Professional Documents

Culture Documents

Humastar 180 Service Manual

Humastar 180 Service Manual

Uploaded by

Zeljko TomicCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Humastar 180 Service Manual

Humastar 180 Service Manual

Uploaded by

Zeljko TomicCopyright:

Available Formats

HumaStar 180

| Service Manual

Cat No. 16900/200

REVISION LIST OF THE MANUAL

Rev. /DATE. 01/2004-07 02/2005-07 03/2010-11 04/2011-01 REVISION DESCRIPTION First edition Addition of Chapter 8 Adaption to new Corporate Design Addition of Chapter 5

SYSTEM VERSION

COPYRIGHT

Copyright 2010, Human GmbH, Wiesbaden, Germany. All rights reserved. No part of this documentation may be reproduced in any form, nor processed, copied or distributed by means of electronic systems, without prior permission of Human GmbH in writing. Since all precautionary measures were taken into account in producing these operating instructions, the manufacturer accepts no responsibility for any errors or omissions. This includes any liability for damage that could arise from possible incorrect operation based on this information. Subject to changes without notice as result of technical development.

SERVICE UND SUPPORT

CONTENTS

TABLE OF CONTENTS 1 SAFETY INSTRUCTIONS

1.1 INTRODUCTION 1.2 USER WARRANTY 1.3 INTENDED USE OF THE INSTRUMENT 1.4 GENERAL SAFETY WARNINGS 1.5 DISPOSAL MANAGEMENT CONCEPT 1.6 BIOHAZARD WARNING 1.7 INSTRUMENT DISINFECTION

5 5 5 5 6 6 7 7 11 11 11 12 13 13 14 17 20 23 23 23 25 25 25 25 25 31 31 31 31 32 32 32 32 32 32

2 SYSTEM INTRODUCTION

2.1 INTRODUCTION 2.2 CHARACTERISTICS 2.3 SPECIFICATIONS 2.4 FUNCTIONAL DESCRIPTION

2.4.1 2.4.2 2.4.3 2.4.4

Process Management Liquid Handling Carousels, Temperature Control and Cooling Measurement System

3 ELECTRONICS

3.1 INTRODUCTION 3.2 SCHEMATIC DIAGRAM OF ELECTRONICS

4 SERVICE SOFTWARE EULY SERVICE

4.1 INTRODUCTION 4.2 INSTALLATION OF EULY SERVICE 4.3 SERIAL SETTINGS 4.4 SCRIPT

4.4.1 Example for a reading through Euly Service Script

4.5 REAGENTROTOR 4.6 CUVETTEROTOR 4.7 BELT 4.8 PIPETTOR 4.9 EULYTEST 4.10 ENDURANCE TEST 4.11 DEVICE DATA 4.12 FW UPDATE 4.13 PHOTO

4.14 PUMPS-VALVES 4.15 INFO

32 32 33 33 33 33 33 34 34 34 35 35 35 35 37 37 37 39 39 40 42 44 45 47 48 49 49 49 54 59 64 67 71 72 74 76

5 MAINTENANCE

5.1 INTRODUCTION 5.2 SYRINGES 5.3 SYRINGE VALVES 5.4 TUBINGS 5.5 PHOTOMETER 5.6 X-DRIVE 5.7 Z-DRIVES 5.8 LIQUID DETECTION 5.9 MAGNETIC VALVES 5.10 PROBES 5.11 MEMBRANE PUMPS

6 TESTS/TROUBLESHOOTING

6.1 INTRODUCTION 6.2 FUNCTIONAL TESTS 6.3 TROUBLESHOOTING

6.3.1 6.3.2 6.3.3 6.3.4 6.3.5 6.3.6 6.3.7

Reagent Rotor Cuvette Rotor Belt Pipettor Liquid Detection Liquid Flood Communication

7 REPLACEMENT

7.1 INTRODUCTION 7.2 CAROUSEL UNIT WITH NEW REAGENTROTORSENSOR 7.3 CAROUSEL UNIT WITH OLD REAGENTROTORSENSOR (POTENTIOMETER) 7.4 CENTERING MAGNET 7.5 COVER 7.6 CUVETTE DRIVE MOTOR ASSEMBLY 7.7 CUVETTE ROTOR BOARD 7.8 MASTER BOARD 7.9 PHOTOMETER 7.10 PIPETTOR ARM

CONTENTS

7.11 PROBES 7.12 REAGENT ROTOR CONTROL BOARD 7.13 REAGENT ROTOR POTENTIOMETER 7.14 SYRINGE PUMPS 7.15 WASHING PUMPS

80 82 83 89 92 95 95 95

8 ADDITIONAL INFORMATIONS

8.1 INTRODUCTION 8.2 PIPETTOR ARM

SAFETY INSTRUCTIONS

1 SAFETY INSTRUCTIONS

1.1 Introduction

This manual is considered part of the instrument and must be available to the operator and the maintenance personnel. For accurate installation, use and maintenance, please read the following instructions carefully. In order to avoid damage to the instrument or personal injury, carefully read the GENERAL SAFETY WARNINGS, describing the appropriate operating procedures. Please contact your HUMAN authorised local Technical Service in the event of instrument failure or other difficulties with the instrument.

1.2 User Warranty

HUMAN warrants that instruments sold by one of its authorised representatives shall be free of any defect in material or workmanship, provided that this warranty shall apply only to defects which become apparent within one year from the date of delivery of the new instrument to the purchaser. The HUMAN representative shall replace or repair any defective item within this warranty period at no charge, except for transportation expenses to the point of repair. This warranty excludes the HUMAN representative from liability to replace any item considered as expendable in the course of normal usage, e.g.: lamps, valves, syringes, glassware, fuses, tubing etc. The HUMAN representative shall be relieved of any liability under this warranty if the product is not used in accordance with the manufacturers instructions, altered in any way not specified by HUMAN, not regularly maintained, used with equipment not approved by HUMAN or used for purposes for which it was not designed.

1.3 Intended Use of the Instrument

The instrument must be used for its intended purpose (see paragraph 2). It must be operated in perfect technical conditions, by qualified personnel, in such working conditions and maintained as described in this manual, in the GENERAL SAFETY WARNINGS. This manual contains instructions for qualified professional operators.

[IVD]

1.4 General Safety Warnings

Use only chemical reagents and accessories specified and supplied by HUMAN and/or mentioned in this manual. Place the product so that it has proper ventilation. The instrument should be installed on a flat, stationary working surface, that is free of vibrations. Do not operate in area with excessive dust. Operate at temperature and at a humidity level in accordance with the specifications listed in this manual. Do not operate this instrument with covers and panels removed. Use only the power cord specified for this product, with the grounding conductor of the power cord connected to earth ground. Use only the fuse type and rating specified by the manufacturer for this instrument. The use of fuses with improper ratings may pose electrical and fire hazards. To avoid fire or shock hazard, observe all ratings and markings on the instrument. Do not power the instrument in environments that are potentially explosive or at risk of fire. Prior to cleaning and/or performing maintenance on the instrument, switch off the instrument and remove the power cord. Only cleaning materials described in this manual may be used, as other materials may damage parts. It is recommended to always wear protective clothing and eye protection while using this instrument. All warning symbols that appear in this manual must be carefully observed.

1.5 Disposal Management Concept

The applicable local regulations governing disposal must be observed. It is the users responsibility to arrange for proper disposal of the individual components. All parts which may contain potentially infectious materials must be disinfected by suitable, validated procedures (autoclaving, chemical treatment) prior to disposal. Applicable local regulations for disposal must be carefully observed. The instruments and electronic accessories (without batteries, power packs etc.) must be disposed of according to the applicable local regulations for the disposal of electronic components.

HumaStar 180 | Service manual

SAFETY INSTRUCTIONS

Batteries, power packs and similar power sources must be removed from electric/electronic parts and disposed of in accordance with applicable local regulations.

1.6 Biohazard Warning

Analytical instruments for in vitro diagnostic application involve the handling of human samples and controls which should be considered at least potentially infectious. Therefore every part and accessory of the respective instrument which may have come into contact with such samples must equally be considered as potentially infectious. The BIOHAZARD warning label must be affixed to the instrument prior to first use with biological material!

FIGURE 1 Biological Hazard Symbol

1.7 Instrument Disinfection

Before performing any servicing on the instrument it is very important to thoroughly disinfect all possibly contaminated parts. Before the instrument is removed from the laboratory for disposal or servicing, it must be decontaminated. Decontamination must be performed by authorised welltrained personnel, and in observance of all necessary safety precautions.

HumaStar 180 | Service manual

SAFETY INSTRUCTIONS

Notes:

10

HumaStar 180 | Service manual

SYSTEM INTRODUCTION

11

2 SYSTEM INTRODUCTION

Characteristics, Specifications & Performance Functional Description

2.1 Introduction

HumaStar 180 is a fully automated, random access Clinical Chemistry Analyser for wet chemistry applications. It has an open structure, so that reagents from most manufacturers can be used on the system. HumaStar 180 is computer controlled and uses the Software Package DETect for data reduction and result evaluation. HumaStar 180 has been developed in a way as to maximise throughput at maximum comfort, and at the same time to minimise maintenance efforts to be taken by the user. HumaStar 180 is fitted with a patented, maintenance free measuring street, featuring 20 photometer channels for individual wavelength selection and maximum flexibility.

2.2 Characteristics

Access Modes: Processing Modes: Analysis Modes: Random Access Stat (immediate access and execution) Patient by Patient Test by Test Endpoint (Substrates) Kinetic (Enzymes) Initial Rate (fixed time kinetics) Serum Blank (differential) Turbidimetric (immunoturbidimetry) Multi Standard (quantitative) Bichromatic Multi Chemistry Intermethodes Calculation (mathematical)

12

2.3 Specifications

TABLE 1

Throughput: Carousel:

Liquid Handling:

Measurement System:

Temperature Control:

around 150 Tests/hr under speed optimised conditions 25 reagent positions (with SW update up too 50 positions) 25 sample positions (random access) 25 serum cup positions (minimum 300l volume) 300 test positions (75x4 cuvettes) Customized carousels available ! 2 independent Syringes: Sample: 1 - 200l in 1l steps Reagent: 1 - 900l in 1l steps CV less 2,0% for Volumes > 10l High pressure washing Autocleaning Backflush function Easy maintenance Maintenance Free ! Light sources: LED Detectors: Photodiodes Temperature controlled 5 inbuilt photometers, 4 channels each 20 independent channels up to 20 different wavelegths at a time Wavelength range: 340 900 nm Standard filters: 340, 405, 505, 546 & 620nm (4 each) Resolution: 0,0001 ABS Accuracy: <1% CV at 1ABS / 405nm Linearity: 0.0000 3.0000 OD better than +/- 1% Drift: less than 0.001 OD / hr Reagent cooling (ambient minus 10C) (water circulation w/ external cooler) Cuvette heating (electrical) in carousel and reading path: 37C Liquid heating (electrical) in probes

HumaStar 180 | Service manual

SYSTEM INTRODUCTION

13

Power Requirements:

Measures: Environmental: Options: Disposables:

Overvoltage Cat.: Pollution Degree: Method of Disposal: Usage:

II 2 - Contaminated Waste - Commercial

85-264V, 50/60 Hz (autodetecting) Power Consumption: max 150 VA Mains Fuse: 2 x 2A T (slow blow) Dimensions: 810 x 550 x 550 (w x d x h) Weight: 28kg Operation: 18 - 35C, 10 - 90% rel. Hum. Storage: -40C 70C, 5 95% rel. Hum. External ISE module f. electrolytes Handheld Barcode Reader f. pos. Sample ID Cuvette block for 4 tests each (typical reading volume 200l) Reagent bottles Serum Cups (1,5ml-minimum volume 300l)

2.4 Functional Description

The Clinical Chemistry Analyser HumaStar 180 comprises the following main functional units: Process Management Liquid Handling Carousels Temperature control Cooling (optional) Measurement System DETect Software package

The following explains the functions of all these units, as well as their interference within eachother.

2.4.1 PROCESS MANAGEMENT The working principal of HumaStar 180 is based on a modular system, which is controlled by a PC via the Process Manager (inbuilt in HumaStar 180).

14

Each module is fitted with its own intelligence and functions as a slave to the Process Manager. The process manager is connected to a PC via RS 232 and receives his orders from DETect Software package running on the PC. When a process is started on DETect (e.g.: testing a sample for certain paramters), DETect cuts the complete process into the required steps: Washing the probes Pipetting the reagent(s) Pipetting the sample Mixing Incubating Reading

These process steps are sent to the process manager in the instrument, one at a time, exactly whenappropriate. The process manager himself distributes the necessary commands to the modules. The modules fulfill the order and report back to the process manager, which himself provides DETect with the actual status accordingly.

2.4.2 LIQUID HANDLING The functional unit Liquid Handling consists of two independent Liquid paths, one for Sample pipetting and one for Reagent pipetting. All involved electrical components such as drive motors, valves and syringes are connected to and controlled by the central Process Manager.

FIGURE 2 Liquid Path

Z Movement Valve Positions: VP a X Movement

3 6 13 10 9 8

Waste

4 11 5 2

VP b

VP c

7 12 14

System Liquid 1

HumaStar 180 | Service manual

SYSTEM INTRODUCTION

15

Explanation: 1 2 3 4 5 System Liquid Bottle Membrane Pump Syringe 3-way Valve Syringe Pump & Syringe Syringe Pump Drive 6 7 8 9 10 Probe w. liquid detection Cuvette Reagent Container Primary Sample Tube Serum Cups 11 12 13 14 Wash Station Splitting Valve Waste Membrane Pump Waste Bottle

Both liquid paths are built up identical, with the only difference of the size of the syringes and the probes: Syringe: 1ml for Reagent path 250 l for Sample path Probe: 0.5 mm inner diameter for Reagent path 0.4 mm inner diameter for Sample path

X- and Z movement are realised by the pipetting arm, which holds the probes and the probes drives, together with all necessary motors, sensors and electronics. 2.4.2.1 Pipetting cycle The system is able to pippete reagents in either single- or multi pipetting mode. Multipipetting mode means that, a multiple of the required reagent volume per test of one reagent will be aspirated and then be distributed into the different target containers (cuvettes) accordingly. A complete pipetting cycle incorporates the following steps: Single Pipetting (Sample or Reagent) Wash probe - move probe in Z direction into wash station - flush with System liquid for a pre-defined time span - lift probe in Z direction to top position Pick up source liquid - move probe in X direction to source container (reagent container, sample tube or serum cup) - move probe in Z direction into source container until liquid is detected - aspirate the required test volume (driven by syringe pumps) - lift probe in Z direction to top position

16

REAGENT Pipetting: Pipette liquid into target container - move probe in X direction to target container (Cuvette) - move probe in Z direction into target container - pipet required test volume into target container - lift probe in Z direction to top position SAMPLE Pipetting: Pipette liquid into target container - move probe in X direction to target container (Cuvette) - move probe in Z direction into target container until liquid is detected - pipet required test volume into target container - mix by aspirating and re-pipetting - lift probe in Z direction to top position Move probe in X direction to home (Washstation) Multi Pipetting (Reagent only) Wash probe - move probe in Z direction into wash station - flush with System liquid for a pre-defined time span - lift probe in Z direction to top position Pick up source liquid - move probe in X direction to source container (reagent container) - Move probe in Z direction into source container until liquid is detected - aspirate a multiple of the required test volume (driven by syringe pumps) - lift probe in Z direction to top position Pipet liquid into target container - move probe in X direction to target container 1 (Cuvette) - move probe in Z direction into target container 1 - pipet required test volume into target container 1 - lift probe in Z direction to top position - move probe in X direction to target container 2 (Cuvette) - Move probe in Z direction into target container 2 - pipet required volume into target container 2 - lift probe in Z direction to top position - repeat for target containers 3 - n Move probe to home (Washstation)

HumaStar 180 | Service manual

SYSTEM INTRODUCTION

17

2.4.3 CAROUSELS, TEMPERATURE CONTROL AND COOLING HumaStar 180 is using two Carousels, the Inner and the Outer Carousel. Both carousels are directly connected to and controlled by the central Process Manager. - The INNER Carousel for carrying Samples, Reagents, Standards, Calibrators and Controls. The inner carousel can optionally be cooled. This option comprises an external cooling unit and cooled liquid is circulated underneath the inner carousel. - The OUTER Carousel for carrying the disposable Cuvettes. The outer carousel is temperature controlled to 37 C (standard).

FIGURE 3 Carousels, loaded, inside Instrument

Inner

Outer

Please refer to Chapter 2 for instructions on how to remove, load and replace the inner carousel.

2.4.3.1 Inner Carousel The inner carousel can easily be removed for loading. *2 Controls, marked as C1 and C2

1 2 3

10 Standards / Calibrators marked as S1, S2 ... S10 (if less or no Std/ Cal are used, these positions can be used for additional Samples) 13 free positions marked as 26, 27 ....... 48

FIGURE 4 Inner Carousel The Inner Carousel features: 1 25 Positions for Reagents, marked as 1, 2 ... 25 2 25 Positions for Primary Sample Tubes, marked as 1, 2 ... 25 3 25 Positions for Serum Cups for:*

18

FIGURE 5 Reagent bottle

Empty Bottles can be ordered from Human: Cat. number 16900/2

FIGURE 6 Serum cup

1.5 ml Serum Cups can be ordered from Human: Cat. number 16904

max 10,5 mm

2.4.3.2 Outer Carousel The outer carousel can not be removed for loading. Graph 1.17 just gives a better impression of what the outer carousel is like.

FIGURE 8 Cuvette Block

FIGURE 7 Outer Carousel

The Outer Carousel features 75 Positions for Cuvette Blocks

Each Cuvette Block contains 4 Cuvettes, for one test each. Total loading volume: Cuvettes for 300 Tests. These Cuvette Blocks are unique and can only be ordered from Human: Cat number 16900/1

2.4.3.3 Functions of the Carousels Temperature control of Outer Carousel The temperature control of the outer carousel is effected by thermo resistors, connected to an electronic regulating circuit. Together with temperature sensitive sensors connected to the same regulating circuit, a stable temperature is provided to the cuvettes throughout the whole test run.

HumaStar 180 | Service manual

SYSTEM INTRODUCTION

19

Cooling Option of Inner Carousel The cooling of the inner carousel is effected by cooled water circulating underneath the inner carousel, within a closed spiral copper tube. This copper tube is connected to an external cooling generator, the system is closed and independent from a tap water connection. Insulation In order to prevent temperature interferences between the (optionally) cooled inner and the temp. controlled outer carousel, an insulation ring is dividing the two carousels. Rotation Both Carousels are controlled and rotated independently, within a co-axial mechanical system. Besides keeping samples, reagents and test containers in stable temperature environment, actually the main function of the carousels is to provide the Y movement of the source and target containers within the pipetting and measuring system of HumaStar 180. The carousels are rotated while other processes within the complete system are being performed. By doing so, the time required for rotating and positioning the carousels is not a critical factor in terms of process time and throughput. The Inner Carousel is only to be rotated during pipetting steps, as described under 2.4.3. It is rotated in either clockwise or counter clockwise direction and provides the source containers required for a specific pipetting step to be positioned precisely underneath the probes. The Outer Carousel is to be rotated during pipetting steps as described under 2.4.3. Additionally, the outer carousel is to be rotated during measurement steps as described under 2.4.4 For pipetting, it is rotated in either clockwise or counter clockwise direction and provides the target containers required for a specific pipetting step to be positioned precisely underneath the probes. For measurement steps, it is rotated in either clockwise or counter clockwise direction and provides the target containers required for the measurement step to be positioned precisely at the entrance position of the Linear Photometer street.

20

2.4.4 MEASUREMENT SYSTEM HumaStar 180 is fitted with a unique Linear Photometer, featuring 20 independent measurement channels for fast and accurate reading of test results in the cuvettes. These 20 channels are organised in 5 groups of 4 channels each, whereas each group of 4 channels is controlled by two electronic boards: One light emitting board and one detection board. These are directly connected to the central Process Manager Each of the 5 light emitting boards is fitted with 4 light sources (LED, light emitting diodes) and the respective control electronics. Each of the 5 detection boards is fitted with 4 detectors (Silicon Diodes) and the respective signal converter electronics, as well as with a RS 232 port which connects it with the Process Manager.

FIGURE 9 Measurement system

Cuvettes in outer carousel

1 Cuvette block in Reading Position

Cuvette Transport Notch

Cuvette Transport Belt

Cuvette Transport Motor

Detection board Detector Interference Filter Optics (lens) Cuvette Block

Optics (lens) Light source "LED"

Light beam

Light emitting board

HumaStar 180 | Service manual

SYSTEM INTRODUCTION

21

For reading, the cuvette block is transported from the outer carousel through the linear photometer by a transport belt. Depending on the wavelength required for the measurement, the cuvette block will be positioned into the 4 light beams of the respective photometer block. The light emitted by the LEDs is directed through a focusing lens. This lens ensures a light beam, which is as parallel as required for having homogenous measurement conditions. While passing the cuvettes, respectively the liquid in the cuvettes, a part of the light energy is being absorbed by the liquid in the cuvette. The remaining light energy is now passing another lens and the respective interference filter and is then being measured by the detectors.

22

HumaStar 180 | Service manual

ELECTRONICS

23

3 ELECTRONICS

Schematic Diagrams

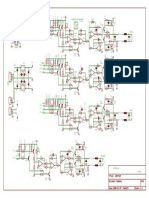

3.1 Introduction

This chapter gives information on the electrical and electronical components of the Human system.

FIGURE 10

3.2 Schematic Diagram of Electronics

24

FIGURE 11

HumaStar 180 | Service manual

SERVICE SOFTWARE EULY SERVICE

25

4 SERVICE SOFTWARE EULY SERVICE

4.1 Introduction

This chapter gives the instructions on how to test functionality of all independent modules of HumaStar 180 by using the Service Software EulyService.

4.2 Installation of Euly Service

EULY SERVICE REQUIRES EXCEL 2000 and will not work with older versions ! Copy the Service-Software-Folder to your local harddrive. Start Microsoft Excel . Open the file EulyService.xls. Activate macros (set the security-level accordingly). Microsoft Excel will display a new Menu point EulyService.

4.3 Serial Settings

Set the serial port by selecting the menucommand EulyService -> Serial Settings.

4.4 Script

A script consists of a string of commands, which are explained in this section of the Service manual.

26

The menucommand EulyService -> Script launches displays the following screen.

FIGURE 12 EuLy Service Script Screen

List of predefined saved scripts, if there is any

Contents of predefined saved scripts, if there is any

Result window of tests performed

In the list Scripts: a script can be selected. In the field Scripttext: the text of the selected script is shown. In the field Iterations: the number of iterations can be entered. By clicking Start the selected script is started. In the field Result: the results are shown. By clicking Stop the script is stopped. Script features a command set that allows service personnel to check and confirm functionality of modules of HumaStar 180. Every single module and its sub-functions can be checked independently.

When processing commands, Euly Service does not check for sensors ! It is the responsibility of the Service engineer to make sure, that only command strings are being entered, that can not damage mechanical parts.

Script requires command strings that determine the module, the subfunction and the actual command for the respective function. A command string consists of: - Module Code - Command - Parameter The Module codes, Commands and Parameters are explained on the following pages (all letters are case sensitive !)

HumaStar 180 | Service manual

SERVICE SOFTWARE EULY SERVICE

27

IMPORTANT NOTES: Before starting X-movement of the pipetting arm, both probes must be in top position ! Commands: Zi (initialises left Probe) and Zj (initialises right Probe) Before starting Cuvette Rotor movements, make sure the Belt drive is initialised! Command: Mi Photometer Belt Movements: positioning within the photometer is only possible after switching all LEDs on, and initialise Belt. Command: Xh (where X here stands for the photometer number 1 5) Command: Mi to initialise Belt

28

HumaStar 180 | Service manual

FIGURE 13

Module r g v s W w 1 2 3 4 5 6 7 d1 IR OR

These steps always require initialisation first !

Mod. Code 0r 0g 0v gives firmware version of module gives status of all sensors system "Rest" for xxxxx milliseconds MV off MV off MV off MV off MV ON MV ON MV ON MV ON Initialise Move Valve to Input position Move Valve to Output position Move Valve to Bypass position Move syringe to position xxxx (0-1000) Move syringe down for xxxx steps Move syringe up for xxxx steps start syringe prime cycle Initialise Move Valve to Input position Move Valve to Output position 0d2BR 0d2AxxxxR 0d2PxxxxR 0d2DxxxxR DxxxxR pR 0d2pR Move Valve to Bypass position Move syringe to position xxxx (0-1000) Move syringe down for xxxx steps Move syringe up for xxxx steps start syringe prime cycle WP off WP ON WP ON WP off WP ON WP ON AP off AP ON AP off AP ON AP off AP ON WP off AP ON WP off AP off (*)

(*)

Module Function performs a reset on all modules gives status of module

Command

Parameter

Command String:

Effect

Master

0 (zero)

Reset all modules

Get State

Get Version 0s xxxxx Wxxxxx 0w0 0w1 0w2 0w3 0w4 0w5 0w6 0w7 0d1ZR 0d1IR 0d1OR 0d1BR 0d1AxxxxR 0d1PxxxxR 0d1DxxxxR 0d1pR 0d2ZR 0d2IR 0d2OR 0 (zero)

Get Sensors

Wait

Washer Pumps

MV = Magnetic Valve WP = Wash Pump AP = Aspiration Pump

Sample Pipettor

ZR

BR AxxxxR PxxxxR DxxxxR pR

Reagent Pipettor IR OR

These steps always require initialisation first !

d2

ZR

BR AxxxxR PxxxxR

Module g v i x a,b (with comma !) move cuvette to a (0-6) from b (0-5) (*) Mxa,b Mi position belt in valid position Mv gives firmware version of module Mg gives status of module

Mod. Code

Module Function

Command Parameter Command String:

Effect

Photometer drive

Get State

Get Version

Initialise

Position

SERVICE SOFTWARE EULY SERVICE

Pipettor X drive g v i n g v i j m n l r g v p x g v p x a a Cxa Rg Rv Rp Rxa Cp Cv Cg xxxx Zrxxxx xxxx Zlxxxx a,b Zna,b (with comma !) a,b Zma,b (with comma !) Zj Zi Zv gives firmware version of module Initialises left probe to top position Initialises right probe to top position left probe to liquid, a steps into liquid, but max b steps (1mm = 10 steps) right probe to liquid, a steps into liquid, but max b steps (1mm = 10 steps) move left probe to pos. xxxx (0 - 1200) move rigth probe to pos. xxxx (0 - 1200) gives status of module gives firmware version of module gives position of Cuvette Rotor (1 - 75) moves Cuvette Rotor to pos a (1 - 75) gives status of module gives firmware version of module gives position of ReagTray (1 - 25) moves ReagTray to pos a (1 - 25) Zg gives status of module a Xna move arm to X-Position (0 - 10) (*) Xi Initialises X - drive to wash position Xv gives firmware version of module Xg gives status of module

Get State

Get Version

(*) 0 = Rotor 1 = Photometer 1 2 = Photometer 2 3 = Photometer 3 4 = Photometer 4 5 = Photometer 5 6 = Waste disposal Before cuvettes can be moved / positioned within the photometer, the LED's must be turned on: -> See following page

Initialise X-drive

This step requires initialisation first

X-position

Probe Z drive

Get State

Get Version

Initialise Left Probe

(*) 10 = 9= 8= 7= 6= 5= 4= 3= 2= 1= 0=

Initialise Right Probe

Left Probe to liquid

Spl probe at serum cup pos. Reag probe at Reag bttle Spl probe at prim. tube Reag probe at CuvPos 4 Reag probe at CuvPos 3 Reag probe at CuvPos 2 Reag probe at CuvPos 1 Spl probe at CuvPos 4 Spl probe at CuvPos 3 Spl probe at CuvPos 2 Spl probe at CuvPos 1 both probes at Washpos

These steps require initialisation of the respective module first

Right Probe to liquid

Z-position left Probe

Z-position right Probe

Cuvette rotor

Get State

Get Version

Get Position

Goto Position

Reagent Tray

Get State

Get Version

Get Position

FIGURE 14

Goto Position

29

30

FIGURE 15

HumaStar 180 | Service manual

Module Get State Get Version Wait Photometer Offset Dark Reading LED power on Read OD Get OD values LED power off d Xd a Xa m Xm h Xh c Xc o Xo W xxxxx wait for xxxxx millisec Offset Photometer X (1-5) Wxxxxx (NO module code !!) v Xv g Xg gives status of Photometer X (1-5)

Mod. Code

Module Function

Command

Parameter Command String:

Effect

Photometer 1 - 5

1-5

gives firmware ver. of Photometer X (1-5)

Read and store dark value of Photom X (1-5) turns on LED's of Photometer X (1-5) read OD in Photometer X (1-5) gives reading of all 4 channels of Photometer X (1-5) turns off LED's of Photometer X (1-5)

In this table, the module is determined by a number from 1 - 5, which stand for Photometer 1 to Photometer 5 The table shows an "X" for the respective photometer number

This command set allows to make readings "manually". In order to make a reading, the following steps must be perormed in exactly this order (for each photometer individually): 1. LED power off 2. Sleep for 500 milliseconds (this is required to ensure there is no more light emitted) 3. Photometer Offset 4. Dark Reading 5. Sleep for 300 ms (required to finish dark reading) 6. LED power on 7. Sleep for 60000 milliseconds (this is required to make sure the LED's are stable) 8. Read OD 9. Get OD values To repeat a reading, only steps 8 and 9 need to be repeated.

SERVICE SOFTWARE EULY SERVICE

31

4.4.1 EXAMPLE FOR A READING THROUGH EULY SERVICE SCRIPT The following commandset can be entered line after line, before starting the actual reading. When saving the commandset as a script, this commandset will be available for later tests as well:

FIGURE 16 Commandset for reading with Photometer 1.

After the command set has been entered and maybe stored as a script, select the Start, button and one command after the other will be sent to the instrument. During processing all steps, the feedback from the instrument will be displayed in the Result Window of Euly Service.

4.5 ReagentRotor

Menucommand for adjusting and testing the Reagent Rotor.

4.6 CuvetteRotor

Menucommand for adjusting and testing the Cuvette Rotor.

4.7 Belt

Menucommand for adjusting and testing the Belt.

32

4.8 Pipettor

Menucommand for adjusting and testing the Pipettor.

4.9 EulyTest

Menucommand for testing the liquid detection.

4.10 Endurance Test

Menucommand for testing the instrument.

4.11 Device Data

Menucommand for reading and saving the Device Data.

4.12 FW Update

Menucommand for updating the firmware.

4.13 Photo

Menucommand for testing the Photometer.

4.14 Pumps-Valves

Menucommand for testing the Pumps and Valves.

4.15 Info

Menucommand for displaying program information.

HumaStar 180 | Service manual

MAINTENANCE

33

5 MAINTENANCE

5.1 Introduction

This chapter gives information on maintenance procedures for the Eurolyser system. The required maintenance varies with usage of the Eurolyser system. Therefore the following recommendations are only general guidelines and should be adapted according to the needs.

5.2 Syringes

Reasons to change the part: - The Syringe Seal looks worn. - Leakage of the Syringe. - At least once a year. Remarks: You can either change the Syringe Seal or the complete Syringe. If you change only the Syringe Seal change the whole Syringe every forth time.

5.3 Syringe Valves

Reasons to change the part: - Leakage of the Syringe Valve. - Continued formation of drops on the corresponding probe.

5.4 Tubings

Reasons to change the part: - The Tubings look worn. - Leakage of the Tubings.

34

5.5 Photometer

Reasons for maintenance of the part: - The Photometer is dirty. - At least once every 6 months. Instructions: 1. Clean the wall of the photometer with a small amount of glass cleaner on a cotton wool stick. 2. Perform a Belt Adjust (either with the Service Software or with the Application Software).

5.6 X-Drive

Reasons for maintenance of the part: - The X-Positioning is not accurate (e.g. small (unwanted) movements on a certain position). - At least once every 6 months. Instructions: 1. Clean the spindle and the two axis (use only alcohol) with a cotton wool stick. 2. Lubricate spindle and axis with a small amount of the Special Lubricant (BE1072).

5.7 Z-Drives

Reasons for maintenance of the part: - The Z-Positioning is not accurate (e.g. small (unwanted) movements on a certain position). - At least once every 6 months. Instructions: 1. Clean the spindle (use only alcohol) with a cotton wool stick. 2. Lubricate spindle and axis with a small amount of the Special Lubricant (BE1072).

HumaStar 180 | Service manual

MAINTENANCE

35

5.8 Liquid Detection

Reasons for maintenance of the part: - The Liquid Detection is not accurate (e.g. sometimes aspiration of air due to a too high position). - At least once every 6 months. Instructions: 1. Clean the leads of the probe cables and use an electronic contact spray in order to have a low resistant contact. 2. Perform a Liquid Detection Adjust with the Service Software.

5.9 Magnetic Valves

Reasons to change the part: - Leakage of the Magnetic Valve. - Magnetic Valve does not open. - Preventive Maintenance. - At least every second year.

5.10 Probes

Reasons for maintenance of the part: - Probe is blocked. Instructions: 1. Use the Cleaning Set Reagent & Sample Probe.

5.11 Membrane Pumps

Reasons for maintenance of the part: - Leakage of Membrane Pump . - Bad performance of Membrane Pump. - Preventive Maintenance. Instructions: 1. Disassemble the pump header. 2. Replace the Membrane. 3. Clean the parts of the pump header. 4. Assemble the pump header.

36

HumaStar 180 | Service manual

TESTS/TROUBLESHOOTING

37

6 TESTS/TROUBLESHOOTING

6.1 Introduction

This chapter gives information on testing components of the Human system.

6.2 Functional Tests

General EulyService-Scripts for Testing: - AllState: Shows the State of all moduls. - AllVersion: Shows the firmware-version of all moduls. - Reset: Resets the instrument / stops all movements. Sensors: Start EulyService-Script SensorTest with 1000 iterations. Check the state of the doorsensor, cuevettesensor, button and liquidsensors. Reagentrotor: Insert empty tray on the reagentrotor. Select menucommand EulyService -> ReagentRotor and click Test Digital. Start EulyService-Script ReagRotorTest1. Start EulyService-Script ReagRotorTest2. Insert full tray on the reagentrotor. Start EulyService-Script ReagRotorTest1. Start EulyService-Script ReagRotorTest2. Cuevtterotor: Select menucommand EulyService -> CuevetteRotor and click Test Digital. Start EulyService-Script CuvRotorTest1. All positions are positioned in both directions. Select menucommand EulyService -> CuevetteRotor and click Test Sensor. Cuevettesensor is tested with and without cuevettes. Insert a cuvette on position 1 (marked with 2 dots) and remove all other cuvettes. Start EulyService-Script CuvRotorTest5.

38

Pipettor: Start EulyService-Script PipettorSensorTest with 1000 Iterations. Open and close the pipettor and check the results. Start EulyService-Script PipettorXTest. Positions the X-drive. Fill traypositions R2 and S2 with water (traypositions R1 and S1 have to be empty). Select menucommand EulyService -> EulyTest. Enable LiquidDetection. Click Start. Check results on sheet EulyTest. Dispenser: Start EulyService-Script DispenserTest. Initalizes the dispenser. Pumps and Valves: Select menucommand EulyService -> Pumps-Valves. Switch the pumps and valves on and off. Photometerstreet: Start EulyService-Script PhotoLEDsOn. Switches on the photometer-LEDs. Insert a cuvette on position 1 (marked with 2 dots). Start EulyService-Script BeltTest1. The cuevette is positioned to all photometer-modules. Endurance Test: Fill traypositions R2 and S2 with water. Empty all other sample-positions and R1. Insert a cuvette filled with water to position 1 (marked with 2 dots) of the cuvette rotor. Select menucommand EulyService -> EnduranceTest. Click Start. Check results on sheet EnduranceTest.

HumaStar 180 | Service manual

TESTS/TROUBLESHOOTING

39

6.3 Troubleshooting

6.3.1 REAGENT ROTOR Step Check 1 Is the green LED on? Result No No No No No Yes 2 Is the message displayed on Yes Result: Error occured processing 0g: Timeout...? No Is the message displayed on Yes Result: ... R: State: BUSY ...? Yes Is the message displayed on Yes Result: ... R: State: READY ...? Yes Is manual movement possible? No No Yes 5 Does the rotor move in clockwise No direction? No Yes Does the rotor move in No counter-clockwise direction? No Yes Does the rotor move in No counter-clockwise direction? No Yes Action Switch on the instrument. Control the mains cable. Control the mains voltage. Control the mains fuses. Control the master board fuses. Proceed with step 2. Start EulyService-Script AllState. Go to Communication Troubleshooting Table Proceed with step 3. Replace reagent-flat-cable. Replace reagent rotor control board. Proceed with step 4. Start EulyService-Script Reset. Try to move the rotor manually. Remove possible blocking. Replace carousel unit. Proceed with step 5. Start EulyService-Script ReagFastCW. Replace reagent rotor control board. Replace carousel unit. Start EulyService-Script ReagSlowCW. Replace reagent rotor control board. Replace carousel unit. Start EulyService-Script ReagSlowCCW. Replace reagent rotor control board. Replace carousel unit. Proceed with step 6.

TABLE 2 Switch off the power before changing any electronicmodule or connecting or disconnecting any cable. Wait 5 seconds after switching on the power before starting any command.

40

Step Check 6 Is the test ok? 7

Result

No Yes

Does the adjustment fail? 8 Does the adjustment fail? 9 Result: "R: State: READY RTimeout"

Yes No

Yes No Yes No

Action Select menucommand EulyService>ReagentRotor and click Test Digital. Replace carousel unit. Proceed with step 7. Select menucommand EulyService>ReagentRotor and click Adjust. (not required with new Reagentrotorsensor) Replace carousel unit. Proceed with step 8. Select menucommand EulyService>ReagentRotor and click Adjust Digital. Replace carousel unit. Proceed with step 9. Start EulyService-Script ReagRotorTest1. Replace carousel unit. If the error occurs from time to time replace carousel unit.

6.3.2 CUVETTE ROTOR

TABLE 3

Step Check 1 Is the green LED on?

Result No No No No No Yes

2 Is the message displayed on Result: Yes Error occured processing 0g: Timeout...? No

Action Switch on the instrument. Control the mains cable. Control the mains voltage. Control the mains fuses. Control the master board fuses. Proceed with step 2. Start EulyService-Script AllState. Goto Communication Troubleshooting Table Proceed with step 3.

HumaStar 180 | Service manual

TESTS/TROUBLESHOOTING

41

Step Check Result 3 Is the message displayed on Result: "... C: Yes State: BUSY ..."? Yes Is the message displayed on Yes Result: "... C: State: READY ..."? 4 Is manual movement possible? Yes Yes No No Is manual movement possible? No No Yes 5 Does the rotor move in clockwise direcNo tion? No No Yes Does the rotor move in clockwise direction? No No No Yes Does the rotor move in counter-clockwise direction? No No No Yes Does the rotor move in counter-clockwise direction? No No No

Action Replace cuvette-flat-cable. Replace cuvette rotor board. Proceed with step 4. Start EulyService-Script Reset. Try to move the rotor manually. Proceed with step 5. Remove possible blocking. Put the cuvette rotor motor 2 mm away from the rotor. Remove possible blocking. Replace carousel unit. Replace cuvette drive motor assembley. Start EulyService-Script CuvFastCW. Replace cuvette rotor board. Replace cuvette drive motor assembley. Replace carousel unit. Start EulyService-Script CuvSlowCW. Replace cuvette rotor board. Replace cuvette drive motor assembley. Replace carousel unit. Start EulyService-Script CuvFastCCW. Replace cuvette rotor board. Replace cuvette drive motor assembley. Replace carousel unit. Start EulyService-Script CuvSlowCCW. Replace cuvette rotor board. Replace cuvette drive motor assembley. Replace carousel unit.

42

Step Check 6

Is the test ok?

Result Action Yes Proceed with step 6. Select menucommand EulyService->CuvetteRotor and click Test Digital. No Replace cuvette rotor board. No Yes Replace carousel unit. Proceed with step 7. Select menucommand EulyService ->CuvetteRotor and click Adjust. Replace cuvette rotor board. Replace carousel unit. Proceed with step 8. Start EulyService-Script CuvRotorTest1. Replace carousel unit. If the error occurs from time to time replace carousel unit.

Does the adjustment fail?

Yes Yes No

8 Result: C: State: READY C-Timeout Yes No

6.3.3 BELT Step Check 1 Is the green LED on?

TABLE 4

Result Action No Switch on the instrument. No Control the mains cable. No Control the mains voltage. No Control the mains fuses. No Control the master board fuses. Yes Proceed with step 2. Start EulyService-Script AllState. Is the message displayed on Yes Goto Communication Result: Error occured processing 0g: TimeTroubleshooting Table out...? No Proceed with step 3. Is the message displayed on Yes Replace photometer-flat-cable. Result: ... M: State: BUSY ...?

HumaStar 180 | Service manual

TESTS/TROUBLESHOOTING

43

Yes Is the message displayed on Result: ... M: Yes State: READY ...? 4 Does the belt move in clockwise direction? No No Yes Does the belt move in clockwise direction? No No Yes Does the belt move in counter-clockwise direction? No No Yes Does the belt move in counter-clockwise direction? No No No 5

Replace photometer. Proceed with step 4. Start EulyService-Script BeltFastCW. Remove possible blocking. Replace photometer. Start EulyService-Script BeltSlowCW. Remove possible blocking. Replace photometer. Start EulyService-Script BeltFastCCW. Remove possible blocking. Replace photometer. Start EulyService-Script BeltSlowCCW. Remove possible blocking. Replace photometer. Proceed with step 5. Select menucommand EulyService->Belt and click Adjust and check results on sheets Belt1 and Belt2. Replace photometer. Proceed with step 6. Insert cuvette in outer carussel position 1. Start EulyServiceScript BeltTest1. Replace photometer. If the error occurs from time to time replace photometer.

Does the adjustment fail? 6

Yes No

Result: M: State: READY M-Timeout

Yes No

44

6.3.4 PIPETTOR Step 1

TABLE 5

Check Is the green LED on?

Result No No No No No Yes

2 Is the message displayed Yes on Result: "Error occured processing 0g: Timeout..."? No Is the message displayed Yes on Result: "... Z: State: BUSY X: State: BUSY ..."? Yes Is the message displayed Yes on Result: "... Z: State: BUSY X: State: READY ..."? Yes Is the message displayed Yes on Result: "... Z: State: READY X: State: BUSY ..."? Is the message displayed Yes on Result: "... Z: State: READY X: State: READY..."? Yes

Action Switch on the instrument. Control the mains cable. Control the mains voltage. Control the mains fuses. Control the master board fuses. Proceed with step 2. Start EulyService-Script AllState. Goto Communication Troubleshooting Table Proceed with step 3. Replace x-flat-cable.

Replace pipettor arm. Replace z-flat-cable.

Replace pipettor arm. Replace pipettor arm.

Proceed with step 4.

Is manual movement easily Yes possible? No No

Start EulyService-Script Reset. Try to move the needles manually. Proceed with step 5. Remove possible blocking. Clean the spindles (use only alcohol) with a cotton wool stick and lubricate the spindles with a small drop of thin oil. Replace pipettor arm.

No

HumaStar 180 | Service manual

TESTS/TROUBLESHOOTING

45

Step 5

Check

Result

Action Be sure to have the arm in the frontmost position. Start EulyService-Script PipettorTest1. Clean the spindles (use only alcohol) with a cotton wool stick and lubricate the spindles with a small drop of thin oil. Replace pipettor arm. Proceed with step 6. Try to move the z-carriage manually. Proceed with step 7. Remove possible blocking. Clean the spindle and the two axis (use only alcohol) with a cotton wool stick and lubricate spindle and axis with a small drop of thin oil. Replace pipettor arm. Start EulyService-Script PipettorTest2. Clean the spindle and the two axis (use only alcohol) with a cotton wool stick and lubricate spindle and axis with a small drop of thin oil. Replace pipettor arm. If the error occurs from time to time replace pipettor arm.

Is the message displayed on Result: "... Z: State: READY Zx-Timeout"?

Yes

6 Is manual movement possible?

Yes No Yes Yes No No

No 7 Is the message displayed on Result: "... Z: State: READY X-Timeout"? Yes

Yes No

6.3.5 LIQUID DETECTION Step Check 1 Is the green LED on? Result No No No No No Yes Action Switch on the instrument. Control the mains cable. Control the mains voltage. Control the mains fuses. Control the master board fuses. Proceed with step 2.

TABLE 6

46

Step Check Result 2 Is the message displayed on Yes Result: "Error occured processing 0g: Timeout..."? No 3 Is the message displayed on Yes Result: "... Z: State: BUSY X: State: BUSY ..."? Yes Is the message displayed on Yes Result: "... Z: State: BUSY X: State: READY ..."? Yes Is the message displayed on Yes Result: "... Z: State: READY ..."? 4

Action Start EulyService-Script AllState. Goto Communication Troubleshooting Table Proceed with step 3. Replace x-flat-cable.

Replace pipettor arm. Replace z-flat-cable.

Replace pipettor arm. Proceed with step 4. Make sure to have a low resistant contact of the probe-cables (clean the leads and use a electronic contact spray). Select menucommand EulyService ->Pipettor and click Adjust Liquidsensor.... Replace pipettor arm. Proceed with step 5. Start menucommand EulyService ->EulyTest. Select Liquid Detection. Click Start and check the results on sheet EulyTest. Replace pipettor arm. If the error occurs from time to time replace pipettor arm.

Is the adjustment successful? 6

No Yes

Are the results ok?

No Yes

HumaStar 180 | Service manual

TESTS/TROUBLESHOOTING

47

6.3.6 LIQUID FLOOD Step Check Result Action 1 Are there any traces of leakage No Proceed with step 2. obvious from outside? Syringe or valve leakage? Yes Replace the syringe with piston or the whole syringe pump. Did a wrong pipettor position Yes Goto Pipettor Arm Troubleshooting cause the liquid flood? Table. 2 Disassemble the cover. Are there any obvious leakages Yes Replace the particular tube or whole in the tubes? tubing system. Are there any obvious leakages Yes Replace the washing pumps. in the washing pumps? No Proceed with step 3. 3 Select menucommand EulyService>Pumps-Valves and test the pumps and valves. Any obvious leakage? Yes Replace the involved part(s) (tube or tube system, connector,...). Overflow at wash station after Yes Try to clean the tubes inside with a some time? longer wash cycle (some minutes) and cleaning solution. Yes Replace the whole tubing system. Yes Replace the washing pumps. No

TABLE 7

48

6.3.7 COMMUNICATION

TABLE 8

Step Check 1 Is the green LED on?

Result No No No No No Yes Yes

2 Is an error message displayed: ...Dll-Error: 5...?

Is the message displayed on Result: Error occured processing 0g: Timeout...?

No Yes

Action Switch on the instrument. Control the mains cable. Control the mains voltage. Control the mains fuses. Control the master board fuses. Proceed with step 2. Start EulyService-Script AllState. The serial port is opened by another application. Close all applications. Restart the computer and try again. Proceed with step 3. Control the serial or USB cable.

Yes Yes Yes

Control the serial port settings. Close all applications. Restart the computer and try again. Replace master board.

HumaStar 180 | Service manual

REPLACEMENT

49

7 REPLACEMENT

7.1 Introduction

This chapter gives information on replacing components of the Human system.

7.2 Carousel Unit with new Reagentrotorsensor

Disassembling the Carousel Unit 1. Disassemble the cover (see Disassembling the Cover). 2. Disconnect the tubing for cooling from the liquid connection block.

FIGURE 17

Tubing for cooling

Liquid connection

block

3. Disconnect the reagent-code-flat-cable from the reagent control board.

50

4. Disconnect the reagent-position-cable from the reagent control board

FIGURE 18

Reagent-code-flat-cable

Reagent-position-cable

5. Disconnect the cuvette-temperature-cable (white and brown) from the master board.

FIGURE 19

Cuvettetemperature-cable

6. Disassemble the cuvette rotor board (see Disassembling the Cuvette Rotor Board).

HumaStar 180 | Service manual

REPLACEMENT

51

7. Remove the 5 screws on the bottom of the instrument fixing the carousel unit.

FIGURE 20

Screws for carousel unit

8. Remove the carousel unit. Assembling the Carousel Unit 1. Assemble the carousel unit (tubing for cooling right, all cables back). 2. Fix the carousel unit with 5 screws. 3. Assemble the cuvette rotor board (see Assembling the Cuvette Rotor Board). 4. Connect the cuvette-temperature-cable (white and brown) to the master board. 5. Connect the reagent-position-flat-cable to the reagent control board. 6. Connect the tubing for cooling to the liquid connection block. 7. Adjust the carousel unit (see Adjusting the Carousel Unit). 8. Assemble the cover (see Assembling the Cover). Adjusting the Carousel Unit 1. Adjust the centering magnet (see Adjusting the Centering Magnet). 2. Select menucommand EulyService -> CuevetteRotor. 3. Click Adjust. 4. Disconnect the centering-magnet-cable. 5. Start EulyService-Script CuvRotorTest1.

52

6. Adjust the cuvette rotor board until the cuvette rotor position is aligned with the photometer.

FIGURE 21

Open screws for adjusting cuvette rotor position

Centering-magnetcable

7. Tighten the 2 screws. 8. Connect the centering-magnet-cable. 9. Execute functional test for cuvette rotor. 10. Make sure the Reagentrotor-FW-Version is 22 or higher (check with EulyService-Script AllVersion). If not update the firmware and start the EulyService-Script ReagRotor_V2x_EEPROM. 11. Select menucommand EulyService -> ReagentRotor. 12. Click Adjust Digital and follow the instructions. See picture for alignment (e.g. position 1).

HumaStar 180 | Service manual

REPLACEMENT

53

FIGURE 22

13. Execute functional test for reagent rotor.

54

7.3 Carousel Unit with old Reagentrotorsensor (Potentiometer)

Disassembling the Carousel Unit 1. Disassemble the cover (see Disassembling the Cover). 2. Disconnect the tubing for cooling from the liquid connection block.

FIGURE 23

Tubing for cooling

Liquid connection block

3. Disconnect the reagent-code-flat-cable from the reagent control board. 4. Disconnect the reagent-position-cable from the reagent control board.

FIGURE 24

Reagent-code-flat-cable

Reagent-position-

cable

HumaStar 180 | Service manual

REPLACEMENT

55

5. Disconnect the cuvette-temperature-cable (white and brown) from the master board. Cuvette-temperature-cable

FIGURE 25

6. Disassemble the cuvette rotor board (see Disassembling the Cuvette Rotor Board). 7. Remove the 5 screws on the bottom of the instrument fixing the carousel unit.

FIGURE 26

Screws for carousel

unit

56

8. Remove the carousel unit. Assembling the Carousel Unit 1. Assemble the carousel unit (tubing for cooling right, all cables back). 2. Fix the carousel unit with 5 screws. 3. Assemble the cuvette rotor board (see Assembling the Cuvette Rotor Board). 4. Connect the cuvette-temperature-cable (white and brown) to the master board. 5. Connect the reagent-position-cable to the reagent control board. 6. Connect the reagent-position-flat-cable to the reagent control board. 7. Connect the tubing for cooling to the liquid connection block. 8. Adjust the carousel unit (see Adjusting the Carousel Unit). 9. Assemble the cover (see Assembling the Cover). Adjusting the Carousel Unit 1. Adjust the centering magnet (see Adjusting the Centering Magnet). 2. Select menucommand EulyService -> CuevetteRotor. 3. Click Adjust.

FIGURE 27

Centering-magnetcable

4. Disconnect the centering-magnet-cable. 5. Start EulyService-Script CuvRotorTest1.

HumaStar 180 | Service manual

REPLACEMENT

57

6. Adjust the cuvette rotor board until the cuvette rotor position is aligned with the photometer.

FIGURE 28

Open screws for adjusting cuvette rotor position

7. Tighten the 2 screws. 8. Connect the centering-magnet-cable. 9. Execute functional test for cuvette rotor. 10. Make sure the Reagentrotor-FW-Version is 11 (check with EulyService-Script AllVersion). If not update the firmware (select the file R25_V11_Adr22. hex) and start the EulyService-Script ReagRotor_V11_EEPROM. 11. Start EulyService-Script ReagRotorPosition with 1000 Iterations.

58

12. Insert tray and align border between position 1 and 25 with photometer.

FIGURE 29

13. Remove tray. 14. Adjust the centerring until the position shown by EulyService-Script ReagRotorPosition is on the threshold between 1 and

FIGURE 30

HumaStar 180 | Service manual

REPLACEMENT

59

15. Tighten the screws. 16. Insert the tray and test position 1 and 25. 17. Select menucommand EulyService -> ReagentRotor. 18. Click Adjust Digital and follow the instructions. 19. Remove the tray. 20. Select menucommand EulyService -> ReagentRotor. 21. Click Adjust and follow the instructions. 22. Execute functional test for reagent rotor.

7.4 Centering Magnet

Adjusting the Centering Magnet 1. Adjust the distance between the carousel unit and the photometer to a minimum of 0.3mm. The distance can be varied by moving the carousel unit and/or by moving the photometer within the holes for the corresponding screws.

FIGURE 31

> 0.3mm

2. Adjust the height of the cuvette ring to 0.3mm above the photometer. To change the height open all 6 screws, rotate the spacing bolts 1/6-rotation each and tighten the screws. Repeat this until the height is as desired.

60

FIGURE 32

Top of cuvette ring

0.3mm

Top of photometer

HumaStar 180 | Service manual

REPLACEMENT

61

FIGURE 33

Open screws for adjusting the height of the cuvette ring

62

FIGURE 34

Spacing bolts for adjusting the height of the cuvette ring

HumaStar 180 | Service manual

REPLACEMENT

63

3. Adjust the height of the centering magnet to the centre of the fixing area on the cuvette rotor.

FIGURE 35

FIGURE 36

64

Adjust the position of the centering magnet so that the cuvette rotor position is aligned with the photometer.

FIGURE 37

Alignment

7.5 Cover

Disassembling the Cover 1. Disassemble the pipettor arm (see Disassembling the Pipettor Arm). 2. Disassemble the inlet tubing from the sample syringe pump. 3. Disassemble the inlet tubing from the reagent syringe pump. Inlet tubing sample syringe Inlet tubing reagent syringe

FIGURE 38

HumaStar 180 | Service manual

REPLACEMENT

65

4. Remove the 6 screws on the bottom of the instrument fixing the main cover.

FIGURE 39

Screws for main cover

5. Lift the main cover. 6. Disconnect the doorlock-cable (yellow-brown).

FIGURE 40

Doorlock-cable

7. Disconnect the syringe-pump-cable from the master board.

66

8. Disconnect the doorsensor-LED-key-flat-cable from the master board.

FIGURE 41

Syringe-pump-

cable

Doorsensor-LED-key-

flat-cable

9. Remove the inlet tubings from the main cover. 10. Remove the main cover. Assembling the Cover 1. Lead the inlet tubings through the main cover. 2. Connect the doorsensor-LED-key-flat-cable to the master board. 3. Connect the syringe-pump-cable to the master board. 4. Connect the doorlock-cable (yellow-brown). 5. Put the main cover on the instrument. 6. Fix the main cover with 6 screws. 7. Assemble the inlet tubing to the reagent syringe pump. 8. Assemble the inlet tubing to the sample syringe pump. 9. Assemble the pipettor arm (see Assembling the Pipettor Arm).

HumaStar 180 | Service manual

REPLACEMENT

67

7.6 Cuvette Drive Motor Assembly

Disassembling the Cuvette Drive Motor Assembly 1. Disassemble the cover (see Disassembling the Cover). 2. Disconnect the cuvette-motor-cable from the cuvette rotor board.

FIGURE 42

Cuvette-motorcable

68

3. Unscrew the slug.

FIGURE 43

Slug

HumaStar 180 | Service manual

REPLACEMENT

69

4. Disassemble the cuvette drive motor assembly (1 screw on the bottom of the instrument).

FIGURE 44

Screw for cuvette drive motor assembley

Assembling the Cuvette Drive Motor Assembly 1. Assemble the cuvette drive motor assembly.

70

2. Adjust the cuvette drive motor assembly to a pressure of 8N by rotating.

FIGURE 45

Pressure = 8N

3. Tighten the slug. 4. Connect the cuvette-motor-cable to the cuvette rotor board.

HumaStar 180 | Service manual

REPLACEMENT

71

7.7 Cuvette Rotor Board

Disassembling the Cuvette Rotor Board 1. Disassemble the cover (see Disassembling the Cover).

FIGURE 46

Cuvette-flat-cable

Screws for cuvette rotor board

Cuvette-motor-cable

Centering-magnetcable

Disconnect the cuvette- flat-cable from the cuvette rotor board. Disconnect the cuvette-motor-cable from the cuvette rotor board. Disconnect the centering-magnet-cable from the cuvette rotor board. Remove the cuvette rotor board (2 screws). Avoid scratching the bottom surface of the carousel unit. Assembling the Cuvette Rotor Board 1. Assemble the cuvette rotor board (2 screws). 2. Connect the centering-magnet-cable to the cuvette rotor board. 3. Connect the cuvette-motor-cable to the cuvette rotor board. 4. Connect the cuvette-flat-cable to the cuvette rotor board. 5. Adjust the cuvette rotor (see Adjusting the Carousel Unit). 6. Assemble the cover (see Assembling the Cover).

2. 3. 4. 5.

72

7.8 Master Board

Disassembling the Master Board 1. Disassemble the cover (see Disassembling the Cover).

FIGURE 47

24V-cable

Outer-temperaturecable

Washingpumps-cable

Doorlockvalves-cable

X-flat-cable X-15V-cable

Cuvette-temperature-cable

Photometer-temperature-cable

Z-24V-cable

Cuvettesensor-cable Photometerflat-cable

Reagent-flat-cable

Cuvette-flat-cable

2. Disconnect the 24V-cable from the master board. 3. Disconnect the cuvette-temperature-cable from the master board. 4. Disconnect the outer-temperature-cable from the master board. 5. Disconnect the photometer-temperature-cable from the master board. 6. Disconnect the washing-pumps-cable from the master board. 7. Disconnect the doorlock-valves-cable from the master board. 8. Disconnect the Z-24V-cable from the master board. 9. Disconnect the x-flat-cable from the master board. 10. Disconnect the X-15V-cable from the master board. 11. Disconnect the cuvette-sensor-cable from the master board. 12. Disconnect the photometer-flat-cable from the master board. 13. Disconnect the cuvette-flat-cable from the master board. 14. Disconnect the reagent-flat-cable from the master board.

HumaStar 180 | Service manual

REPLACEMENT

73

FIGURE 48

Screws for master board

15. Remove the master board (4 screws on the bottom of the instrument). Assembling the Master Board 1. Assemble the master board (4 screws on the bottom of the instrument). 2. Connect the reagent-flat-cable to the master board. 3. Connect the cuvette-flat-cable to the master board. 4. Connect the photometer-flat-cable to the master board. 5. Connect the cuvette-sensor-cable to the master board. 6. Connect the X-15V-cable to the master board. 7. Connect the x-flat-cable to the master board. 8. Connect the Z-24V-cable to the master board. 9. Connect the doorlock-valves-cable to the master board. 10. Connect the washing-pumps-cable to the master board. 11. Connect the photometer-temperature-cable to the master board. 12. Connect the outer-temperature-cable to the master board. 13. Connect the cuvette-temperature-cable to the master board. 14. Connect the 24V-cable to the master board. 15. Assemble the cover (see Assembling the Cover).

74

7.9 Photometer

Disassembling the Photometer 1. Disassemble the cover (see Disassembling the Cover).

FIGURE 49

Photometer-temperature-cable

Photometer-flat-cable

2. Disconnect the photometer-flat-cable from the master board. 3. Disconnect the photometer-temperature-cable (red and black) from the master board. 4. Remove the centering magnet.

HumaStar 180 | Service manual

REPLACEMENT

75

FIGURE 50

Screws for photometer

5. Remove the 8 screws on the bottom of the instrument fixing the photometer. 6. Remove the photometer. Assembling the Photometer 1. Assemble the photometer. 2. Fix the photometer with 8 screws. 3. Assemble the centering magnet. 4. Adjust the centering magnet (see Adjusting the Centering Magnet). 5. Connect the photometer-temperature-cable (red and black) to the master board. 6. Connect the photometer-flat-cable to the master board. 7. Assemble the cover (see Assembling the Cover). 8. Execute functional test for photometer.

76

7.10 Pipettor Arm

Disassembling the Pipettor Arm 1. Remove the top cover (5 screws below the top cover).

FIGURE 51

Screws for top cover

2. Disassemble the outlet tubing from the sample syringe pump. 3. Disassemble the outlet tubing from the reagent syringe pump.

FIGURE 52

Outlet tubing sample syringe

Outlet tubing reagent syringe

HumaStar 180 | Service manual

REPLACEMENT

77

4. Remove the safety ring.

Cable driller for

FIGURE 53

Z-24V-cable

Saftey ring

5. 6. 7. 8.

Disconnect the Z-24V-cable (red and black) from the Zdrive board. Open the cable driller fixing the Z-24V-cable behind the X-drive board. Disconnect the X-15V-cable (yellow and black) from the X-drive board. Disconnect the X-flat-cable from the X-drive board.

FIGURE 54

Z-24V-cable

X-flat-cable

X-15V-cable

9. Remove the pipettor arm.

78

Assembling the Pipettor Arm 1. Assemble the pipettor arm. 2. Connect the X-flat-cable to the X-drive board. 3. Connect the X-15V-cable (yellow and black) to the X-drive board. 4. Lead the Z-24V-cable behind the X-drive board to the Z-drive board and connect the Z-24V-cable (red and black) to the Zdrive board. 5. Fix the Z-24V-cable with a cable driller behind the X-drive board. 6. Assemble the safety ring. 7. Assemble the outlet tubing to the sample syringe pump. 8. Assemble the outlet tubing to the reagent syringe pump. 9. Assemble the top cover (5 screws). Adjusting the Pipettor Arm 1. Select menucomand EulyService -> Pipettor. 2. Press Adjust X (adjust the needles centred above the holes in the washingdevice).

FIGURE 55

Needles

Holes in washingdevice

HumaStar 180 | Service manual

REPLACEMENT

79

3. Press Adjust Z (adjust the needles just above the cuvette rotor).

FIGURE 56

Needles

Top of cuvette rotor

4. Execute functional test for the pipettor.

80

7.11 Probes

Disassembling the Probe 1. Remove the top cover (5 screws below the top cover).

FIGURE 57

Screws for top cover

2. Disconnect the Z-24V-cable (red and black) from the Zdrive board.

FIGURE 58

Reagent-probe-cable

Sample-probe-cable

3. Disconnect the probe-cable. 4. Open the screws fixing the probe and remove the probe.

HumaStar 180 | Service manual

REPLACEMENT

81

Assembling and Adjusting the Probe 1. Connect the probe-cable (shield is middle-connector). 2. Insert the probe into a water-bath with 39. 3. Switch on power-supply. 4. Select menucomand EulyService -> Pipettor. 5. Click Switch off Temperaturecontrol. 6. Connect the Z-24V-cable (red and black) to the Z-drive board. 7. Wait 2 minutes.

FIGURE 59

Shield (middle) Liquidsensor-sampleprobe-potentiometer Liquidsensor-reagentprobe-potentiometer Temperature-sampleprobe-potentiometer Temperature-reagentprobe-potentiometer

8. Click Adjust Temperature Sample/Reagent Probe. 9. Switch off power-supply. 10. Take the probe out of the water-bath and assemble on the Pipettor Arm. 11. Switch on power-supply. 12. Click Adjust Liquidsensor Sample/Reagent Probe. 13. Assemble the top cover (5 screws). 14. Select menucomand EulyService -> EulyTest. 15. Enable LiquidDetection. 16. Click Start. 17. Check results on sheet EulyTest.

82

7.12 Reagent Rotor Control Board

Disassembling the Reagent Rotor Control Board 1. Disassemble the cover (see Disassembling the Cover).

FIGURE 60

Reagent-flat-cable

Reagent-code-flatcable

Screws for reagent rotor control board

Reagent-positioncable (not present on all instruments) 2. Disconnect the reagent-flat-cable from the reagent rotor control board. 3. Disconnect the reagent-code-flat-cable from the reagent rotor control board. 4. Disconnect the reagent-position-cable from the reagent rotor control board (if present). 5. Remove the reagent rotor control board (4 screws). unit. Assembling the Reagent Rotor Control Board 1. Assemble the reagent rotor control board (4 screws). 2. Connect the reagent-position-cable to the reagent rotor control board (if present). 3. Connect the reagent-position-flat-cable to the reagent rotor control board. 4. Connect the reagent-flat-cable to the reagent rotor control board. 5. Adjust the reagent rotor (see Adjusting the Carousel Unit). 6. Assemble the cover (see Assembling the Cover).

HumaStar 180 | Service manual

REPLACEMENT

83

7.13 Reagent Rotor Potentiometer

Disassembling the Reagent Rotor Potentiometer 1. Remove the cover from the centerring.

FIGURE 61

2. Remove the 4 screws from the centerring.

84

FIGURE 62

Screws

Centerring

3. Disassemble the centerring.

FIGURE 63

Coupler

4. Disassemble the coupler.

HumaStar 180 | Service manual

REPLACEMENT

85

Reagent rotor potentiometer ring

FIGURE 64

Slug

5. Disassemble the reagent rotor potentiometer ring (fixed with a slug).

FIGURE 65

Reagent rotor potentiometer

86

6. Disassemble the reagent rotor potentiometer (by removing the silicon). Assembling the Reagent Rotor Potentiometer

New reagent rotor

FIGURE 66

potentiometer

Wires Old reagent rotor potentiometer

1. Disconnect the wires from the old reagent rotor potentiometer and connect to the new reagent rotor potentiometer one by one. 2. Assemble the reagent rotor potentiometer and fix it with silicon. 3. Assemble the reagent rotor potentiometer ring (as low as possible). 4. Assemble the coupler. 5. Assemble the centerring. Adjusting the Reagent Rotor 1. Start EulyService-Script ReagRotorPosition with 1000 Iterations. 2. Insert tray and align border between position 1 and 25 with photometer.

HumaStar 180 | Service manual

REPLACEMENT

87

FIGURE 67

3. Remove tray. 4. Adjust the centerring until the position shown by EulyService-Script ReagRotorPosition is on the threshold between 1 and 25.

FIGURE 68

5. 6. 7. 8.

Tighten the screws. Insert the tray and test position 1 and 25. Assemble the cover of the centerring. Select menucommand EulyService -> ReagentRotor.

88

9. Click Adjust Digital and follow the instructions. 10. Remove the tray. 11. Select menucommand EulyService -> ReagentRotor. 12. Click Adjust and follow the instructions. 13. Execute functional test for reagent rotor.

HumaStar 180 | Service manual

REPLACEMENT

89

7.14 Syringe Pumps

Disassembling the Syringe Pump

Tubings

FIGURE 69

Screws for syringe pumps

Sample syringe pump

Reagent syringe pump

1. Disassemble the tubings from the syringe pump. 2. Disassemble the syringe pump (2 screws each).

90

FIGURE 70

Syringe-pumpscable

3. Disconnect the syringe-pumps-cable from the syringe pump.

HumaStar 180 | Service manual

REPLACEMENT

91

Assembling the Syringe Pump Reagent syringe pump Sample syringe pump

FIGURE 71

Jumper

1. Install the jumpers on the syringe pump according the figure.Connect the syringe-pumps-cable to the syringe pump. 2. Assemble the syringe pump (2 screws). 3. Assemble the tubings to the syringe pump.

92

7.15 Washing Pumps

Disassembling the Washing Pumps 1. Disassemble the cover (see Disassembling the Cover). 2. Disconnect the washing-pumps-cable from the master board. Washing-pumpscable

FIGURE 72

3. Disconnect the tubings from the washing pumps.

FIGURE 73

Tubings

HumaStar 180 | Service manual

REPLACEMENT

93

4. Disassemble the washing pumps (4 screws on the bottom of the instrument).

FIGURE 74

Screws for washing pumps

Assembling the Washing Pumps 1. Assemble the washing pumps (4 screws). 2. Connect the tubings to the washing pumps. 3. Secure the tubings with cable drillers. 4. Connect the washing-pumps-cable to the master board. 5. Assemble the cover (see Assembling the Cover).

ADDITIONAL INFORMATIONS

95

8 ADDITIONAL INFORMATIONS

8.1 Introduction

This chapter gives additional information on the components of the Human system.

8.2 Pipettor Arm

1. Z-Motors: There are two types of Z-motors, which are from different manufacturers (escap and maxon) - Both motors have to be from the same manufacturer - After either changing the Z-drive-board or the Z-motors start one of the following EulyService-Script: Z_Enc16_EEPROM for motor from manufacturer escap Z_Enc32_EEPROM for motor from manufacturer maxon 2. X-Motor: There are two types of X-motors, which are from different manufacturers (escap and maxon) - After either changing the X-drive-board or the X-motor start one of the following EulyService-Script: X_Enc16_EEPROM for motor from manufacturer escap X_Enc32_EEPROM for motor from manufacturer maxon There are two types of sensor systems for the reagent rotor: - No hardware-change of the Reagent Rotor Control Board 1. Potentiometer and reflective sensors: - Firmware has to be V11 2. Magnet and hallsensors: - Firmware has to be V22 or higher

96

HumaStar 180 | Service manual

97

HUMAN Gesellschaft fr Biochemica und Diagnostica mbH Max-Planck-Ring 21 65205 Wiesbaden Germany Tel.: +49 6122/9988 0 Fax: +49 6122/9988 100 eMail: human@human.de www.human.de

You might also like

- Manual of M8000A Multi-Parameter Patient MonitorDocument193 pagesManual of M8000A Multi-Parameter Patient MonitorAhmed AboelelaNo ratings yet

- w2-d Operations ManualDocument95 pagesw2-d Operations ManualZeljko Tomic67% (3)

- BS-360E Operator's Manual V2.0 enDocument383 pagesBS-360E Operator's Manual V2.0 enSidharth WalavalkarNo ratings yet

- AR800 Service ManualDocument100 pagesAR800 Service ManualZeljko Tomic100% (1)

- 067D0068-01 01 B Lis 120 2120Document88 pages067D0068-01 01 B Lis 120 2120المسكينالمصريNo ratings yet

- BS-400 (v5 0)Document369 pagesBS-400 (v5 0)elias martinezNo ratings yet

- abxPENTRA60 User ManualDocument120 pagesabxPENTRA60 User ManualKader SmailiNo ratings yet

- Rotofix - Service ManualDocument34 pagesRotofix - Service ManualRoberto Guzman CalderonNo ratings yet

- Kubota 5100 ADocument25 pagesKubota 5100 AZeljko Tomic100% (1)

- Alcon Infiniti Ophthalmic Surgical Instrument - Service ManualDocument54 pagesAlcon Infiniti Ophthalmic Surgical Instrument - Service ManualZeljko Tomic100% (1)

- Humastar 80Document101 pagesHumastar 80Nelson Santos83% (6)

- Humalyte UserDocument188 pagesHumalyte UserAyaovi JorlauNo ratings yet

- V2C Service ManualDocument278 pagesV2C Service ManualCentro Medico Dr PlusNo ratings yet

- BC5500 Operation ManualDocument345 pagesBC5500 Operation ManualAyaovi Jorlau100% (1)

- Sm-E7219-1a (Ca-400) Tyb40Document529 pagesSm-E7219-1a (Ca-400) Tyb40spirisNo ratings yet

- 2010 - 01 - 2818 - 22 - 08BS-380 (390) Service Manual (v3.0)Document289 pages2010 - 01 - 2818 - 22 - 08BS-380 (390) Service Manual (v3.0)Fabián Medina67% (3)

- BM800 Service Manual Sec 13 V06Document7 pagesBM800 Service Manual Sec 13 V06Shark's SenNo ratings yet

- Olympus M521-M526-AU640 - Service Manual PDFDocument951 pagesOlympus M521-M526-AU640 - Service Manual PDFAleksanderNo ratings yet

- Mythic 22 Workbook-V3 PDFDocument139 pagesMythic 22 Workbook-V3 PDFthanh tamNo ratings yet

- 2.BS-200 Working Principle PDFDocument62 pages2.BS-200 Working Principle PDFBangkit TeguhmNo ratings yet

- H50&H50P Service Manual V7.0 enDocument262 pagesH50&H50P Service Manual V7.0 enSunand Nambiar100% (1)

- BS-400&420 - HL7 Interface Manua - V3.0 - ENDocument47 pagesBS-400&420 - HL7 Interface Manua - V3.0 - ENEmilioPerezBallesteros100% (1)

- Operation ManualDocument50 pagesOperation ManualAhmed TawfikNo ratings yet

- 3.8 HDSD NeoChem 100Document117 pages3.8 HDSD NeoChem 100huy Lê xuan Thanh100% (1)

- BS-300 Service Manual (v1.3)Document115 pagesBS-300 Service Manual (v1.3)Phan QuanNo ratings yet

- BS-800M Operation Manual V6.0 enDocument833 pagesBS-800M Operation Manual V6.0 enservicio Tecnico BIOTECNo ratings yet

- RIQAS Instrument and Reagent Supplier CodesDocument20 pagesRIQAS Instrument and Reagent Supplier CodesYasmin LeónNo ratings yet

- Service Manual: For Blood Glucose Analysers of The Eco-SeriesDocument31 pagesService Manual: For Blood Glucose Analysers of The Eco-SeriesАлександр БлаговNo ratings yet

- BC-2800 Operation Maunal (1.5) PDFDocument271 pagesBC-2800 Operation Maunal (1.5) PDFChris Valdez DrumsNo ratings yet

- B - Series User's ManualDocument15 pagesB - Series User's ManualNikolay PenevNo ratings yet

- BC-2800Vet Operator ManualDocument84 pagesBC-2800Vet Operator ManualHoai NamNo ratings yet

- 10-Maintenance of GeneXpertDocument18 pages10-Maintenance of GeneXpertJ Luis Moreno LopézNo ratings yet

- Ecl 2010 SMDocument685 pagesEcl 2010 SMXavier MuñozNo ratings yet

- Roche AVL9120,9130,9140,9180,9181 - Service Manual PDFDocument114 pagesRoche AVL9120,9130,9140,9180,9181 - Service Manual PDFJose Rolando Orellana Rodriguez0% (1)

- Abl90 Manual OperaçãoDocument59 pagesAbl90 Manual OperaçãoMarlos CarapetoNo ratings yet

- Mitsubishi p93dw Digi Monochrome PrinterDocument65 pagesMitsubishi p93dw Digi Monochrome PrinterTony KututoNo ratings yet

- BC-2100 Operation Manual (1.7)Document272 pagesBC-2100 Operation Manual (1.7)Sanjay KumarNo ratings yet

- CAL 8000 Operator Manual PDFDocument126 pagesCAL 8000 Operator Manual PDFYasushi KoezukaNo ratings yet

- Sysmex CA-50 Blood Coadulation Analyzer - User Manual PDFDocument195 pagesSysmex CA-50 Blood Coadulation Analyzer - User Manual PDFHirabteb Arshia Co. IVD ManufacturerNo ratings yet

- BS-120 Service Training (@2010-OTC)Document135 pagesBS-120 Service Training (@2010-OTC)Edwin Rozo100% (1)

- BC 5300vetDocument372 pagesBC 5300vetAnonymous GhWU5YK8100% (1)

- Host Interface Manual: BS-200/BS-220/BS-120/BS-130Document41 pagesHost Interface Manual: BS-200/BS-220/BS-120/BS-130Daniel CortesNo ratings yet

- MRX Software Version 7 Instructions For UseDocument326 pagesMRX Software Version 7 Instructions For UseGavin TexeirraNo ratings yet

- Twelve-Channel ECG: Blood Gas and Chemistry AnalyzerDocument2 pagesTwelve-Channel ECG: Blood Gas and Chemistry AnalyzerWilliam LukeNo ratings yet