Professional Documents

Culture Documents

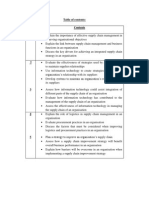

Measurement, Analysis & Improvement Management Responsibility

Measurement, Analysis & Improvement Management Responsibility

Uploaded by

Yasith WeerasingheCopyright:

Available Formats

You might also like

- Construction Vehicles to Crochet: A Dozen Chunky Trucks and Mechanical Marvels Straight from the Building SiteFrom EverandConstruction Vehicles to Crochet: A Dozen Chunky Trucks and Mechanical Marvels Straight from the Building SiteRating: 5 out of 5 stars5/5 (3)

- Ipscmi Sample Exam Paper Certified International Supply Chain Manager BLUE OCEAN Training & ConsultancyDocument5 pagesIpscmi Sample Exam Paper Certified International Supply Chain Manager BLUE OCEAN Training & ConsultancyYasith Weerasinghe100% (1)

- Material Recommendation PROTOS en 2011-03-31 PDFDocument20 pagesMaterial Recommendation PROTOS en 2011-03-31 PDFmetoui62No ratings yet

- Komatsu PW130-7K Hydraulic Excavator Service Repair Manual SN K40001 and Up PDFDocument29 pagesKomatsu PW130-7K Hydraulic Excavator Service Repair Manual SN K40001 and Up PDFfhjsjkmekmd100% (2)

- Polymer Pencil Mini PlantDocument4 pagesPolymer Pencil Mini Plantcareindia100% (1)

- Paper Mill READYDocument85 pagesPaper Mill READYagility dreamsNo ratings yet

- 002 Mar 1988Document24 pages002 Mar 1988Glodean100% (4)

- NTB05 015bDocument7 pagesNTB05 015bdthibodeNo ratings yet

- Roll CrusherDocument7 pagesRoll CrusherSudarshan Devarapalli100% (1)

- 1 ConfortDocument26 pages1 ConfortmscarreraNo ratings yet

- Identifying Standardized Data For Manufa PDFDocument8 pagesIdentifying Standardized Data For Manufa PDFZafr O'ConnellNo ratings yet

- Size ReductionDocument28 pagesSize ReductionveenaNo ratings yet

- Recycling and Filament Extruder For 3D PrinterDocument54 pagesRecycling and Filament Extruder For 3D PrinterRJ Munn50% (2)

- D.K. Process & Packaging MachineDocument26 pagesD.K. Process & Packaging MachinePankaj SharmaNo ratings yet

- Dyeing MachineDocument63 pagesDyeing Machineanowartex100% (2)

- Mahul Patta Processing Unit - SonhatDocument22 pagesMahul Patta Processing Unit - Sonhatharsh vardhanNo ratings yet

- Technical Performance 03Document14 pagesTechnical Performance 03sarath832No ratings yet

- 4 Seco ULCDocument60 pages4 Seco ULCmscarreraNo ratings yet

- Woven Sacks DPR Input - Odissa GoIDocument3 pagesWoven Sacks DPR Input - Odissa GoIUdhayakumar VenkataramanNo ratings yet

- Size ReductionDocument28 pagesSize Reductionchurvalooo100% (1)

- Singer Quantum Stylist 9960 Sewing Machine Service ManualDocument33 pagesSinger Quantum Stylist 9960 Sewing Machine Service ManualiliiexpugnansNo ratings yet

- Bag FilterDocument64 pagesBag FilterAtul Jain100% (1)

- Bag FilterDocument64 pagesBag FilterFahad Rocking100% (2)

- Mineral Water PlantDocument7 pagesMineral Water Plantsivavasireddy100% (2)

- Activity 7Document14 pagesActivity 7Angel Mae PalasNo ratings yet

- Manual 110823 120c Cartoning MachineDocument61 pagesManual 110823 120c Cartoning Machineandrea772100% (2)

- Questions Wings Ultra Thin MachineDocument1 pageQuestions Wings Ultra Thin MachinePayal PatidarNo ratings yet

- Manufacturing Process (Fabric Facemask)Document5 pagesManufacturing Process (Fabric Facemask)RAIHAANA MINONG NAMLANo ratings yet

- Overview of Dyeing and Printing ProcessDocument5 pagesOverview of Dyeing and Printing ProcessChahat ThakkarNo ratings yet

- 144-Article Text-736-1-10-20190930Document7 pages144-Article Text-736-1-10-20190930Fajar kurnia AkbarNo ratings yet

- Project ReportDocument8 pagesProject ReportSukhvinder SinghNo ratings yet

- Mineral Water ProjectDocument11 pagesMineral Water ProjectSrinivasareddy DantuNo ratings yet

- Modifikasi Sistem Transmisi Pada Mesin Pencacah Sampah - Limbah Plastik Dengan Sistem Crusher Dan Silinder Pemotong Tipe ReelDocument11 pagesModifikasi Sistem Transmisi Pada Mesin Pencacah Sampah - Limbah Plastik Dengan Sistem Crusher Dan Silinder Pemotong Tipe ReelmyunusanisNo ratings yet

- Spreading and Cutting MachinaryDocument21 pagesSpreading and Cutting Machinarypsyish100% (1)

- MR - Ranjeet Kumar Kurkure Process Line With PackingDocument12 pagesMR - Ranjeet Kumar Kurkure Process Line With PackingRanjeet BhaiNo ratings yet

- Operation Management of Particle Board PlantDocument18 pagesOperation Management of Particle Board PlantMainul AlamNo ratings yet

- Automatic Potato Chips Making MachineDocument9 pagesAutomatic Potato Chips Making MachineShyam AdhikaryNo ratings yet

- Qasir Spinning ReportDocument60 pagesQasir Spinning ReportRana AtiqueNo ratings yet

- 1 Production Line: PP AS-IS ReportDocument6 pages1 Production Line: PP AS-IS ReportDipak BanerjeeNo ratings yet

- Blow MoldingDocument30 pagesBlow MoldingHOANGVUNL1988100% (1)

- Chapter 3 ThesisDocument8 pagesChapter 3 ThesisJabber Reyes AmborNo ratings yet

- Word Toilet Roll Plan2Document15 pagesWord Toilet Roll Plan2ajayikayode100% (1)

- Textile TestingDocument10 pagesTextile TestingSha Md Ali RanaNo ratings yet

- Trutzschler BlowroomDocument56 pagesTrutzschler BlowroomSudipto Mandal88% (8)

- Eco Paper ProjectDocument13 pagesEco Paper ProjectBridget ArputharajNo ratings yet

- AMM - Chap 13 - Production and Operating Cost of Ag MachinesDocument28 pagesAMM - Chap 13 - Production and Operating Cost of Ag MachinesJohn CennaNo ratings yet

- Proposal For A Spinning Project For Cameroon-ScribdDocument10 pagesProposal For A Spinning Project For Cameroon-ScribdSiddique AhmedNo ratings yet

- Dl650 Op GuideDocument344 pagesDl650 Op GuideHtoo WaiNo ratings yet

- Terrot Single JerseyDocument6 pagesTerrot Single JerseyAli HabboushNo ratings yet

- Cashew ProcessDocument10 pagesCashew ProcessAratiNo ratings yet

- PROJECTREPORTTHATTIL (Autosaved)Document17 pagesPROJECTREPORTTHATTIL (Autosaved)Jeeson VincentNo ratings yet

- Segundo Conjunto de Ejercicios: 1 Punto 1Document2 pagesSegundo Conjunto de Ejercicios: 1 Punto 1Ana C SimancaNo ratings yet

- Hammer MillsDocument56 pagesHammer MillskokiskoNo ratings yet

- Jute Processing (201718)Document13 pagesJute Processing (201718)Joy ShahaNo ratings yet

- Manufacturing of Woven Jumbo Bag Flexible Intermediate Bulk ContainersDocument1 pageManufacturing of Woven Jumbo Bag Flexible Intermediate Bulk ContainersCalvawell MuzvondiwaNo ratings yet

- Filter Drum Cloth Replacement 40-2345Document6 pagesFilter Drum Cloth Replacement 40-2345Saadat BilalNo ratings yet

- Orient Paper MillsDocument17 pagesOrient Paper MillsEr Mohneesh0% (1)

- The Guide: NorgrenDocument16 pagesThe Guide: Norgrenem07150No ratings yet

- Metalworking for Home Machinists: 53 Practical Projects to Build YourselfFrom EverandMetalworking for Home Machinists: 53 Practical Projects to Build YourselfNo ratings yet

- Understanding Plastics Recycling: Economic, Ecological, and Technical Aspects of Plastic Waste HandlingFrom EverandUnderstanding Plastics Recycling: Economic, Ecological, and Technical Aspects of Plastic Waste HandlingNo ratings yet

- Cricut Maker 3 Guide for Beginners: A Step-by-Step Guide to Master, Configure, and Take Care of Your Cricut Maker 3 MachineFrom EverandCricut Maker 3 Guide for Beginners: A Step-by-Step Guide to Master, Configure, and Take Care of Your Cricut Maker 3 MachineNo ratings yet

- Internet of Things in Power Distribution Networks - State of The ArtDocument5 pagesInternet of Things in Power Distribution Networks - State of The ArtYasith Weerasinghe100% (1)

- INTRODUCTIONDocument1 pageINTRODUCTIONYasith WeerasingheNo ratings yet

- Strategic Supply Chain Management and Logistics-120626131827-Phpapp01Document15 pagesStrategic Supply Chain Management and Logistics-120626131827-Phpapp01awais04100% (1)

- Management System Based On The ISO 9001:2008 International Quality StandardsDocument48 pagesManagement System Based On The ISO 9001:2008 International Quality StandardsYasith WeerasingheNo ratings yet

- Literature ReviewDocument1 pageLiterature ReviewYasith WeerasingheNo ratings yet

- (60Sq) (30Sq) : Floor 1 35 FeetDocument2 pages(60Sq) (30Sq) : Floor 1 35 FeetYasith WeerasingheNo ratings yet

- PWC Reverse Logistics PDFDocument97 pagesPWC Reverse Logistics PDFYasith Weerasinghe100% (2)

- Part 03 - Eport-Factory Layout PlanDocument1 pagePart 03 - Eport-Factory Layout PlanYasith WeerasingheNo ratings yet

- DRDRDocument1 pageDRDRYasith WeerasingheNo ratings yet

- California Management Review, Vol 44, No 3 For Guidance On Demand and Supply Uncertainties 10 May 2014Document1 pageCalifornia Management Review, Vol 44, No 3 For Guidance On Demand and Supply Uncertainties 10 May 2014Yasith WeerasingheNo ratings yet

- S.No Name of The University State: Category "A"Document6 pagesS.No Name of The University State: Category "A"Yasith WeerasingheNo ratings yet

- Blockbuster Blu-Ray Zone Movie TitlesDocument55 pagesBlockbuster Blu-Ray Zone Movie TitlesYasith WeerasingheNo ratings yet

- Alcholism ResearchDocument68 pagesAlcholism ResearchYasith WeerasingheNo ratings yet

- A Dossier On The Brand Samsung Product: Samsung Mobile: Submitted To Prof Srinivas Govindrajan On 10-Aug-2013Document27 pagesA Dossier On The Brand Samsung Product: Samsung Mobile: Submitted To Prof Srinivas Govindrajan On 10-Aug-2013Yasith WeerasingheNo ratings yet

- The Significance of Improving Customer Reliability Through Customer Service A Study Based On Upcountry Manpower AgencyDocument10 pagesThe Significance of Improving Customer Reliability Through Customer Service A Study Based On Upcountry Manpower AgencyYasith WeerasingheNo ratings yet

- FixdadaDocument1 pageFixdadaYasith WeerasingheNo ratings yet

- BSC Ugc 120106Document6 pagesBSC Ugc 120106Yasith WeerasingheNo ratings yet

- The Impact of Resource Commitment On Reverse Logistics and Customer Loyalty A Study Based On Consumer Electronics Retail Industry in Sri LankaDocument2 pagesThe Impact of Resource Commitment On Reverse Logistics and Customer Loyalty A Study Based On Consumer Electronics Retail Industry in Sri LankaYasith WeerasingheNo ratings yet

- PDocument1 pagePYasith WeerasingheNo ratings yet

- Shortnotes GhgsourcingDocument11 pagesShortnotes GhgsourcingYasith WeerasingheNo ratings yet

- Spray Adhesives Brochure High ResDocument8 pagesSpray Adhesives Brochure High ResHauntingFire007No ratings yet

- List of Project ReportDocument36 pagesList of Project ReportKhalif Ahamed UsmanNo ratings yet

- Role of The Smear Layer in Adhesive Dentistry (Saikaew) (2022)Document8 pagesRole of The Smear Layer in Adhesive Dentistry (Saikaew) (2022)Angie Acosta RodriguezNo ratings yet

- Adhesion: Past, Present, and Future - Dental Asia - November/December 2019Document5 pagesAdhesion: Past, Present, and Future - Dental Asia - November/December 2019pooja100% (1)

- Tutorial How To Build A Toothpick BridgeDocument10 pagesTutorial How To Build A Toothpick Bridgeyonathan tsegayeNo ratings yet

- Principles of AdhesionDocument44 pagesPrinciples of AdhesionOmar Hesham SalahNo ratings yet

- Olimpic k800 Edge BanderDocument20 pagesOlimpic k800 Edge BanderBassem AlDoueiryNo ratings yet

- Technocracy Reloaded Preview Manuscript 4Document51 pagesTechnocracy Reloaded Preview Manuscript 4KiffNo ratings yet

- Applied FinishesDocument13 pagesApplied FinishesSanal SamsonNo ratings yet

- Folding Carton Manufacturing: Intelligent Solutions For State-Of-The-Art Production ProcessesDocument8 pagesFolding Carton Manufacturing: Intelligent Solutions For State-Of-The-Art Production Processesmanuel estradaNo ratings yet

- SLV General Introduction To Welding TechnologyDocument35 pagesSLV General Introduction To Welding TechnologyMohammad Sobhan RajabiNo ratings yet

- quizletBT ADocument13 pagesquizletBT ADarren VergaraNo ratings yet

- Squash Court Paint DatasheetDocument3 pagesSquash Court Paint DatasheetDaan BloemartsNo ratings yet

- DK2131 CH37Document7 pagesDK2131 CH37azzaassNo ratings yet

- Aba Ardex RebrandingDocument4 pagesAba Ardex RebrandingHarsa VardhanNo ratings yet

- Fao Fisheries Technical Paper 134rev1Document72 pagesFao Fisheries Technical Paper 134rev1Wagner AbreuNo ratings yet

- Pagel-Joint Seal 100: Polymeric Water Swellable Water Bar For JointsDocument2 pagesPagel-Joint Seal 100: Polymeric Water Swellable Water Bar For JointsZaid AhmedNo ratings yet

- Case StudyDocument10 pagesCase StudyTheAvilashNo ratings yet

- Duct Mate CatalogDocument64 pagesDuct Mate CatalogJM ArcillaNo ratings yet

- Concrete Terms and Industry TerminologyDocument12 pagesConcrete Terms and Industry TerminologyNguyen Dang Hanh100% (8)

- 3M DP125Document7 pages3M DP125echobravo1No ratings yet

- First Time Fabric Art - Step-By-Step Basics For Painting and Printing On FabricDocument85 pagesFirst Time Fabric Art - Step-By-Step Basics For Painting and Printing On FabricabcNo ratings yet

- JC 12 Clinical Efficacy of Methods For Bonding To ZirconiaDocument37 pagesJC 12 Clinical Efficacy of Methods For Bonding To ZirconiaMrinmayee ThakurNo ratings yet

- Butyl V Asphalt Tech Bulletin 051HJ - 11-12Document1 pageButyl V Asphalt Tech Bulletin 051HJ - 11-12Shajit KumarNo ratings yet

- CAB O SIL TS720pdfDocument2 pagesCAB O SIL TS720pdfsriatul2006No ratings yet

- TDS - Paper WS - Niklakett - Medium - PlusDocument1 pageTDS - Paper WS - Niklakett - Medium - PlusSundar MoorthiNo ratings yet

- Cahier Des Charges: Technical SpecificationsDocument15 pagesCahier Des Charges: Technical SpecificationsalbertoNo ratings yet

Measurement, Analysis & Improvement Management Responsibility

Measurement, Analysis & Improvement Management Responsibility

Uploaded by

Yasith WeerasingheOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Measurement, Analysis & Improvement Management Responsibility

Measurement, Analysis & Improvement Management Responsibility

Uploaded by

Yasith WeerasingheCopyright:

Available Formats

Measurement, Analysis & Improvement

Management Responsibility

Desired

Quality Quantity Time Cost Quality

Actual

Quantity Time Cost

Stimulus Initial wood cost. Electricity cost for cutting machine. Electricity cost for peeling machine. Electricity cost for chopping machine. Initial cost for solution. Electricity cost for blower machine. Warehouse cost. Number of logs insert differs from the size.(3-2) No difference between desired & actual.

Response Develop Measurement Equipment. --------------

Right size of logs. Cut logs into standard size.

2 logs at a time. -

2 Minutes

Initial wood cost. Electricity cost per cost driver unit. Electricity cost per cost driver unit. Electricity cost per cost driver unit. Initial cost for solution. Electricity cost per cost driver unit. Warehouse cost. (per ton) Feed Hopper Machine Cost. Electricity cost per cost driver unit. Electricity cost per cost driver unit. Printed sheets cost. (per unit)

Right size of logs.

3 logs at a time. -

2 Minutes

1 Minute

1 Minute

Standard peeling size.

100 veneers per log.

2 minutes

Standard peeling size.

85 veneers per log.

2 minutes

Shape of the logs is different from one another. Waste of veneer differs from cycle to cycle.

Change the current standard.

Standard sticks chop size. Soak every stick completely. Dry every single stick.

1000020000 chopped sticks. -

2 Minutes

Standard sticks chop size. Soak every stick. Dry all sticks.

2 Minutes

17000 approx chopped sticks. -

2 Minutes

Implementing a 5s programme.

2 Minutes

No difference between desired & actual. No difference between desired & actual.

--------------

2 Minutes

2 Minutes

--------------

Store according to the safety standards. Right quality feed hopper machine. Soak in 3 solutions according to the standards. Dry every single stick.

Not exceeding 2 tons per cycle. Right amount of sticks per a cycle. -

2 Minutes

1 Minute

Store according to the safety standards. Quality feed hopper machine.

1.8 tons per cycle.

2 Minutes

Obsolete stock area consumes a space.

Start Continues Eliminate procedure.

2 Minutes

5 Minutes

Soak in 3 solutions according to the standards. Dry all sticks.

Right amount of sticks per a cycle. -

1 Minute

Feed Hopper Machine Cost.

No difference between desired & actual.

---------------

2 Minutes

Electricity cost of conveyer belt. Electricity cost for blower machine. Printed sheets cost.

No difference between desired & actual.

---------------

5 Minutes

No difference between desired & actual.

----------------

Right quality printed paper.

1000 sheets per cycle.

1 Minute

Right quality printed paper.

890 approx sheets per cycle.

1 Minute

Damaged papers inside 10,000 pack bundles.

Change the suppliers of printed paper.

Standard creasing dimensions. Cut into right sizes.

1 Minute

Electricity cost per cost driver unit. Electricity cost per cost driver unit. -

Standard creasing dimensions. Cut into right sizes.

1 Minute

1 Minute

1 Minute

Fold using creased lines. Glue only the relevant areas. Pressurize to the standards.

250 pieces per cycle. -

2 Minutes

Fold using creased lines. Glue only the relevant areas.

250 pieces per cycle. -

2 Minutes

Electricity cost for creasing machine. Electricity cost for cutting machine. -

No difference between desired & actual.

----------------

No difference between desired & actual.

----------------

No difference between desired & actual. No difference between desired & actual. No difference between desired & actual.

----------------

2 Minutes

Initial adhesive glue cost. Electricity cost per cost driver unit. Electricity cost per cost driver unit. Electricity cost per cost driver unit.

2 Minutes

Initial adhesive glue cost. Electricity cost for pressure machine. Electricity cost for filling machine. Electricity cost for packing Machine.

-----------------

2 Minutes

Pressurize to the standards.

2 Minutes

----------------

Fill sticks using standards. Pack boxes to the standards.

45 sticks per box.

1 Minute

12 boxes per 1 Minute pack.

Fill sticks using standards. Pack boxes to the standards.

45 sticks per 1 Minute box. 12 boxes per pack. 1 Minute

No difference between desired & actual. No difference between desired & actual.

---------------

----------------

Shortened Logs

Shortened logs are peeled in a peeling machine.

Peeled Logs

Peeled logs are runs through a chopper machine.

Chopped Sticks

Chopped sticks are soaked into a solution of ammonium phosphate.

Soaked Sticks

Stripped logs are shortened using a cutting machine.

Feeded sticks are dipping into a series of three tanks using a conveyer belt.

Feeded Sticks

Dried stored sticks are feeding into a feed hopper machine.

Dried Stored Sticks

Half dried sticks and Completely dried sticks are stored in a storing area.

Half Dried Sticks

Soaked sticks are dried using a blowing machine.

Stripped Logs

Dipped Sticks

Completly Dried Sticks

Insert logs into the debarking machine.

Dipped sticks are drying through another blower machine.

Completed Sticks

Completed sticks are filled into the Completed boxes with the help of a filling machine.

Filled Match Boxes

Filled match boxes are packed using a packing machine.

Packed Match Boxes

Insert printed sheets to a creasing machine.

Completed Boxes

Glued boxes are pressurized with a pressure machine.

Glued Boxes

Folded pieces are glued in a gluing machine.

Creased Printed Sheets

Creased printed sheets are passing through a punching machine.

Punched Printed Sheets

Punched printed sheets are cut with a cutting machine.

Cut Pieces

Cut pieces are flap folded using a folding machine.

Folded Pieces

Shortened Logs

Shortened logs are peeled in a peeling machine.

Peeled Logs

Peeled logs are runs through a chopper machine.

Chopped Sticks

Chopped sticks are soaked into a solution of ammonium phosphate.

Soaked Sticks

Stripped logs are shortened using a cutting machine.

Dipped Sticks

Feeded sticks are dipping into a series of three tanks using a conveyer belt.

Feeded Sticks

Dried sticks are feeding into a feed hopper machine.

Dried Sticks

Soaked sticks are dried using a blowing machine.

Stripped Logs

Dipped sticks are drying through another blower machine.

Completed Sticks

Insert logs into the debarking machine.

Completed sticks are filled into the Completed boxes with the help of a filling machine.

Filled Match Boxes

Filled match boxes are packed using a packing machine.

Packed Match Boxes

Insert printed sheets to a creasing machine.

Completed Boxes

Glued boxes are pressurized with a pressure machine.

Glued Boxes

Folded pieces are glued in a gluing machine.

Creased Printed Sheets

Creased printed sheets are passing through a punching machine.

Punched Printed Sheets

Punched printed sheets are cut with a cutting machine.

Cut Pieces

Cut pieces are flap folded using a folding machine.

Folded Pieces

You might also like

- Construction Vehicles to Crochet: A Dozen Chunky Trucks and Mechanical Marvels Straight from the Building SiteFrom EverandConstruction Vehicles to Crochet: A Dozen Chunky Trucks and Mechanical Marvels Straight from the Building SiteRating: 5 out of 5 stars5/5 (3)

- Ipscmi Sample Exam Paper Certified International Supply Chain Manager BLUE OCEAN Training & ConsultancyDocument5 pagesIpscmi Sample Exam Paper Certified International Supply Chain Manager BLUE OCEAN Training & ConsultancyYasith Weerasinghe100% (1)

- Material Recommendation PROTOS en 2011-03-31 PDFDocument20 pagesMaterial Recommendation PROTOS en 2011-03-31 PDFmetoui62No ratings yet

- Komatsu PW130-7K Hydraulic Excavator Service Repair Manual SN K40001 and Up PDFDocument29 pagesKomatsu PW130-7K Hydraulic Excavator Service Repair Manual SN K40001 and Up PDFfhjsjkmekmd100% (2)

- Polymer Pencil Mini PlantDocument4 pagesPolymer Pencil Mini Plantcareindia100% (1)

- Paper Mill READYDocument85 pagesPaper Mill READYagility dreamsNo ratings yet

- 002 Mar 1988Document24 pages002 Mar 1988Glodean100% (4)

- NTB05 015bDocument7 pagesNTB05 015bdthibodeNo ratings yet

- Roll CrusherDocument7 pagesRoll CrusherSudarshan Devarapalli100% (1)

- 1 ConfortDocument26 pages1 ConfortmscarreraNo ratings yet

- Identifying Standardized Data For Manufa PDFDocument8 pagesIdentifying Standardized Data For Manufa PDFZafr O'ConnellNo ratings yet

- Size ReductionDocument28 pagesSize ReductionveenaNo ratings yet

- Recycling and Filament Extruder For 3D PrinterDocument54 pagesRecycling and Filament Extruder For 3D PrinterRJ Munn50% (2)

- D.K. Process & Packaging MachineDocument26 pagesD.K. Process & Packaging MachinePankaj SharmaNo ratings yet

- Dyeing MachineDocument63 pagesDyeing Machineanowartex100% (2)

- Mahul Patta Processing Unit - SonhatDocument22 pagesMahul Patta Processing Unit - Sonhatharsh vardhanNo ratings yet

- Technical Performance 03Document14 pagesTechnical Performance 03sarath832No ratings yet

- 4 Seco ULCDocument60 pages4 Seco ULCmscarreraNo ratings yet

- Woven Sacks DPR Input - Odissa GoIDocument3 pagesWoven Sacks DPR Input - Odissa GoIUdhayakumar VenkataramanNo ratings yet

- Size ReductionDocument28 pagesSize Reductionchurvalooo100% (1)

- Singer Quantum Stylist 9960 Sewing Machine Service ManualDocument33 pagesSinger Quantum Stylist 9960 Sewing Machine Service ManualiliiexpugnansNo ratings yet

- Bag FilterDocument64 pagesBag FilterAtul Jain100% (1)

- Bag FilterDocument64 pagesBag FilterFahad Rocking100% (2)

- Mineral Water PlantDocument7 pagesMineral Water Plantsivavasireddy100% (2)

- Activity 7Document14 pagesActivity 7Angel Mae PalasNo ratings yet

- Manual 110823 120c Cartoning MachineDocument61 pagesManual 110823 120c Cartoning Machineandrea772100% (2)

- Questions Wings Ultra Thin MachineDocument1 pageQuestions Wings Ultra Thin MachinePayal PatidarNo ratings yet

- Manufacturing Process (Fabric Facemask)Document5 pagesManufacturing Process (Fabric Facemask)RAIHAANA MINONG NAMLANo ratings yet

- Overview of Dyeing and Printing ProcessDocument5 pagesOverview of Dyeing and Printing ProcessChahat ThakkarNo ratings yet

- 144-Article Text-736-1-10-20190930Document7 pages144-Article Text-736-1-10-20190930Fajar kurnia AkbarNo ratings yet

- Project ReportDocument8 pagesProject ReportSukhvinder SinghNo ratings yet

- Mineral Water ProjectDocument11 pagesMineral Water ProjectSrinivasareddy DantuNo ratings yet

- Modifikasi Sistem Transmisi Pada Mesin Pencacah Sampah - Limbah Plastik Dengan Sistem Crusher Dan Silinder Pemotong Tipe ReelDocument11 pagesModifikasi Sistem Transmisi Pada Mesin Pencacah Sampah - Limbah Plastik Dengan Sistem Crusher Dan Silinder Pemotong Tipe ReelmyunusanisNo ratings yet

- Spreading and Cutting MachinaryDocument21 pagesSpreading and Cutting Machinarypsyish100% (1)

- MR - Ranjeet Kumar Kurkure Process Line With PackingDocument12 pagesMR - Ranjeet Kumar Kurkure Process Line With PackingRanjeet BhaiNo ratings yet

- Operation Management of Particle Board PlantDocument18 pagesOperation Management of Particle Board PlantMainul AlamNo ratings yet

- Automatic Potato Chips Making MachineDocument9 pagesAutomatic Potato Chips Making MachineShyam AdhikaryNo ratings yet

- Qasir Spinning ReportDocument60 pagesQasir Spinning ReportRana AtiqueNo ratings yet

- 1 Production Line: PP AS-IS ReportDocument6 pages1 Production Line: PP AS-IS ReportDipak BanerjeeNo ratings yet

- Blow MoldingDocument30 pagesBlow MoldingHOANGVUNL1988100% (1)

- Chapter 3 ThesisDocument8 pagesChapter 3 ThesisJabber Reyes AmborNo ratings yet

- Word Toilet Roll Plan2Document15 pagesWord Toilet Roll Plan2ajayikayode100% (1)

- Textile TestingDocument10 pagesTextile TestingSha Md Ali RanaNo ratings yet

- Trutzschler BlowroomDocument56 pagesTrutzschler BlowroomSudipto Mandal88% (8)

- Eco Paper ProjectDocument13 pagesEco Paper ProjectBridget ArputharajNo ratings yet

- AMM - Chap 13 - Production and Operating Cost of Ag MachinesDocument28 pagesAMM - Chap 13 - Production and Operating Cost of Ag MachinesJohn CennaNo ratings yet

- Proposal For A Spinning Project For Cameroon-ScribdDocument10 pagesProposal For A Spinning Project For Cameroon-ScribdSiddique AhmedNo ratings yet

- Dl650 Op GuideDocument344 pagesDl650 Op GuideHtoo WaiNo ratings yet

- Terrot Single JerseyDocument6 pagesTerrot Single JerseyAli HabboushNo ratings yet

- Cashew ProcessDocument10 pagesCashew ProcessAratiNo ratings yet

- PROJECTREPORTTHATTIL (Autosaved)Document17 pagesPROJECTREPORTTHATTIL (Autosaved)Jeeson VincentNo ratings yet

- Segundo Conjunto de Ejercicios: 1 Punto 1Document2 pagesSegundo Conjunto de Ejercicios: 1 Punto 1Ana C SimancaNo ratings yet

- Hammer MillsDocument56 pagesHammer MillskokiskoNo ratings yet

- Jute Processing (201718)Document13 pagesJute Processing (201718)Joy ShahaNo ratings yet

- Manufacturing of Woven Jumbo Bag Flexible Intermediate Bulk ContainersDocument1 pageManufacturing of Woven Jumbo Bag Flexible Intermediate Bulk ContainersCalvawell MuzvondiwaNo ratings yet

- Filter Drum Cloth Replacement 40-2345Document6 pagesFilter Drum Cloth Replacement 40-2345Saadat BilalNo ratings yet

- Orient Paper MillsDocument17 pagesOrient Paper MillsEr Mohneesh0% (1)

- The Guide: NorgrenDocument16 pagesThe Guide: Norgrenem07150No ratings yet

- Metalworking for Home Machinists: 53 Practical Projects to Build YourselfFrom EverandMetalworking for Home Machinists: 53 Practical Projects to Build YourselfNo ratings yet

- Understanding Plastics Recycling: Economic, Ecological, and Technical Aspects of Plastic Waste HandlingFrom EverandUnderstanding Plastics Recycling: Economic, Ecological, and Technical Aspects of Plastic Waste HandlingNo ratings yet

- Cricut Maker 3 Guide for Beginners: A Step-by-Step Guide to Master, Configure, and Take Care of Your Cricut Maker 3 MachineFrom EverandCricut Maker 3 Guide for Beginners: A Step-by-Step Guide to Master, Configure, and Take Care of Your Cricut Maker 3 MachineNo ratings yet

- Internet of Things in Power Distribution Networks - State of The ArtDocument5 pagesInternet of Things in Power Distribution Networks - State of The ArtYasith Weerasinghe100% (1)

- INTRODUCTIONDocument1 pageINTRODUCTIONYasith WeerasingheNo ratings yet

- Strategic Supply Chain Management and Logistics-120626131827-Phpapp01Document15 pagesStrategic Supply Chain Management and Logistics-120626131827-Phpapp01awais04100% (1)

- Management System Based On The ISO 9001:2008 International Quality StandardsDocument48 pagesManagement System Based On The ISO 9001:2008 International Quality StandardsYasith WeerasingheNo ratings yet

- Literature ReviewDocument1 pageLiterature ReviewYasith WeerasingheNo ratings yet

- (60Sq) (30Sq) : Floor 1 35 FeetDocument2 pages(60Sq) (30Sq) : Floor 1 35 FeetYasith WeerasingheNo ratings yet

- PWC Reverse Logistics PDFDocument97 pagesPWC Reverse Logistics PDFYasith Weerasinghe100% (2)

- Part 03 - Eport-Factory Layout PlanDocument1 pagePart 03 - Eport-Factory Layout PlanYasith WeerasingheNo ratings yet

- DRDRDocument1 pageDRDRYasith WeerasingheNo ratings yet

- California Management Review, Vol 44, No 3 For Guidance On Demand and Supply Uncertainties 10 May 2014Document1 pageCalifornia Management Review, Vol 44, No 3 For Guidance On Demand and Supply Uncertainties 10 May 2014Yasith WeerasingheNo ratings yet

- S.No Name of The University State: Category "A"Document6 pagesS.No Name of The University State: Category "A"Yasith WeerasingheNo ratings yet

- Blockbuster Blu-Ray Zone Movie TitlesDocument55 pagesBlockbuster Blu-Ray Zone Movie TitlesYasith WeerasingheNo ratings yet

- Alcholism ResearchDocument68 pagesAlcholism ResearchYasith WeerasingheNo ratings yet

- A Dossier On The Brand Samsung Product: Samsung Mobile: Submitted To Prof Srinivas Govindrajan On 10-Aug-2013Document27 pagesA Dossier On The Brand Samsung Product: Samsung Mobile: Submitted To Prof Srinivas Govindrajan On 10-Aug-2013Yasith WeerasingheNo ratings yet

- The Significance of Improving Customer Reliability Through Customer Service A Study Based On Upcountry Manpower AgencyDocument10 pagesThe Significance of Improving Customer Reliability Through Customer Service A Study Based On Upcountry Manpower AgencyYasith WeerasingheNo ratings yet

- FixdadaDocument1 pageFixdadaYasith WeerasingheNo ratings yet

- BSC Ugc 120106Document6 pagesBSC Ugc 120106Yasith WeerasingheNo ratings yet

- The Impact of Resource Commitment On Reverse Logistics and Customer Loyalty A Study Based On Consumer Electronics Retail Industry in Sri LankaDocument2 pagesThe Impact of Resource Commitment On Reverse Logistics and Customer Loyalty A Study Based On Consumer Electronics Retail Industry in Sri LankaYasith WeerasingheNo ratings yet

- PDocument1 pagePYasith WeerasingheNo ratings yet

- Shortnotes GhgsourcingDocument11 pagesShortnotes GhgsourcingYasith WeerasingheNo ratings yet

- Spray Adhesives Brochure High ResDocument8 pagesSpray Adhesives Brochure High ResHauntingFire007No ratings yet

- List of Project ReportDocument36 pagesList of Project ReportKhalif Ahamed UsmanNo ratings yet

- Role of The Smear Layer in Adhesive Dentistry (Saikaew) (2022)Document8 pagesRole of The Smear Layer in Adhesive Dentistry (Saikaew) (2022)Angie Acosta RodriguezNo ratings yet

- Adhesion: Past, Present, and Future - Dental Asia - November/December 2019Document5 pagesAdhesion: Past, Present, and Future - Dental Asia - November/December 2019pooja100% (1)

- Tutorial How To Build A Toothpick BridgeDocument10 pagesTutorial How To Build A Toothpick Bridgeyonathan tsegayeNo ratings yet

- Principles of AdhesionDocument44 pagesPrinciples of AdhesionOmar Hesham SalahNo ratings yet

- Olimpic k800 Edge BanderDocument20 pagesOlimpic k800 Edge BanderBassem AlDoueiryNo ratings yet

- Technocracy Reloaded Preview Manuscript 4Document51 pagesTechnocracy Reloaded Preview Manuscript 4KiffNo ratings yet

- Applied FinishesDocument13 pagesApplied FinishesSanal SamsonNo ratings yet

- Folding Carton Manufacturing: Intelligent Solutions For State-Of-The-Art Production ProcessesDocument8 pagesFolding Carton Manufacturing: Intelligent Solutions For State-Of-The-Art Production Processesmanuel estradaNo ratings yet

- SLV General Introduction To Welding TechnologyDocument35 pagesSLV General Introduction To Welding TechnologyMohammad Sobhan RajabiNo ratings yet

- quizletBT ADocument13 pagesquizletBT ADarren VergaraNo ratings yet

- Squash Court Paint DatasheetDocument3 pagesSquash Court Paint DatasheetDaan BloemartsNo ratings yet

- DK2131 CH37Document7 pagesDK2131 CH37azzaassNo ratings yet

- Aba Ardex RebrandingDocument4 pagesAba Ardex RebrandingHarsa VardhanNo ratings yet

- Fao Fisheries Technical Paper 134rev1Document72 pagesFao Fisheries Technical Paper 134rev1Wagner AbreuNo ratings yet

- Pagel-Joint Seal 100: Polymeric Water Swellable Water Bar For JointsDocument2 pagesPagel-Joint Seal 100: Polymeric Water Swellable Water Bar For JointsZaid AhmedNo ratings yet

- Case StudyDocument10 pagesCase StudyTheAvilashNo ratings yet

- Duct Mate CatalogDocument64 pagesDuct Mate CatalogJM ArcillaNo ratings yet

- Concrete Terms and Industry TerminologyDocument12 pagesConcrete Terms and Industry TerminologyNguyen Dang Hanh100% (8)

- 3M DP125Document7 pages3M DP125echobravo1No ratings yet

- First Time Fabric Art - Step-By-Step Basics For Painting and Printing On FabricDocument85 pagesFirst Time Fabric Art - Step-By-Step Basics For Painting and Printing On FabricabcNo ratings yet

- JC 12 Clinical Efficacy of Methods For Bonding To ZirconiaDocument37 pagesJC 12 Clinical Efficacy of Methods For Bonding To ZirconiaMrinmayee ThakurNo ratings yet

- Butyl V Asphalt Tech Bulletin 051HJ - 11-12Document1 pageButyl V Asphalt Tech Bulletin 051HJ - 11-12Shajit KumarNo ratings yet

- CAB O SIL TS720pdfDocument2 pagesCAB O SIL TS720pdfsriatul2006No ratings yet

- TDS - Paper WS - Niklakett - Medium - PlusDocument1 pageTDS - Paper WS - Niklakett - Medium - PlusSundar MoorthiNo ratings yet

- Cahier Des Charges: Technical SpecificationsDocument15 pagesCahier Des Charges: Technical SpecificationsalbertoNo ratings yet