Professional Documents

Culture Documents

Bayfield Mud Company

Bayfield Mud Company

Uploaded by

Mica VillaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bayfield Mud Company

Bayfield Mud Company

Uploaded by

Mica VillaCopyright:

Available Formats

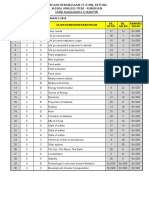

CASE: BAYFIELD MUD COMPANY In November 1994, John Wells, a customer service representative of Bayfield Mud Company, was

summoned to the Houston warehouse of wet land Drilling, Inc., to in spect three boxcars of mud-treating agents that Bayfield Mud Company had shipped to the Houston firm. (Bayfield s Corporate Offices and its largest plant are locate d in orange, Texas, which is just west of the Louisiana-Texas border.) Wet-land Drilling had filed a complaint that the 50 Pound bags of treating agents that it had just received from Bayfield were short-weight by approximately 5%. The light-weight bags were initially detected by one of Wet-Land s receiving clerks, who noticed that the rail road side scale tickets indicated that the net weight s were significantly less on all three of the boxcars than those of identical sh ipments received on October 25, 1994. Bayfield s traffic department was called to de termine if lighter-weight dunnage or pallets were used on the shipments. (This m ight explain the lighter weights.) Bayfield indicated, however, that no changes had been made in the loading or palletizing procedures. Hence, Wet-Land randomly checked 50 of the bags and discovered that the average net weight was 47.51 pou nds. They noted from past shipments that the bag net weights averaged exactly 50 .0 pounds, with an acceptable standard deviation of 1.2 pounds. Consequently, t hey concluded that the sample indicated a significance short-weight. (Students m ay wish to verify this conclusion.) Bayfield, was then contacted, and Wels was s ent to investigate the complaint and issued a 5% credit to Wet-Land. Wet-Land management, however, was not completely satisfied with only the issuanc e of credit for the short shipment. The charts followed by their mud engineers o n the drilling platforms were based on 50-pound bags of treating agents. Lighter -weight bags might result in poor chemical control during the drilling operation and might adversely affect drilling efficiency. (Mud-treating agents are used t o control the pH and other chemical properties of the open during drilling opera tions.) This could cause severe economic consequences because of the extremely h igh cost of oil and natural gas well-drilling operations. Consequently, special use instructions had to accompany the delivery of these shipments to the drillin g platforms. Moreover, the light-weight shipments had to be isolated in Wet-Land s w arehouse, causing extra handling and poor space utilization. Hence, Wells was in formed that Wet-Land Drilling might seek e new supplier of mud-treating agents i f, in the future, it received bags that deviated significantly from 50 pounds. The quality control department at Bayfield suspected that the light-weight bags may have resulted from growing pains at the orange plant. Because of the earlier energ y crises, oil and natural gas exploration activity had greatly increased. This i ncreased activity, in turn, created increased demand for products produced by re lated industries, including drilling muds. Consequently, Bayfield had to expand from one shift (6 A.M. to 2 P.M.) to a two-shift (2 P.M. to 10 P.M.) operation i n mid 1992, and finally to a three-shift operation (24 hours per day) in the fal l of 1994. The additional night shift bagging crew was staffed entirely by new employees. T he most experienced foremen were temporarily assigned to supervise the night shi ft employees. Most emphasis was placed on increasing the output of bags to meet the ever-increasing demand. It was suspected that only occasional reminders were made to double-check the bag weight feeder. (A double check is performed by sys tematically weighting a bag on a scale to determine if the proper weight is bein g loaded by the weight-feeder. If there is significant deviation from 50 pounds, corrective adjustments are made to the weight-release mechanism.) To verify this expectation, the quantity control staff randomly sampled the bag output and prepared the following chart. Six bags were sampled and weighted each hour. S.N0 Time Average Weight (Pounds) Range

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59

6 AM 49.6 7 50.2 8 50.6 9 50.8 10 49.9 11 50.3 12 Noon 48.6 1 PM 49 2 49 3 49.8 4 50.3 5 51.4 6 51.6 7 51.8 8 51.0 9 50.5 10 49.2 11 49.0 12 Mid Night 1 AM 47.6 2 47.4 3 48.2 4 48.0 5 48.4 6 48.6 7 50.0 8 49.8 9 50.3 10 50.2 11 50.0 12 Noon 50.0 1 PM 50.1 2 49.7 3 48.4 4 47.2 5 46.8 6 46.8 7 50.0 8 47.4 9 47.0 10 47.2 11 48.6 12 Midnight 1 AM 49.6 2 50.0 3 50.0 4 47.2 5 47.0 6 48.4 7 48.8 8 49.6 9 50.0 10 51.0 11 50.4 12 Noon 50.0 1PM 48.9 2 49.8 3 49.8 4 50.0

Smallest 48.7 50.7 49.1 51.2 49.6 51.4 50.2 51.8 49.2 52.3 48.6 51.7 46.2 50.4 46.4 50.0 46.0 50.6 48.2 50.8 49.2 52.7 50.0 55.3 49.2 54.7 50.0 55.6 48.6 53.2 49.4 52.4 46.1 50.7 46.3 50.8 48.4 45.4 44.3 49.7 44.1 49.6 45.2 49.0 45.5 49.1 47.1 49.6 47.4 52.0 49.2 52.2 49.0 52.4 49.4 51.7 49.6 51.8 49.0 52.3 48.8 52.4 49.4 53.6 48.6 51.0 47.2 51.7 45.3 50.9 44.1 49.0 41.0 51.2 46.2 51.7 44.0 48.7 44.2 48.9 46.6 50.2 47.0 50.0 49.8 48.2 48.4 51.7 49.0 52.2 49.2 50.0 46.3 50.5 44.1 49.7 45.0 49.0 44.8 49.7 48.0 51.8 48.1 52.7 48.1 55.2 49.5 54.1 48.7 50.9 47.6 51.2 48.4 51.0 48.8 50.8 49.1 50.6

Largest

50.2

50.4

60 61 62 63 64 65 66 67 68 69 70 71 72

5 47.8 6 46.4 7 46.4 8 47.2 9 48.4 10 49.2 11 48.4 12 Midnight 1 AM 47.4 2 48.8 3 49.6 4 51.0 5 50.5

45.2 44.0 44.4 46.6 47.2 48.1 47.0 47.2 46.8 47.2 49.0 50.5 50.0

51.2 49.7 50.0 48.9 49.5 50.7 50.8 46.4 49.0 51.4 50.6 51.5 51.9

49.2

Discussion Questions: 1. 2. What is your analysis of the bag weight problem? What procedures would you recommend to maintain proper quality control?

You might also like

- Case Study - Bayfield Mud Company - POMDocument16 pagesCase Study - Bayfield Mud Company - POMKarma Ac83% (6)

- An Introduction To Subsea ControlsDocument88 pagesAn Introduction To Subsea Controlsammp201180% (5)

- Time Study Format 147Document17 pagesTime Study Format 147Godwin Richmond100% (1)

- Container Handbook PDFDocument975 pagesContainer Handbook PDFBaher Saleh0% (1)

- Modern Groundwater Exploration: Discovering New Water Resources in Consolidated Rocks Using Innovative Hydrogeologic Concepts, Exploration, Drilling, Aquifer Testing and Management MethodsFrom EverandModern Groundwater Exploration: Discovering New Water Resources in Consolidated Rocks Using Innovative Hydrogeologic Concepts, Exploration, Drilling, Aquifer Testing and Management MethodsNo ratings yet

- Software Quality and Software Quality Assurance: (An Overview)Document21 pagesSoftware Quality and Software Quality Assurance: (An Overview)Muhammad Naeem0% (1)

- SnatchBot Chatbots Everything You Need To Know To Create Your OwnDocument110 pagesSnatchBot Chatbots Everything You Need To Know To Create Your OwnAmitGuptaNo ratings yet

- 31 Indicating Recording SystemsDocument4 pages31 Indicating Recording SystemsAhmed Abdoul ZaherNo ratings yet

- Bayfield Mud Company (Statistical Process Control)Document4 pagesBayfield Mud Company (Statistical Process Control)Jonathan Arias0% (1)

- Case Study BayfieldDocument3 pagesCase Study BayfieldSajal AroraNo ratings yet

- Case Study 1Document4 pagesCase Study 1María Fernanda Cortés GómezNo ratings yet

- BUS5910 U5 Case Study King Stapleton Bioethic Fish Processors LTDDocument4 pagesBUS5910 U5 Case Study King Stapleton Bioethic Fish Processors LTDAliNo ratings yet

- PIA Technical Standard TS-104 Parachute Industry Association PublicationsDocument4 pagesPIA Technical Standard TS-104 Parachute Industry Association PublicationsMike BNo ratings yet

- Excavation Man Hour: Post Author:info - Projectestimate Post Published:november 10, 2019 Post category:MAN-HOURDocument5 pagesExcavation Man Hour: Post Author:info - Projectestimate Post Published:november 10, 2019 Post category:MAN-HOURAl Patrick Dela CalzadaNo ratings yet

- SOP 75v4 Specific-Gravity FinalDocument22 pagesSOP 75v4 Specific-Gravity FinalAldwiNo ratings yet

- Ship Stability For Container ProfessionalsDocument129 pagesShip Stability For Container ProfessionalsGc Sekhar100% (1)

- Saturating Method Porosity Determination by LiquidDocument9 pagesSaturating Method Porosity Determination by Liquidali ahmedNo ratings yet

- 21 Soil-1, HW-2Document1 page21 Soil-1, HW-2Muhammad Usman ArshidNo ratings yet

- PIA Technical Standard 104: Parachute Industry Association PublicationsDocument15 pagesPIA Technical Standard 104: Parachute Industry Association PublicationsPetruAndrei TimofteNo ratings yet

- Foam Characterization Using Glass Coker Experimental Set UpDocument11 pagesFoam Characterization Using Glass Coker Experimental Set UpS Bharadwaj ReddyNo ratings yet

- Bureau of Mines Report of Investigations 5243Document19 pagesBureau of Mines Report of Investigations 5243Yoami PerdomoNo ratings yet

- 139 005 PDFDocument12 pages139 005 PDFEsteban TelloNo ratings yet

- Wayne, C. Et Al. Silicone Oil. A New Technique Preserving Waterlogged RopeDocument13 pagesWayne, C. Et Al. Silicone Oil. A New Technique Preserving Waterlogged RopeTrinidad Pasíes Arqueología-ConservaciónNo ratings yet

- Executive Summary:: Reservoir Engineering Lab SN 02 / Group F Experiment 1 27TH MARCH 2016Document14 pagesExecutive Summary:: Reservoir Engineering Lab SN 02 / Group F Experiment 1 27TH MARCH 2016MelindaNo ratings yet

- Northborough, CambridgeshireDocument40 pagesNorthborough, CambridgeshireWessex ArchaeologyNo ratings yet

- Laboratory Exercise No. 3: Determination of Water Content of A Soil SampleDocument12 pagesLaboratory Exercise No. 3: Determination of Water Content of A Soil SampleAngelieV.RemediosNo ratings yet

- Flowrate of Tank 6Document5 pagesFlowrate of Tank 6api-407838023No ratings yet

- Sandell1960 PDFDocument8 pagesSandell1960 PDFomempoderosoNo ratings yet

- MN 7 of 2020 - Lessons Learned From A Recent Fuel Oil Spill in PortDocument5 pagesMN 7 of 2020 - Lessons Learned From A Recent Fuel Oil Spill in PortDivan YonNo ratings yet

- STS-1 Orbiter Final Mission ReportDocument249 pagesSTS-1 Orbiter Final Mission ReportBob Andrepont100% (2)

- 2 Spe 96798 HPWBM - HodderDocument12 pages2 Spe 96798 HPWBM - HodderPT100% (1)

- Apparent and True Specific Gravity and Porosity of Lump CokeDocument3 pagesApparent and True Specific Gravity and Porosity of Lump CokeLuis Alberto Curtidor GuataquiNo ratings yet

- Perkara Ujian Tov Tahun 5 2010: NO. Tahun Jawapan Tajuk/Kemahiran/Kandungan Bil. Betul Bil. Salah Ranking SalahDocument2 pagesPerkara Ujian Tov Tahun 5 2010: NO. Tahun Jawapan Tajuk/Kemahiran/Kandungan Bil. Betul Bil. Salah Ranking SalahMenix MaigolNo ratings yet

- Gallo Winery Project Center ME - MQP C-Term 2006 Trip ReportDocument5 pagesGallo Winery Project Center ME - MQP C-Term 2006 Trip ReportOmar RuizNo ratings yet

- 15CN03211 Fisayo Assignment4 527 ReportDocument9 pages15CN03211 Fisayo Assignment4 527 ReportAkande AyodejiNo ratings yet

- Temp in Sea ContainersDocument8 pagesTemp in Sea ContainersrafaelhlttrindadeNo ratings yet

- Soil Mechanics Lab RecordDocument55 pagesSoil Mechanics Lab RecordshubhamNo ratings yet

- Flotation Release AnalysisDocument12 pagesFlotation Release AnalysiswitkerzNo ratings yet

- Aminpro-FK Test - EnglishDocument10 pagesAminpro-FK Test - EnglishpeilinlanNo ratings yet

- Wells Placer ExaminationDocument195 pagesWells Placer Examinationdaks4uNo ratings yet

- Clay Chemistry and Drilling FluidsDocument16 pagesClay Chemistry and Drilling FluidsDoni Aditya SaputraNo ratings yet

- The System - Calcium Oxalate - Sulphuric AcidDocument43 pagesThe System - Calcium Oxalate - Sulphuric AcidSebastian MoraNo ratings yet

- 01-014 Mannville Horizontal NGC Project (Final)Document42 pages01-014 Mannville Horizontal NGC Project (Final)hallibelstarkNo ratings yet

- Current Steamflood TechnologyDocument11 pagesCurrent Steamflood Technologyoreamig100% (1)

- Experiment-5 (Atterbergs Limits)Document25 pagesExperiment-5 (Atterbergs Limits)mathewosendNo ratings yet

- Atmos Pipeline Assessment by U.S. Army Corps of EngineersDocument110 pagesAtmos Pipeline Assessment by U.S. Army Corps of Engineerswfaachannel8No ratings yet

- 22 - Figueroa Floculante Cuajone 2009Document6 pages22 - Figueroa Floculante Cuajone 2009José RamosNo ratings yet

- Cover Page For Uche NwokoroDocument6 pagesCover Page For Uche NwokoroShammah ChidiNo ratings yet

- Flotation - Release AnalysisDocument35 pagesFlotation - Release AnalysiswitkerzNo ratings yet

- Rule Development For Container Stowage On Deck: March 2011Document9 pagesRule Development For Container Stowage On Deck: March 2011LiubovNo ratings yet

- Iron Ore Fines Aide-MemoireDocument8 pagesIron Ore Fines Aide-MemoireAsif SiddiquiNo ratings yet

- Synopsis of Midway PaperDocument6 pagesSynopsis of Midway Paperknowme73No ratings yet

- Boiler and Furnace Testing 1918Document20 pagesBoiler and Furnace Testing 1918ZerotheoryNo ratings yet

- SOP 54v7 Atterberg Limits FinalDocument20 pagesSOP 54v7 Atterberg Limits Finalcelsopatrick.srbcNo ratings yet

- Testing Ores For: State of IdahoDocument21 pagesTesting Ores For: State of IdahoRussell HartillNo ratings yet

- Arnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"Document5 pagesArnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"OSDocs2012No ratings yet

- Mazoe Floatation ProjectDocument14 pagesMazoe Floatation ProjectEDSON CHENJERAINo ratings yet

- CAFG Haslingfield Grey Report April 2014Document122 pagesCAFG Haslingfield Grey Report April 2014Peter WorledgeNo ratings yet

- Engineering Bulletin No 1: Boiler and Furnace TestingFrom EverandEngineering Bulletin No 1: Boiler and Furnace TestingRating: 4.5 out of 5 stars4.5/5 (2)

- Packaging Closures and Sealing SystemsFrom EverandPackaging Closures and Sealing SystemsNigel TheobaldNo ratings yet

- Christmas CollectionDocument19 pagesChristmas CollectionMica Villa100% (5)

- Cruz v. PHCDocument2 pagesCruz v. PHCMica Villa100% (2)

- LabStan (Art1-6)Document84 pagesLabStan (Art1-6)Mica VillaNo ratings yet

- 3L/Epublit of T6Fljbilippine9' Flllanila: G, Upreme (OurtDocument18 pages3L/Epublit of T6Fljbilippine9' Flllanila: G, Upreme (OurtMica VillaNo ratings yet

- Poea Rules and Regulations On Recruitment and EmploymentDocument39 pagesPoea Rules and Regulations On Recruitment and EmploymentkwinrayNo ratings yet

- CASES (Labor)Document65 pagesCASES (Labor)Mica VillaNo ratings yet

- Negotiable InstrumentDocument6 pagesNegotiable InstrumentMica VillaNo ratings yet

- Infringement of Intellectual Property Rights PDFDocument15 pagesInfringement of Intellectual Property Rights PDFMica VillaNo ratings yet

- ObliCon Samplex (De Chavez)Document1 pageObliCon Samplex (De Chavez)Mica VillaNo ratings yet

- Tolentino Vs Sec FinanceDocument2 pagesTolentino Vs Sec FinanceMica VillaNo ratings yet

- Animated PowerPoint TemplateDocument36 pagesAnimated PowerPoint TemplateGrace GraceNo ratings yet

- Liferay 6.x Portal Enterprise Intranets Cookbook - Sample ChapterDocument23 pagesLiferay 6.x Portal Enterprise Intranets Cookbook - Sample ChapterPackt PublishingNo ratings yet

- 1DV2 (1K1DV450E1) T115SEC Vega ForceDocument58 pages1DV2 (1K1DV450E1) T115SEC Vega ForceGAYLE GONo ratings yet

- Noise Reduction in Images Using AutoencodersDocument7 pagesNoise Reduction in Images Using AutoencodersIJRASETPublicationsNo ratings yet

- Bsnlspeedtest in Blog BSNL DNS Address HTMLDocument13 pagesBsnlspeedtest in Blog BSNL DNS Address HTMLArun KumarNo ratings yet

- Defining BiodiversityDocument2 pagesDefining BiodiversityJohn OsborneNo ratings yet

- M215HJJ-L30 Ips LCD PanelDocument37 pagesM215HJJ-L30 Ips LCD PanelNitin Pawar100% (1)

- TOP 40 COBOL Interview Questions PDFDocument24 pagesTOP 40 COBOL Interview Questions PDFNarayan Mahato0% (1)

- Cientifica WP3 PDFDocument11 pagesCientifica WP3 PDFRupesh KumarNo ratings yet

- Document Tabs For Application in DepEdDocument1 pageDocument Tabs For Application in DepEdLea Jane Ilagan Razona100% (3)

- Cable Tensionmeter-TN-001-T5 Operation and Service ManualDocument28 pagesCable Tensionmeter-TN-001-T5 Operation and Service ManualDade SobarnaNo ratings yet

- Connex Trafo Gis Pi enDocument7 pagesConnex Trafo Gis Pi enDaniel VilcapomaNo ratings yet

- Shiny PDFDocument2 pagesShiny PDFBhaktiNo ratings yet

- Calcul TermicDocument33 pagesCalcul TermicPitique De TarencriqueNo ratings yet

- Single Supply, Rail-to-Rail, Low Cost Instrumentation AmplifierDocument16 pagesSingle Supply, Rail-to-Rail, Low Cost Instrumentation Amplifierandrew.cookNo ratings yet

- Procedure Title: Land - PTW Procedure: Scope Objective Referenced Documents Associated FormsDocument36 pagesProcedure Title: Land - PTW Procedure: Scope Objective Referenced Documents Associated Formssenator100% (1)

- PM1 Flowline Shutdown - Startup FrquencyDocument6 pagesPM1 Flowline Shutdown - Startup FrquencyKELINASHNo ratings yet

- Rigid Inclusions: A Ground Improvement Technique: Delhi Technological UniversityDocument14 pagesRigid Inclusions: A Ground Improvement Technique: Delhi Technological UniversityANKITSINGH 2K20GTE04No ratings yet

- Donor Coach MTDC02Document1 pageDonor Coach MTDC02Huzaifa UjjainNo ratings yet

- Öhlins Motorcycle Shock Owner ManualDocument12 pagesÖhlins Motorcycle Shock Owner ManualPete PetrášNo ratings yet

- Hydraulic Proportional Servo TechnologiesDocument37 pagesHydraulic Proportional Servo Technologiescristi_amaNo ratings yet

- Septic TANK DesignDocument4 pagesSeptic TANK Designadnan88% (8)

- Magicolor7450 7450MKIIFieldServiceDocument371 pagesMagicolor7450 7450MKIIFieldServicebronsonbaddogNo ratings yet

- Describe The Construction of A Electromagnetic Velocity Sensor and Explain Its WorkingDocument8 pagesDescribe The Construction of A Electromagnetic Velocity Sensor and Explain Its WorkingJiten Thakur100% (1)

- Simple Bank AgreementDocument30 pagesSimple Bank AgreementNora RadovanNo ratings yet

- Aerodynamic Analysis and Optimization of Horizontal Axis Wind Turbine Blades by Using CFDDocument9 pagesAerodynamic Analysis and Optimization of Horizontal Axis Wind Turbine Blades by Using CFDESWARANM91No ratings yet

- HAWC2 Course: Lesson 3: Aerodynamic Modeling and Implementation in Hawc2Document52 pagesHAWC2 Course: Lesson 3: Aerodynamic Modeling and Implementation in Hawc2Mahmoud MoussaNo ratings yet