Professional Documents

Culture Documents

Pumps

Pumps

Uploaded by

Eloi Magpantay HernandezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pumps

Pumps

Uploaded by

Eloi Magpantay HernandezCopyright:

Available Formats

Model 3498

Extra Large Capacity, Single Stage, Double Suction Pumps designed for a Wide Variety of Industrial, Municipal, and Marine Applications

Specifications

go to top

Capacities to 225,000 GPM (51,098 m3/h) Heads to 800 Ft. (244 m) Temperatures to 275 F (135 C) Working Pressures to 250 PSI (1724 kPa)

go to top

Design Features

Horizontally Split Casing In-line suction and discharge nozzles in lower half casing for ease of inspection/maintenance. Double Suction Impeller Assures Hydraulic Axial Balance for lower thrust bearing loads, longer pump life, and lower maintenence. Dual Volute Casing Assures Radial Balance for lower radial bearing loads, longer pump life and low maintenance. (Availability is size dependent.) Wear Rings Easily replaceable wear rings renew running clearances and protect against impeller, casing wear. Overall cost of operation is minimized. Sealing Flexibility Choice of packing or wide range of mechanical seals. Installation Versatility Horizontal or vertical mounting, clockwise or counterclockwise rotation. Material Flexibility Available in a wide variety of metals from cast iron to stainless steels.

go to top

Services

Process Quench water, stripper bottoms, reboiler circulation, cooling tower. Pulp & Paper Primary and secondary cleaner, filtrate, mill water supply, fan pump, headbox supply, shower. Primary Metals Cooling water, quench and leaching Municipal High lift, low lift, wash water, waste water, raw water. Power Generation Cooling tower, component cooling, service water, ash slucing, heater drain. Marine Bilge and ballast, cargo, cooling water, fire pump. General River water, brine, sea water.

30HK Indoor Water-Cooled Chillers 40 to 60 Nominal Tons 50/60 Hz

Carrier Corporation supplies superior water-cooled HVAC Chillers for commercial use including the 30HK Indoor Water-Cooled Chillers.

Features

Compact design (<36" wide) fits through standard door without disassembly Clamp on victaulic cooler connections; ASME stamped Shell and tube condenser; ASME stamped Serviceable semi-hermetic reciprocating compressors High efficiency suction cut-off unloading Dual independent refrigerant circuits (30HK sizes 040-060) UL, CSA listed, manufactured in ISO 9002 facility, ARI certified for performance ComfortLink control system with microprocessor based leaving chilled fluid temperature control High efficiency suction cutoff unloading Factory charge Oil pump and oil heater (each compressor) Compressor suction and discharge shut off valves High side pressure relief valve, sight glass, filter drier, TXV, liquid line shut valves

Options

Flow switch Scrolling Marquee Display Automatic lead/lag package Control power transformer Energy management option

Oil safety switch Pressure gage panel Sound reduction panels Part winding starter Data Port / Data Link Condenser with 90/10 cu/ni tubes and end tube sheets (special order)

You might also like

- St. Augustine Choir Booklet-1Document255 pagesSt. Augustine Choir Booklet-1Henry Kaweesa97% (58)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Financial Time Series Analysis and Prediction With Feature Engineering and Support Vector Machines - Newton - LinchenDocument5 pagesFinancial Time Series Analysis and Prediction With Feature Engineering and Support Vector Machines - Newton - LinchenNewton Linchen100% (1)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- A Smart Motor Controller For E-Bike Applications PDFDocument4 pagesA Smart Motor Controller For E-Bike Applications PDFaungwinnaing100% (1)

- f1 in School Project MGMTDocument13 pagesf1 in School Project MGMTFaizal AbdullahNo ratings yet

- Job Order CostingDocument49 pagesJob Order CostingKuroko71% (7)

- Equipment:: Figure 1: Vertical Turbine PumpDocument8 pagesEquipment:: Figure 1: Vertical Turbine PumphamizanNo ratings yet

- Double Flap Gate ValvesDocument16 pagesDouble Flap Gate ValvesMatias MancillaNo ratings yet

- Double Flap Gate ValvesDocument16 pagesDouble Flap Gate Valveskselvan_1No ratings yet

- Absorption Chillers 07Document52 pagesAbsorption Chillers 07Sujadi Cherbond100% (1)

- Skymark Vac8 25t Engineering Guide PDFDocument16 pagesSkymark Vac8 25t Engineering Guide PDFBraulio Ramón PeñaNo ratings yet

- AOS Cyclone Mxi BTH English CANCG10210 - 0920 - CompressedDocument6 pagesAOS Cyclone Mxi BTH English CANCG10210 - 0920 - CompressedMatteo TorresNo ratings yet

- Centrifugal Pumps: A World of Steady and Dependable Flow ControlDocument14 pagesCentrifugal Pumps: A World of Steady and Dependable Flow ControlYimmy Alexander Parra MarulandaNo ratings yet

- Cross FluteDocument6 pagesCross FluteAvicena AlbiruniNo ratings yet

- 3000 Brochure PDFDocument24 pages3000 Brochure PDFFarooque ShaikhNo ratings yet

- Ficha TecnicaDocument4 pagesFicha TecnicaRodrigo LeónNo ratings yet

- Hidrostal Submersible Immersible PDFDocument8 pagesHidrostal Submersible Immersible PDFariyamanjulaNo ratings yet

- Dunhm-Bush PRODUCT GUIDEDB Global Product GuideDocument19 pagesDunhm-Bush PRODUCT GUIDEDB Global Product GuideFalak KhanNo ratings yet

- MC HighPressureStageCasingPump E10026Document6 pagesMC HighPressureStageCasingPump E10026govindkaniNo ratings yet

- Heavy Duty Wastewater Pumps: Performance OverviewDocument1 pageHeavy Duty Wastewater Pumps: Performance OverviewbayuNo ratings yet

- McI Ecoplus TMDocument32 pagesMcI Ecoplus TMJunaid YNo ratings yet

- Aoscg10210series300 PDFDocument6 pagesAoscg10210series300 PDFAnonymous PCsoNCt0mFNo ratings yet

- Dectron DSV Series CatalogDocument4 pagesDectron DSV Series Catalogbluemojo0% (2)

- Valve Automation BrochureDocument8 pagesValve Automation Brochuredarkchess76No ratings yet

- A Flooded Screw ChillerDocument29 pagesA Flooded Screw ChillerDiêm Công Việt100% (3)

- Appendix 3 FinalDocument96 pagesAppendix 3 FinalMehedi IslamNo ratings yet

- Brosur Shakti WordDocument18 pagesBrosur Shakti Worddekyun49No ratings yet

- Mokveld-Product Sheet Angle ChokeDocument2 pagesMokveld-Product Sheet Angle Chokeyulianus_sr100% (1)

- DepVAPOR290409 PDFDocument8 pagesDepVAPOR290409 PDFltrevino100No ratings yet

- RTHDDocument32 pagesRTHDizmaya72660No ratings yet

- BB VerticalTrayDeaerator Jan11Document16 pagesBB VerticalTrayDeaerator Jan11GHEZELASHEGHINo ratings yet

- Prime Surface Plate CoilDocument12 pagesPrime Surface Plate CoilGrimmo1979No ratings yet

- Doosan Steam TurbinesDocument24 pagesDoosan Steam TurbinesUhrin Imre0% (1)

- AHLSTAR E Centerline Supported End Suction Single Stage Centrifugal PumpsDocument6 pagesAHLSTAR E Centerline Supported End Suction Single Stage Centrifugal PumpsAnonymous PsMDskNo ratings yet

- Tubine Bypass SystemDocument12 pagesTubine Bypass Systemkalyanm203515No ratings yet

- Hed and Hed-Ds: Between Bearings, Two-Stage, Radially Split PumpsDocument8 pagesHed and Hed-Ds: Between Bearings, Two-Stage, Radially Split PumpsdwiaguspriyonoNo ratings yet

- Dunham Bush Package UnitsDocument8 pagesDunham Bush Package UnitsStephanie StewartNo ratings yet

- Vacuum Pumps and Systems For Power IndustryDocument5 pagesVacuum Pumps and Systems For Power IndustryAnnas FauzyNo ratings yet

- BAC Brochure GeneralDocument12 pagesBAC Brochure GeneralTran Ngoc HaNo ratings yet

- CPC Pumps BrochureDocument8 pagesCPC Pumps BrochureRosa SparksNo ratings yet

- Catalogo Ir 675-825Document4 pagesCatalogo Ir 675-825dany riversNo ratings yet

- Model IC CatalogueDocument9 pagesModel IC Cataloguejfl2096No ratings yet

- SJM Vertical Mixed Flow PumpDocument6 pagesSJM Vertical Mixed Flow PumpSérgio GnipperNo ratings yet

- Chiller o Enfriador Parker Hiross Bulice-03-EnDocument4 pagesChiller o Enfriador Parker Hiross Bulice-03-EnDaniel MarNo ratings yet

- Bac TXV Stxvv00enDocument3 pagesBac TXV Stxvv00enjcrocafellaNo ratings yet

- Boletin Tecnico No. 3 Turbinas de Vapor ElliottDocument12 pagesBoletin Tecnico No. 3 Turbinas de Vapor Elliottcristobal_tl227750% (2)

- At Temper at orDocument8 pagesAt Temper at orrobin_samuel88No ratings yet

- Valve Automation Brochure USDocument8 pagesValve Automation Brochure USprufino2No ratings yet

- GulfSea Hydraulic HVI Plus Series PDFDocument2 pagesGulfSea Hydraulic HVI Plus Series PDFObydur RahmanNo ratings yet

- Cyclone Xi: Commercial Gas Water HeatersDocument5 pagesCyclone Xi: Commercial Gas Water HeatersjupocNo ratings yet

- Ledeen Actuator General Catalogue - Entire LineDocument24 pagesLedeen Actuator General Catalogue - Entire LineJair LamasNo ratings yet

- Pumps, Tanks, & AccessoriesDocument8 pagesPumps, Tanks, & Accessoriesسامح الجاسمNo ratings yet

- Ensuring Efficient Reliability For Marine Thermal Systems: Industry OverviewDocument24 pagesEnsuring Efficient Reliability For Marine Thermal Systems: Industry Overviewpetar petar100% (1)

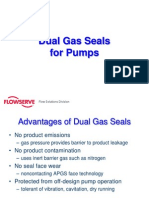

- Flowserve Pump Gas SealsDocument37 pagesFlowserve Pump Gas Sealsmujeebmehar50% (2)

- AwshcDocument9 pagesAwshcEduardo RivasNo ratings yet

- Kunkle OverviewDocument8 pagesKunkle Overviewsamix999No ratings yet

- CPC Pumps Corporate BrochureDocument8 pagesCPC Pumps Corporate BrochureArdiBarkahNo ratings yet

- Donaldson Indust Water Process ChillersDocument6 pagesDonaldson Indust Water Process ChillersJeEJyZaNo ratings yet

- GE Oil Nuovo PignoneDocument27 pagesGE Oil Nuovo PignoneRogelio Soria100% (1)

- Plan Api 23Document20 pagesPlan Api 23JAIMENo ratings yet

- 4030 / 4280 Series: End Suction PumpsDocument8 pages4030 / 4280 Series: End Suction PumpsShrikant WalseNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Supervisi Akademik Melalui Pendekatan Kolaboratif Oleh Kepala Sekolah Dalammeningkatkan Kualitas Pembelajarandisd Yari DwikurnaningsihDocument11 pagesSupervisi Akademik Melalui Pendekatan Kolaboratif Oleh Kepala Sekolah Dalammeningkatkan Kualitas Pembelajarandisd Yari DwikurnaningsihKhalid Ibnu SinaNo ratings yet

- MODBUS TCP/IP (0x/1x Range Adjustable) : HMI SettingDocument5 pagesMODBUS TCP/IP (0x/1x Range Adjustable) : HMI SettingÁnh VũNo ratings yet

- Understand Trading in 2 Hours SteveRyanDocument63 pagesUnderstand Trading in 2 Hours SteveRyanAkash Biswal100% (3)

- A&H Carrefour LayoutDocument1 pageA&H Carrefour LayoutAshraf EhabNo ratings yet

- ATS3445 Tutorial 1 2023Document16 pagesATS3445 Tutorial 1 2023april ngNo ratings yet

- MATHEMATICS WEEK3 2nd GRADE 4Document11 pagesMATHEMATICS WEEK3 2nd GRADE 4Jonah A. RecioNo ratings yet

- The Sabbath As FreedomDocument14 pagesThe Sabbath As Freedomapi-232715913No ratings yet

- Nanotechnology and Its ApplicationDocument28 pagesNanotechnology and Its ApplicationsorinamotocNo ratings yet

- Extracting DnaDocument6 pagesExtracting DnaIya AlabastroNo ratings yet

- Working With MongoDB - 518Document11 pagesWorking With MongoDB - 518Sivaraman AlagappanNo ratings yet

- Indonesian Sign Language Visualization Model (BISINDO) Website-Based Oral Health On Tooth Brushing Behavior in Deaf ChildrenDocument6 pagesIndonesian Sign Language Visualization Model (BISINDO) Website-Based Oral Health On Tooth Brushing Behavior in Deaf ChildrenInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- COOKERY 9 Q3.Mod1Document5 pagesCOOKERY 9 Q3.Mod1Jessel Mejia Onza100% (4)

- Brachy Quality GuideDocument270 pagesBrachy Quality GuideTejinder SinghNo ratings yet

- ATS Kingston Heath CustomerDocument63 pagesATS Kingston Heath CustomerDevNo ratings yet

- Welcome Back! B1 SVDocument4 pagesWelcome Back! B1 SVMagda StręciwilkNo ratings yet

- Fin542 Individual AssignmentDocument10 pagesFin542 Individual AssignmentAliff FarhanNo ratings yet

- XC9572 PDFDocument9 pagesXC9572 PDFAvs ElectronNo ratings yet

- BKKM 1931 Week 04Document105 pagesBKKM 1931 Week 04quirkycactusNo ratings yet

- Marked Fake Deck Tricks3Document7 pagesMarked Fake Deck Tricks3Tito Banerjee100% (1)

- Fxrate 06 06 2023Document2 pagesFxrate 06 06 2023ShohanNo ratings yet

- Av 10 Universal Remote Control ManualDocument13 pagesAv 10 Universal Remote Control Manualovidiu200970% (10)

- A Practical Grammar of The Sanskrit LanguageDocument408 pagesA Practical Grammar of The Sanskrit LanguageungulataNo ratings yet

- Statement of Principle Self-Care Including Self-Medication - The Professional Role of The PharmacistDocument5 pagesStatement of Principle Self-Care Including Self-Medication - The Professional Role of The PharmacistAprilia R. Permatasari0% (1)

- Vizsgaanyag PDFDocument30 pagesVizsgaanyag PDFSipka GergőNo ratings yet

- Tone and MoodDocument8 pagesTone and MoodKristine PanalNo ratings yet