Professional Documents

Culture Documents

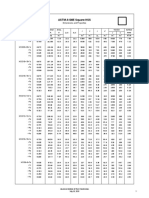

Al 6061-T6 Section Properties

Al 6061-T6 Section Properties

Uploaded by

Suresh KumarCopyright:

Available Formats

You might also like

- Profile Laminate-CornierDocument7 pagesProfile Laminate-CornierdarabafloNo ratings yet

- Final Report RSADocument27 pagesFinal Report RSAMounesh Panchal67% (3)

- Industrial Ventilation Design Guidebook OLD VERSIONDocument343 pagesIndustrial Ventilation Design Guidebook OLD VERSIONwalter_micale_yahoo100% (11)

- Standard Pneumatic Cylinder Force Calculation (KGF)Document2 pagesStandard Pneumatic Cylinder Force Calculation (KGF)D KANCUTZNo ratings yet

- Base Plate For Axial LoadsDocument88 pagesBase Plate For Axial Loadsfaizan ashiqueNo ratings yet

- Elements of Soil Mechanics, 8th Edition Bearing Capacity FactorsDocument14 pagesElements of Soil Mechanics, 8th Edition Bearing Capacity FactorsdiditjayacuteNo ratings yet

- Elements of Soil Mechanics, 8th Edition Bearing Capacity FactorsDocument14 pagesElements of Soil Mechanics, 8th Edition Bearing Capacity Factorsthiru2025No ratings yet

- Elements of Soil Mechanics, 8th Edition Bearing Capacity FactorsDocument14 pagesElements of Soil Mechanics, 8th Edition Bearing Capacity FactorsPoco SmithNo ratings yet

- ch9t8 PDFDocument1 pagech9t8 PDFReimart H BornilloNo ratings yet

- Aluminium Conductor Steel Reinforced (Acsr) : Characteristics of A1/S1 B Conductors As Per IEC 1089/91 TYPE A1/S1 BDocument12 pagesAluminium Conductor Steel Reinforced (Acsr) : Characteristics of A1/S1 B Conductors As Per IEC 1089/91 TYPE A1/S1 Briddler_007No ratings yet

- Pipe Friction Loss Spreadsheet - Hazen Williams Apr17Document4 pagesPipe Friction Loss Spreadsheet - Hazen Williams Apr17saham cuanNo ratings yet

- S10.s4 Bearing-CapacityDocument20 pagesS10.s4 Bearing-CapacityRodolfo Jesus Calle FloresNo ratings yet

- Bearing Capacity TablesDocument5 pagesBearing Capacity TablesPipoy ReglosNo ratings yet

- Tablica Nosive 3Document5 pagesTablica Nosive 3Patrik SfikoNo ratings yet

- C ChannelDocument1 pageC ChannelJuan Gutier CcNo ratings yet

- Updated SBC CalculationDocument8 pagesUpdated SBC CalculationSURYA CHEJERLANo ratings yet

- Z Purlin Data SheetDocument19 pagesZ Purlin Data SheetAkhil VNNo ratings yet

- C Purlin Data SheetDocument6 pagesC Purlin Data SheetAkhil VNNo ratings yet

- Practical Electronics - SWG - Wikibooks, Open Books For An Open WorldDocument5 pagesPractical Electronics - SWG - Wikibooks, Open Books For An Open WorldSandeep Kumar SinghNo ratings yet

- Simulating A M/M/1 Queueing System: Results From One Run: Arrival Rate (Customers/sec) Departure Rate (Custutomers/sec)Document44 pagesSimulating A M/M/1 Queueing System: Results From One Run: Arrival Rate (Customers/sec) Departure Rate (Custutomers/sec)Dr. Ir. R. Didin Kusdian, MT.No ratings yet

- Tabel MaterialDocument19 pagesTabel MaterialBang OchimNo ratings yet

- ASTM A1085 Square HSS: Surface Area Design Wall Thickness, T Nominal Wt. Area, Shape TorsionDocument3 pagesASTM A1085 Square HSS: Surface Area Design Wall Thickness, T Nominal Wt. Area, Shape TorsionamadhubalanNo ratings yet

- As Per DW/143, EN 1886: 1998, EN 1751:1999 Standard As Per SMACNA StandardDocument6 pagesAs Per DW/143, EN 1886: 1998, EN 1751:1999 Standard As Per SMACNA Standardketan mehtaNo ratings yet

- Pipe (Carbon Steel) (OK)Document1 pagePipe (Carbon Steel) (OK)Phan Tri ThongNo ratings yet

- Mi1008 FPS II Engineering Manual 513 WEBDocument34 pagesMi1008 FPS II Engineering Manual 513 WEBErich ThomasNo ratings yet

- Engineering Tables - Standard Wire Gauge - Wikibooks, Open Books For An Open WorldDocument5 pagesEngineering Tables - Standard Wire Gauge - Wikibooks, Open Books For An Open WorldSuleman KhanNo ratings yet

- Friction Loss Charts 2008Document36 pagesFriction Loss Charts 2008idiayNo ratings yet

- SRP ИскопDocument11 pagesSRP ИскопNella NelicaNo ratings yet

- Tablica Nosive 4Document5 pagesTablica Nosive 4Patrik SfikoNo ratings yet

- Friction Loss Charts 2008: H 100 C Q DDocument36 pagesFriction Loss Charts 2008: H 100 C Q DSiva NesanNo ratings yet

- Pipe Friction Loss Spreadsheet - Hazen Williams Apr17Document6 pagesPipe Friction Loss Spreadsheet - Hazen Williams Apr17Kapil BairagiNo ratings yet

- Bonjean DataDocument14 pagesBonjean DataAurvin SinghNo ratings yet

- Engineering Tables - Standard Wire Gauge - Wikibooks, Open Books For An Open WorldDocument5 pagesEngineering Tables - Standard Wire Gauge - Wikibooks, Open Books For An Open WorldMaya MenanNo ratings yet

- A1085 Dimensions and Properties Round HssDocument3 pagesA1085 Dimensions and Properties Round HssRaul Flores BegazoNo ratings yet

- W-Beam Pier PropertiesDocument1 pageW-Beam Pier PropertiesSathish KumarNo ratings yet

- Comparison Steel ShapeDocument80 pagesComparison Steel ShapeRaditya PurnamahadiNo ratings yet

- Wire Gauge ChartDocument2 pagesWire Gauge Chartkrishna0% (1)

- Steel Section Tables PDFDocument5 pagesSteel Section Tables PDFjustinmallari09No ratings yet

- W Steel Section Tables 080307 PDFDocument5 pagesW Steel Section Tables 080307 PDFlimberthNo ratings yet

- W Steel Section Tables 080307 PDFDocument5 pagesW Steel Section Tables 080307 PDFMehman NasibovNo ratings yet

- W Steel Section Tables 080307 PDFDocument5 pagesW Steel Section Tables 080307 PDFDylanLiNo ratings yet

- Steel Section TablesDocument5 pagesSteel Section TablespudenaliNo ratings yet

- W Steel Section Tables 080307 PDFDocument5 pagesW Steel Section Tables 080307 PDFAlejandro OspinaNo ratings yet

- W Steel Section Tables 080307 PDFDocument5 pagesW Steel Section Tables 080307 PDFNgocTraiNguyenNo ratings yet

- Bare Overhead Conductors-2015Document63 pagesBare Overhead Conductors-2015Weber HahnNo ratings yet

- Design of Weld For Gantry1Document4 pagesDesign of Weld For Gantry1pragneshNo ratings yet

- Pipe Conversion ChartDocument7 pagesPipe Conversion ChartramyzottyNo ratings yet

- Deflection For UDL and Point Load at The Centre by Heritier Mbuyi TshikalaDocument9 pagesDeflection For UDL and Point Load at The Centre by Heritier Mbuyi TshikalaWataNo ratings yet

- Tabel Baja LengkapDocument32 pagesTabel Baja LengkapNugroho PratomoNo ratings yet

- XFMRDocument33 pagesXFMRamro emadNo ratings yet

- Hdpe ChartDocument2 pagesHdpe Chartmohamedaymansufpme2021No ratings yet

- FF Olets Brochure PDFDocument18 pagesFF Olets Brochure PDFअभि ना. कुंभारNo ratings yet

- Engineering Tables - Standard Wire Gauge - Wikibooks, Open Books For An Open WorldDocument4 pagesEngineering Tables - Standard Wire Gauge - Wikibooks, Open Books For An Open Worldrekhnor magbanuaNo ratings yet

- Standard Metric and USA Bolt Shank Dimensions: MM MMDocument2 pagesStandard Metric and USA Bolt Shank Dimensions: MM MMLan MendietaNo ratings yet

- Keamanan Pengangkatan Sesaat Setelah Demoulding (Mutu Beton 50% Mutu Beton Rencana)Document3 pagesKeamanan Pengangkatan Sesaat Setelah Demoulding (Mutu Beton 50% Mutu Beton Rencana)ihsan fachroziNo ratings yet

- Wolfson - Eenheid (High Speed)Document5 pagesWolfson - Eenheid (High Speed)Oscar GarayNo ratings yet

- Foundation RehabilitationDocument17 pagesFoundation RehabilitationsahilkaushikNo ratings yet

- Worksheet Ms. Enorio EDITEDDocument13 pagesWorksheet Ms. Enorio EDITEDDarryl Hannah Amado SilvaNo ratings yet

- Passing Select-Options To Smart Forms: by VenkatDocument43 pagesPassing Select-Options To Smart Forms: by VenkatsudhakpNo ratings yet

- Guideline For Reducing CCR Circulation Rate With Lower Oxygen Concentration in White Burn ModeDocument3 pagesGuideline For Reducing CCR Circulation Rate With Lower Oxygen Concentration in White Burn ModevkumaranNo ratings yet

- Curso: Programación de Obras: Docente: Ing. Karina M. Espinoza Mezarina Ciclo: IxDocument25 pagesCurso: Programación de Obras: Docente: Ing. Karina M. Espinoza Mezarina Ciclo: IxEliazarPeraltaNo ratings yet

- 2 Earthing System - MaintenanceDocument55 pages2 Earthing System - MaintenanceVikas RazdanNo ratings yet

- The Prediction of Gold Price Using ARIMA Model: Abstract-Although, 2016 and 2017 Have Risen, The InternationalDocument4 pagesThe Prediction of Gold Price Using ARIMA Model: Abstract-Although, 2016 and 2017 Have Risen, The InternationalpydyNo ratings yet

- MOXA Tech Note - Using Wonderwares InTouch With IoLogik 4000 ServersDocument15 pagesMOXA Tech Note - Using Wonderwares InTouch With IoLogik 4000 ServersEko Tri WasistoNo ratings yet

- Model Predictive Control For Integrating Processes: Lou Heavner - Consultant, APCDocument23 pagesModel Predictive Control For Integrating Processes: Lou Heavner - Consultant, APCsamim_khNo ratings yet

- Cơ Sở Toán Học Cho Mật Mã - Huỳnh Trọng ThưaDocument34 pagesCơ Sở Toán Học Cho Mật Mã - Huỳnh Trọng ThưaHồng HuyNo ratings yet

- IUPAC Provisional Recommendations: Table VII Ligand AbbreviationsDocument12 pagesIUPAC Provisional Recommendations: Table VII Ligand AbbreviationsSalih PaşaNo ratings yet

- Ye Tu19 Turning IDocument36 pagesYe Tu19 Turning IferNo ratings yet

- CV Hiero Kp.Document1 pageCV Hiero Kp.hieroNo ratings yet

- Versamax Io Guide 0Document36 pagesVersamax Io Guide 0joberhrNo ratings yet

- Power Generation: Powered by Perkins Diesel Engine 50Hz, 380v, 415v, 3 Phase, 4 Wire, 1500rpmDocument2 pagesPower Generation: Powered by Perkins Diesel Engine 50Hz, 380v, 415v, 3 Phase, 4 Wire, 1500rpmTegas Shidik PermanaNo ratings yet

- Selection of Appropriate Software Development Life Cycle Using Fuzzy LogicDocument16 pagesSelection of Appropriate Software Development Life Cycle Using Fuzzy LogicTįtánìâ Rïyå-çhànNo ratings yet

- ZTE NetNumen U31 (RAN) Optional Features Description - V1.10 - 20120705Document74 pagesZTE NetNumen U31 (RAN) Optional Features Description - V1.10 - 20120705هشام رويدي0% (1)

- Answers Chapter 8 (Structured Questions)Document10 pagesAnswers Chapter 8 (Structured Questions)Kavi Vitya100% (1)

- Chapter 10Document59 pagesChapter 10Abd Alkader Alwer50% (2)

- ORM FeatureDocument10 pagesORM Featureaniket somNo ratings yet

- Hackerearth Online Judge: Prepared By: Mohamed AymanDocument21 pagesHackerearth Online Judge: Prepared By: Mohamed AymanPawan NaniNo ratings yet

- Open-Ocean Barrier Islands: Global in Uence of Climatic, Oceanographic, and Depositional SettingsDocument17 pagesOpen-Ocean Barrier Islands: Global in Uence of Climatic, Oceanographic, and Depositional SettingsMicheleFontanaNo ratings yet

- Friction Factor CalculationsDocument2 pagesFriction Factor CalculationsHu Hin AngNo ratings yet

- Chap 2 EngineDocument18 pagesChap 2 EngineNick Seiff PatrickNo ratings yet

- Assignment 1 Linear Equations: SC505 - Linear Algebra and Optimization Autumn 2021Document1 pageAssignment 1 Linear Equations: SC505 - Linear Algebra and Optimization Autumn 20212021 21004No ratings yet

- Module 1Document44 pagesModule 1bhara.r433No ratings yet

- Azure InterviewDocument4 pagesAzure InterviewsatishNo ratings yet

- Neet Structural Organisation in Animals Important QuestionsDocument18 pagesNeet Structural Organisation in Animals Important QuestionsARKA NEET BIOLOGYNo ratings yet

- Number Sense: FactorsDocument38 pagesNumber Sense: FactorsBrian NeisesNo ratings yet

Al 6061-T6 Section Properties

Al 6061-T6 Section Properties

Uploaded by

Suresh KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Al 6061-T6 Section Properties

Al 6061-T6 Section Properties

Uploaded by

Suresh KumarCopyright:

Available Formats

structural shapes/ allowable beam loads

TABLE 15A-ALLOWABLE

!Depth Weight d Ib/ft in. 2 .577

Aluminum Association Standard Channels, Alloy 6061-T6

SPAN IN FEET

2 3 1.22 0.26 0.94 2.32 0.26 2.13 3.97 0.17 3.40 5.53 0.17 5.13 8.23 0.13 7.66 2.98 0.30 2.28 4.15 0.30 3.55 6.17 0.23 5.21 8.23 0.23 7.42 9.97 0.18 8.67 2.38 0.47 1.44 3.32 0.47 2.64 4.94 0.36 3.79 6.59 0.36 5.52 7.98 0.28 6.32 4.12 0.51 2.57 5.49 0.51 4.30 6.65 0.41 4.52 9.39 0.41 7.70 3.53 0.70 1.80 4.70 0.70 3.34 5.70 0.56 3.10 8.05 0.56 6.19 8.65 0.47 5.33 4.99 0.73 2.26 7.05 0.73 4.78 7.57 0.61 3.83 6.73 0.77 2.89 9.87 0.77 6.79 8.88 0.66 3.99 6.05 0.95 2.25 8.88 0.95 5.28 7.99 0.81 3.07 7.27 0.99 2.44 6.66 1.17 1.98

'Total uniformly distributed load (W) on a simply supported single span, cal. culated using the section properties listed in Table 14A, the allowable stresses for Building and Similar Type Structures (Table 3.3.25) and effective r, (Sec. tion 4.9) of the Aluminum Association's Specifications For Aluminum Structures. Since the actual conditions of use can effect allowable loads, the information in Table 15A is intended for use by engineers and architects qualified to assess these effects.

UNIFORM BEAM LOADS·

1 3.67 0.03 3.67 6.97 0.03 6.97 9.36 0.01 9.36 12.24 0.01 12.24

10

II

12

13

14

15

16

17

18

19

20

21

1.84 0.11 1.62 3.46 0.11 3.45 5.95 0.08 5.75 8.30 0.08 8.30

1.071

1.135

1.S97

1.738

14.40 12.35 0.01 0.06 14.40 12.35

EXAMPLE

Span in Ft. 3 a. 1.22 b. 0.26 c. 0.94 a b c

2.331

18.24 16.47 10.98 0.01 0.06 0.13 18.24 16.47 10.69 18.00 13.30 0.04 0.10 18.00 12.71

2N [

2.212

3.089

22.80 18.79 14.09 11.27 0.04 0.10 0.18 0.28 22.80 18.79 13.24 9.88

= W, Kips } Laterally = deft. in In. supported = W,Kips Not laterally

supported

2.834

20.18 15.14 12.11 10.09 0.09 0.15 0.24 0.34 19.84 13.65 10.01 7.65

4.030

29.60 22.20 17.76 14.80 12.68 11.10 0.09 0.15 0.24 0.34 0.47 0.61 29.60 21.76 16.35 12.81 10.34 8.53 26.64 19.98 15.99 13.32 11.42 0.07 0.13 0.20 0.29 0.40 26.64 18.49 13.61 10.41 7.60 9.99 0.52 5.37

3.205

4.715

30.56 24.45 20.37 17.46 15.28 13.58 12.22 11.11 10.19 0.13 0.20 0.29 0.40 0.52 0.66 0.81 0.99 1.17 30.41 22.90 17.97 14.51 11.97 9.84 7.59 6.03 4.91 29.61 23.69 19.74 16.92 14.80 13.16 11.84 10.77 0.11 0.18 0.26 0.35 0.46 0.58 0.71 0.86 28.17 20.90 16.13 12.79 9.24 6.83 5.25 4.15 9.87 1.03 3.36 9.11 1.20 2.78 8.46 1.40 2.34

4.147

5.789

41.70 33.36 27.80 23.83 20.85 18.54 16.68 15.17 13.90 12.83 11.92 0.11 0.18 0.26 0.35 0.46 0.58 0.72 0.86 1.03 1.20 1.40 41.71 31.88 25.10 20.33 16.82 14.13 11.29 8.92 7.22 5.96 5.01 30.63 25.52 21.88 19.14 17.02 15.31 13.92 12.76 11.78 10.94 10.21 0.16 0.23 0.31 0.41 0.51 0.63 0.77 0.91 1.07 1.24 1.42 27.81 21.58 17.20 13.38 9.81 7.48 5.88 4.73 3.89 3.26 2.76 44.08 36.73 31.49 27.55 24.49 22.04 20.04 18.37 16.95 15.74 14.69 0.16 0.23 0.31 0.41 0.51 0.63 0.77 0.91 1.07 1.24 1.42 42.91 33.89 27.54 22.84 19.25 16.43 12.86 10.37 8.53 7.14 6.07 35.13 30.11 26.35 23.42 21.08 19.16 17.56 16.21 15.06 14.05 13.17 12.40 0.21 0.28 0.36 0.46 0.57 0.69 0.82 0.96 1.12 1.28 1.46 1.65 30.64 24.57 20.09 15.32 11.65 9.13 7.34 6.02 5.03 4.26 3.66 3.18 49.04 42.04 36.78 32.69 29.42 26.75 24.52 22.63 21.02 19.62 18.39 17.31 0.21 0.28 0.36 0.46 0.57 0.69 0.82 0.96 1.12 1.28 1.46 1.65 46.11 37.58 31.27 26.44 22.63 18.85 15.16 12.45 10.40 8.82 7.58 6.58 48.19 42.16 37.48 33.73 30.66 28.11 25.95 24.09 22.49 21.08 19.84 18.74 17.75 16.87 16.06 0.23 0.30 0.38 0.47 0.57 0.68 0.80 0.93 1.07 1.22 1.37 1.S4 1.71 1.90 2.09 41.S6 34.27 28.67 22.67 17.64 14.06 11.46 9.51 8.01 6.84 5.91 5.15 4.53 4.02 3.59 72.29 63.25 56.23 50.6{) 46.00 42.17 38.93 36.15 33.74 31.63 29.77 28.11 26.63 25.30 ~4.1O 0.23 0.30 0.38 0.47 0.57 0.68 0.80 0.93 1.07 1.22 1.37 1.S4 1.71 1.90 2.09 68.19 57.18 48.71 42.02 36.62 32.18 27.42 22.79 19.23 16.44 14.21 12.41. 10.93 9.71 8.68

4.983

6.970

10

6.136

10

8.360

12

8.274

12

11.822

SECTION

PROPERTIES

allowable beam loads / structural shapes

TABLE 15B-ALLOWABLE

Pepth d in.

UNIFORM BEAM LOADS·

Standard I-Beams, Alloy 6061- T6

SPAN IN FEET

Aluminum Association

Weight Ib/ft

2 9.36 0.08 9.36

3 6.29 0.17 5.79 7.64 0.17 7.27

4 4.72 0.30 3.96 5.73 0.30 5.07 8.90 0.23 7.80

5 3.77 0.47 2.91 4.59 0.47 3.79 7.12 0.36 5.73 8.51 0.36 7.13

10

II

12

13

14

15

16

17

18

19

20

21

1.637

9.36 0.01 9.36

2;030

10.80 10.80 om 0.07 10.80 10.80

'Total uniformly distributed load (W) on a simply supported single span, calculated using the section properties listed in Table 14A, the allowable stresses for Building and Similar Type Structures [Table 3.3.25) and effective ry [Section 4.9) of the Aluminum Association's Specifications For Aluminum Structures. Since the actual conditions of use can effect allowable loads, the information in Table 15B is intended {or use by engineers and architects qualified to assess these effects.

2.311

14.40 14.40 11.86 0.01 0.05 0.13 14.40 14.40 11.36

5.93 0.51 4.35 7.09 0.51 5.56

5.08 0.70 3.03 6.08 0.70 4.32 8.84 0.73 5.71 9.28 0.95 4.32

2.793

16.32 16.32 14.19 10.64 0.01 0.04 0.13 0.23 16.32 16.32 13.79 9.58

EXAMPLE

Span in Ft. 3 a. 6.29 b. 0.17 c. 5.79 a = W, Kips } Laterally b :::: dell. in In. supported c:::: W,Kips Not laterally supported

3.700

22.80 22.80 17.67 14.14 11.18 10.10 0.03 0.10 0.18 0.28 0.41 0.56 22.80 22.80 16.37 12.20 9.49 7.62

3" I

4.030

27.36 23.21 18.57 15.47 13.26 11.61 10.32 0.08 0.15 0.24 0.34 0.47 0.61 0.77 27.36 21.92 16.29 12.61 10.05 7.40 5.55

4.692

30.24 26.92 21.53 17.94 15.38 13.46 11.96 10.77 0.07 0.15 0.24 0.34 0.47 0.61 0.77 0.95 30.24 25.74 19.26 15.03 12.09 9.74 7.37 5.77 38.64 31.03 25.86 22.17 19.40 17.24 15.52 14.11 12.93 0.13 0.20 0.29 0.40 0.52 0.66 0.81 0.99 1.17 38.05 28.58 22.38 18.04 14.86 11.69 9.07 7.24 5.92 44.16 37.80 31.50 27.00 23.62 21.00 18.90 17.18 15.75 14.54 13.50 0.11 0.18 0.26 0.35 0.46 0.58 0.71 0.86 1.03 1.20 1.40 44.16 35.49 27.79 22.38 18.38 14.72 11.24 8.85 7.14 5.89 4.,?3 48.00 42.91 35.76 30.65 26.82 23.84 21.46 19.51 17.88 16.51 15.33 0.10 0.18 0.25 0.35 0.46 0.58 0.71 0.86 1.03 1.20 1.40 48.00 40.70 32.01 25.90 21.41 17.98 14.09 11.17 9.06 7.50 6.32 57.43 47.86 41.02 35.89 31.91 28.72 26.10 23.93 22.09 20.51 19.14 0.16 0.23 0.31 0.41 0.51 0.63 0.77 0.91 1.07 1.24 1.42 55.72 43.99 35.72 29.60 24.93 20.91 16.46 13.27 10.93 9.15 7.78 55.78 47.81 41.83 37.18 33.47 30.42 27.89 25.74 23.90 22.31 20.92 19.69 0.21 0.28 0.36 0.46 0.57 0.69 0.82 0.96 1.12 1.28 1.46 1.65 52.20 42.43 35.18 29.62 25.23 19.99 15.96 13.02 10.81 9.12 7.79 6.73 65.78 56.38 49.34 43.85 39.47 35.88 32.89 30.36 28.19 26.31 24.67 23.22 0.21 0.28 0.36 0.46 0.57 0.69 0.82 0.96 1.12 1.28 1.46 1.65 62.29 50.84 42.37 35.88 30.77 26.66 21.22 17.43 14.57 12.35 10.61 9.21 77.09 67.45 59.96 53.96 49.05 44.97 41.51 38.54 35.97 33.72 31.74 29.98 28.40 26.98 25.70 0.23 0.30 0.38 0.47 0.57 0.68 O.KO 0.93 1.07 1.22 1.37 1.54 1.71 1.90 2.G9 72.03 60.18 51.04 43.81 37.95 32.30 26.14 21.54 18.03 15.30 13.14 11.40 9.99 8.82 7.84 89.28 83.74 74.44 66.99 60.90 55.83 51.53 47.85 44.66 41.87 39.41 37.22 35.26 33.50 31.90 0.22 0.30 0.38 0.47 0.57 0.68 O.SO 0.93 1.07 1.22 1.37 1.54 1.71 1.90 2.09 89.28 76.25 65.03 56.15 48.99 43.10 37.62 31.25 26.36 22.53 19.47 17.00 14.97 13.29 11.87

5.800

6.181

7.023

8.361

10

8.646

10

10.286

12

11.672

12

14.292

SECTION

PROPERTIES

aluminum association channels and I-beams! structural shapes

TABLE 14A-ALUMINUM ASSOCIATION STANDARD CHANNELSDIMENSIONS, AREAS, WEIGHTS AND SECTION PROPERTIES

Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers. Size Depth d in. 2..00 2..00 3.00 3.00 4.00 4.00 S.OO S.OO 6.00 6.00 7.00 7.00 8.00 8.00 9.00 9.00 10.00 10.00 12..00 12..00 Width b in. 1.00 1.25 1.50 1.75 2.00 2.25 2.25 2.75 2.50 3.25 2.75 3.50 3.00 3.75 3.25 4.00 3.50 4.25 4.00 5.00 Area " Weight lb/ft in" 0.491 0.911 0.965 1.358 1.478 1.982 1.881 2.627 2.410 3.427 2.725 4.009 3.526 4.923 4.237 5.927 5.218 7.109 7.036 10.053 Flange Thickness Web Thickness tw in. 0.13 0.17 0.13 0.17 0.15 0.19 0.15 0.19 0.17 0.21 0.17 0.21 0.19 0.25 0.23 0.29 0.25 0.31 0.29 0.35· Fillet Radius R in. 0.10 0.15 0.25 0.25 0.25 0.25 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.35 0.35 0.35 0.35 0.40 0.40 0.45 Axis X-X I in.' 0.288 0.546 1.41 1.97 3.91 5.21 7.88 11.14 14.35 21.04 22.09 33.79 37.40 52.69 54.41 78.31 83.22 116.15 159.76 239.69 S in." 0.288 0.546 0.94 1.31 1.95 2.60 3.15 4.45 4.78 7.01 6.31 9.65 9.35 13.17 12.09 17.40 16.64 23.23 26.63 39.95 r in. 0.766 0.774 1.21 1.20 1.63 1.62 2.05 2.06 2.44 2.48 2.85 2.90 3.26 3.27 3.58 3.63 3.99 4.04 4.77 4.88 I in.' 0.045 0.139 0.22 0.42 0.60 1.02 0.98 2.05 1.53 3.76 2.10 5.13 3.25 7.13 4.40 9.61 6.33 13.02 11.03 25.74

x-r L

d

~[---r

1-!=b1_l

'R y

-----x

Section Propertles j " Axis S in" 0.064 0.178 0.22 0.37 0.45 0.69 0.64 1.14 0.90 1.76 1.10 2.23 1.57 2.82 1.89 3.49 2.56 4.47 3.86 7.60

v-v

r in. 0.303 0.397 0.47 0.55 0.64 0.72 0.72 0.88 0.80 1.05 0.88 1.13 0.96 1.20 1.02 1.27 1.10 1.35 1.25 1.60 x in. 0.298 0.471 0.49 0.62 0.65 0.78 0.73 0.95 0.79 1.12 0.84 1.20 0.93 1.22 0.93 1.25 1.02 1.34 1.14 1.61

!r 10.

0.577 1.071 1.135 1.597 1.738 2.331 2.212 3.089 2.834 4.030 3.205 4.715 4.147 5.789 4.983 6.970 6.136 8.360 8.274 11.822

0.13 0.26 0.20 0.26 0.23 0.29 0.26 0.32 0.29 0.35 0.29 0.38 0.35 0.41 0.35 0.44 0.41 0.50 0.47 0.62

• Areas and section properties. listed are based on nominal dimensions. See "Aluminum Standards and Data" for applicable tolerances.

t Weights

t 1= moment of inertia; S=section modulus; r .. radius of gyration. per foot are based on nominal dimensions and a density of 0.098 pound per cubic inch which is the density of alloy 6061.

TABLE 14B-ALUMINUM ASSOCIATION STANDARD I-BEAMSDIMENSIONS, AREAS, WEIGHTS AND SECTION PROPERTIES

Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers. Size Depth d in. 3.00 3.00 4.00 4.00 5.00 6.00 6.00 7.00 8.00 8.00 9.00 10.00 10.00 12..00 1200 Width b in. 2.50 2.50 3.00 3.00 3.50 4.00 4.00 4.50 5.00 5.00 5.50 6.00 6.00 7.00 7.00 Area in." Flange Thickness tf in. 0.20 0.26 0.23 0.29 0.32 0.29 0.35 0.38 0.35 0.41 0.44 0.41 0.50 0.47 0.62 Web Thickness tw in. 0.13 0.15 0.15 0.17 0.19 0.19 0.21 0.23 0.23 0.25 0.27 0.25 0.29 0.29 0.31 Section Properties L" Fillet Radius R in. 0.25 0.25 0.25 0.25 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.40 0.40 0.40 0.40 Axis I in.' 2.24 2.71 5.62 6.71 13.94 21.99 25.50 42.89 59.69 67.78 102.02 132.09 155.79 255.57 317.33

!$:~

ib-!j_j

'.

x-x

S in." 1.49 1.81 2.81 3.36 5.58 7.33 8.50 12.25 14.92 16.94 22.67 26.42 31.16 42.60 52.89 r in. 1.27 1.25 1.69 1.68 2.11 2.53 2.53 2.95 3.37 3.37 3.79 4.24 4.22 5.07 5.11 I in.' 0.52 0.68 1.04 1.31 2.29 3.10 3.74 5.18 7.30 8.55 12.22 14.78 18.03 26.90 35.48

Axis V-V S in." 0.42 0.54 0.69 0.87 1.3 I 1.55 1.87 2.57 2.92 3.42 4.44 4.93 6.01 7.69 10.14 r in. 0.61 0.63 0.73 0.74 0.85 0.95 0.97 1.08 1.18 1.20 1.31 1.42 1.44 1.65 1.71

Weight Ib/ft 1.637 2.030 2.3 I I 2.793 3.700 4.030 4.692 5.800 6.181 7.023 8.361 8.646 10.286 11.672 14.292

1.392 1.726 1.965 2.375 3.146 3.427 3.990 4.932 5.256 5.972 7.110 7.352 8.747 9.925 12.153

• Areas . and section properties listed are based on nominal dimensions. See "Aluminum Standards and Data" for applicable tolerances.

t I-moment of inertia; S-section modulus; r_radius of gyration. t Weights per foot are based on nominal dimensions and a densitl. of 0.098 pound per cubic inch which is the density of alloy 606 .

SECTION

PROPERTIES

structural shapes/wide flange sections

TABLE 16-WIDE-FLANGE SECTION5-H-BEAMSt

t Areas

and section properties listed are based on nominal dimensions. Weights per foot are based on nominal dimensions and a density of 0.098 pounds per cubic inch, the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for applicable tolerances.

r-

Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers. Size Nominal Depth and Width 2x2 2x2 2Y.zx 2 4x4 5x5 6x4 6x6 6x6 6x6 6x6 8x5V<! 8 x 61h 8x8 8x8 8x8 8x8 10x5% Web Actual Actual ThickDepth Width ness Weight d b t ... Ib/ft in. in. in. 0.78 1.43 1.80 4.76 6.49 4.16 5.40 7.85 8.30 9.18 5.90 8.32 10.72 11.24 11.82 12.99 7.30 2.00 2.00 2.50 4.00 5.00 6.00 6.00 6.00 6.00 6.00 8.00 8.00 8.00 8.00 8.00 8.00 9.90 2.000 2.000 2.000 4.000 5.000 4.000 6.000 5.933 6.000 6.125 5.250 6.500 8.000 7.938 8.000 8.125 5.750 0.094 0.188 0.250 0.313 0.313 0.230 0.240 0.250 0.313 0.438 0.230 0.245 0.288 0.313 0.375 0.500 0.240 Avg Flange Thickness in. 0.125 0.232 0.247 0.370 0.415 0.279 0.269 0.451 0.451 0.451 0.308 0.398 0.433 0.458 0.458 0.458 0.340· Axis X-X r. in. 0.125 0.188 0.250 0.313 0.313 0.250 0.250 0.313 0.313 0.. 13 3 0.320 0.400 0.400 0.313 0.313 0.313 0.312 r. in. 0.125 0.094 0.125 0.145 0.165 0 0 0.180 0.180 0.180 0 0 0 0.179 0.179 0.179 0 d. in. 1~ IYs 1% 2% 3¥s I in.' 0.481 0.782 1.453 10.80 23.94 21.75 30.17 44.25 45.37 47.62 56.73 84.15 109.66 113.33 115.97 121.31 S in: 0.481 0.782 1.162 5.40 9.58· 7.25 10.06 14.75 15.12 15.87 14.18 21.04 27.41 28.33 28.99 30.33 21.56 r in. 0.85 0.80 0.97 1.63 2.08 2.48 2.56 2.57 2.54 2.47 3.36 3.44 3.47 3.45 3.40 3.31 4.15 I in" 0.154 0.275 0.292 3.52 7.73 2.98 9.69 14.02 14.49 15.49 7.44 18.23 36.97 33.87 34.73 36.50 10.77 Axis y-y

Area in.' 0.664 1.217 1.529 4.05 5.52 3.54 4.59 6.68 7.06 7.81 5.02 7.08 9.12 9.55 10.05 11.05 6.21

Slope 0 1: 11.4 1:7 1: 11.3 I: 13.6 0 0 1: 15.6 I: 15.6 1: 15.6 0 0 0 1:18.9 I: 18.9 1: 18.9 0

. m.

S

r in. 0.48 0.47 0.44 0.93 1.18 0.92 1.45 1.45 1.43 1.41 1.22 1.61 2.01 1.88 1.86 1.82 1.32

0.154 0.275 0.292 1.76 3.09 1.49 3.23 4.67 4.83 5.16 2.83 5.61 9.24 8.47 8.68 9.13 3.75

4'/8

4¥s 4% 4%

4'M1

6% 6% 6% 61/.1 6V<! 6V<!

8Y.z 106.74

TABLE 17-WIDE FLANGE SECTION5-ARMY-NAVY SERIESt t Areas and section properties listed are based on nominal dimensions. Weights per foot

are based on nominal dimensions and a density of 0.098 pounds per cubic inch, the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for applicable tolerances.

y

Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers. Size Nominal Depth and Width in. 2Y.zx 2 3x2 4x2 4x3 4 x 3 /z

1

Weight lb/ft 0.928 1.001 1.139 1.788 3.060 2.867 5.366

Actual Depth d in. 2.50 3.00 4.00 4.00 4.00 4.00 5.00

Actual Width b in. 2.00 2.00 2.00 3.00 3.50 4.50 5.00

Web & Flange Thickness tw, tt in. 0.125 0.125 0.125 0.156 0.250 0.188 0.312

Axis X-X

AxisY-Y

Area in.' 0.789 0.851 0.969 1.521 2.602 2.438 4.563-

in. 0·156 0.156 0.125 0.188 0.188 0.312 0.312

r,

in.

r.

d. in. 2

I in" 0.831 1.262 2.424 4.136 6.968 7.091 19.683

. m.

in. 1.027 1.217 1.582 1.649 1.637 1.706 2.077'

I in" 0.155 0.155 0.155 0.659 1.638 2.786 6.444

. m.

S

r in. 0.443 0.426 0.400 0.658 0.793 1.069 1.188

0.125 0.125 0.125 0.156 0.250 0.125 0.125

0.665 0.841 1.212 2.068 3.484 3.545 7.873

0.155 0.155 0.155 0-439 0.936 1.238 2.578

21/z

3~ 3V<! 3 3 3%

4x4Y.z 5x5

SECTION

PROPERTIES

american standard I-beams/ structural shapes

TABLE 18-I-BEAM5-AMERICAN

t Areas

STANDARDt

and section properties listed are based o.n nominal dimensions. Weig~ts.per foot are based on nominal dimensions and a density of 0.098 pounds per cubic mc~, the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for apphcable tolerances.

y Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers.

Size Web ThickDepth Weight Width ness d b tw in. in. lb/ft in. 3 3 3 4 4 5 5 5 6 6 6 7 7 7 8 8 8 9 10 10 10 12 12 12 12 12 1.96 2.25 2.59 2.64 3.28 3.43 4.23 5.10 4.30 5.10 5.96 5.27 6.05 6.92 6.35 7.96 8.81 7.51 8.76 10.37 12.10 10.99 12.09 14.08 15.56 17.28 2.330 2.411 2.509 0.170 0.251 0.349 Area in2 1.67 1.91 2.21 2.25 2.79 2.92 3.60 4.34 3.66 4.34 5.07

Avg Flange Thickness in. 0.257 0.257 0.257 0.289 0.289 0.323 0.323 0.323 0.355 0.355 0.355

Axis X-X

I ;

r in. 1.23 1.19 1.15 1.64 1.56 2.05 1.95 1.87 2.46 2.36 2.28 2.86 2.77 2.69 3.27 3.10 3.03 3.67 4.07 3.91 3.78 4.83 4.72 4.77 4.66 4.56 I in!

Axis y-y

,.

"

in. 0.27 0.27. 0.27 0.29 0.29 0.31 0.31 0.31 0.33 0.33 0.33 0.35 0.35 0.35 0.37 0.37 0.37 0.39 0.41 0.41 0.41 0.45 0.45 0.56 0.56 0.56

r,

r, in. 0.10 0.10 0.10 0.11 0.11 0.13 0.13 0.13 0.14 0.14 0.14 0.15 0.15 0.15 0.16 0.16 0.16 0.17 0.19 0.19 0.19

d1 in. 1% 1% 2% 2% 31h 3th 31h 41h 41h 41h 5Y<t 5Y<t 5Y<t 6Y<t 6Y<t 6Y<t 7 8 8 8

I in.' 2.52 2.71 2.93 6.06 6.79 12.26 13.69 15.22 22.08 24.11 26.31 36.69 39.40 42.40 57.55 64.85 68.73 85.90 123.39 134.81 147.06

S in." 1.68 1.80 1.95 3.03 3.39 4.90 5.48 6.09 7.36 8.04 8.77 10.48 11.26 12.12 14.39 16.21 17.18 19.09 24.68 26.96 29.41 36.35 38.23 45.36 47.88 50.81

ffi.

in. 0.52 0.52 0.52 0.58 0.57 0.64 0.63 0.62 0.71 0.69 0.68 0.77 0.75 0.73 0.83 0.80 0.79 0.89 0.95 0.92 0.90 1.00 0.98 1.06 1.05 1.03

PA

0.46 0.51 0.59 0.76 0.90 1.21 1.41 1.66 1.82 2.04 2.31 2.63 2.88 3.17 3.73 4.31 4.66 5.09 6.78 7.50 8.36 9.35 9.87 13.54 14.50 15.71

0.39 0.42 0.47 0.57 0.65 0.81 0.90 1.01 1.09 1.19 1.30 1.44 1.53 1.64 1.86 2.07 2.19 2.35 2.91 3.13 3.38 3.74 3.89 5.16 5.42 5.74

2.660 . 0.190 2.796 0.326 3.000 3.137 3.284 3.330 3.443 3.565 3.660 3.755 3.860 4.000 4.171 4.262 4.330 4.660 4.797 4.944 5.000 5.078 5.250 5.355 5.477 0.210 0.347 0.494 0.230 0.343 0.465 0.250 0.345 0.450 0.270 0.441 0.532 0.290 0.310 0.447 0.594 0.350 0.428 0.460 0.565 0.687

4.48 0.389 5.15 0.389 5.8S' 0.389 5.40 6.77 7.49 6.38 7.45 8.82 10.29 9.35 10.28 11.97 13.23 14.70 0.421 0.421 0.421 0.453 0.487 0.487 0.487 0.538 0.538 0.653 0.653 0.653

0.21 9% 218.13 0.21 9% 229.36 0.28 . 9Y<t 272.15 0.28 9Y<t 287.27 0.28 9Y<t 304.84

SECTION

PROPERTIES

structural shapes! army-navy and special channels

TABLE 19-CHANNELS-ARMY-NAVYt t Areas and section properties listed are based on nominal

dimensions. Weights per foot are based on nominal dimensions and a density of 0.098 pounds per cubic inch. the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for applicable tolerances.

Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers. Size Web Thickness t. in. 0.156 0.188 0.188 0.250 0.188 0.250 0.188 0.250 0.188 Flange Thickness in. 0.156 0.188 0.188 0.250 0.188 0.250 0.188 0.250 0.312

tr

Axis X-X

Axis y-y

Depth Weight d in. Ib/ft 3 3 4 4 5 5 6 6 7 0.993 1.354 1.575 2.205 UsI0 2.499 2.128 2.940 3.611

Width b in. 1.375 1.750 1.750 2.000 1.750 2.000 2.000 2.250 3.000

Area in" 0.845 1.151 1.339 1.875 1.539 2.125 1.809 2.500 3.070

r, in. 0.125 0.188 0.188 0.250 0.250 0.250 0.188 0.250 0.188

r. in. 0.156 0.188 0.188 0.250 0.188 0.250 0.188 0.250 0.188

d, in. 2~ 21~ 31,4 3 4 4 51;4 5 6

I in.' 1.098 1.553 3.080 4.313 5.268 7.384 9.007 12.538 25.019

S in" 0.732 1.036 1.540 2.156 2.107 2.954 3.002 4.179 7.148

r in. 1.140 1.162 1.516 1.517 1.850 1.864 2.231 2.239 2.855

I in.' 0.138 0.322 0.352 0.647 0.375 0.692 0.581 1.031 3.032

S in.' 0.138 0.262 0.273 0.452 0.281 0.466 0.377 0.608 1.471

r in. 0.404 0.529 0.512 0.588 0.493 0.571 0.567 0.642 0.994

x in. 0.373 0.521 0.461 0.568 0.415 0.516 0.456 0.555 0.939

TABLE 2D-SPECIAL CHANNELSt

t Areas

and section properties listed are based on nominal dimensions. Weights per foot are based on nominal dimensions and a density of 0.098 pounds per cubic inch, the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for applicable tolerances.

Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers. Size Web Thickness t. in. 0.250 0.375 0.318 0.188 0.500 0.438 0.500 0.375 0.380 0.425 0.375 0.438 0.500 Avg Flange Thickness in. 1:12.1 0 1:34.9 1:10.7 0 1:9.8 0 1:49.6 1: 14.43 1:28.5 1:9 1:9 1:9 0.320 0.375 0.344 0.312 0.375 0.562 0.375 0.442 0.468 0.524 Axis X-X AxisY-Y

Depth Weight d in. Ib/ft 3 3 4 5 5 5 6 6 8 8 110 10

10

Width b in. 2.000 2.000 2.500 2.875 2.500 2.875 3.000 3.500 3.000 3.500 3.500 3.563 3.625

Area in" 1.90 2.30 2.82 2.64 4.03 4.95 4.91 5.04 5.60 6.68 7.30 7.93 8.55

Slope

r, in. 0.250 0.188 0.375 0.250 0.375 0.250 0.375 0.480 0.550 0.525

r. in. 0 0.375 0.125 0.094 0.250 0.094 0.250 0.420 0.220 0.375 0.188 0.188 0.188

d, in.

I in.' 2.61 2.89 6.84 11.20 13.37 18.13 24.05 28.22 54.15 63.76

in..

1.74 1.92 3.42 4.48 5.35 7.25 8.02 9.41 13.54 15.94 21.92 22.97 24.01

r in. 1.17 1.12 1.56 2.06 1.82 1.91 2.21 2.37 3.11 3.09 3.88 3.81 3.75

I in.' 0.68 0.78 1.62 1.91 1.94 3.57 3.52 5.58 4.10 7.06 7.19 7.73 8.25

S in" 0.52 0.59 0.95 0.96 1.08 1.87 1.61 2.31 1.88 2.84 2.80 2.93 3.04

r in. 0.60 0.58 0.76 0.85 0.69 0.85 0.85 1.05 0.86 1.03 0.99 0.99 0.98

x in. 0.68 0.67 0.81 0.89 0.71 0.96 0.81 1.09 0.81 1.01 0.93 0.92 0.91

2.24 2.70 3.32 3.10 4.74 5.82 5.77 5.93 6.59 7.86 8.58 9.32 10.05

I'MI

2% 3~ 3% 3 4~ 4 5% 5*

1*

0.544 0.625 0.544 0.625 0.544- 0.625

109.62 7% 7Y.z 114.87 71/2 120.Q3

SECTION

PROPERTIES

american standard channels! structural shapes

TABLE 21-CHANNELS-AMERICAN STANDARDt t Areas and section properties listed are based on nominal dimensions. Weights

per foot are based on nominal dimensions and a density of 0.098 pounds per cubic inch, the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for applicable tolerances.

Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers.

Size Web Thickness Area t.. Width b in. in.' in. 1.410 1.427 1.498 1.560 1.596 1.580 1.647 1.720 1.750 1.885 2.032 1.920 1.945 2.034 2.157 2.090 2.110 2.194 2.299 2.404 2.290 2.343 2.435 2.527 2.430 2.485 2.648 2.812 2.600 2.739 2.886 3.033 2.960 3.047 3.170 3.292 3.400 3.716 0.170 0.187 0.258 0.320 0.356 0.180 0.247 0.320 0.190 0.325 0.472 0.200 0.225 0.314 0.437 0.210 0.230 0.314 0.419 0.524 0.250 0.303 0.395 0.487 0.230 0.285 0.448 0.612 0.240 0.379 0.526 0.673 0.300 0.387 0.510 0.632 0.400 0.716 1.20 1.26 1.47 1.66 1.76 1.57 1.84 2.13 1.97 2.64 3.38 2.40 2.55 3.09 3.82 2.87 3.01 3.60 4.33 5.07 3.62 4.04 4.78 5.51 3.92 4.41 5.88 7.35 4.49 5.88 7.35 8.82 6.30 7.35 8.82 10.29 9.96 14.70

Depth Weight d in. lb/ft 3 3 3 3 3 4 4 4 5 5 5 6 6 6 6 7 7 7 7 7 8 8 8 8 9 9 9 9 10 10 10 10 12 12 12 12 15 15 1.42 1.48 1.73 1.95 2.07 1.85 2.16 2.50 2.32 3.11 3.97 2.83 3.00 3.63 4.48 3.38 3.54 4.23 5.10 5.96 4.25 4.75 5.62 6.48 4.60 5.19 6.91 8.65 5.28 6.91 8.64 10.37 7.41 8.64 10.37 12.10 11.71 17.28

Avg Flange Thickness in. 0.270 0.270 0.270 0.270 0.270 0.293 0.293 0.293 0.317 0.317 0.317 0.340 0.340 0.340 0.340 0.364 0.364 0.364 0.364 0.364 0.387 0.387 0.387 0.387 0.409 0.409 0.409 0.409 0.434 0.434 0.434 0.434 0.498 0.498 0.498 0.498 0.647 0.647

Axis X-X

Axis y-y

in. 0.27 0.27 0.27 0.27 0.27 0.28 0.28 0.28 0.29 0.29 0.29 0.30 0.30 0.30 0.30 0.31 0.31 0.31 0.31 0.31 0.32 0.32 0.32 0.32 0.33 0.33 0.33 0.33 0.34 0.34 0.34 0.34 0.38 0.38 0.38 0.38 0.50 0.50

r,

in. 0.10 0.10 0.10 0.10 0.10 0.11 0.11 0.11 0.11 0.11 0.11 0.12 0.12 0.12 0.12 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.14 0.14 0.14 0.14 0.14 0.14 0.14 0.14 0.17 0.17 0.17 0.17 0.24 0.24

r,

d1 in.

I in' 1.66 1.69 1.85 1.99 2.07 3.83 4.19 4.58 7.49 8.90 10.43 13.12 13.57 15.18 17.39 21.27 21.84 24.24 27.24 30.25 33.85 36.11 40.04 43.96 47.68 51.02 60.92 70.89 67.37 78.95 91.20 103.45 131.84 144.37 162.08 179.65 314.76 403.64

in"

1.10 1.13 1.24 1.33 1.38 1.92 2.10 2.29

in. 1.17 1.16 1.12 1.10 1.08 1.56 1.51 1.47

I in' 0.20 0.21 0.25 0.28 0.31 0.32 0.37 0.43 0.48 0.63 0.81 0.69 0.73 0.87 1.05 0.97 1.01 1.17 1.38 1.59 1.40 1.53 1.75 1.98 1.75 1.93 2.42 2.94 2.28 2.81 3.36 3.95 3.99 4.47 5.14 5.82

S in" 0.20 0.21 0.23 0.25 0.27 0.28 0.31 0.34 0.38 0.45 0.53 0.49 0.51 0.56 0.64 0.63 0.64 0.70 0.78 0.86 0.81 0.85 0.93 1.01 0.96 1.01 1.17 1.34 1.16 1.32 1.48 1.66 1.76 1.89 2.06 2.24

in. 0.40 0.41 0.41 0.41 0.42 0.45 0.45 0.45 0.49 0.49 0.49 0.54 0.54 0.53 0.52 0.58 0.58 0.57 0.56 0.56 0.62 0.61 0.61 0.60 0.67 0.66 0.64 0.63 0.71 0.69 0.68 0.67 0.80 0.78 0.76 0.75

in. 0.44 0.44 0.44 0.45 0.46 0.46 0.45 0.46 0.48 0.48 0.51 0.51 0.51 0.50 0.51 0.54 0.54 0.52 0.53 0.55 0.56 0.55 0.55 0.57 0.60 0.59 0.58 0.61 0.63 0.61 0.62 0.65 0.69 0.67 0.67 0.69 0.79 0.80

PA

B~

1% 1% 1%

2% 2% 23A 3% 3% 3% 4th 4th 4Yz 4Yz 5th 5Yz 5Yz 51h 5th 61;4 61;4 61;4 61;4

3.QO 1.95 3.56 1.83 4.17 1.76 4.37 4.52 5.06 5.80 6.08 6.24 6.93 7.78 8.64 8.46 9.03 10.01 10.99 10.60 11.34 13.54 15.75 13.47 15.79 18.24 20.69 21.97 24.06 27.01 29.94 41.97 53.82 2.34 2.31 2.22 2.13 2.72 2.69 2.60 2.51 2.44 3.06 2;99 2.90 2.82 3.49 3.40 3.22 3.11 3.87 3.66 3.52 3.43 4.57 4.43 4.29 4.18 5.62 5.24

71;4 81;4 81;4 81;4 81;4 10 10 10 10 12% 12%

n~

71;4 71;4

8.13 3.11 0.90 11.04 3.78 0.87

SECTION

PROPERTIES

structural shapes/angles with equal legs

TABLE 22-ANGLES WITH EQUAL LEGSt

t Areas

and section properties listed are based on nominal dimensions. Weights per foot are based on nominal dimensions and a density of 0.098 pounds per cubic inch the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for appIi~able tolerances. Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers. Size Depth and Width dxb in. IVz x IVz IVz x IV2 I%x I%x I%x 2x2 2x2 2x2 2Vzx2% 2V2X2% 21/~x2% 2V2X2% 3x3 3x3 3x3 3x3 3% x 3112 3%x3V2 3%x3% 3%x 31/2 3%x3% 3V2 X3V2 3% x 3% 4x4 4x4 4x4 4x4 4x4 4x4 4x4 4x4 4x4 5x5 5x5 5x5 5x5 5x5 5x5 5x5 6x6 6x6 6x6 6x6 6x6 6x6 6x6 8x8 8x8 8x8 1% 1% 1% Leg Thickness t in. VB Axis X-X, Y-Y AxisZ-Z

Weight Ib/ft 0.43 0.81 0.58 0.96 1.38 0.57 1.11 1.59 0.72 1.40 2.05 2.65 1.68 2.47 3.23 3.94 1.99 2.46 2.93 3.38 3.83 4.26 4.68 2.28 2.83 3.38 3.90 4.41 4.92 5.42 5.92 6.40 4.28 4.91 5.58 6.23 6.88 7.51 8.15 5.12 5.94 6.75 7.56 8.35 9.14 9.91 9.14 13.48 17.67

Area in." 0.36 0.69 0.42 0.81 1.17 0.49 0.94 1.37 0.62 1.19 1.71 2.26 1.43 2.10 2.77 3.35 1.69 2.09 2.49 2.87 3.25 3.62 3.99 1.94 2.41 2.86 3.31 3.75 4.18 4.61 5.03 5.44 3.60 4.12 4.74 5.30 5.85 6.40 6.93 4.35 5.05 5.74 6.43 7.10 7.77 8.43 7.77 11.46 15.02

r. in.

r, in. VB VB VB VB VB VB VB VB VB VB VB

I in.' 0.074 0.135 0.121 0.223 0.306 0.18 0.34 0.47 0.37 0.69 0.98 1.22 1.18 1.70 2.16 2.57 1.93 2.37 2.79 3.18 3.56 3.92 4.26 2.94 3.61 4.26 4.87 5.46 6.02 6.56 7.08 7.57 8.37 9.65 10.89 12.08 13.22 14.33 15.39 14.85 17.15 19.38 21.54 23.64 25.67 27.64 47.74 68.86 88.11

S in.' 0.068 0.130 0.094 0.181 0.259 0.13 0.24 0.35 0.20 0.39 0.56 0.72 0.54 0.80 1.04 1.26 0.76 0.94 1.11 1.28 1.45 1.61 1.77 1.00 1.24 1.48 1.71 1.93 2.15 2.36 2.57 2.77 2.30 2.67 3.03 3.39 3.73 4.07 4.41 3.38 3.93 4.46 4.99 5.51 6.02 6.52 8.16 11.99 15.60

in.

x,y in. 0.41 0.46 0.47 0.52 0.57 0.53 0.58 0.63 0.65 0.71 0.76 0.80 0.82 0.87 0.92 0.97 0.94 0.97 1.00 1.02 1.05 1.07 1.09 1.07 1.10 1.12 1.15 1.17 1.20 1.22 1.24 1.26 1.36 1.38 1.41 1.43 1.46 1.48 1.51 1.60 1.63 1.66 1.68 1.71 1.73 1.76 2.15 2.26 2.35

I in! 0.031 0.057 0.050 0.093 0.134 0.08 0.14 0.20 0.15 0.29 0.41 0.53 0.49 0.70 0.91 1.12 0.80 0.98 1.15 1.32 1.49 1.65 1.81 1.21 1.48 1.75 2.01 2.26 2.51 2.76 3.00 3.25 3.44 3.96 4.47 4.97 5.47 5.96 6.44 6.07 7.01 7.92 8.82 9.70 10.57 11.43 19.51 28.20 36.46

r in. 0.29 0.29 0.34 0.34 0.34 0.40 0.39 0.39 0.50 0.49 0.48 0.48 0.58 0.58 0.58 0.58 0.69 0.68 0.68 0.68 0.68 0.67 0.67 0.79 0.78 0.78 0.78 0.78 0.77 0.71 0.77 0.77 0.98 0.97 0.97 0.97 0.97 0.97 0.96 1.18 1.18 1.17 1.17 1.17 1.17 1.16 1.58 1.57 1.56

¥I6 ¥I6 ¥I6 ¥I6 ¥I6 % % %

1,4 1,4

0.45 0.44 0.53 0.52 0.51 0.61 0.60 0.59 0.77 0.76 0.75 0.73 0.91 0.90 0.89 0.88 1.07 1.06 1.06 1.05 1.05 1.04 1.03 1.23 1.23 1.22 1.21 1.21 1.20 1.19 1.19 1.18 1.52 1.52 1.52 1.51 1.50 1.50 1.49 1.85 1.84 1.84 1.83 1.82 1.82 1.81 2.48 2.45 2.42

VB

VB 1/4

1fs

%

1/4 112

% % X6 X6 X6

1fs

%

%

1/2

Xc.

% % % % % % % % % % % % % % % %

% % 1/2 % % %

1/4 1,4

Ys % X6

%

% %

¥J,

';6 Ys 1f4 X,

%

1f4 1f4 1f4 1f4

1,4

1/4

1,4 1/4 1,4

¥J,

1f4

1,4

';6

%

1/2

I~, %

1f4 1f4 % 1f4

1,4

¥J,

%

1/2

';6

1~6

%

% % % % % % % % % % % % % % % % %

1~6

%

¥J, 1/2 ,;,

% % % % % % %

V2 %

% % %

SECTION

PROPERTIES

angles with unequal legs/structural shapes

TABLE 23-ANGLES

WITH UNEQUAL LEGSt

Size Depth and Width dxb in. 1% X IV" 1% x 11/4 2x 2x Leg Thickness t in. Vs

Axis

x-x

~-

Axis

-~

v-v

r

x a 26°22' 25°47'

Axis Z-Z

Weight lb/ft 0.42 0.81 0.46 0.88 0.93 0.50 0.96 1.38 1.04 1.04 0.54 1.04 0.57 1.11 1.61 0.65 1.26 1.83 2.36 1.27 1.40 2.05 2.65 1.54 2.25 2.93 1.68 2.08 2.47 2.86 3.23 1.84 2.28 2.70 3.12 3.53 1.99 2.46 2.93 3.38 3.83 4.26 4.69 2.63 3.13 3.62 4.10 4.12

Area in! 0.36 0.69 0.39 0.75 0.79 0.42 0.81 1.17 0.88 0.88 0.46 0.88 0.49 0.94 1.37 0.55 1.07 1.55 2.01 1.08 1.19 1.74 2.26 1.31 1.92 2.49 1.43 1.77 2.10 2.43 2.74 1.57 1.94 2.30 2.66 3.00 1.69 2.09 2.49 2.87 3.25 3.62 3.99 2.23 2.66 3.08 3.49 3.50

r. in.

r. in.

I in" 0.108 0.199 0.158 0.291 0.302 0.17 0.31 0.43 0.33 0.43 0.30 0.55 0.32 0.59 0.82 0.34 0.65 0.91 1.13 0.98 1.06 1.51 1.90 1.12 1.60 2.03 1.73 2.12 2.49 2.84 3.17 1.84 2.26 2.65 3.03 3.38 2.68 3.29 3.88 4.43 4.96 5.47 5.95 3.40 4.02 4.61 5.17 8.74

S in! 0.090 0.172 0.117 0.224 0.228 0.12 0.23 0.33 0.24 0.29 0.18 0.35 0.19 0.36 0.51 0.19 0.38 0.54 0.69 0.51 0.52 0.76 0.99 0.53 0.78 1.01 0.72 0.89 1.06 1.22 1.37 0.74 0.92 1.09 1.26 1.42 0.96 1.19 1.42 1.63 1.85 2.05 2.25 1.19 1.43 1.65 1.87 2.77

in. 0.55 0.54 0.63 0.62 0.62 0.63 0.62 0.60 0.61 0.70 0.81 0.79 0.81 0.79 0.77 0.79 0.78 0.76 0.75 0.95 0.94 0.93 0.92 0.92 0.91 0.90 1.10 1.09 1.09 1.08 1.08 1.08 1.08 1.07 1.07 1.06 1.26 1.25 1.25 1.24 1.24 1.23 1.22 1.23 1.23 1.22 1.22 1.58

y in. 0.54 0.60 0.65 0.70 0.68 0.60 0.66 0.70 0.62 0.76 0.87 0.92 0.81 0.86 0.91 0.72 0.78 0.83 0.87 1.08 0.97 1.03 1.07 0.89 0.94 0.99 1.09 1.12 1.14 1.17 1.19 1.01 1.04 1.06 1.09 1.11 1.21 1.24 1.26 1.29 1.31 1.34 1.36 1.15 1.18 1.21 1.23 1.84

I in.' 0.046 0.083 0.047 0.086 0.114 0.08 0.15 0.20 0.23 0.15 0.05 0.09 0.09 0.16 0.22 0.20 0.37 0.51 0.63 0.16 0.38 0.53 0.66 0.70 1.00 1.26 0.73 0.89 1.05 1.19 1.32 1.28 1.52 1.79 2.04 2.27 1.29 1.58 1.86 2.12 2.~6 2.60 2.82 2.42 2.85 3.27 3.67 1.46

S in! 0.048 0.092 0.049 0.093 0.113 0.07 0.14 0.19 0.18 0.14 0.05 0.10 0.67 0.14 0.20 0.13 0.25 0.36 0.46 0.14 0.25 0.36 0.46 0.38 0.55 0.72 0.38 0.48 0.57 0.65 0.73 0.S7 0.69 0.82 0.94 1.06 0.56 0.70 0.83 0.96 1.08 1.20 1.32 0.93 1.11 1.29 1.46 0.77

in. 0.36 0.35 0.35 0.34 0.38 0.44 0.43 0.41 0.51 0.42 0.34 0.32 0.42 0.41 0.40 0.60 0.58 0.57 0.56 0.39 0.56 0.55 0.54 0.73 0.72 0.71 0.71 0.71 0.71 0.70 0.69 0.90 0.89 0.88 0.88 0.87 0.87 0.87 0.86 0.86 0.85 0.85 0.84 1.04 1.04 1.03 1.03 0.64

in.

0.30 0.35 0.28 0.33 0.37 0.36 0.41 0.45 0.49 0.39 0.25 0.30 0.32 0.37 0.42 0.48 0.53 0.58 0.62 0.34 0.48 fr.53 0.58 0.64 0.69 0.74 0.60 0.62 0.65 0.67 0.70 0.76 0.79 0.82 0.84 0.86 0.72 0.74 0.77 0.79 0.82 0.84 0.86 0.91 0.94 0.!l6 0.99 0.60

I in.' 0.026 0.048 0.028 0.053 0.067 0.04 0.08 0.12 0.11 0.09 0.Q3 0.06 0.05 0.10 0.14 0.10 0.19 0.27 0.35 0.11 0.22 0.31 0.40 0.35 0.51 0.65 0.41 0.50 0.59 0.67 0.76 0.63 0.74 0.87 1.00 1.13 0.70 0.85 1.01 1.15 1.30 1.44 1.58 1.15 1.36 1.57 1.77 0.96

in. 0.27 0.26 0.27 0.26 0.29 0.32 0.32 0.32 0.36 0.32 0.27 0.26 0.33 0.32 0.32 0.43 0.42 0.42 0.42 0.32 0.43 0.42 0.42 0.52 0.51 0.51 0.53 0.53 0.53 0.53 0.53 0.63 0.62 0.62 0.61 0.61 0.64 0.64 0.64 0.63 0.63 0.63 0.63 0.72 0.72 0.71 0.71 0.52

1/4

0/.6 0/.6 0/.6 0/.6

%

1/s VB

Vs Vs

}I/4 }II"

Vs % %

21 °05' 20°31' 24°14' 28°44' 28°20' 27°37' 34°44' 23°09' 14°45' 14°10' 19°40' 19°25' 18°42' 31 °57' 31 °51' 31 °28' 30°56' 14°22' 23°22' 23°0' 22"25' 34°03' 33°54' 33°37' 26°23' 26°18' 26°10' 26°0' 25°48' 36°13' 35°40' 35°37' 35°32' 35°26' 28°42' 28°40' 28°35' 28°28' 28°20' 28° 11' 28°0' 36°54' 36°53' 36°50' 36°46' 14°12'

2xl% 2 x }lIz 2 x 11/z 2 x 11/z 2x 1% 2% x ]112 2Vz x IV4 21/z x 1%

lis

1/4

%

1/4

%

VB

%

21/z x ]1/z 21/z x l1/z 21/z x l1/z

2Vzx2 2Vzx2 2Vzx2 2Vzx2 3 x IVz *3 x2 *3 x2 3x2 *3 x 21/z *3 x 2Vz 3 x2Vz 3Vz x 2Vz 31/z x2Vz 31/z x 2Vz 31/z x 2Vz 31/z x 2Vz 3% x '3 3Vz x 3 31/z x 3 3Vz x 3 31/z x 3 4x3 4x3 4x3 4x3 4x3 4x3 4x3 4 x 3Y:z 4 x 3Y:z 4 x 3~6 4x3Y:z 5x2Y:z

VB

% %

VB 1/4

% % % % %

% % %

1/s 0/.6 VB 0/.6 VB 0/.6 1fs % 1fs % VB 0/.6 %2 %2 % % VB % 1fs % 1/s % VB

Vs

liz

% % liz

1/4

%

X6

*6

Vz

%

*6 *6 *6 *6 *6 *6 *6 *6 X6 X6 X6 X6

% % % % % % % % % % % % % %

VB 1/s 1fs

0/.6 0/.6 0/.6

% % % % % %

1/4

II"

~;6

1/4

% % % %

*6

ljz

V"

%

X6

II"

Y16 % X6

%

Vz

*6

1f4 1f4 II"

V" *6 X6 X6 X6 lJ"

*6

Vz Vz

o/s o/s o/s

1/4

SECTION

PROPERTIES

structural shapes/unequal angles, tees

TABLE 23-ANGLES

Size Depth and Width dxb in. 5x3 5x3 5x3~ 5 x 312 5x3V2 5 x 3% 5 x3Vz 5x3% 6x 6x 6x 6x 6x 6x 6x 6x 6x4 6x4 6x4 6x4 6x4 6x4 6x4 8x6 8x6 8x6 3% Leg Thickness t in.

WITH UNEQUAL LEGS (Cont.)t

Axis X-X Axis y-y Axis Z-Z

Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers.

Weight tb/ft 3.35 4.40 3.01 3.58 4.15 4.70 5.24 5.79 3.39 4.04 4.67 5.31 5.92 6.54 7.13 7.72 4.24 4.91 5.58 6.24 6.88 7.51 8.15 9.84 10.76 11.68

Area in." 2.85 3.74 2.57 3.05 3.53 4.00 4.46 4.92 2.88 3.43 3.98 4.51 5.04 5.56 6.07 6.57 3.60 4.18 4.74 5.30 5.85 6.40 6.93 8.37 9.15 9.93

r, in.

r. in.

I in.' 7.15 9.24 6.39 7.56 8.69 9.77 10.82 11.82 10.64 12.60 14.50 16.34 18.11 19.83 21.49 23.09 13.02 15.02 16.95 18.82 20.63 22.39 24.08 53.57 57.99 62.60

S in! 2.15 2.83 1.85 2.21 2.56 2.90 3.24 3.56 2.64 3.15 3.65 4.14 4.62 5.09 5.56 6.01 3.17 3.69 4.19 4.69 5.17 5.64 6.11 9.74 10.58 11.47

r in. t.S9 1.57 U8 1.58 1.57 1.56 1.56 1.55 1.92 1.92 1.91 1.90 1.90 1.89 1.88 1.87 1.90 1.90 1.89 1.88 1.88 1.87 1.86 2.53 2.52 2.51

y in. 1.68 1.73 1.55 1.58 1.61 1.63 1.66 1.68 1.97 2.00 2.03 2.06 2.08 2.11 2.13 2.16 1.90 1.93 1.96 1.98 2.01 2.03 2.06 2.50 2.52 2.54

I in.' 1.93 2.48 2.58 3.04 3.49 3.91 4.32 4.70 2.70 3.19 3.66 4.11 4.53 4.94 5.33 5.71 4.63 5.34 6.01 6.65 7.27 7.86 8.43 25.94 27.98 30.15

S in.

r in. 0.82 0.81 1.00 1.00 0.99 0.99 0.98 0.98 0.97 0.96 0.96 0.95 0.95 0.94 0.94 0.93 1.13 1.13 1.13 1.12 1.11 1.11 1.l0 1.76 1.75 1.74

x in. 0.69 0.74 0.81 0.84 0.87 0.89 0.92 0.94 0.74 0.77 0.80 0.82 0.85 0.87 0.89 0.92 0.91 0.94 0.97 0.99 1.02 1.04 1.07 1.50 1.53 1.55

I in.' 1.17 U2 1.45 1.71 1.97 2.22 2.46 2.70 1.65 1.95 2.24 2.52 2.80 3.07 3.34 3.61 2.67 3.07 3.47 3.86 4.24 -, 4.61 4.98 13.89 15.02 16.24

r in. 0.64 0.64 0.75 0.75 0.75 0.74 0.74 0.74 0.76 0.75 0.75 0.75 0.75 0.74 0.74 0.74 0.86 0.86 0.86 0.85 0.85 0.85 0.85 1.29 1.28 1.28

o/s

Vz

0/.4

X6 o/s ¥I,

1f2

~6

¥I, ¥I, Y16 ¥I, ¥I, ¥I,

I/Z

31/z 3% 3% 3%

3V2

X,

V2

% Vz

I/Z

¥I,

I/Z

~,

%

3112

3%

1116

0/.4

1f2

%

Vz

X, X6 X6 X6 X6 X6 X, X, X, X, X, r., X6 r.6 r.6 X6

% % % % %

0.84 1.10 0.96 1.15 1.33 1.50 1.67 1.84 0.98 1.17 1.35 1.53 1.71 1.88 2.05 2.21 1.50 1.74 1.98 2.21 2.44 2.66 2.87 5.77 6.25 6.77

19°40' 19°26' 25°33' 25°32' 25°27' 25°22' 25°15' 25°07' 18°52' 18°51' 18°47' 18°42' 18°35' 18°28' 18°20' 18°11' 23°33' 23°31' 23°27' 23°22' 23°16' 23 '10' 23°02' 28°52' 28°47' 28°43'

¥I6 1fz ~6 % 1116

0/.4

'Ys %

V2

I/Z 1/2 I/Z

I/Z

V2 liz

% %

1116

1fz V2 V2

% %

X6

I--b

TABLE 24-ARMY-NAVY AND SPECIAL TEESt

t Areas

~x

d

---_Lx

_Ii

2

tY

and section properties listed are based on nominal dimensions. Weights per foot are based on nominal dimensions and a density of 0.098 pounds per cubic inch. the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for applicable .....J ~ tolerances. is I Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers. Y Size Stem Thickness in. 0.125 0.125 0.125 0.125 0.156 0.156 0.156 0.188 0.188 0.250 0.250 0.312 0.375 0.375 0.500 1.125 0.500

t,

Flange b in. 1.50 1.75 2.00 2.00 2.50 2.50 3.00 3.00 4.00 4.00 4.00 :1:6 :1:6 :1:6 :j:7.5 :j:7.5 :1:8

Stem d in. 1.25 1.625 1.00 1.75 1.25 2.00 2.00 2.50 3.00 4.00 5.00 3 4 4 7.5 7.5 6

Weight Ib/ft 0.384 0.476 0.421 0.531 0.652 0.789 0.881 1.170 1.502 2.271 2.565 3.24 3.88 4.79 9.46 14.42 11.24

Flange Thickness tt in. 0.125 0.125 0.125 0.125 0.156 0.156 0.156 0.188 0.188 0.250 0.250 0.312 0.313 0.450 0.750 0.750 0.860

Axis X-X Area in" 0.326 0.405 0.358 0.451 0.554 0.671 0.749 0.995 1.277 1.931 2.181 2.75 3.30 4.07 8.04 12.26 9.56 r, in. 0.125 0.125 0.125 0.125 0.125 0.125 0.125 0.188 0.188 0.250 0.250 :1:0.312 :1:0.313 :1:0.312 :1:0.625 to.625 to.500 I in.' 0.045 0.100 0.025 0.128 0.062 0.241 0.254 0.565 1.028 2.978 5.542 1.83 4.78 5.02 40.34 69.34 22.93 S in" 0.049 0.083 0.032 0.098 0.063 0.161 0.164 0.302 0.448 1.021 1.571 0.77 1.59 1.61 7.28 14.46 4.82 r in. 0.371 0.496 0.266 0.532 0.333 0.599 0.582 0.753 0.897 1.242 1.594 0.81 1.20 1.11 2.24 2.38 1.55 y in. 0.327 0.434 0.212 0.451 0.265 0.500 0.456 0.632 0.708 1.084 1.473 0.62 1.00 0.88 1.96 2.71 1.24 I in.' 0.032 0.052 0.Q78 0.Q78 0.188 0.189 0.330 0.393 0.947 1.239 1.240 5.63 5.65 8.12 13.60 14.38 36.76

Axis Y-Y S in.' 0.043 0.059 0.Q78 0.Q78 0.151 0.151 0.220 0.262 0.474 0.619 0.620 1.88 1.88 2.71 4.53 4.80 9.19 r in. 0.314 0.357 0.466 0.415 0.583 0.530 0.663 0.629 0.861 0.801 0.754 1.43 1.31 1.41 1.30 1.08 1.96

*Both Flange and stem of these shapes have square ends. Fillet radius, r, applies only to juncture of stem and flange.

10

SECTION

PROPERTIES

tees and zees/ structural shapes

TABLE 25-TEE SECTIONSt t Areas and section properties listed are based

on nominal dimensions. Weights per foot tz are based on nominal dimensions and a density of 0.098 pounds per cubic inch, the j_ density of alloy 6061. See ALUMINUM STANDARDS AND DATA for applicable -l ~t tolerances. y Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers. Size Weigbt Ib/ft 0.31 0.44 0.62 0.68 0.87 0.86 1.26 1.50 1.42 1.00 1.91 2.11 2.13 2.72 2.70 2.76 3.74 4.22 5.41 2.96 4.02 ThickAxis X-X Area in." 0.27 0.37 0.52 0.58 0.74 0.73 1.07 1.28 1.21 0.85 1.62 1.80 1.81 2.31 2.30 2.34 3.18 3.59 4.60 2.52 3.42 tt in. t. in. r. in. I in.' 0.023 0.049 0.067 0.114 0.142 0.269 0.37 0.43 0.53 0.08 0.89 1.49 0.94 1.83 0.60 1.72 4.56 8.56 10.84 1.78 2.37 S in.' 0.032 0.053 0.075 0.108 0.137 0.195 0.26 0.31 0.33 0.09 0.50 0.72 0.51 0.86 0.40 0.77 1.58 2.43 3.14 0.78 1.06 r in. 0.293 0.363 0.359 0.433 0.438 0.606 0.59 0.58 0.66 0.31 0.74 0.91 0.72 0.89 0.51 0.86 1.20 1.54 1.54 0.84 0.83 y in. 0.292 0.326 0.352 0.437 0.464 0.624 0.58 0.61 0.64 0.30 0.73 0.92 0.68 0.88 0.48 0.75 1.11 1.48 1.54 0.71 0.76 I in.' 0.011 0.038 0.056 0.056 0.075 0.060 0.18 0.23 0.26 0.28 0.44 0.44 0.75 0.90 2.10 1.77 2.12 2.13 2.83 2.52 4.13 AxisY-Y

T x:··'

I

--I.

r-b-+T---.I

Flange b in.

I

Stem d in.

I

ness

in.

t

m.

.S

in. 0.206 0.319 0.328 0.312 0.319 0.286 0.41 0.42 0.46 0.57 0.52 0.50 0.65 0.63 0.96 0.87 0.82 0.77 0.79 1.00 1.10

11/2 11f2 1% 11/2 1% 2 2 21,4 2V2 2V2 2V2 3 3 4 4 4 4 4 41/2 5

11f.l }1,4 2

Va Va

Illz Illz

y.,

~: ~

Y., Y.,

1,4

%: %z ~z

1,4

~: ~:

%z %z ~z

Va

1fs

Va

1f.l

2 2 21f.l 21/2 3 21/2 3 2 3 4 5 5 3 3

Ilk

*, Y1,

1f.l

*,

1/4

*, o/s *, Y1,

o/s

%

~z

% % %

*, *,

o/s

Y., *, Y.,

0.023 0.051 0.075 0.075 0.100 0.080 0.18 0.23 0.23 0.22 0.35 0.35 0.50 0.60 1105 0.89 1.06 1.06 1.42 1.12 1.65

1f.l 1f.l 1f.l

Y.,

1f.l 1f.l

*, Y1,

% % Y., % % liz Y.,

o/s

o/s

o/s

~, ~, o/s ~, ~, r.,

%

~,

% 1'16 %

~,

Y1, Y1,

% 1fz

1,4

~, r.,

~,

% %

1/2 1/2

TABLE 26-ZEE SECTIONSt

t Areas

and section properties listed are based on nominal dimensions. Weights per foot are based on nominal dimensions and a density of 0.098 pounds per cubic inch, the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for applicable tolerances. ' Size Nominal Deptb in. 1% 2 2% 3 3 4 4 4 4 4 5 5 5 6 Weight lblft 1.08 0.92 1.00 2.33 3.38 2.85 3.85 4.32 4.78 6.22 4.01 4.84 6.19 9.72 Axis

r, r,

ThickWidth ness t b in. in. 1% 11f.l 1l,4 21\.{, 21\.{, 3\.{, 3Va 3y', 3\.{, 3y', 3%

Area in.' 0.92 0.78 0.85 1.98 2.87 2.42 3.04 3.67 4.06 5.29 3.41 4.12 5.27 8.27

Actual Depth d in. 1% 2 2% 3 3 4 4\t1, 4Vs 4 Ws 5 5\t1, 5 6Vs

x-x

in. 0.695 0.765 0.902 1.21 1.16 1.62 1.62 1.62 1.54 1.55 1.98 1.99 1.91 2.29

r

Axis Y-Y I in.' 0.551 0.186 0.186 2.64 3.76 4.01 5.24 6.54 6.53 9.05 5.94 7.40 8.82 16.07 S in.' 0.333 0.161 0.161 1.03 1.50 1.36 1.76 2.18 2.30 3.11 1.92 2.37 2.94 4.90 r in. 0.773 0.488 0.467 1.15 1.14 1.29 1.31 1.33 1.27 1.31 1.32 1.34 1.29 1.39

Axis

z-z

in. 0.331 0.283 0.310 0.54 0.53 0.67 0.68 0.68 0.66 0.68 0.74 0.75 0.73 0.83

r

in.

in.

I in.' 0.446 0.458 ·0.694 2.89 3.86

S in.' 0.510 0.458 0.584 1.92 2.57 3.16 3.92 4.68 4.84 6.19 5.36 6.41 7.69 14.12

I' in.' 0.101 0.063 0.082 0.59 0.82 1.08 1.39 1.72 1.74 2.41 1.89 2.33 2.82 5.70

Y., Y.6 *6

% Y.,

%

1,4 1f.l

Y., Vs Y.6 lis Y., 1fs Y., lJ4

Y.,

48°49' 29°12' 23°12' 43°24' 44°31' 36°47' 37°24' 37°55' 37°50' 38°41' 30°40' 31°08' 31°09' 27°44'

1f.l 1f.l 1f.l

r..

%

1\tI,

~,

Y1, Ik

3Y16

3%

3%

Y.,

*, *, *, Y., *, Y., *, *,

6.32 7.97 lJ4 9.66 1f.l 9.68 % 12.76 % 13.41 1,4 16.23 1,4 19.23 % 43.24

SECTION

PROPERTIES

11

structural shapes/bulb angles and wing channels

TABLE 27-BULB ANGLESt t Areas and section properties listed are based

on nominal dimensions. Weights per foot are based on nominal dimensions and a density of 0.098 pounds per cubic inch, the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for applicable tolerances. Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers. All dimensions in inch units Size Legs bxd 4 x 3112 5 X 2112 5 x 311z 6 X 3112 Size Legs bxd 4 X 3112 5 x 2112 5 x 3112 6x3112 Wt Ib/ft 4.20 2.51 4.63 3.70 Wt Ib/ft 4.20 2.51 4.63 3.70 Thickness t. % 1/4 % 0.28 t, % Area 3.57 2.13 3.92 3.14 d 3.50 2.50 3.50 3.51 b 4.00 5.00 5.00 6.01 d. 1.50 0.88 1.50 1.06 b. b, r. r2 % 0.42 % 0.54 r. 0.20 r.6 0.25

r.

r.

r.

% 0.20 % 0.24

III

% 0.31

1111 X6 '18 0 0.20 0.79 1.17 ~6 r.6 0.97 0 0.24 Axis y-y

0 r.6 0 0.21 %0 0 0.27 Axis Z-Z

Thickness t. % 1/4 % 0.28

1,

Axis X-X I S 1.18 0.41 1.19 0.98

r

0.92 0.62 0.90 0.93

y 0.93 0.50 0.85 0.74

I 7.95 7.10 13.66 15.44

S 3.58 2.49 4.89 4.33

r

1.49 1.82 1.87 2.22

x 1.78 2.15 2.20 2.44

I 2.24 0.64 2.50 1.94

r

0.79 0.55 0.80 0.79

% 3.02 1/4 0.82 % 3.17 0.31 2.70

20°13' 9°35' 13°45' 13°21'

TABLE 28-BULB ANGLES, ARMY-NAVY SERIESt

t Areas

and section properties listed are based on nominal dimensions. Weights per foot are based on nominal dimensions and a density of 0.098 pounds per cubic inch, the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for applicable tolerances. Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers. All dimensions in inch units Size Legs bxd Ix% 1112 x 7/8 1% x 11/4 2xI 2112 x JlI2 3x2 3'12 x 2lj2 ThickWeight ness Ib/ft t 0.149 0.247 0.478 0.517 0.995 1.344 2.068 0.063 0.078 0.125 0.125 0.188 0.188 0.250 Axis X-X Axis Y-Y Axis Z-Z

Area 0.127 0.210 0.407 0.440 0.846 1.143 1.758

b 1.00 1.50 1.75 2.UO 2.50 3.00 3.50

d 0.750 0.875 1.25 1.00 1.50 2.00 2.50

r.

0.095 0.117 0.156 0.188 0.250 0.312 0.375

S 0.010 O.oI8 0.058 0.047 0.144 0.244 0.495

r

0.221 0.248 0.373 0.294 0.453 0.585 0.747

y 0.157 0.166 0.265 0.185 0.298 0.397 0.517

S 0.026 0.066 0.132 0.190 0.425 0.749 1.271

r

0.354 0.530 0.602 0.703 0.872 1.077 1.243

x 0.379 0.601 0.634 0.854 0.986 1.229 1.364

I 0.0046 0.0100 0.0425 0.0349 0.1546 0.3304 0.8174

r

0.190 0.218 0.323 0.282 0.427 0.538 0.682

0.006 0.013 0.057 0.038 0.173 0.392 0.982

0.016 0.059 0.148 0.217 0.643 1.326 2.715

20°42' 13°46' 20°13' 7°25' 11°07' 13°56' 16°25'

TABLE 29-WING CHANNELSt t Areas and section properties listed are based on

nominal dimensions. Weights per foot are based on nominal dimensions and a density of 0.098 pounds per cubic inch, the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for applicable tolerances. Users are encouraged to ascertain current availability of particular structural shapes through inquiries to their suppliers. All dimensions in inch units. Size Thickness t.

7.32

Axis X-X Area 0.44 0.66 0.16 0.97 1.08 0.95 1.57 4.11 b. 2~6 1% 1% 1%; 2 2% 2Vs b, 1'18 1'18

Jll)2 27.32

Axis Y-Y y I S 0.276 0.402 0.473 0.490 0.71 0.79 1.01 3.64

Width Weight Depth Ib/ft d b 3112 4 4 4 4% 5 5 7112 0.52 0.77 0.90 1.14 1.26 1.12 1.85 4.83 % %

t,

7.32

b, 21/4 2 2 1112 2111 3 2 2%

r, 7.32

r,

7.32

r,

0 1/8 1/8 'Is

l)2

r,

S 0.116 0.139 0.251 0.517 0.634 0.485 0.709 3.15

r

0.293 0.288 0.440 0.789 0.788 0.597 0.704 1.24

r

1.044 1.107 1.112 1.006 1.25 1.44 1.27 1.82

2 )IX6 1112 IVs 3%

1'18

VB

Y32

1/8

'I,; VB

7.32

'18

%6 X6

VB

'18

r.6 X6

VB

1%

1% 1'18 21~6

)I~,

'18 'Is 'Is

VB

'18 '18

1fs

%6 0 0 0

'18 %, 'Is

VB

III

YI6

0 0 0 0 0 0 0

0.038 0.054 0.148 0.603 0.668 0.339 0.778 6.28

0.420 0.484 0.359 0.804 0.533 0.946 0.833 0.980 0.946 1.69 0.803 1.97 0.778 2.53 1.38 13.66

12

SECTION

PROPERTIES

round tube/structural shapes

TABLE 30 ROUND TUBEt

Outside Diam 0.375 Wall Thickness 0.Q35 0.049 0.058 0.065 0.028 0.035 0'()49 0.058 0.065 0.028 0.Q35 0.049 0.058 0.065 0.Q35 0.049 0.058 0.065 0.083 0.Q35 0.049 0.058 0.065 0.Q35 0.049 0.058 0.065 0.083 0.095 0.063 0.078 0.094 0.125 0.063 0.078 0.094 0.125 0.156 0.188 0.129 0.250 0.063 0.078 0.094 0.125 0.156 0.188 0.219 0.250 0.063 0.078 0.094 0.125 0.156 0.188 0.219 0.250 0.313 0.375 0.438 0.063 0.078 0.094 0.125 0.156 0.188 0.219 0.250 0.313 0.375 0.438 0.500 Inside Diam 0.305 0.277 0.259 0.245 0.444 0.430 0.402 0.384 0.370 0.569 0.555 0.527 0.509 0.495 0.680 0.652 0.634 0.620 0.584 0.805 0.777 0.759 0.745 0.930 0.902 0.884 0.870 0.834 0.810 1.124 1.094 1.062 1.000 1.374 1.344 1.312 1.250 1.188 1.124 1.062 1.000 1.624 1.594 1.562 1.500 1.438 1.374 1.312 1.250 1.874 1.844 1.812 1.750 1.688 1.624 1.562 1.500 1.374 1.250 1.124 2.374 2.344 2.312 2.250 2.188 2.124 2.062 2.000 1.874 1.750 1.624 1.500 Area 0.0374 0.0502 0.0578 0.0633 0.0415 0.0511 0.0694 0.0805 0.0888 0.0525 0.0649 0.0887 0.1033 0.1144 0.0786 0.1079 0.1261 0.1399 0.1739 0.0924 0.1272 0.1489 0.1654 0.1061 0.1464 0.1716 0.1909 0.2391 0.2701 0.2332 0.2870 0.3405 0.4418 0.2823 0.3480 0.4142 0.5400 0.6596 0.7731 0.8805 0.9817 0.3313 0.4090 0.4878 0.6381 0.7823 0.9204 1.0523 1.1781 0.3804 0.4700 0.5614 0.7363 0.9050 1.0677 1.2241 1.3744 1.6567 1.9144 2.1476 0.4786 0.5910 0.7087 0.9327 1.1505 1.3622 1.5677 1.7671 2.1476 2.5035 2.8348 3.1416 Wtlihtt I ft 0.0440 0.0590 0.0679 0.0745 0.0488 0.0601 0.0817 0.0947 0.104 0.06i8 0.0763 0.104 0.122 0.134 0.0925 0.127 0.148 0.165 0.205 0.109 0.150 0.175 0.195 0.125 0.172 0.202 0.225 0.281 0.318 0.282 0.338 0.402 0.520, 0.342 0.410· 0.488 0.635 0.775 0.911 1.03 1.15 0.400 0.482 0.575 0.751 0.919 1.09 1.23 1.39 0.460 0.554 0.662 0.866 1.06 1.26 1.44 1.62 1.95 2.25 2.53 0.579 0.698 0.836 1.10 1.35 1.61 1.85 2.08 2.54 2.94 3.34 3.70 0.0006 0.0007 0.0007 0.0008 0.0012 0.0014 0.0018 0.0020 0.0021 0.0023 0.0028 0.0037 0.0042 0.0045 0.0050 0.0067 0.0076 0.0083 0.0098 0.0082 0.0109 0.0125 0.0137 0.0124 0.0166 0.0191 0.0210 0.0253 0.0280 0.0412 0.0491 0.0578 0.0708 0.0730 0.0883 0.1028 0.1287 0.1509 0.1699 0.1859 0.1994 0.1181 0.1440 0.1678 0.2119 0.2508 0.2849 0.3147 0.3405 0.1787 0.2160 0.2556 0.3250 0.3873 0.4431 0.4928 0.5369 0.6099 0.6656 0.7068 0.3557 0.4275 0.5137 0.6594 0.7935 0.9165 1.0292 1.1321 1.3108 1.4571 1.5752 1.6690 Section Properties S 0.0029 0.0036 0.0040 0.0042 0.0046 0.0056 0.0071 0.0080 0.0086 0.0075 0.0091 0.0119 0.0134 0.0145 0.0134 0.0178 0.0203 0.0221 0.0262 0.0187 0.0249 0.0285 0.0312 0.0247 0.0331 0.0382 0.0419 0.0507 0.0559 0.0659 0.0785 0.0925 0.1133 0.0973 0.1180 0.1371 0.1716 0.2012 0.2265 0.2479 0.2659 0.1350 0.1647 0.1918 0.2422 0.2866 0.3256 0.3597 0.3891 0.1787 0.2160 0.2556 0.3250 0.3873 0.4431 0.4928 0.5369 0.6099 0.6656 0.7068 0.2846 0.3420 0.4110 0.5275 0.6348 0.7332 0.8234 0.9057 1.0486 1.1657 1.2602 1.3352 r 0.1208 0.1166 0.1140 0.1120 0.1672 0.1649 0.1604 0.1576 0.1555 0.2113 0.2090 0.2044 0.2015 0.1993 0.2531 0.2484 0.2455 0.2433 0.2376 0.2972 0.2926 0.2896 0.2873 0.3414 0.3367 0.3337 0.3314 0.3255 0.3217 0.4204 0.4125 0.4101 0.4002 0.5087 0.5030 0.4983 0.4881 0.4783 0.4688 0.4595 0.4507 0.5970 0.5930 0.5865 0.5762 0.5662 0.5564 0.5469 0.5377 0.6854 0.6780 0.6748 0.6644 0.6542 ·0.6442 0.6345 0.6250 0.6068 0.5896 0.5737 0.8621 0.8500 0.8514 0.8409 0.8305 0.8202 0.8102 0.8003 0.7813 0.7629 0.7454 0.7289

0.500

0.625 All dimensions in inch units 0.750 For Round Tube the nominal size is equal to the outside diameter. and section properties listed are based on nominal dimensions. Weights per foot are based on nominal dimensions and a density of 0.098 pounds per cubic inch, the density of alloy 6061. See ALUMIc NUM STANDARDS AND DATA for applicable tolerances.

0.875

t Areas

1.00

1.25

1.50

1.75

2.00

2.50

SECTION

PROPERTIES

13

structural

shapes/ round tube (continued)

Section Properties Outside Diam 3.00 Wall Thickness 0.063 0.078 0.094 0.125 0.156 0.188 0.219 0.250 0.313 0.375 0.438 0.500 0.625 0.750 0.156 0.250 0.375 0.500 0.125 0.156 0.219 0.250 0.500 0.625 0.750 0.188 0.250 0.375 0.500 0.750 0.156 0.188 0.219 0.250 0.438 0.500 0.625 0.750 1.000 0.078 0.094 0.188 0.219 0.250 0.313 0.500 1.000 0.094 0.109 0.500 0.750 0.125 0.156 0.313 0.500 1.000 0.188 0.250 0.313 0.375 0.500 0.188 0.250 0.313 0.375 0.500 0.250 0.313 0.375 0.500 0.250 0.375 0.500 0.750 Inside Diam 2.874 2.844 2.812 2.750 2.688 2.624 2.562 2.500 2.374 2.250 2.124 2.000 1.750 1.500 -3.188 3.000 2.750 2.500 3.750 3.688 3.562 3.500 3.000 2.750 2.500 4.124 4.000 3.750 3.500 3.000 4.688 4.624 4.562 4.500 4.124 4.000 3.750 3.500 3.000 5.844 5.812 5.624 5.562 5.500 5.374 5.000 4.000 6.812 6.782 6.000 5.500 7.750 7.688 7.374 7.000 6.000 8.624 8.500 8.374 8.250 8.000 9.624 9.500 9.374 9.250 9.000 10.500 10.374 10.250 10.000 11.500 11.250 11.000 10.500 Area 0.5768 0.7140 0.8560 1.1290 1.3959 1.6567 1.9113 2.1598 2.6384 3.0925 3.5220 3.9270 4.6633 5.3014 1.6414 2.5525 3.6816 4.7124 1.5217 1.8867 2.5985 2.9452 5.4978 6.6268 7.6576 2.5403 3.3379 4.8597 6.2832 8.8357 2.3777 2.8348 3.2858 3.7306 6.2709 7.0686 8.5903 10.0138 12.5664 1.450 1.740 3.4238 3.9730 4.5160 5.5837 8.6394 15.7080 2.034 2.360 10.2102 14.7262 3.083 3.8503 7.5472 11.7810 21.9912 5.1910 6.8720 8.5290 10.1600 13.3500 5.7800 7.6580 9.5100 11.3400 14.9200 8.4430 10.4900 12.5200 16.4900 9.190 13.560 18.000 26.400 Weittt Ib ft S r

TABLE 30 ROUND TUBe

(Contd.)t

All dimensions

in inch units

3.50

4.00 For Round Tube the nominal size is equal to the outside diameter

and section properties listed are based on nominal dimensions. Weights per foot are based on nominal dimensions and a density of 0.098 pounds per cubic inch, the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for applicable tolerances.

t Areas

4.50

5.00

6.00

7.00

8.00

9.00

10.00

11.00

12.00

0.4149 0.681 0.6224 1.0388 0.5060 0.7600 1.0320 0.842 0.6031 0.9047 1.0280 1.01 0.7791 1.1687 1.0174 1.33 1.4153 0.9435 1.0069 1.64 1.6454 1.0969 1.95 0.9966 1.2397 2.25 1.8595 0.9864 2.54 2.0586 1.3724 0.9763 2.4143 1.6095 3.U 0.9566 1.8120 3.64 2.7180 0.9375 4.15 2.9751 1.9834 0.9191 3.1907 2.1271 4.62 0.9014 2.3438 5.48 3.5157 0.8683 6.24 3.7276 2.4851 0.8385 ------1.3137 1.93 2.2990 1.1835 3.00 3.3901 1.9372 ' 1.1524 2.6050 4.33 4.5588 1.1128 5.54 5.4487 3.1135 1.0753 2.8591 1.4296 1.79 1.3707 1.7452 2.22 3.4903 1.3601 3.06 4.6598 2.3299 1.3391 2.6001 3.46 5.2002 1.3288 4.2952 6.47 8.5903 1.2500 9.7590 4.8975 1.2135 7.79 9.01 10.6489 5.3245 1.1793 ---.~---.--2.6296 3.00 5.9166 1.5261 7.5625 3.3611 1.5052 3.93 1.4644 5.72 10.4217 4.6319 7.39 12.7627 5.6723 1.4252 10.39 16.1528 7.1790 1.3520 ---------2.7921 1.7134 2.79 6.9803 3.2877 1.7028 3.34 8.2192 3.7636 1.6922 3.87 9.4089 4.2203 1.6817 4.39 10.5507 6.5869 1.6205 7.38 16.4673 8.31 18.1132 7.2453 1.6008 20.9724 8":3890 1.5625 10.10 9.3254 11.78 23.3134 1.5258 14.78 26.7035 10.6814 1.4577 6.620 2.210 2.2750 1.71 2.620 2.2452 2.05 7.851 4.8248 2.0561 4.04 14.4744 4.68 16.6224 5.5408 2.0454 18.6992 6.2330 2.0348 5.31 7.5485 2.0139 6.59 22.6458 10.16 33.200 10.9792 1.9526 17.0170 1.8028 18.48 51.0509 2.5161 2.40 12.285 3.510 3.980 2.4250 2.78 13.910 15.4976 2.3049 12.01 54.2416 17.32 72.9408 20.8402 2.2255 24.585 6.150 2.8210 3.64 7.4057 2.7737 4.52 29.6226 55.8447 13.9612 2.7202 8.90 83.2031 20.8008 2.6575 13.86 137.4447 34.3612 2.5000 25.87 .---------_ 11.2000 3.1160 6.28 50.4200 14.6300 3.0950 65.8200 8.32 17.9100 3.0740 10.32 80.5700 21.0400 12.29 94.6700 3.0520 121.0000 26.8900 3.0100 16.16 ----13.9200 3.4700 6.99 69.5900 3.4480 9.27 91.0600 18.2100 11.51 111.7000 22.3400 3.4270 131.5000 3.4060 13.72 26.3000 18.06 168.8000 33.7600 3.3630 122.0000 22.1900 3.8020 10.22 149.9000 27.2600 3.7800 12.70 15.14 176.9000 32.1600 3.7590 227.8000 41.4200 3.7170 19.96 --------_._----_-_._---_ ..... _._._ 26.780 4.1770 160.700 10.1S5 38.800 4.1350 16.! I 233.300 4.0780 300.600 50.950 21.25 422.000 70.250 4.0010 31.18

14

SECTION

PROPERTIES

pipe/ structural shapes

TABLE 31

Norninal Pipe Size

'Ill "

PIPEt

Schedule No.*

Outside Diam in. 0.405 0.540 0.675

Inside Diam in. 0.269 0.215 0.364 0.302 0.493 0.413 0.710 ').674 0.622 0.546 0.466 0.920 0.884 0.824 0.742 0.~14 1.185 1.097 1.049 0.957 0.815 1.530 1.442 1.380 1.278 1.160 1.770 1,682 1.610 1.500 1.338 2.245 2.157 2.067 1.939 1.689 2.709 2.635 2.469 2.323 2.125 3.334 3.260 3.068 2,900 2.626 3.834 3.760 3.548 3.364 4.334 4.260 4.026 3.826 3.626 3.438 5.345 5.299 5.047 4.813 4.563 4.313 6.407 6.361 6.065 5.761 5.501 5.189

Wall Thickness in. 0.068 0.095 0.088 0.119 0.091 0.126 0.065 0.083 0.109 0.147 0.187 0.065 ' 0.083 0.113 0.154 0.218 0.065 0.109 0.133 0.179 0.250 0.065 0.109 0.140 0.191 0.250 0.065 0.109 0.145 0.200 0.281 0.065 0.109 0.154 0.218 0.343 0.083 0.120 0.203 0,276 0.375 0.083 0.120 0.216 0.300 0.437 0.083 0.120 0.226 0.318 0.083 0.120 0.237 0.337 0.437 0.531 0.109 0.134 0.258 0.375 0.500 0.625 0.109 0.134 0.280 0.432 0.562 0.718

Section Properties Area in." 0.0720 0.0925 0.1250 0.1574 0.1670 0.1'173 0.1583 0.197 0.2503 0.3200 0.384 0.2011 0.2521 0.3326 0.4335 0.570 0.2553 0.4130 0.4939 0.6388 0.836 0.326 0.531 0.668 0.882 1.107 0.375 0.613 0.799 1.068 1.431 0.472 0.776 1.074 1.477 2.19 0.728 1.039 1.704 2.254 2.945 0.891 1.274 2.228 3.016 4.213 1.021 1.463 2.680 3.678 1.152 1.651 3.174 4.407 5.59 6.62 1.88 2.29 4.30 6.11 7.95 9.70 2.225 2.73 5.581 8.405 10.70 13.32 Wei~htt Ib ft 0.085 0.109 0.147 0.185 0.196 0.256 0.186 0.232 0.294 0.376 0.451 0.237 0.297 0.391 0.510 0.670 0.300 0.486 0.581 0.751 0.984 0.383 0.625 0.786 1.037 1.302 0.441 0.721 0.940 1.256 1.681 0.555 0.913 1.264 1.737 2.575 0.856 1.221 2.004 2.650 3.464 1.048 1.498 2.621 3.547 4.945 1.201 1.720 3.151 4.326 1.354 1.942 3.733 5.183 6.560 7.786 2.196 2.688 5.057 7.188 9.353 11.40 2.624 3.213 6.564 9.884 12.59 15.67 I in.' 0.0011 0.0012 0.0033 0.0038 0.0073 0.0086 0.0119 0.0143 0.0171 0.0201 0.0221 0.0245 0.0297 0.0370 0.0448 0.0527 0.0500 0.0757 0.0873 0.1056 0.1251 0.104 0.161 0.195 0.242 0.284 0.158 0.247 0.310 0.391 0.482 0.315 0.499 0.666 0.868 1.163 0.710 0.987 1.530 1.924 2.351 1.301 1.822 3.017 3.894 5.04 1.960 2.755 4.788 6.281 2.810 3.963 7.232 9.611 11.66 13.27 6.96 8.43 15.16 20.67 25.74 30.03 11.82 14.40 28.14 40.49 49.6 59.0 S in.' 0.0053 0.0060 0.0123 0.0139 0.0216 0.0255 0.0280 0.0341 0.0407 0.0478 0.0527 0.0129 0.0566 0.Q705 0.0853 0.1004 0.0760 0.1151 0.1328 0.1606 0.1903 0.125 0.193 0.235 0.291 0.342 0.166 0.260 0.326 0.412 0.508 0.265 0.420 0.561 0.731 0.979 0.494 0.687 1.064 1.339 1.637 0.744 1.041 1.724 2.225 2.879 0.9799 1.378 2.394 3.140 1.249 1.161 3.214 4.272 5.18 5.90 2.50 3.03 5.45 7.43 9.25 10.80 3.57 4.35 8.50 12.22 14.98 17.81 r in. 0.1215 0.1146 0.1628 0.1547 0.2090 0.1991 0.274 0.269 0.2613 0.2505 0.240 0.3491 0.3432 0.3337 0.3214 0.304 0.4425 0.4282 0.4205 0.4066 0.387 0.564 0.550 0.540 0.524 0.506 0.649 0.634 0.623 0.605 0.581 0.817 0.802 0.787 0.766 0.728 0.988 0.975 0.947 0.924 0.894 1.208 1.l96 1.l64 1.136 1.094 1.385 1.372 1.337 1.307 1.562 1.549 1.510 1.477 1.444 1.416 1.924 1.920 1.878 1.839 1.799 1.760 2.348 2.295 2.246 2.195 2.153 2.104

40 80 40 80 40 80 5 10 40 80 160 5 10 40 80 160 5 10 40 80 160 5 10 40 80 160 5 10 40 80 160 5 10 40 80 160 5 10 40 80 160 5 10 40 80 160 5 10 40 80 5 10 40 80 120 160 5 10 40 80 120 160 5 10 40 80 120 160

1,4_

1/2 For Pipe the outside diameter is from 0.280 in. to 0.75 in. larger than the nominal pipe size. For schedule 40 Pipe in sizes 2 in. and above the inside diameter is roughly equal to the nominal pipe size,

0.840

1.050

1.315

and section properties listed are based on nominal dimensions. Weights per foot are based on nominal dirnensions and a density of 0.098 pounds per cubic inch, the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for applicable tolerances.

t Areas

}I,4

1.660

JI/2

1.900

2.375

21/2

2.875

3.500

31/2

4.000

4.500

• Schedule numbers conform to ANSI Standard for Wrought Iron and wroutt Steel Pipe, B36.1O and B36.1 .

5.563

6.625

SECTION

PROPERTIES

15

structural shapes/pipe (continued) and square tube

TABLE 31 PIPE (Contd.)t

Nominal Pipe Size Schedule No.· Outside Diam in. Inside Diam in. 8.407 8.329 8.125 8.071 7.981 7.813 7.625 7.4.39 7.189 7.001 6.813 10.482 10.420 10.250 10.192 10.136 10.020 9.750 9.564 9.314 12.42 12.39 12.09 12.00 11.75 Wall Thickness in. 0.109 0.148 0.250 0.277 0.322 0.406 0.500 0.593 0.718 0.812 0.906 0.134 0.165 0.250 0.279 0.307 0.365 0.500 0.593 0.718 0.165 0.180 0.330 0.375 0.500 Section Properties Area in." 2.92 3.94 6.58 7.27 8.399 10.48 12.76 14.96 17.84 19.93 21.97 4.48 5.49 8.25 9.18 10.07 11.91 16.10 18.92 22.63 6.53 7.11 12.88 14.58 19.24 Weightt

Iblft

I in.' 26.6 35.4 57.7 63.35 72.49 88.8 105.7 121.4 140.6 153.7 165.9 62.6 76.9 113.7 125.9 137.4 160.7 211.9 244.8 286.2 129.3 140.5 248.5 279.3 361.5

S in." 6.17 8.21 13.39 14.69 16.81 20.58 24.51 28.14 32.60 35.63 38.48 11.65 14.30 21.16 23.42 25.57 29.90 39.43 45.5 53.2 20.28 22.0 38.97 43.81 56.71

r in. 3.02 3.00 2.96 2.95 2.94 2.91 2.88 2;85 2.81 2.78 2.75 3.74 3.743 3.71 3.704 3.694 3.674 3.628 3.60 3.56 4.45 4.445 4.393 4.377 4.335

5 10 20 30 40 60 80 100 120 140 160 5 10 20

8.625

3.429 4.635 7.736 8.543 9.878 12.33 15.01 17.60 20.97 23.44 25.84 5.256 6.453 9.698 10.79 11.84 14.00 18.93 22.25 26.61 7.672 8.359 15.14 17.14 22.63

10

• Schedule numbers conform to ANSI Standard for Wrought Iron and Wroutt Steel Pipe, B36.10 and B36.1 .

30 40 60 80 100

10

10.75

12

30

12.75

TABLE 32 SQUARE TUBEt

Outside Width and Depth in. 0.375

Section Properties

Thickness in. 0.022 0.028 0.035 0.049 0.022 0.028 0.035 0.049 0.058 0.065 0.022 0.028 0.035 0.049 0.058 0.065 0.022 0.028 0.035 0.049 0.058 0.065 0.083 0.028 0.035 0.049 0.058 0.065 0.083 0.028 0.035 0.049 0.058 0.065 0.083

Area in.' 0.0316 0.0387 0.0473 0.0649 0.0431 0.0529 0.0652 0.0883 0.1032 0.1134 0.0546 0.0668 0.0833 0.1134 0.1317 0.1457 0.0640 0.0805 0.1000 0.1374 0.1606 0.1881 0.2215 0.0949 0.1176 0.1519 0.1995 0.2106 0.2626 0.1089 0.1350 0.1864 0.2186 0.2431 0.3050

Weightt

Iblft

in.' 0.0006 0.0007 0.0009 0.0011 0.0016 0.0020 0.0024 0.0030 0.0034 0.0036 0.0032 0.0040 0.0048 0.0063 0.0071 0.0077 0.0057 0.0071 0.0086 0.0113 0.0130 0.0141 0.0167 0.0113 0.0137 0.0185 0.0212 0.0231 0.0277 0.0171 0.0210 0.0281 0.0324 0.0356 0.0430

S in." 0.0032 0.0039 . 0.0048 0.0058 0.0064 0.0080 0.0096 0.0120 0.0136 0.0144 0.0102 0.0128 0.0154 0.0202 0.0227 0.0246 0.0152 0.0189 0.0229 0.0301 0.0346 0.0376 0.0445 0.0258 0.0313 0.0423 0.0484 0.0528 0.0633 0.0342 0.0420 0.0562 0.0648 0.0712 0.0860

r in. 0.1367 0.1338 0.1367 0.1311 0.1927 0.1943 0.1921 0.1841 0.1816 0.1783 0.2427 0.2448 0.2400 0.2357 0.2327 0.2299 0.2984 0.2969 0.2932 0.2866 0.2844 0.2737 0.2746 0.3450 0.3413 0.3488 0.3259 0.3312 0.3248 0.3962 0.3937 0.3884 0.3850 0.3826 0.3754

0.0372 0.0455 0.0556 0.0763 0.0507 0.0622 0.0767 0.1038 0.1214 0.1334 0.0642 0.0786 0.0980 0.1334 0.1549 0.1713 0.0753 0.0947 0.1176 0.1616 0.1889 0.2212 0.2605 0.1116 0.1383 0.1786 0.2346 0.2477 0.3088 0.1281 0.1588 0.2192 0.2571 0.2859 0.3587

0.500

I

-- 0.625

0.750

0.875

and section properties listed are based on nominal dimensions. Weights per foot are based on nominal dirnensions and a density of 0.098 pounds per cubic inch, the density of alloy 6061. See ALUMINUM STANDARDS AND DATA for applicable tolerances.

t Areas

1.000

16

SECTION

PROPERTIES

square tube (continued)/ structural shapes

TABLE 32 SQUARE TUBE

Outside Width and Depth in. 1.125 Section Properties

{Contd.)t

Thickness in. 0..035 0..0.49 0..0.58 0..0.65 0..0.83 0..0.95 0..]20. 0..035 0..0.49 0..0.58 0..0.65 0..0.83 0..0.95 0..120. 0..0.35 0..0.49 0..0.58 0..0.65 0..0.83 0..0.95 0..120. o..Q35 0..0.49 0..0.58 0..0.65 0..0.83 0..0.95 0..120. 0..0.49 0..0.58 0..0.65 0..0.83 0..0.95 0..120. 0..156 0..0.49 0..0.58 0..0.65 0..0.83 0..0.95 0..120. 0..156 0..0.49 0..0.58 0..0.65 0..0.83 0..0.95 0..120. 0..156 0..0.58 0..0.65 0..0.83 0..0.95 0..120. 0..156 0..188 0..0.58 0..0.65 0..0.83 0..0.95 0..120. 0..156 0..188 0..0.65 0..0.83 0..0.95 0..120. 0..156 0..188 0..219

Area in! 0..1520. 0..210.0. 0..2469 0..2751 0..3453 0..390.8 0..4818 0..170.8 0..2355 0..2766 0..30.91 0..3877 0..4388 0..5425 0..1875 0..2594 0..30.56 0..340.7 0..4282 0..4858 0..60.27 0..20.51 0..2839 0..3346 0..3731 0..4710. 0..5337 0..6632 0..3334 0..3926 0..4381 0..5537 0..6284 0..7821 0..9947 0..3824 0..450.6 0..50.31 0..6365 0..7239 0..90.24 1.150.7 0..4314 0..50.86 0..5681 0..7195 0..8189 1.0.224 1.30.67 0..5666 0..6331 0..80.25 0..9139 1.1424 1.4627 1.7386

Weight+ Ib/ft 0..1788 0..2470. 0..290.4 0..3235 0..40.61 0..4596 0.5666 0..20.0.9 0..2769 0..3253 0..3635 0..4559 0..5160. 0..6380. 0..220.5 0..30.51 0..3594 0..40.0.7 0..50.36 0..5713 0..70.88 0..2412 0..3339 0..3935 0..4388 0..5539 0..6276 0..7799 0..3921 0..4617 0..5152 0..6512 0..7390. 0..9197 1.1698 0..4497 0..5299 0..5916 0..7485 0..8513 1.0.612 1.3532 0..50.73 0..5981 0..6681 0..8461 0..9630. 1.20.23 1.5367 0..6663 0..7446 0..9437 1.0.747 1.3435 1.720.1 2.0.446 0..7345 0..8210. 1.0.413 1.1865 1.4846 1.90.36 2.2658 0..8974 1.1390. 1.2982 1.6256 2.0.869 2.4868 2.8650.

1 in.' 0..0.30.3 0..0.40.8 0..0.471 0..0.518 0..0.630. 0..0.698 0..0.824 0..0.419 0..0.566 0..0.656 0..0.723 0..0.883 0..0.982 0..1167 0..0.562 0..0.763 0..0.885 0..0.977 0..1199 0..1336 0..1696 0..0.734 0..0.999 0..1162 0..1283 0..1580. 0..1865 0..2119 0..160.9 0..1875 0..20.76 0..2568 0..2883 0..3487 0..4252 0..2427 0..2834 0..3143 0..390.5 0..4389 0..5337 0..6568 0..3485 0..40.75 0..4524 0..5639 0..6351 0..7755 0..960.2 0..5634 0..6261 0..7823 0..8824 1.0.813 1.3453 1.5592

.. ..

_

S in.' 0..0.538 0..0.725 0..0.837 0..0.930. 0..1120. 0..1241 0..1465 0..0.670. 0..0.90.6 0..10.50. 0..1157 0..1413 0..1571 0..1867 0..0.817 0..1110. 0..1287 0..1421 0..1744 0..1943 --'--__ 0..2467 0..0.979 0..1332 0..1549 0..1711 0..210.7 0..2486 0..2825 0..1839 0..2143 0..2372 0..2935 0..3293 0..3982 0..4859 0..2427 0..2834 0..3143 0..390.5 0..4389 0..5337 0..6568 0..30.97 0..3622 0..40.21 0..50.12 0..5645 0..6893 0..8535 0..450.7 0..50.0.8 0..6258 0..70.59 0..8650. 1.0.762 1.2473 0..5488 0..610.4 0..7641 0..8631 1.0.60.5 1.3242 1.5411 0..730.8 0..9164 1.0.362 1.2762 1.5997 1.8662 2.10.64