Professional Documents

Culture Documents

Mag Welding of Mild Steel Ferroline

Mag Welding of Mild Steel Ferroline

Uploaded by

canakyuzOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mag Welding of Mild Steel Ferroline

Mag Welding of Mild Steel Ferroline

Uploaded by

canakyuzCopyright:

Available Formats

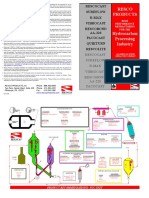

Gases for welding & cutting

TIG welding

Product Group ISO 14175

I1 R1 R1 R1 R1 I2 I3

DIN EN ISO 14175

Applications Abbreviation Group IdentNo.

I

MAG welding of mild steel

Product reducing H2 less-active N2

Ferroline C8 Ferroline C18 Ferroline C25 Ferroline X4 Ferroline X8 Ferroline C6 X1 Ferroline C12 X2 Ferroline C5 X5 Ferroline He20 C8 Carbon dioxide

Composite in % - Vol. Ar He H2

100 98,0 95,0 92,5 95,5 10 85 70 50 30 99,985 84,985 69,985 49,985 100 98,75 97,50 83,75 82,985 2,0 5,0 7,5 1,5

oxidizing CO2

N2

High and low alloyed steels aluminum + non ferrous metals Stainless Steels (high alloyed) Stainless Steels (high alloyed) (DC-)welding of aluminum (AC-)welding of aluminum + generally copper and nickel alloys 0,015 0,015 0,015 0,015

Components in % - Vol. inert O2 Ar He

Group ISO 14175

M 20 M 21 M 21 M 22 M 22 M 24 M 24 M 23 M 20 C1

Ar

92 82 75 96 92 93 86 90 72

Composite in % - Vol. CO2 O2

8 18 25 4 8 1 2 5

Applications He

mild steel mild steel mild steel low/restr. high alloyed steels low/restr. high alloyed steels mild steel mild steel low/restr. high alloyed steels mild steel mild steel

Welding Argon Inoxline H2 Inoxline H5 Inoxline H7 Inoxline He3 H1 Helium Argon-Helium Aluline He15 Aluline He30 Aluline He50 Aluline He70 Aluline N Aluline He15 N Aluline He30 N Aluline He50 N Welding Argon special Inoxline N1 Inoxline N2 Inoxline He15 N1 Inoxline He15 H2 N

Tungsten electrode Shielding gas nozzle Shielding gas

M1

I3

3 100 90 15 30 50 70 15 30 50

M2

Aluminum-alloys

M3

I1

Gas sensitive materials like titanium, niobium, tantalium 1,25 2,50 1,25 0,015 Duplex, Superduplex Nickel-Base alloys C R N

N2 Z

15 15

(-)

Power source

(+)

O Z

Electric arc Finished weld Workpiece

a)

1 100 2 100 3 balance 0,5 He 95 1 0,5 CO2 5 balancea) 0,5 H2 5 2 0,5 CO2 5 balancea) 3 0,5 O2 3 balancea) 4 0,5 CO2 5 0,5 O2 3 balancea) 0 5 < CO2 15 balancea) 1 15 < CO2 25 balancea) < O2 10 2 3 balancea) < O2 10 3 0,5 CO2 5 3 balancea) 4 5 < CO2 15 0,5 O2 3 balancea) 5 5 < CO2 15 3 < O2 10 balancea) 6 15 < CO2 25 0,5 O2 3 balancea) 7 15 < CO2 25 3 < O2 10 balancea) 1 25 < CO2 50 balancea) 2 10 < O2 15 balancea) < CO2 50 3 25 2 < O2 10 balancea) < CO2 25 4 5 10 < O2 15 balancea) 5 25 < CO2 50 10 < O2 15 balancea) 1 100 2 balance 0,5 O2 30 1 balancea) 0,5 H2 15 2 balancea) 15 H2 50 1 2 balancea) 3 balancea) 4 balancea) 0,5 H2 10 5 0,5 H2 50 1 100 Mixed gases with components not includes in the table or mixed gases with a composition outside of the given areas. b)

6 12 5 8 100

20

Drive Rolls Wire-electrode Shielding gas noozle Shielding gas

(+)

Power source

(-)

Electric arc Finished weld Workpiece

100 0,5 N2 5 5 < N2 50 0,5 N2 5 Rest

MAG welding of stainless steels

Product Group ISO 14175

M13 M12 Z M12 M14

Composition in % - Vol. Ar CO2 O2 He

98 97,5 2,5 67,88 0,12 83 2 96 3 2 30 15 1

Applications H2

high-alloyed steels high-alloyed steels Ni-alloys high-alloyed steels low/restr. high alloyed steels

Filler material

For this classification, argon may be replaced in whole or in part by helium. b) Two mixed gases with the same Z classification may not replace each other.

Root shielding

Product Group ISO 14175 Composite in % - Vol. Ar N2 H2 Applications Product Group ISO 14175

I1 Z I2 85 70 50 30 99,985 84,985 69,985 49,985

Inoxline X2 Inoxline C2 Inoxline He30 H2 C Inoxline He15 C2 Inoxline C3 X1

MIG welding

Composite in % -Vol. Ar He H2

100 82,985 15 100 15 30 50 70 15 30 50 2

Argon

I1

100

Forming gas H Inoxline H2 Inoxline H5

N5 R1 R1 98 95

95 - 80

5 - 20 2 5

Steels as: austenitic + ferritic, Duplex, Superduplex, fine grain structural non ferritic metals, CU-Ni Stainless steels Stainless steels, Nickel and Ni-base alloys Stainless steels, Nickel and Ni-base alloys

Applications N2

Aluminum, non ferrous metals 0,015 Ni-base-alloys Copper

Schweiargon Inoxline He15 H2 N Helium Aluline He15 Aluline He30 Aluline He50 Aluline He70 Aluline N Aluline He15 N Aluline He30 N Aluline He50 N

(+)

Power source

(-)

Messer Group GmbH Technology Management Welding and Cutting Gahlingspfad 31 47803 Krefeld Phone +49 2151 7811-0 Fax +49 2151 7811-501 welding-technology@messergroup.com www.messergroup.com

I3

Copper, aluminum, nickel + CuNife-alloys 0,015 0,015 Aluminum-alloys 0,015 0,015

Stand 12/2010

You might also like

- Weld SurveillanceDocument33 pagesWeld SurveillancecanakyuzNo ratings yet

- Halogen Free Hardeners For WaterglassDocument18 pagesHalogen Free Hardeners For WaterglassYtyus BlackNo ratings yet

- Fluid Flow in PipesDocument29 pagesFluid Flow in PipesitzGeekInside90% (20)

- Classification of PollutionDocument2 pagesClassification of PollutionmaryaniNo ratings yet

- Poster - Gases - en MESSER PDFDocument1 pagePoster - Gases - en MESSER PDFVladan TimotijevicNo ratings yet

- Gases For Welding and Cutting - OverviewDocument1 pageGases For Welding and Cutting - OverviewtomasinkaNo ratings yet

- NOVI KATALOG GASOVA MESSER - EnG Inert Gas Welding Indert Gas Welding Selected Reference TablesDocument6 pagesNOVI KATALOG GASOVA MESSER - EnG Inert Gas Welding Indert Gas Welding Selected Reference TablesIvan DulicNo ratings yet

- International StandardDocument4 pagesInternational StandardZoran DanilovNo ratings yet

- Inert Gas Welding Indert Gas Welding Selected Reference TablesDocument6 pagesInert Gas Welding Indert Gas Welding Selected Reference Tableshooky1No ratings yet

- International - Standard ISO 14175Document3 pagesInternational - Standard ISO 14175Geom_MengoliNo ratings yet

- GM Aw and GT Aw ConsumablesDocument118 pagesGM Aw and GT Aw Consumablessepe00No ratings yet

- Poster Welding Gases enDocument1 pagePoster Welding Gases enTien Duong ChuNo ratings yet

- Aluminio BRONMETAL enDocument12 pagesAluminio BRONMETAL enPerica RakićNo ratings yet

- LNT26 EngDocument1 pageLNT26 EngMustafaNo ratings yet

- Av Catalogo Completo 2005Document20 pagesAv Catalogo Completo 2005Marin LaurentiuNo ratings yet

- LNT26Document1 pageLNT26soft4gsmNo ratings yet

- En 10305 1 Sunny SteelDocument6 pagesEn 10305 1 Sunny Steelmohamed belkadiNo ratings yet

- Welding Gases and Their ApplicationDocument1 pageWelding Gases and Their ApplicationFredNo ratings yet

- Classifications: For 560mpa Low Temperature Service Steel (1.5% Ni)Document1 pageClassifications: For 560mpa Low Temperature Service Steel (1.5% Ni)BHARANINo ratings yet

- Gases de Proteccion MIG-MAG-GMAW. Standard ISO 14175 Vs en 439Document3 pagesGases de Proteccion MIG-MAG-GMAW. Standard ISO 14175 Vs en 439xevi00No ratings yet

- Bohler SG2 PDFDocument1 pageBohler SG2 PDFInaamNo ratings yet

- Classifications: For Atmospheric Corrosion Resisting SteelDocument1 pageClassifications: For Atmospheric Corrosion Resisting Steelhuynh thanh truongNo ratings yet

- TDS ATLANTIC CHT81Ni1Document1 pageTDS ATLANTIC CHT81Ni1Andi Baso Temalala STNo ratings yet

- FontargenDocument282 pagesFontargenMIHAINo ratings yet

- Bohler Ars 5 - e 71 T-1 C (M) H8Document1 pageBohler Ars 5 - e 71 T-1 C (M) H8Mario MolinaNo ratings yet

- Chinese To DinDocument7 pagesChinese To Dindnageshm4n244No ratings yet

- Aluminium SpecificationDocument2 pagesAluminium SpecificationklhlNo ratings yet

- Select Arc Catalogue Part 1Document10 pagesSelect Arc Catalogue Part 1lionheartedNo ratings yet

- Al Busbar 6060 DatasheetDocument1 pageAl Busbar 6060 DatasheetpiirsaluNo ratings yet

- FSH TigDocument105 pagesFSH TigChee WeiNo ratings yet

- Electrodes EnglishDocument139 pagesElectrodes Englishcostelino72No ratings yet

- SF 71MCDocument1 pageSF 71MCGESTION Y CONTROL DE PROYECTOS IngeminNo ratings yet

- Ultramag Sg3: Mild Steel Solid WireDocument1 pageUltramag Sg3: Mild Steel Solid Wireabidaliabid1No ratings yet

- Data SAF2205 04Document8 pagesData SAF2205 04il_yoo_1No ratings yet

- MIP Bohler Welding Austria 63Document1 pageMIP Bohler Welding Austria 63thod3rNo ratings yet

- Welded Pipes - API 5L Grade X65 PSL 2Document2 pagesWelded Pipes - API 5L Grade X65 PSL 2Minh TrungNo ratings yet

- Chinese To DinDocument7 pagesChinese To DinDamla KaymakçıNo ratings yet

- Aluminium AlloysDocument43 pagesAluminium AlloysArg SreekarNo ratings yet

- Consumables For Duplex Stainless SteelDocument6 pagesConsumables For Duplex Stainless SteelMohamed FaragNo ratings yet

- HCL, CL Corrosion DataDocument8 pagesHCL, CL Corrosion DataShah RajendraNo ratings yet

- Bavaria en BA-TIG 310Document1 pageBavaria en BA-TIG 310cocoNo ratings yet

- DATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Document2 pagesDATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Dries VandezandeNo ratings yet

- 1 0 Next: ExamplesDocument2 pages1 0 Next: ExamplesSatish MehtaNo ratings yet

- Böhler SG 2: Solid Wire, UnalloyedDocument1 pageBöhler SG 2: Solid Wire, Unalloyedrombi aritonangNo ratings yet

- Welding PresentationDocument48 pagesWelding Presentationedu_canete100% (2)

- Data 6005ADocument1 pageData 6005AErick De La RoSaNo ratings yet

- Welded Stainless Steel Tubes: SectionDocument6 pagesWelded Stainless Steel Tubes: Sectionrudiskw456No ratings yet

- Pipes, Tubes, Fittings, FlangesDocument121 pagesPipes, Tubes, Fittings, FlangesCarl Jones100% (2)

- UK Material CodesDocument34 pagesUK Material CodesAan Sarkasi Amd100% (1)

- UTP For LNG PDFDocument5 pagesUTP For LNG PDFkamals55No ratings yet

- Aluminium AloyDocument2 pagesAluminium AloyGian GiovaniNo ratings yet

- Aluminum Material ComparisonDocument1 pageAluminum Material ComparisonWahad TnainNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Vibrational Spectra of Organometallics: Theoretical and Experimental DataFrom EverandVibrational Spectra of Organometallics: Theoretical and Experimental DataNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- XXIVth International Congress of Pure and Applied Chemistry: Plenary and Main Section Lectures Presented at Hamburg, Federal Republic of Germany, 2–8 September 1973From EverandXXIVth International Congress of Pure and Applied Chemistry: Plenary and Main Section Lectures Presented at Hamburg, Federal Republic of Germany, 2–8 September 1973No ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Extractive Metallurgy 2: Metallurgical Reaction ProcessesFrom EverandExtractive Metallurgy 2: Metallurgical Reaction ProcessesRating: 5 out of 5 stars5/5 (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- SCE Man1Document2 pagesSCE Man1canakyuzNo ratings yet

- APM WhitepaperDocument17 pagesAPM WhitepapercanakyuzNo ratings yet

- Brochure and Operator InstructionsDocument6 pagesBrochure and Operator InstructionscanakyuzNo ratings yet

- Alloy 890Document4 pagesAlloy 890canakyuzNo ratings yet

- Corrosion Solutions: Sridhar SrinivasanDocument54 pagesCorrosion Solutions: Sridhar SrinivasancanakyuzNo ratings yet

- Sample CylinderDocument9 pagesSample CylindercanakyuzNo ratings yet

- Hot Bolting and The Morsafe™ Clamp Thomas Lamb1, Ian Thompson2Document4 pagesHot Bolting and The Morsafe™ Clamp Thomas Lamb1, Ian Thompson2canakyuzNo ratings yet

- RescoDocument2 pagesRescocanakyuzNo ratings yet

- Material Selection For Flare TipsDocument200 pagesMaterial Selection For Flare Tipscanakyuz100% (2)

- Steel Grades 2 PDFDocument2 pagesSteel Grades 2 PDFcanakyuz0% (1)

- Plasite 4550Document4 pagesPlasite 4550canakyuzNo ratings yet

- Rockwool ProcessDocument179 pagesRockwool Processcanakyuz100% (1)

- Ultracorr: Ultracorr 2 IS Wall Thickness MonitorDocument2 pagesUltracorr: Ultracorr 2 IS Wall Thickness MonitorcanakyuzNo ratings yet

- EMAT CatalogDocument4 pagesEMAT CatalogcanakyuzNo ratings yet

- Failure Modeling and Maintenance Optimization For A Railway LineDocument14 pagesFailure Modeling and Maintenance Optimization For A Railway LinecanakyuzNo ratings yet

- Consider Penetration When Determining Fillet Weld SizeDocument3 pagesConsider Penetration When Determining Fillet Weld SizecanakyuzNo ratings yet

- Ceramic Weld Backing EvaluationDocument106 pagesCeramic Weld Backing EvaluationcanakyuzNo ratings yet

- Purging CostSavingsDocument2 pagesPurging CostSavingscanakyuzNo ratings yet

- Drilling Fluids ManualDocument444 pagesDrilling Fluids ManualShivaram Suppiah100% (1)

- Chapter 4 - Distributed-Parameters Models: Profa. Liliane Lona - em RevisãoDocument39 pagesChapter 4 - Distributed-Parameters Models: Profa. Liliane Lona - em RevisãoMônica CarneiroNo ratings yet

- Jhajjar Paper NEET 2024Document32 pagesJhajjar Paper NEET 2024adibanigar271No ratings yet

- Vasitesa Sygef PVDFDocument380 pagesVasitesa Sygef PVDFIsrael AristaNo ratings yet

- Determining The Water Holding Capacity of Microbial CelluloseDocument4 pagesDetermining The Water Holding Capacity of Microbial CellulosegoldennanukNo ratings yet

- COLUMN INTERNALS Part 1 - TRAYSDocument85 pagesCOLUMN INTERNALS Part 1 - TRAYSMohammadShamimNo ratings yet

- ABIDocument27 pagesABIekramNo ratings yet

- ReddDocument183 pagesReddXQNo ratings yet

- 08 - Water and SolutionsDocument32 pages08 - Water and Solutionsayulg2100% (2)

- MBrace Lam PDFDocument2 pagesMBrace Lam PDFFrancois-No ratings yet

- Refining of Crude and Its Corrosion Control Using Distributed Control SystemDocument7 pagesRefining of Crude and Its Corrosion Control Using Distributed Control Systemcoolguy12345No ratings yet

- Class 12 MLM Chemistry em PDFDocument77 pagesClass 12 MLM Chemistry em PDFkalaiarasiNo ratings yet

- Solstice N40 TDS 141216 VF PDFDocument2 pagesSolstice N40 TDS 141216 VF PDFnaren233No ratings yet

- Astm C-88Document5 pagesAstm C-88Fernanda MenesesNo ratings yet

- Properties of Extremely Dry Concrete Made With EcoCement and Recycled Coarse AggregateDocument9 pagesProperties of Extremely Dry Concrete Made With EcoCement and Recycled Coarse AggregateCNo ratings yet

- Module 2Document7 pagesModule 2Fiona Belle DaganteNo ratings yet

- Sample Lesson Plan in Science V Using Explicit InstructionDocument6 pagesSample Lesson Plan in Science V Using Explicit InstructionKrimson Mike DolorzoNo ratings yet

- GAPS Guidelines: Boiler FundamentalsDocument4 pagesGAPS Guidelines: Boiler FundamentalstilayeyidegNo ratings yet

- 3b - Serway - MillikanDocument7 pages3b - Serway - Millikanalejandro1rs1orNo ratings yet

- CationsDocument6 pagesCationsPierce MoralesNo ratings yet

- Graphical Representation of One-Dimensional, Transient Conduction in The Plane Wall, Long Cylinder, and SphereDocument5 pagesGraphical Representation of One-Dimensional, Transient Conduction in The Plane Wall, Long Cylinder, and Spherevincent02hk_57881301No ratings yet

- Synthesis of GrapheneDocument21 pagesSynthesis of GrapheneLeo banikNo ratings yet

- Performancereport 2012-13Document112 pagesPerformancereport 2012-13dddNo ratings yet

- Aditya SharmaDocument12 pagesAditya SharmaAnish kumarNo ratings yet

- BlowoutDocument14 pagesBlowoutNelson TorresNo ratings yet

- Hardness Conversion Chart - ..Document2 pagesHardness Conversion Chart - ..Fabio Emanuele BrandaNo ratings yet

- hw1 sp11Document26 pageshw1 sp11Christopher Lennon Dela CruzNo ratings yet