Professional Documents

Culture Documents

Technical Info:-: Home About Us Technical Info Quality Policy Enquiry Form Contact Us

Technical Info:-: Home About Us Technical Info Quality Policy Enquiry Form Contact Us

Uploaded by

ajaykrishnaaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Info:-: Home About Us Technical Info Quality Policy Enquiry Form Contact Us

Technical Info:-: Home About Us Technical Info Quality Policy Enquiry Form Contact Us

Uploaded by

ajaykrishnaaCopyright:

Available Formats

NIKO STEEL INDUSTRIES

Home

About Us

Technical Info

Quality Policy

Enquiry Form

Contact Us

TECHNICAL INFO :Pipes & Tubes

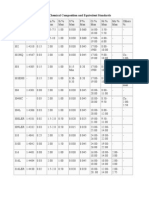

CHEMICAL COMPOSITION MECHANICAL COMPOSITION

Sheets, Coils & Plates

Structural Steel

Round Bar & Wire

Pipe Fittings

Flanges

Mn

Si

Cr

Ni

Mo

Other elements

max

max

max

0.045 0.030 1.00

1820

810.5

---

---

0.045 0.030 1.00

1820

8-12

---

---

0.10

0.040 0.030 0.75

1820

8-12

---

---

---

0.06

0.045 0.030 1.00

1719

8-11

---

n=0.12-0.25

---

1.4311

0.03

0.045 0.030 0.75

1719

8-12

---

n=0.12-0.25

309S

S30908

1.4828

0.08

0.045 0.030 0.75

2224

1215

---

---

310S

S31008

1.4845

0.08

0.045 0.030 1.50

2426

1922

---

---

316

S31600

1.4401

0.06

0.045 0.030 1.00

1618.5

10.5- 2-2.5

13.5

---

316H

S31603

1.4919

0.10

0.040 0.030 0.75

1618

11- 2-2.5

13.5

---

316L

---

1.4404

0.03

0.045 0.030 1.00

1618.5

1114

2-2.5

---

316LN

---

1.4406

0.03

0.045 0.030 1.00

1618.5

1114

2-2.5

n=0.12-0.25

316Ti

S31635

1.4571

0.08

0.045 0.030 1.00

1618.5

317

---

---

0.08

0.045 0.030 1.00

1820

317L

S31703

1.4438

0.03

0.045 0.030 1.00 17.519.5

Grade

AISI

UNS

Euro

Norm

En10088

304

S30400

1.4301

0.08

304L

S30403

1.4306

0.03

304H

S30409

1.4948

304N

---

304LN

max max

Valves

Gaskets

Non Ferrous Metal

OUR CLIENTS

http://www.nikosteel.com/pipe_chem.htm[04-Jun-12 7:58:02 PM]

10.5- 2-2.5

13.5

Ti=5xcmin;0.8max

1115

3-4

---

1316.5

3-4

---

NIKO STEEL INDUSTRIES

321

S32100

1.4541

0.08

0.045 0.030 1.00

1719

9-12

---

Ti=5xcmin;0.6max

321H

S32109

---

0.10

0.030 0.030 0.75

1719

9-13

---

Ti=4xcmin;0.6max

347

S34700

1.4550

0.08

0.045 0.030 1.00

1719

9-13

---

Nb+Ta=10xcmin;1max

347H

S34709

---

0.10

0.030 0.030 0.75

1719

9-13

---

Nb+Ta=8xcmin;1max

409

---

1.4512

0.08

0.045 0.045 1.00 10.511.75

---

---

Ti=6xcmin;0.75max

410

---

1.4006

0.15

0.040 0.030 1.00 11.513.5

---

---

---

430

---

1.4016

0.12

0.040 0.030 1.00

---

---

---

2304

Duplex

S32304

1.4362

0.03 2.50 0.040 0.030 1.00 21.5- 3-5.5 0.0524.5

0.60

2205

Duplex

S31803

1.4462

0.03 2.00 0.030 0.020 1.00

2123

4.56.5

2.53.5

N0.08-0.20

2507 S32750

S.Duplex

1.4410

0.03 1.20 0.035 0.020 0.80

2426

6-8

3-5

N0.240.32,Cu0.05max

1618

N0.05-0.20,Cu0.050.6

Fe are balanced in above mentioned alloys.

Grade AISI

Density

g/cm3

Tensile Strength

MPa

Yield Strength

MPa

Elongation

min%

304

8.0

515

205

35

304L

8.0

485

170

35

304H

8.0

515

205

35

304N

8.0

550

240

35

304LN

8.0

515

205

35

309S

8.0

515

205

35

310S

8.0

515

205

35

316

8.0

515

205

35

316H

8.0

515

205

35

316L

8.0

485

170

35

316LN

8.0

515

205

35

316Ti

8.0

485

170

35

317

8.0

515

205

35

317L

8.0

515

205

35

321

8.0

515

205

35

321H

8.0

515

205

35

http://www.nikosteel.com/pipe_chem.htm[04-Jun-12 7:58:02 PM]

NIKO STEEL INDUSTRIES

347

8.0

515

205

35

347H

8.0

515

205

35

409

---

415

205

20

410

7.8

415

205

20

430

7.8

415

240

20

2304 Duplex

7.8

600

400

25

2205 Duplex

7.8

620

450

25

2507 S.Duplex

7.8

795

550

15

Home | About Us | Technical Info | Quality Policy | Enquiry Form | Contact Us

Copyright NIKO STEEL INDUSTRIES. All Rights Reserved

Site Developed by www.mesotek.com

http://www.nikosteel.com/pipe_chem.htm[04-Jun-12 7:58:02 PM]

You might also like

- Aircraft Landing Gear ADVDocument28 pagesAircraft Landing Gear ADVBhagyaraj NP100% (1)

- ASME-GB Steel Grades Comparison TableDocument11 pagesASME-GB Steel Grades Comparison TableAsad Hafeez100% (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Standard Holes and Tapping ChartDocument1 pageStandard Holes and Tapping ChartajaykrishnaaNo ratings yet

- Werkstoffe E PDFDocument12 pagesWerkstoffe E PDFirajfarji2481No ratings yet

- Chemical Analyses-Stainless Steels Duplex and Special AlloysDocument8 pagesChemical Analyses-Stainless Steels Duplex and Special AlloysStuartNo ratings yet

- Chemical Compositions - Paawan Impex & Trading Pvt. Ltd.Document4 pagesChemical Compositions - Paawan Impex & Trading Pvt. Ltd.Prabhakar KattulaNo ratings yet

- Home About Us Products Display News Contact ProductsDocument8 pagesHome About Us Products Display News Contact ProductsBosz InNo ratings yet

- Star Steels A PDFDocument24 pagesStar Steels A PDFsocomenin2013No ratings yet

- Equivalent Standards - A - SA516-70, A - SA515-70, ST52-3, S355J2+N, SAILMA 350HI, SAILMA 450HIDocument10 pagesEquivalent Standards - A - SA516-70, A - SA515-70, ST52-3, S355J2+N, SAILMA 350HI, SAILMA 450HIPuneet BahriNo ratings yet

- SSWM Mill Certificate 919 SSWMDocument1 pageSSWM Mill Certificate 919 SSWMkerrilocke56No ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- ME Pipe Clamp - CatalogueDocument20 pagesME Pipe Clamp - CatalogueRashesh PadiaNo ratings yet

- 12 - Right Angle Drives: Catalog Series Material Pages RatiosDocument16 pages12 - Right Angle Drives: Catalog Series Material Pages RatiosODG_290473No ratings yet

- Steel GradesDocument12 pagesSteel GradesDidar Singh Thethi100% (1)

- STD PipingDocument51 pagesSTD PipingRodrigo Iván Latorre AlmirallNo ratings yet

- Low Alloy Steels Part2Document1 pageLow Alloy Steels Part2fedaquiNo ratings yet

- ALLOY-20 - FI - US - EN Very Good All AboutDocument55 pagesALLOY-20 - FI - US - EN Very Good All Aboutmahmoud_allam3No ratings yet

- DIN 3015 ClampsDocument20 pagesDIN 3015 ClampsRasheshNo ratings yet

- Chemical CompositionDocument13 pagesChemical Compositionssharma3474No ratings yet

- Valve MOC and ImportantDocument22 pagesValve MOC and ImportantUdhayakumar VenkataramanNo ratings yet

- Cutting Edge BrochureDocument2 pagesCutting Edge BrochureKen SmithNo ratings yet

- Hot Dip Galvani SheetDocument3 pagesHot Dip Galvani SheetumarNo ratings yet

- Peeled Round Steel BarsDocument9 pagesPeeled Round Steel BarsaxgasaNo ratings yet

- Dunaferr - Cold - RolledDocument12 pagesDunaferr - Cold - RolledMihály PálffyNo ratings yet

- Dumpdata A50Document224 pagesDumpdata A50KillburnNo ratings yet

- Selection of MaterialsDocument1 pageSelection of MaterialsNur Sonia AbdNo ratings yet

- Material PropertiesDocument4 pagesMaterial Propertiesbratkp100% (1)

- BW145E Racing ApplicationsDocument0 pagesBW145E Racing ApplicationsNego CuencaNo ratings yet

- 4 - Stainless Steels - Wrought and CastDocument24 pages4 - Stainless Steels - Wrought and CastdennykvgNo ratings yet

- Staineless Steel Wire Flux Cored WireDocument6 pagesStaineless Steel Wire Flux Cored Wiregazwang478No ratings yet

- S+C Steels and Alloys - Schmidt + Clemens GroupDocument3 pagesS+C Steels and Alloys - Schmidt + Clemens GroupLuis DuarteNo ratings yet

- Metal Conduits and ConnectorsDocument28 pagesMetal Conduits and ConnectorskingoglobalNo ratings yet

- Boiler Tube/Pipe: Covered Arc Welding Electrodes Gas Tungsten Arc Welding WiresDocument6 pagesBoiler Tube/Pipe: Covered Arc Welding Electrodes Gas Tungsten Arc Welding WiresCarlos PadillaNo ratings yet

- Classif AçosDocument7 pagesClassif AçoslavascudoNo ratings yet

- Chemical ChartDocument6 pagesChemical ChartAnurag SarkarNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- RCC54 Circular Column ChartingDocument1 pageRCC54 Circular Column ChartingSMT VIETNAMNo ratings yet

- Tech - Spec - 2023 02 17 16 53 43Document4 pagesTech - Spec - 2023 02 17 16 53 43Binay YadavNo ratings yet

- GCMT 13 MS CN FLR 001 1 Jun Rev.2 Flare Stack CalculationDocument28 pagesGCMT 13 MS CN FLR 001 1 Jun Rev.2 Flare Stack CalculationMedyRiomaNo ratings yet

- ESP Pricelist May 2013Document80 pagesESP Pricelist May 2013torjaniceNo ratings yet

- Mat. 17MnV6 CaracteristiciDocument2 pagesMat. 17MnV6 CaracteristiciDani VaduvaNo ratings yet

- 1.0425 P265GH BOILER HTTP WWW - Ccsteels.com Structural Steel 37 PDFDocument2 pages1.0425 P265GH BOILER HTTP WWW - Ccsteels.com Structural Steel 37 PDFVaibhav GuptaNo ratings yet

- 5183 Aluminum Welding WireDocument1 page5183 Aluminum Welding Wiresank79No ratings yet

- Certificate of Analysis: Brammer Standard Company, IncDocument2 pagesCertificate of Analysis: Brammer Standard Company, Incdpk.kushwahNo ratings yet

- Agip STD - Piping Project SpecificationDocument1 pageAgip STD - Piping Project Specificationhalim_kaNo ratings yet

- ASTM A 269 Standar Spec. For Seamless and Welded Autenitic SS TubingDocument6 pagesASTM A 269 Standar Spec. For Seamless and Welded Autenitic SS TubingJose TorresNo ratings yet

- Leaded Tin Bronze C54400Document3 pagesLeaded Tin Bronze C54400nfcastingsNo ratings yet

- Aluminio BRONMETAL enDocument12 pagesAluminio BRONMETAL enPerica RakićNo ratings yet

- Saffron Consulting Engineers PVT LTDDocument5 pagesSaffron Consulting Engineers PVT LTDengineerkranthi4055No ratings yet

- Compression SpringsDocument75 pagesCompression SpringsAmr EhabNo ratings yet

- 500L Elevated OGST Inlet: 10" ANSI: Do Not Scale Drawing SizeDocument1 page500L Elevated OGST Inlet: 10" ANSI: Do Not Scale Drawing SizeCesar SerranoNo ratings yet

- Pipe and Fitting ChartDocument12 pagesPipe and Fitting Chartyulianus_sr100% (3)

- Materials AvailableDocument3 pagesMaterials AvailableKmt_AeNo ratings yet

- Wall Thickness Calculation-12 InchDocument23 pagesWall Thickness Calculation-12 InchChirag ShahNo ratings yet

- Material Selection and NameDocument6 pagesMaterial Selection and NameHlaingm KyawNo ratings yet

- En 10083 C50 Steel Plate High Carbon SteelDocument2 pagesEn 10083 C50 Steel Plate High Carbon SteelMatteo BuffoNo ratings yet

- Process Specification For Pickling, Etching, and Descaling of MetalsDocument10 pagesProcess Specification For Pickling, Etching, and Descaling of MetalsGys100% (1)

- Comp SteelsDocument8 pagesComp Steelskgupta27No ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

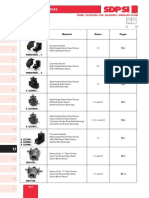

- Guide To Selection: Call Toll Free 800-562-0357Document7 pagesGuide To Selection: Call Toll Free 800-562-0357ajaykrishnaaNo ratings yet

- Ajay Covering LetterDocument1 pageAjay Covering LetterajaykrishnaaNo ratings yet

- Over Cap FeederDocument1 pageOver Cap FeederajaykrishnaaNo ratings yet

- Tool Steel CompositionDocument5 pagesTool Steel CompositionajaykrishnaaNo ratings yet

- En 8Document3 pagesEn 8ajaykrishnaaNo ratings yet

- Mild Steel Sheets:-: Range of Sheet, Plate, Strip, Flat & BlankDocument2 pagesMild Steel Sheets:-: Range of Sheet, Plate, Strip, Flat & BlankajaykrishnaaNo ratings yet

- Catia Interview Question and AnwersDocument64 pagesCatia Interview Question and AnwersajaykrishnaaNo ratings yet

- Speed and Accuracy Applications: Linear Drive UnitsDocument31 pagesSpeed and Accuracy Applications: Linear Drive UnitsajaykrishnaaNo ratings yet

- THK LM Guide en - A01 - 102Document2 pagesTHK LM Guide en - A01 - 102ajaykrishnaaNo ratings yet

- Ep 35 50Document1 pageEp 35 50ajaykrishnaaNo ratings yet

- Conveyor DesignsDocument34 pagesConveyor Designsajaykrishnaa100% (2)

- DSC Modular Conveyor Systems BrochureDocument32 pagesDSC Modular Conveyor Systems BrochureJuan Manuel LaraNo ratings yet

- Conveyor Chain GuideDocument59 pagesConveyor Chain GuideajaykrishnaaNo ratings yet

- Basic Mathematics by Thomas WardDocument23 pagesBasic Mathematics by Thomas WardazuzardNo ratings yet

- Innovative Designs For Positive Parts TransferDocument21 pagesInnovative Designs For Positive Parts TransferajaykrishnaaNo ratings yet

- FESTO Basic PnuematicsDocument115 pagesFESTO Basic Pnuematicsapi-3769014100% (10)

- Unigraphics NX4 ManualDocument700 pagesUnigraphics NX4 Manualajaykrishnaa100% (7)

- Afttp 1Document2 pagesAfttp 1ajaykrishnaaNo ratings yet

- FESTO Basic PLCDocument180 pagesFESTO Basic PLCapi-3769014100% (25)

- 99 Pneumatic ApplicationsDocument121 pages99 Pneumatic Applicationsapi-3731420100% (7)

- UG Interview QuestionsDocument16 pagesUG Interview Questionsharsharg6_8No ratings yet

- Delcam Power Mill Roughing and Finishing ProgrammeDocument27 pagesDelcam Power Mill Roughing and Finishing Programmeajaykrishnaa68% (19)