratings yet

- Amie Material Science NotesDocument276 pagesAmie Material Science NotesRajendra Kumar Yadav100% (2)

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Document2 pagesAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloNo ratings yet

- Armco 17-4 PH PDB Euro Final Secured 89Document24 pagesArmco 17-4 PH PDB Euro Final Secured 89naeem akramNo ratings yet

- 17 4Document2 pages17 4fedaquiNo ratings yet

- Age HardeningDocument5 pagesAge Hardeninganum_nNo ratings yet

- Copper and Copper Alloys CW614N Brass Rod: Specifications Supplied FormsDocument2 pagesCopper and Copper Alloys CW614N Brass Rod: Specifications Supplied Formsdipesh6030No ratings yet

- Oxford Alloy 182 (ENiCrFe-3)Document1 pageOxford Alloy 182 (ENiCrFe-3)brunizzaNo ratings yet

- Atlas Grade Datasheet 410 Rev May 2008Document2 pagesAtlas Grade Datasheet 410 Rev May 2008Satendra ThakurNo ratings yet

- Amie Material Science Notes PDFDocument276 pagesAmie Material Science Notes PDFAlok KulkarniNo ratings yet

- 17-4 PHDocument4 pages17-4 PHfahimshah1301No ratings yet

- Copper and Copper Alloys CW024A Sheet and Plate: Specifications Generic Physical PropertiesDocument2 pagesCopper and Copper Alloys CW024A Sheet and Plate: Specifications Generic Physical PropertiesAhmed AlsabaaNo ratings yet

- 410 Grade SteelDocument4 pages410 Grade SteelShashank Saxena0% (1)

- Trim Number Chart API ValveDocument2 pagesTrim Number Chart API ValveVelu .cNo ratings yet

- ASME Secc II D Appendix 6 Metallurgical PhenomenaDocument6 pagesASME Secc II D Appendix 6 Metallurgical PhenomenaCARLOS MARIONo ratings yet

- 17-7 Material PDFDocument5 pages17-7 Material PDFJothi ManiNo ratings yet

- Dictionary of Metal TerminologyDocument59 pagesDictionary of Metal TerminologyyogeshNo ratings yet

- AISI 420 Data SheetDocument2 pagesAISI 420 Data SheetVicky GautamNo ratings yet

- Copper and Copper Alloys CW614N Brass Flat Bar and Profiles: Specifications Supplied FormsDocument2 pagesCopper and Copper Alloys CW614N Brass Flat Bar and Profiles: Specifications Supplied FormsAnonymous v7XdaQuNo ratings yet

- Aerospace Material SpecificationDocument8 pagesAerospace Material SpecificationDUNo ratings yet

- Stainless Steel: Aerospace Paper Food Processing Metalworking Petrochemical ChemicalDocument20 pagesStainless Steel: Aerospace Paper Food Processing Metalworking Petrochemical ChemicaljjdNo ratings yet

- Metal Plates Property Table Metal Plate MaterialsDocument1 pageMetal Plates Property Table Metal Plate MaterialsAdil Shahzad QaziNo ratings yet

- 420 Data SheetDocument2 pages420 Data SheetSaransiri WongsiriNo ratings yet

- Technical Update Maintenance Welding of AluminumDocument22 pagesTechnical Update Maintenance Welding of Aluminumaxisd47No ratings yet

- 17.4 PH Material SpecificationDocument2 pages17.4 PH Material SpecificationDevendra BangarNo ratings yet

- Precipitation Hardening Stainless Steels - Alloys, Properties, Fabrication Processes, Supplier Data by AalcoDocument6 pagesPrecipitation Hardening Stainless Steels - Alloys, Properties, Fabrication Processes, Supplier Data by AalcoKalpanaBansalNo ratings yet

- 4 4-MinWangDocument17 pages4 4-MinWanglesly.pramutadiNo ratings yet

- SS and Nickle Base AlloysDocument89 pagesSS and Nickle Base AlloysBHARGAVNo ratings yet

- 8620 Alloy Steels Material Property Data Sheet - Product Availability and Request A QuoteDocument4 pages8620 Alloy Steels Material Property Data Sheet - Product Availability and Request A QuoteManuel NavarroNo ratings yet

- Nickel Alloys Monel 400 N04400Document4 pagesNickel Alloys Monel 400 N04400David Balboa VillenasNo ratings yet

- High Performance: Properties & General DataDocument4 pagesHigh Performance: Properties & General DataRaghNo ratings yet

- Oxford Alloy 420 (ER420)Document1 pageOxford Alloy 420 (ER420)brunizzaNo ratings yet

- Reference Inference: Review of Hot Cracking Phenomena in Austenitic Stainless SteelsDocument4 pagesReference Inference: Review of Hot Cracking Phenomena in Austenitic Stainless SteelsHarish KrishnaNo ratings yet

- Amari Aerospace LTD Stainless Steel 14542 Bar 100Document5 pagesAmari Aerospace LTD Stainless Steel 14542 Bar 100Ria MustikaNo ratings yet

- Stainless Steel 2Document9 pagesStainless Steel 2abraham metinca-primaNo ratings yet

- 17 4PH Spec SheetDocument2 pages17 4PH Spec Sheettrong tan dongNo ratings yet

- Astm A6Document5 pagesAstm A6SHYAM SINGHNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Elements, Atoms, Molecules and Compounds: Type of Matter Sample Drawing Symbol/Formula ElementDocument4 pagesElements, Atoms, Molecules and Compounds: Type of Matter Sample Drawing Symbol/Formula ElementpvpNo ratings yet

- Dow CorningDocument12 pagesDow CorningTamara HamiltonNo ratings yet

- SPB 22 QSV Oil Analysis GuidelinesDocument4 pagesSPB 22 QSV Oil Analysis GuidelinesO mecanico100% (1)

- Clariant Antistatic AgentsDocument20 pagesClariant Antistatic AgentsJose Bustos100% (1)

- Sharon PlywoodDocument6 pagesSharon PlywoodnvkjayanthNo ratings yet

- World/Gmp Grade Isopropyl Alcohol, 99%: Certificate of AnalysisDocument3 pagesWorld/Gmp Grade Isopropyl Alcohol, 99%: Certificate of AnalysisChé FeNo ratings yet

- Determination of Aluminium Back TitrationDocument2 pagesDetermination of Aluminium Back Titrationdhungelsubhash8154100% (4)

- ASTM Ceramic DaftarDocument5 pagesASTM Ceramic DaftarAgung SetioNo ratings yet

- Nova ABS Plastic Formwork by Sandeep NaikwadeDocument11 pagesNova ABS Plastic Formwork by Sandeep NaikwadeNovaFormworkNo ratings yet

- Comparision Between CSEB and Clay BricksDocument7 pagesComparision Between CSEB and Clay BricksShah ZaibNo ratings yet

- Material Declaration Form Material Declaration Form: Matt SigmonDocument1 pageMaterial Declaration Form Material Declaration Form: Matt SigmonEb INo ratings yet

- Poly Drop Brochure 2010Document8 pagesPoly Drop Brochure 2010Marco BusaNo ratings yet

- SF 450 CCTDocument19 pagesSF 450 CCTSoup PongsakornNo ratings yet

- Validation of Special ProcessesDocument3 pagesValidation of Special ProcessesJeyakumarNo ratings yet

- 0620 s19 QP 32 PDFDocument20 pages0620 s19 QP 32 PDFSecretary Of SecretsNo ratings yet

- Zinc and Tin Alloy Wire Used in Thermal Spraying For Electronic ApplicationsDocument4 pagesZinc and Tin Alloy Wire Used in Thermal Spraying For Electronic ApplicationsBang AnNo ratings yet

- Katalog AuftragsschweißenDocument12 pagesKatalog AuftragsschweißentobiaswatzingerNo ratings yet

- Acrodur DS 3530 February 2018 R3 EDFDocument3 pagesAcrodur DS 3530 February 2018 R3 EDFAllen de RichardNo ratings yet

- Smart, Waterproof, Breathable Sportsware - A ReviewDocument13 pagesSmart, Waterproof, Breathable Sportsware - A ReviewKrergkrai ChantalertvittayaNo ratings yet

- 7 Tank ProcessDocument4 pages7 Tank ProcessJalagandeeswaran Kalimuthu100% (1)

- Non Destructive Testing Non Destructive TestingDocument74 pagesNon Destructive Testing Non Destructive TestingPrasant Kumar BeheraNo ratings yet

- ColdGuard Sliding Cold Storage DoorsDocument1 pageColdGuard Sliding Cold Storage DoorsgamunozdNo ratings yet

- KBR-Economic Bottom of The Barrel Processing To Minimize Fuel Oil Production PDFDocument5 pagesKBR-Economic Bottom of The Barrel Processing To Minimize Fuel Oil Production PDFsantiagoNo ratings yet

- Egger Pumpes and Valves OverviewDocument25 pagesEgger Pumpes and Valves Overviewmanny casiquinNo ratings yet

- MMM Brochure IA-IISDocument2 pagesMMM Brochure IA-IISLintangNo ratings yet

- Colloids Shape and Size and Prep NotesDocument12 pagesColloids Shape and Size and Prep NotesNavnath HatvateNo ratings yet

- U W Civil Utility Tunnels and Trenches: Facilities Service S Design GuideDocument9 pagesU W Civil Utility Tunnels and Trenches: Facilities Service S Design GuideRamces AsisiNo ratings yet

- Sikawall®-161 Plaster Mix: Product Data SheetDocument3 pagesSikawall®-161 Plaster Mix: Product Data SheetAcil Nazir CaniagoNo ratings yet

- The Procedure Handbook of Arc Welding (Twelfth Edition)Document742 pagesThe Procedure Handbook of Arc Welding (Twelfth Edition)Adisak Aumpiem100% (1)

- Government of TelanganaDocument4 pagesGovernment of TelanganaDinesh ReddyNo ratings yet

17 4 Stainless Steel Technical Data

17 4 Stainless Steel Technical Data

Uploaded by

anil_stephenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

17 4 Stainless Steel Technical Data

17 4 Stainless Steel Technical Data

Uploaded by

anil_stephenCopyright:

Available Formats

Stainless Steel AL 17-4 Precipitation Hardening Alloy

(UNS Designation S17400)

GENERAL PROPERTIES

Allegheny Ludlum's AL 17-4 Precipitation Hardening Alloy (S17400), Type 630, is a chromium-nickel-copper precipitation hardening stainless steel used for applications requiring high strength and a moderate level of corrosion resistance. High strength is maintained to approximately 600F (316C). The S17400 alloy is martensitic in structure in the annealed condition and is further strengthened by a low temperature treatment which precipitates a copper containing phase in the alloy. In comparison to many alloys in the precipitation hardening family, the S17400 alloy requires a simple heat treatment; a one step process conducted at a temperature in the range 900F (482C) to 1150F (621C) depending on the combination of strength and toughness desired. A wide range of properties can be produced by this one step heat treatment. Heat treatment in the 900F (482C) range produces highest strength, although slightly less than that of alloys like S17700 or S15700. The latter precipitation hardening alloys generally require more steps to complete heat treatment.

Element Typical Composition (Weight Percent) Carbon 0.04 Manganese 0.40 Phosphorus 0.020 Sulfur 0.005 Silicon 0.50 Chromium 15.5 Nickel 4.5 Columbium + Tantalum 0.30 Copper Iron 3.50 Balance

SPECIFICATIONS

The AL 17-4 Precipitation Hardening Alloy (S17400) is covered by the following wrought product specifications. Specification AMS 5604 AMS 5643 AMS 5825 AMS 5827 AMS 7474 ASTM A 564 ASTM SA 564 ASTM A 693 ASME SA 693 ASTM A 705 ASME SA 705 Product Form Sheet, Strip and Plate Bars, Forgings, Tubing and Rings Welding Wire Welding Electrodes Bolts Bars, Wire and Shapes Sheet, Plate and Strip Forgings

FORMS AND CONDITIONS

The Allegheny Ludlum AL 17-4 Precipitation Hardening Alloy is furnished as plate. Long products are produced by Allvac, an Allegheny Technologies Company. In all forms, the material is furnished in the annealed condition.

Trademark of ATI Properties, Inc.

Data are typical and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown herein.

Stainless Steel AL 17-4 Alloy

Visit our Website at www.alleghenyludlum.com

CORROSION AND OXIDATION RESISTANCE

Tests have shown that the corrosion resistance of AL 17-4 Precipitation Hardening Alloy is comparable to that of Type 304 stainless steel in most media. In general, the corrosion resistance of AL 17-4 alloy is superior to that of the hardenable 400 series stainless steels. As with other precipitation hardening alloys, AL 17-4 Precipitation Hardening Alloy is more susceptible to stress corrosion cracking at peak strength. Consequently, in applications in which chloride stress corrosion cracking is a possibility, the material should be precipitation hardened to produce the lowest hardness compatible with the intended end use. This is done by heat treating at the highest temperature which will produce suitable minimum properties. Material in the annealed condition should not generally be put into service. In this condition, the material has an untempered martensite structure and is less ductile than aged material. The untempered martensite may be subject to unpredictable brittle fractures. In corrosive environments, the untempered martensite is more sensitive to embrittling phenomena such as hydrogen embrittlement than material which has had one of the precipitation hardening heat treatments. Similarly, untempered martensite is more sensitive to chloride stress corrosion cracking than material in which the martensite has been tempered. The oxidation resistance of the AL 17-4 alloy is superior to that of 12 percent chromium alloys like Type 410, but slightly inferior to that of Type 430. Precipitation hardening will produce surface oxidation.

PHYSICAL PROPERTIES

Condition Condition Condition Condition

A Density

lb / in g / cm3

3

H 900 0.282 7.81

H 1075 0.283 7.83

H 1150 0.284 7.86

0.280 7.75

Linear Coefficient of Thermal Expansion Units of 10-6 / F (10-6 / C) Temperature Range -100 F to +70 F (-73 C to +21 C) +70 F to 800 F (+21 C to +427 C)

5.8 (10.4) 6.3 (11.3) 6.5 (11.7)

6.0 (10.8) 6.8 (12.2)

6.1 (11.0) 7.2 (13.0)

Magnetic Permeability

Thermal Conductivity Btu - ft / hr -ft2 F (W / m - K) 70 - 212 F (21 - 100 C) 70 - 932 F (21 - 500 C)

Strongly Ferromagnetic in all Conditions

10.6 (18.3) 13.1 (22.7) 98

10.3 (17.8) 13.1 (22.7) 77 80 86

Electrical Resistivity microhm-cm

Data are typical and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown herein.

Stainless Steel AL 17-4 Alloy

Technical Data BLUE SHEET

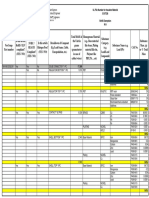

MECHANICAL PROPERTIES

Condition Condition Condition Condition

A

Modulus of Elasticity

106 psi (GPa)

H 900 28.5 (196)

H 1075 28.5 (196)

H 1150 28.5 (196)

SUMMARY OF HEAT TREATING AL 17-4 ALLOY

Minimum Properties Specified in Aerospace Material Specification (AMS) 5604

Heat Treat to Produce Martensitic Structure Precipitation Heat Treatment to Produce Desired Strength Precipitation Hardening Heat Treatment

Yield Strength psi (MPa) Tensile Strength Hardness Rc psi (MPa)

28.5 (196)

Modulus of Rigidity

106 psi (GPa)

11.2 (77.2)

11.2 (77.2)

11.2 (77.2)

11.2 (77.2)

Room temperature tensile properties can vary substantially with heat treatment in the 900F (482C) to 1150F (621C) range. Values shown below are typical room temperature properties which could be expected for

Condition Condition Condition Condition

900 F (482 C) 60 minutes Condition H 900

170,000 (1170)

190,000 (1310)

40 to 47 38 to 45 35 to 42 33 to 39 32 to 38 28 to 37 26 to 36

A

0.2% Offset Yield Strength

psi (MPa)

H 900

H 1075

H 1150

110,000 180,000 135,000 125,000 760 1,240 930 860 150,000 195,000 155,000 145,000 1,030 1,340 1,070 1,000 8 33 10 43 10 31 10 28

Solution Heat Treatment at 1950 F (1066 C)

925 F (496 C) 4 Hours Condition H 925 1025 F (552 C) 4 Hours Condition H 1025 1075 F (579 C) 4 Hours Condition H 1075 1100 F (593 C) 4 Hours Condition H 1100 1150 F (621 C) 4 Hours Condition H 1150 1400 F (760 C) 2 Hours + 1150 F 4 Hours Condition H 1150-M from SA 693

155,000 (1070)

170,000 (1170)

145,000 (1000)

155,000 (1070)

Ultimate Tensile Strength

psi (MPa)

Condition A (This is the condition furnished by Allegheny Ludlum)

125,000 (860)

145,000 (1000)

Elongation (percentage in 2") Hardness Rockwell C scale

115,000 (790)

140,000 (965)

105,000 (725)

135,000 (930)

75,000 (515)

115,000 (790)

Data are typical and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown herein.

Stainless Steel AL 17-4 Alloy

Visit our Website at www.alleghenyludlum.com

HEAT TREATMENT

The AL 17-4 Precipitation Hardening Alloy is furnished in the annealed condition. This is also called the solution heat treated condition, or Condition A. Annealing is conducted by heat treating at approximately 1900F (1040C) to 1950F (1065C) and cooling to room temperature. In this condition, the material possesses a martensitic structure. As a martensitic structure, the AL 17-4 alloy possesses a relatively high strength and hardness in the annealed condition. The strength and hardness of the material is generally somewhat lower in the H 1150 overaged condition. To develop further increase in strength, the annealed material is precipitation hardened by heat treatments at 900F (482C). Heat treatments above 1075F (579C) generally result in material softer than material in the annealed condition. The heat treatments are usually specified as follows: The precipitation hardening reaction can be driven past peak strength by heat treating at an excessively high temperature or by excessive time at the precipitation hardening temperature. The table on page 3 shows the effect of higher temperature heat treatment. A less dramatic downward shift in strength results from excessively long precipitation hardening times. The heat treatments used for the AL 17-4 Precipitation Hardening Alloy are summarized below.

WELDING AND BRAZING

The AL 17-4 Precipitation Hardening Alloy is readily welded using conventional inert gas methods used for stainless grades. Preheating is not usually required. Postweld heat treating is needed to produce the various precipitation hardened heat treatment properties. If matching filler material is used, properties comparable to those of the parent metal can be produced in the weld by postweld precipitation hardening heat treatment. When a number of welding passes are made, a substantial thermal cycling has been conducted on the material. More uniform mechanical properties can be obtained by solution annealing the material before conducting precipitation hardening heat treatments. The solution anneal has the effect of minimizing the effects of the thermal cycling. In the case of welding with non-matching filler, an austenitic stainless steel such as 308L or other ductile austenitic should be used. This filler will not produce the precipitation hardening response, however.

FORMING

The tensile data for the AL 17-4 Precipitation Hardening Alloy indicate that the alloy does not possess the high tensile elongation characteristic of the austenitic stainless steels. The material is capable of being mildly formed but is not capable of being severely formed. Forming is more easily accomplished in the overaged (such as H 1150-M from SA 693) condition than in the annealed, condition.

Condition

Temperature 900 F 10 (482 C 5) 925 F 10 (496 C 5) 1025 F (552 C

Time 60 min. 5 min. 4 hrs. 0.25 hr. 4 hrs. 0.25 hr. 4 hrs. 0.25 hr. 4 hrs. 0.25 hr. 4 hrs. 0.25 hr.

H 900 H 925 H 1025 H 1075 H 1100 H 1150

10 5)

1075 F 10 (579 C 5) 1100 F 10 (593 C 5) 1150 F 10 (621 C 5)

Data are typical and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown herein.

Copyright 2006, Allegheny Ludlum

Starburst Logo is a Registered Trademark of ATI Properties, Inc.

You might also like

- API RP 571 - Damage Mechanisms SpreadsheetDocument12 pagesAPI RP 571 - Damage Mechanisms SpreadsheetSoftware ManagerNo ratings yet

- A Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesFrom EverandA Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesRating: 4 out of 5 stars4/5 (1)

- Stainless Steel AL 17-4 Precipitation Hardening Alloy: General PropertiesDocument5 pagesStainless Steel AL 17-4 Precipitation Hardening Alloy: General PropertiesforuzzNo ratings yet

- Aalco Metals LTD Stainless Steel 155 PH 310Document3 pagesAalco Metals LTD Stainless Steel 155 PH 310Ria MustikaNo ratings yet

- Aisi 4130Document2 pagesAisi 4130Ravi Chaitanya VelamarthyNo ratings yet

- Aisi 4130Document2 pagesAisi 4130ravivelamarthyNo ratings yet

- Aalco Metals LTD Stainless Steel 14542 174 630 Bar 100Document5 pagesAalco Metals LTD Stainless Steel 14542 174 630 Bar 100LORENA GRIJALBA LEONNo ratings yet

- 15-5 PHDocument2 pages15-5 PHfedaquiNo ratings yet

- Electrode Dan Welding Wires 1646204294Document7 pagesElectrode Dan Welding Wires 1646204294Gibran RamadhanNo ratings yet

- Difference Between y Block and Other Xmas TreeDocument6 pagesDifference Between y Block and Other Xmas TreeMOHAMED FAISALKHANNo ratings yet

- Aalco Metals LTD Stainless Steel 1.4542 17 4 PH 100Document4 pagesAalco Metals LTD Stainless Steel 1.4542 17 4 PH 100Sergio CLNo ratings yet

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDocument2 pagesStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdNo ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)adil_farooq_6No ratings yet

- Detail-Material Science NotesDocument276 pagesDetail-Material Science Notessureshbabu7374No ratings yet

- Material - (1 4462)Document2 pagesMaterial - (1 4462)Ashutosh PathakNo ratings yet

- Alloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureDocument2 pagesAlloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureBharathi SrinivasanNo ratings yet

- Aalco Metals LTD Stainless Steel 14021 Bar 311Document2 pagesAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaNo ratings yet

- Amie Material Science NotesDocument276 pagesAmie Material Science NotesRajendra Kumar Yadav100% (2)

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Document2 pagesAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloNo ratings yet

- Armco 17-4 PH PDB Euro Final Secured 89Document24 pagesArmco 17-4 PH PDB Euro Final Secured 89naeem akramNo ratings yet

- 17 4Document2 pages17 4fedaquiNo ratings yet

- Age HardeningDocument5 pagesAge Hardeninganum_nNo ratings yet

- Copper and Copper Alloys CW614N Brass Rod: Specifications Supplied FormsDocument2 pagesCopper and Copper Alloys CW614N Brass Rod: Specifications Supplied Formsdipesh6030No ratings yet

- Oxford Alloy 182 (ENiCrFe-3)Document1 pageOxford Alloy 182 (ENiCrFe-3)brunizzaNo ratings yet

- Atlas Grade Datasheet 410 Rev May 2008Document2 pagesAtlas Grade Datasheet 410 Rev May 2008Satendra ThakurNo ratings yet

- Amie Material Science Notes PDFDocument276 pagesAmie Material Science Notes PDFAlok KulkarniNo ratings yet

- 17-4 PHDocument4 pages17-4 PHfahimshah1301No ratings yet

- Copper and Copper Alloys CW024A Sheet and Plate: Specifications Generic Physical PropertiesDocument2 pagesCopper and Copper Alloys CW024A Sheet and Plate: Specifications Generic Physical PropertiesAhmed AlsabaaNo ratings yet

- 410 Grade SteelDocument4 pages410 Grade SteelShashank Saxena0% (1)

- Trim Number Chart API ValveDocument2 pagesTrim Number Chart API ValveVelu .cNo ratings yet

- ASME Secc II D Appendix 6 Metallurgical PhenomenaDocument6 pagesASME Secc II D Appendix 6 Metallurgical PhenomenaCARLOS MARIONo ratings yet

- 17-7 Material PDFDocument5 pages17-7 Material PDFJothi ManiNo ratings yet

- Dictionary of Metal TerminologyDocument59 pagesDictionary of Metal TerminologyyogeshNo ratings yet

- AISI 420 Data SheetDocument2 pagesAISI 420 Data SheetVicky GautamNo ratings yet

- Copper and Copper Alloys CW614N Brass Flat Bar and Profiles: Specifications Supplied FormsDocument2 pagesCopper and Copper Alloys CW614N Brass Flat Bar and Profiles: Specifications Supplied FormsAnonymous v7XdaQuNo ratings yet

- Aerospace Material SpecificationDocument8 pagesAerospace Material SpecificationDUNo ratings yet

- Stainless Steel: Aerospace Paper Food Processing Metalworking Petrochemical ChemicalDocument20 pagesStainless Steel: Aerospace Paper Food Processing Metalworking Petrochemical ChemicaljjdNo ratings yet

- Metal Plates Property Table Metal Plate MaterialsDocument1 pageMetal Plates Property Table Metal Plate MaterialsAdil Shahzad QaziNo ratings yet

- 420 Data SheetDocument2 pages420 Data SheetSaransiri WongsiriNo ratings yet

- Technical Update Maintenance Welding of AluminumDocument22 pagesTechnical Update Maintenance Welding of Aluminumaxisd47No ratings yet

- 17.4 PH Material SpecificationDocument2 pages17.4 PH Material SpecificationDevendra BangarNo ratings yet

- Precipitation Hardening Stainless Steels - Alloys, Properties, Fabrication Processes, Supplier Data by AalcoDocument6 pagesPrecipitation Hardening Stainless Steels - Alloys, Properties, Fabrication Processes, Supplier Data by AalcoKalpanaBansalNo ratings yet

- 4 4-MinWangDocument17 pages4 4-MinWanglesly.pramutadiNo ratings yet

- SS and Nickle Base AlloysDocument89 pagesSS and Nickle Base AlloysBHARGAVNo ratings yet

- 8620 Alloy Steels Material Property Data Sheet - Product Availability and Request A QuoteDocument4 pages8620 Alloy Steels Material Property Data Sheet - Product Availability and Request A QuoteManuel NavarroNo ratings yet

- Nickel Alloys Monel 400 N04400Document4 pagesNickel Alloys Monel 400 N04400David Balboa VillenasNo ratings yet

- High Performance: Properties & General DataDocument4 pagesHigh Performance: Properties & General DataRaghNo ratings yet

- Oxford Alloy 420 (ER420)Document1 pageOxford Alloy 420 (ER420)brunizzaNo ratings yet

- Reference Inference: Review of Hot Cracking Phenomena in Austenitic Stainless SteelsDocument4 pagesReference Inference: Review of Hot Cracking Phenomena in Austenitic Stainless SteelsHarish KrishnaNo ratings yet

- Amari Aerospace LTD Stainless Steel 14542 Bar 100Document5 pagesAmari Aerospace LTD Stainless Steel 14542 Bar 100Ria MustikaNo ratings yet

- Stainless Steel 2Document9 pagesStainless Steel 2abraham metinca-primaNo ratings yet

- 17 4PH Spec SheetDocument2 pages17 4PH Spec Sheettrong tan dongNo ratings yet

- Astm A6Document5 pagesAstm A6SHYAM SINGHNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Elements, Atoms, Molecules and Compounds: Type of Matter Sample Drawing Symbol/Formula ElementDocument4 pagesElements, Atoms, Molecules and Compounds: Type of Matter Sample Drawing Symbol/Formula ElementpvpNo ratings yet

- Dow CorningDocument12 pagesDow CorningTamara HamiltonNo ratings yet

- SPB 22 QSV Oil Analysis GuidelinesDocument4 pagesSPB 22 QSV Oil Analysis GuidelinesO mecanico100% (1)

- Clariant Antistatic AgentsDocument20 pagesClariant Antistatic AgentsJose Bustos100% (1)

- Sharon PlywoodDocument6 pagesSharon PlywoodnvkjayanthNo ratings yet

- World/Gmp Grade Isopropyl Alcohol, 99%: Certificate of AnalysisDocument3 pagesWorld/Gmp Grade Isopropyl Alcohol, 99%: Certificate of AnalysisChé FeNo ratings yet

- Determination of Aluminium Back TitrationDocument2 pagesDetermination of Aluminium Back Titrationdhungelsubhash8154100% (4)

- ASTM Ceramic DaftarDocument5 pagesASTM Ceramic DaftarAgung SetioNo ratings yet

- Nova ABS Plastic Formwork by Sandeep NaikwadeDocument11 pagesNova ABS Plastic Formwork by Sandeep NaikwadeNovaFormworkNo ratings yet

- Comparision Between CSEB and Clay BricksDocument7 pagesComparision Between CSEB and Clay BricksShah ZaibNo ratings yet

- Material Declaration Form Material Declaration Form: Matt SigmonDocument1 pageMaterial Declaration Form Material Declaration Form: Matt SigmonEb INo ratings yet

- Poly Drop Brochure 2010Document8 pagesPoly Drop Brochure 2010Marco BusaNo ratings yet

- SF 450 CCTDocument19 pagesSF 450 CCTSoup PongsakornNo ratings yet

- Validation of Special ProcessesDocument3 pagesValidation of Special ProcessesJeyakumarNo ratings yet

- 0620 s19 QP 32 PDFDocument20 pages0620 s19 QP 32 PDFSecretary Of SecretsNo ratings yet

- Zinc and Tin Alloy Wire Used in Thermal Spraying For Electronic ApplicationsDocument4 pagesZinc and Tin Alloy Wire Used in Thermal Spraying For Electronic ApplicationsBang AnNo ratings yet

- Katalog AuftragsschweißenDocument12 pagesKatalog AuftragsschweißentobiaswatzingerNo ratings yet

- Acrodur DS 3530 February 2018 R3 EDFDocument3 pagesAcrodur DS 3530 February 2018 R3 EDFAllen de RichardNo ratings yet

- Smart, Waterproof, Breathable Sportsware - A ReviewDocument13 pagesSmart, Waterproof, Breathable Sportsware - A ReviewKrergkrai ChantalertvittayaNo ratings yet

- 7 Tank ProcessDocument4 pages7 Tank ProcessJalagandeeswaran Kalimuthu100% (1)

- Non Destructive Testing Non Destructive TestingDocument74 pagesNon Destructive Testing Non Destructive TestingPrasant Kumar BeheraNo ratings yet

- ColdGuard Sliding Cold Storage DoorsDocument1 pageColdGuard Sliding Cold Storage DoorsgamunozdNo ratings yet

- KBR-Economic Bottom of The Barrel Processing To Minimize Fuel Oil Production PDFDocument5 pagesKBR-Economic Bottom of The Barrel Processing To Minimize Fuel Oil Production PDFsantiagoNo ratings yet

- Egger Pumpes and Valves OverviewDocument25 pagesEgger Pumpes and Valves Overviewmanny casiquinNo ratings yet

- MMM Brochure IA-IISDocument2 pagesMMM Brochure IA-IISLintangNo ratings yet

- Colloids Shape and Size and Prep NotesDocument12 pagesColloids Shape and Size and Prep NotesNavnath HatvateNo ratings yet

- U W Civil Utility Tunnels and Trenches: Facilities Service S Design GuideDocument9 pagesU W Civil Utility Tunnels and Trenches: Facilities Service S Design GuideRamces AsisiNo ratings yet

- Sikawall®-161 Plaster Mix: Product Data SheetDocument3 pagesSikawall®-161 Plaster Mix: Product Data SheetAcil Nazir CaniagoNo ratings yet

- The Procedure Handbook of Arc Welding (Twelfth Edition)Document742 pagesThe Procedure Handbook of Arc Welding (Twelfth Edition)Adisak Aumpiem100% (1)

- Government of TelanganaDocument4 pagesGovernment of TelanganaDinesh ReddyNo ratings yet