Professional Documents

Culture Documents

Spring Constant (K GD 4/ (8nD 3) 1.694936 9.6075087 Spring Force (F - KX) 33.89871 7.5649675

Spring Constant (K GD 4/ (8nD 3) 1.694936 9.6075087 Spring Force (F - KX) 33.89871 7.5649675

Uploaded by

furion304Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spring Constant (K GD 4/ (8nD 3) 1.694936 9.6075087 Spring Force (F - KX) 33.89871 7.5649675

Spring Constant (K GD 4/ (8nD 3) 1.694936 9.6075087 Spring Force (F - KX) 33.89871 7.5649675

Uploaded by

furion304Copyright:

Available Formats

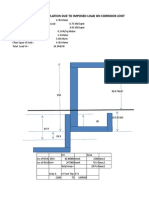

mm Spring free length For compression at 50.

8mm dia opening Rigidity modulus(G)(N/mm2) Number of coill Number of active coill(n) Outer Diameter(D) wire Diameter(d) Max Deflection(x= free length-deflected lenght)

in 38 1.625 78600 11399966 13 13 11 11 10.3 0.406 1.2 0.0472 20 0.7874016

Spring constant(k= Gd^4/[8nD^3] Spring Force(F=-kx)

N/mm 1.694936 N 33.89871

lb/in 9.6075087 lb 7.5649675

lb/in2

N/mm 1.434176

this value is obtained when active coil is not taken in to account

this value is obtained when active coil is not taken in to account

torsional spring spring rate (lb/in or N/mm)= Moment or torque (lb in or Nmm)= stress(psi or Mpa)= #NAME? #NAME? #NAME? mm mean coil dia,D dia of round wire,d Nmber of coils,N Deflection or revolution of spring(/360) I.D in the deflected position body length in deflected position 1.3 0.144444444 in

torsional spring material music wire design assumptions stress #NAME?

Mpa modulus of rigidity,E stress,S tesile strength of material

Psi 30x10^6

esign assumptions

Diameter of spring wire d

10-3 m 10-3 m

13 5.15

1.32

Mean coil diameter D

Number of active coils n

79.3

Shear modulus G = E / ( 2 ( 1+v ) ) 109 Pa

Spring force F

N100

6.47

Spring outer diameter Dout = D + 10-3 m d Spring radius r = D / 2 Spring length closed (solid) Lc = n d Spring deflection f Energy stored W = F f / 2 Spring stiffness k = dF / df = F / f Spring length free L0 > Lc + f Pitch of lead s = L0 / n 10-3 m 2.58

17.16 10-3 m

10-3 m 5.9 J 0.3

16.95 103 N/m

Shear stress

103 N/m 23.06 10-3 m 1.77 106 Pa 570.2 www.tribology-abc.com

Misumi- Specifications Sl no 1 2 3 4 5 6 d 1.2 1.2 1.1 Solid length F MAX. Load N(kgf) 46 16.3 159.8 50 17.5 171.6 43 15 147.1 Load kg 9.80368098 9.80571429 9.80666667 Part number WB5-65 WB5-70 WB5-60

Deflection MAX. Allowable deflection Deflection L*25% 34.5 L*25% 37.5 L*25% 32.25

You might also like

- ProblemsDocument22 pagesProblemsSuresh GoudNo ratings yet

- Spring Load CalculationDocument1 pageSpring Load CalculationSuresh Kumar MittapalliNo ratings yet

- Helical Compression Spring DesignDocument2 pagesHelical Compression Spring DesignkarthegreNo ratings yet

- MAST CalculationDocument2 pagesMAST Calculationshamir_ahmedabad100% (1)

- Fastener Torque Charts Bolt Clamp Loads Suggested Assembly Torque ValuesDocument2 pagesFastener Torque Charts Bolt Clamp Loads Suggested Assembly Torque ValuescuprotecNo ratings yet

- Torispherical Heads THICKNESS CALCULATION FOR INTERNAL PRESSUREDocument3 pagesTorispherical Heads THICKNESS CALCULATION FOR INTERNAL PRESSUREmiteshpatel191No ratings yet

- Double Piston EffectDocument1 pageDouble Piston EffectaiaudcoNo ratings yet

- Z M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Document16 pagesZ M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Babu RajamanickamNo ratings yet

- Cylindrical Shell of Pressure Vessel CalculationDocument24 pagesCylindrical Shell of Pressure Vessel CalculationTinBáoNo ratings yet

- Ramset Specifiers Resource Book Ed3 - Mechanical AnchoringDocument52 pagesRamset Specifiers Resource Book Ed3 - Mechanical Anchoringapsapsaps19880% (1)

- Mesh QualityDocument26 pagesMesh QualityRamesh BammankattiNo ratings yet

- Pressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsDocument9 pagesPressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsJoemarie Martinez100% (1)

- SteelSpan MADDocument6 pagesSteelSpan MADAnonymous pD2ymRUguNo ratings yet

- Pipe Data-ID-OD Thickness & WeightDocument4 pagesPipe Data-ID-OD Thickness & WeightsssmrsmNo ratings yet

- Referencia Descripción PVP /UD Raee: TargettiDocument54 pagesReferencia Descripción PVP /UD Raee: TargettiVEMATEL50% (2)

- Compression Spring CalculationDocument1 pageCompression Spring CalculationvenkateswaranNo ratings yet

- Helical Gear Calculation Using SoftwareDocument10 pagesHelical Gear Calculation Using SoftwareM036No ratings yet

- Cone Weight CalculationDocument10 pagesCone Weight CalculationRajesh OwaiyarNo ratings yet

- Rectangular Steel Bar DesignDocument2 pagesRectangular Steel Bar DesignAmit Kumar PaulNo ratings yet

- SVP Walk Way Support Structure: Embedment Plate and Bolt Design 1 For Top Support - Ismc 100Document6 pagesSVP Walk Way Support Structure: Embedment Plate and Bolt Design 1 For Top Support - Ismc 100aakash prabhuNo ratings yet

- Flanges Carbon Chrome Blind RTJWN SMDocument11 pagesFlanges Carbon Chrome Blind RTJWN SMvalli rajuNo ratings yet

- Weld Neck Flange DesignDocument2 pagesWeld Neck Flange DesignKashif KaziNo ratings yet

- Daftar Standard Di Elibrary RekindDocument48 pagesDaftar Standard Di Elibrary RekindHamzah ZuhdiNo ratings yet

- Strength Calculation ARTDocument34 pagesStrength Calculation ARTdenstar silalahiNo ratings yet

- API 650 Pipe Column DesignDocument4 pagesAPI 650 Pipe Column DesignJoselito CalagosNo ratings yet

- MU Literature SLIDE GATEDocument15 pagesMU Literature SLIDE GATEJulio PCNo ratings yet

- Vessel Data Sheet Process Specification Sheet FormDocument1 pageVessel Data Sheet Process Specification Sheet FormunitedmanticoreNo ratings yet

- Datasheet For Hopper (D-3103)Document1 pageDatasheet For Hopper (D-3103)Joe GrosirNo ratings yet

- AS 1180 (PT 1 To 3 4A To 4B 6) - 1972 Methods of Test For Hose Made From Elastomeric Materials - First Group - MDocument31 pagesAS 1180 (PT 1 To 3 4A To 4B 6) - 1972 Methods of Test For Hose Made From Elastomeric Materials - First Group - MEye Sack ChumleyNo ratings yet

- Pipe Dimensions and Friction FactorDocument24 pagesPipe Dimensions and Friction FactorJuan Pablo ApazaNo ratings yet

- Shaft StabilityDocument2 pagesShaft StabilityPradeep SarodeNo ratings yet

- Flange Design Mmcobc 3.3 2010Document3 pagesFlange Design Mmcobc 3.3 2010bakellyNo ratings yet

- American SteelBook 2Document472 pagesAmerican SteelBook 2MiguelRagasNo ratings yet

- UNI EN 28734 A DIN EN 28734 A ISO 8734 A: Spine Cilindriche TemprateDocument1 pageUNI EN 28734 A DIN EN 28734 A ISO 8734 A: Spine Cilindriche Temprateg_casalinuovo19812344No ratings yet

- Thrust 2 eDocument6 pagesThrust 2 eWaheed AhmadNo ratings yet

- Tightening Torque Calculation For Screw V0001Document4 pagesTightening Torque Calculation For Screw V0001vijay10484No ratings yet

- 1500 Dia Pipe Dish End & Flat End (09.01.12)Document11 pages1500 Dia Pipe Dish End & Flat End (09.01.12)Kamal Kumar MallikarjunaNo ratings yet

- Gear Design CalcDocument2 pagesGear Design Calcomprakashd4196No ratings yet

- ASME/ANSI B16.5: (Inches) (Inches) (Inches) (Inches)Document19 pagesASME/ANSI B16.5: (Inches) (Inches) (Inches) (Inches)Harish PothepalliNo ratings yet

- Spline CalculationDocument2 pagesSpline CalculationPriyanka GsvNo ratings yet

- Capacities of UB SectionsDocument48 pagesCapacities of UB SectionsRohan KarandeNo ratings yet

- FEA Report Piping Saddle PDFDocument7 pagesFEA Report Piping Saddle PDFalprieto2003No ratings yet

- Deflection Calculation Due To Imposed Load On Corridor JoistDocument14 pagesDeflection Calculation Due To Imposed Load On Corridor JoistranjitNo ratings yet

- Spring Design: GD N PC yDocument2 pagesSpring Design: GD N PC yAshokNo ratings yet

- BS EN 12542 - 2010 LPG Equipment and Accessories. Static Welded Steel Cylindrical Tanks, Serially Produced For The Storage of Liqu - Libgen - LiDocument66 pagesBS EN 12542 - 2010 LPG Equipment and Accessories. Static Welded Steel Cylindrical Tanks, Serially Produced For The Storage of Liqu - Libgen - LiRinnoNo ratings yet

- Chap 01 SMDocument20 pagesChap 01 SMMohammed GhisheerNo ratings yet

- Power Correlation For Anchor and Helical Ribbon Impellers in Highly Viscous LiquidsDocument4 pagesPower Correlation For Anchor and Helical Ribbon Impellers in Highly Viscous LiquidsJulián Jair Cadena Sánchez100% (1)

- 080M40 (EN8) Specification Chemical CompositionDocument1 page080M40 (EN8) Specification Chemical CompositionAmar ThakurNo ratings yet

- PlateDocument3 pagesPlateAdnan RanaNo ratings yet

- Custody Transfer Metering Skid - Sea TransportationDocument518 pagesCustody Transfer Metering Skid - Sea Transportationswathi.nayudu2k3No ratings yet

- Lifting TestDocument6 pagesLifting TestHafizi HZnumismaticNo ratings yet

- Simplified Torsion Analysis For Steel Beams: Simple Span Beam With Eccentric Concentrated Load Applied at MidspanDocument4 pagesSimplified Torsion Analysis For Steel Beams: Simple Span Beam With Eccentric Concentrated Load Applied at MidspanIhab El AghouryNo ratings yet

- B Jack Nos For Cs Ss MaterialDocument12 pagesB Jack Nos For Cs Ss MaterialfahadfiazNo ratings yet

- Seismic Load Calculation of The Tank As Per IS 1893Document1 pageSeismic Load Calculation of The Tank As Per IS 1893ParthibanNo ratings yet

- AG - Base Plate With Moment & Axial CompressionDocument4 pagesAG - Base Plate With Moment & Axial CompressionPereira da SilvaNo ratings yet

- Standard Weld JointDocument3 pagesStandard Weld Jointtalparadipak100% (1)

- Deck Stabbing Guide Ring CheckDocument4 pagesDeck Stabbing Guide Ring CheckRamesh SelvarajNo ratings yet

- Deck Stabbing Guide Ring CheckDocument4 pagesDeck Stabbing Guide Ring CheckRamesh SelvarajNo ratings yet

- Deck Stabbing Guide Ring CheckDocument4 pagesDeck Stabbing Guide Ring CheckRamesh SelvarajNo ratings yet

- Numericals On Design of GearsDocument59 pagesNumericals On Design of GearsNAVEEN H V MENo ratings yet