Professional Documents

Culture Documents

Energy Wood

Energy Wood

Uploaded by

Mag FhearadhaighOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Energy Wood

Energy Wood

Uploaded by

Mag FhearadhaighCopyright:

Available Formats

Psresz Resources and Consewation Fact Sheer

FRC-15

Kay M. Eaff m d Don M. Post"

Ontroduction

The University of Florida's School of Forest Resources and Conservation began to study the gasification of wood and other plant material early in 1979, The initial project was to power a n internal combusLion erigine on wood gas to demonscrate the possibilities of the process. A six cylinder ~ h e v r i l e t pickup truck was converted to operate on wood gas as a mobile demonstration unit. Since that time, the School of Forest Resources and Conservation has joined with other IFAS faculties to develop other applications of gasification technology. This fact sheet describes the wood gasifier system that was developed for the truck. Gas generated from wood or coal has been used to power internal combustion engines since their invention. However, the use of liquid petroleum fuels has displaced almost completely the use of wood gas in engines. Some reasons for this are listed below: 1. Storage. Liquid fuel has advantages in storage and transfer through the system. 2. Energy content. For the same volume or the same weight, petroleum fuels provide more energy than wood. 3. Start-up time. For most petro1eu.m fuels, the start-up time is negligible; however it takes 10-15 minutes to generate enough gas from wood to start and run the engine. 4. Maintenance. The wood gas generator, cooler and cleaners require considerable maintenance not required with liquid fuels (neglect of the filters will lead to engine damage). 5. Power. A gasoline engine operated on wood gas produces only about half the power of the same engine using gasoline. 6. Danger. Wood gas is typically 20%, carbon monoxide, an odorless, colorless, tusteless an.d very poisonous gas. Many people have been ' killed by careless use o a .mrood gas generator. The gas generator system should never be operated in a closed spa.ce and any excess gas should be burned before i t is released into t h e atmosphere. Even coi2sidering .these disadvantages, the current

need to conserve petroleum fuels makes the use of wood gas a viable alternative in certain applications. These applications include powering gasoline engines as is illustrated here and also the gas generated from wood or other biomass can be used for space heating and drying operations.

Principles o Operation f

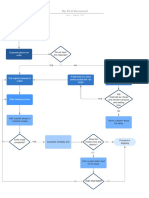

A downdraft wood gas generator for producing engine grade gas is illustrated in Figure 1. Air enters the generator through the air inlets, passes through the air manifold and is distributed to the fuel by the nozzles. Heat from the burning of fuel in the cornbustion zone produces charcoal from the wood above .by driving off water vapor and volatile components. Excess water and a small amount of t a r or creosote which condenses on the sides and top of the fuel hopper are caught in the condensate trap. Otherwise, everything produced frorn the wood fuel is forced downward through the combustion zone and burneci. Ail the oxygen in the air that enters the generator should be used in the combustion zone so that no oxygen enters the reduction zone bellow the choke plate. In the reduction zone, carbon in the hot charcoal combines chemically with carbon dioxide and water vapor to produce t h e fuel gases carbon monoxide and hydrogen. The gas leaving t h e generator should be aboixt 2R%, carbon monoxide. 20% hydrogen, 10% carbon dioxicle and 50%* nni-Lrogen, plus traces of other gases, vapors. soot, ash and water vapor. It is the purpose of -the coolers and cleaners to remove any component of the fuel gas which woulrl damage the engine. The gasifier illustrated in Figure 4 -mill operate for 1to 2 hours on a fuel charge of 100 pounds. The fuel should be small wood blocks no bigger than 6" x 2" x 4". From the generator, -the gas passes through a cyclone separator (Figure 5 ) which removes approsimately 75%.of the particulate matter from the gas. The gas is cooled and. the cleaning is finished in the cooler and cleaner unit ( F i g u ~ e ) . In the cooling 6 process, excess water vapor is coilclensed an6 removed from the gas. As a result, the density ofthe gas and the energy content ape increased. From .the cooler,

"gay M. XofP is .4&smnt Prs$zssor, Geog<;l.~phy Depnrtmem, Un$/er.si~or*Fla>&da, and Don M. Po3-i:is As~ociil~c -vJ'~&) of^----* Schoo! of F,rssc Rsources and Conseg~/a;ion, $PAS, Uniwrslg of Florida, Cdn<zsviE'le, 32:611. FL

the gas goes to the mixing box (Figure 7), where it is mixed with an equal volurrne of air before it is drawn inLo the engine. The exhaust emissions from this syste-m have not been analyzed and the long term effects on the life of the engine operating wi'ih this clean-up system are unknown.

Exampie of a Gas Generator System

The system illustrated in Figures 2 through 7 was built as quickly and cheaply as possible, and was used to power a pickup truck to demonstrate the pot,ential of wood gasification. To that end, it has been successful. However, the design of the system was largely determined by the materials that were available and certainly does not represent an optimum design. The gasifier illustrated is suitable for an engine of 250 to 350 cubic inches displacement. However, anyone interested in a woocl gas system for anything other than a hobby or as a curiosity, should not copy this system but should refer to the technical literature or contact a firm specializing in this type of equipment. A list of such firms and a bibliography of selected gasifier articles is included.

9. Energy Research $. 0. Box 551 Miami FL 33138 "This list is providecl for informational purposes only and no endorsements nor guarantees me implied by the Institute of Food and Agricultural Sciences, University of Florida.

Bibliography

3.. Technology and Economics o f Wood Residue Ga.sification. Proceedings, Tenth Texas Industrial Wood Seminar, Ed. Ken E. Rogers, 1979. This reference includes the transcript of a series of talks. Subjects include: 1. Discussion of the various types of gas generator and applications. Some of the generators are experimental models and others are available on a commercial basis. 2. Economics of converting various systems from fossil fuels to generator gas. 3. Discussion of different fuels available for gasification, fuel handling and processing equipment, waste disposal and handling equipment, stack gas quality. 2. Generator Gas - The Swedish Experience from 1939-1945. Translated by the Solar Energ.1 Research Institute, 1536 Cole Blvd., Golden, Colorado, 80401,1979. This is a very detailed discussion of the operation of internal combustion engines on generator gas. The operation of motor vehicles and the preparation of fuel for them receive the most attention. Tnis reference contains the information needed to convert a gasoline vehicle to wood or charcoal operation. This publicution is n must for anyone considering bzsilding u gasification unit. 3. Williams, R. 0. and B. Horsfield. "Generation of Low-Btu Fuel Gas from Agricultural Residues and Experiments with a Laboratory Scale Gas Producer." 9th Annual Conference on Food, Fertilizer, and Agricultural Residues. Cornell University, Syracuse, Mew York, April 1977. This paper covers the design, construction and operation of a small downdraft gas generator. Farm residues such as rice hulls, cotton gin trash, wood chips, walnut shells and corn cobs are used as fuels.

B

Firms with Experiencein VV6od Gasification*

1. Biomass Fuel Corporation 951 Live Oak Blvd. Yuba City CA 95991 2. Energy Resources Company, Inc. 185 Alewife Brook Parkway Cambridge MA 02138 (617) 661-3111 3. Forest Fuels, Inc. 7 Main Street Meene NH 03431 4. Halcyon Associates, Inc. The Halcyon Maple Street East Andover NH 03231 5. E. R. Mellenger 108 Carmarten Street St. John, New Brunswick Canada 6 . Mr. R. C. Wellman Engineering Company 113 St. Claire Avenue, NE Cleveland OH 44144 7. VJoodex Corpora.tion Eugene OR 97400 8. Econ Box 828 Alexander City AL 35040

-

i his publication was promulgated at a cost of 867'1.45, or 4.5 cents per copy, to inform Florida residents about converting gasoline engines to run on ~vood.9-1 5M-80

'ilaiml l1.l.L'orma:loi and other sGrvices only t o individuals and institutions that iwnction without regard t o race, color, sex 3' i nat!onal ovlgln. Slngla copias 07 E::tenslon publications (excluding 4 -Hand Youth publications) are available fraa t o Florida

COOPERATIVE E><TEF.ISIOfiI SERVICE, U N I V E R S I T ' I O F F L O R I D A , I N S T I T U T E OF FOOD ADID AGRlCULTClRAL SClEFlCES, K R. Telertillar, director, in cooperation wltii the United States Department of Agriculture, publishes this infor. . iirnklon '60 further tho purpose of t h e May 8 and June 3 0 , 1912 Acts of Congress;and is authorized t o provide research, educa-

Pa5/<3Lsn.L~ .?rmm County Exlension Of.;'ices. lnlorrnation on bulk rates or copie$ for out-of-slate purchasers is a9,ailabla f r s ~ n C. ?.A. :-linton, Publications Blz%YibutionCYnter, I F A S Building 6 6 4 , University of Florida, Gainesviile, Florlcla 3 2 6 1 1. Eefors pI.ibii,:.i?ifi3 tiiis P!Jb)lct!ni?, <?cl$'?ors should r-oneact Phis address to determine availability.

You might also like

- Bean Counters Teacher Hand-OutsDocument25 pagesBean Counters Teacher Hand-OutsJustin Henderson100% (1)

- Convert A KilnDocument7 pagesConvert A KilnMag Fhearadhaigh100% (2)

- UZI ReceiverDocument7 pagesUZI Receiverbrowar444100% (1)

- Green Engine Seminar ReportDocument24 pagesGreen Engine Seminar ReportKiran KumarNo ratings yet

- Development and Operational Experience With Topless Wood Gasifier Running A 3.75 KW Diesel Engine PumpsetDocument10 pagesDevelopment and Operational Experience With Topless Wood Gasifier Running A 3.75 KW Diesel Engine PumpsetMag FhearadhaighNo ratings yet

- Design and Development of Pyrolysis Batch Reactor and Characterization of Tire Pyrolysis Oil Using GC Ms and FT IrDocument7 pagesDesign and Development of Pyrolysis Batch Reactor and Characterization of Tire Pyrolysis Oil Using GC Ms and FT Iresatjournals100% (1)

- 3 Executive SummaryDocument8 pages3 Executive Summarygui9871No ratings yet

- Aizaz Muhammad Home Work 2Document6 pagesAizaz Muhammad Home Work 2Aizaz MuhammadNo ratings yet

- Rnichols PDFDocument9 pagesRnichols PDFBun YaminNo ratings yet

- Preparation of Diesel From Plastic WasteDocument13 pagesPreparation of Diesel From Plastic WasteAYUSH SINGHNo ratings yet

- Fuels From Plastic WastesDocument2 pagesFuels From Plastic WastesInternational Jpurnal Of Technical Research And ApplicationsNo ratings yet

- Waste Plastic Pyrolysis: Title of The ProjectDocument11 pagesWaste Plastic Pyrolysis: Title of The ProjectAmrit PathakNo ratings yet

- Chemmatters Feb2010 Green GasolineDocument3 pagesChemmatters Feb2010 Green GasolineMohammad FaizNo ratings yet

- Forced Convective Heat Transfer Using Turbulence PromotersDocument9 pagesForced Convective Heat Transfer Using Turbulence PromotersvinayNo ratings yet

- Exhaust Gas Analysis and Parametric Study of Ethanol Blended Gasoline Fuel in Spark Ignition EngineDocument11 pagesExhaust Gas Analysis and Parametric Study of Ethanol Blended Gasoline Fuel in Spark Ignition EngineAJER JOURNALNo ratings yet

- Batch 5 IntroductionDocument21 pagesBatch 5 IntroductionVinay InjamNo ratings yet

- An Independent Engineering Evaluation of Waste-To-Energy TechnologiesDocument7 pagesAn Independent Engineering Evaluation of Waste-To-Energy TechnologiesJDPSoaresNo ratings yet

- Design and Development of A 20 KW Cleaning and Cooling System For A Wood-Chip GasifierDocument5 pagesDesign and Development of A 20 KW Cleaning and Cooling System For A Wood-Chip GasifierBruno NavarroNo ratings yet

- Simulation Study For Production of Hydrocarbons From WasteDocument9 pagesSimulation Study For Production of Hydrocarbons From WasteAJER JOURNALNo ratings yet

- Waste Tire 1Document13 pagesWaste Tire 1May PassarapornNo ratings yet

- Pytania I OdpowiedziDocument7 pagesPytania I OdpowiedziSami Onur VuralNo ratings yet

- Automobile Engineering: AbstractDocument15 pagesAutomobile Engineering: AbstractPrabir Kumar PatiNo ratings yet

- 2010 Energy Paper XYZDocument7 pages2010 Energy Paper XYZAgung Dedy Pramana PutraNo ratings yet

- TER (Editing)Document27 pagesTER (Editing)Hanah Kryss CastreNo ratings yet

- Review On Recovery and Utilization of Waste Heat in Internal Combustion EngineDocument7 pagesReview On Recovery and Utilization of Waste Heat in Internal Combustion EngineMayur PKNo ratings yet

- Wood Gas GeneratorDocument56 pagesWood Gas GeneratorPools2012No ratings yet

- New Approach of Spark Ignition Engine Fueled With Ethanol: Sun Jun You Fubing Li Gesheng Gao XiaohongDocument4 pagesNew Approach of Spark Ignition Engine Fueled With Ethanol: Sun Jun You Fubing Li Gesheng Gao XiaohongHafiz Muhammad MuneebNo ratings yet

- Hydrogen Generator Booster PDFDocument61 pagesHydrogen Generator Booster PDFbabu100% (2)

- Automotive EmissionsDocument30 pagesAutomotive EmissionsAmarjeet RaiNo ratings yet

- The Methanol Story: A Sustainable Fuel For The FutureDocument9 pagesThe Methanol Story: A Sustainable Fuel For The FutureJan CapekNo ratings yet

- Technical and Economic Feasibility Study of Establishing Ethanol Fuel Plant in Kenana Sugar CompanyDocument26 pagesTechnical and Economic Feasibility Study of Establishing Ethanol Fuel Plant in Kenana Sugar CompanySara TalathiNo ratings yet

- Coal GasificationDocument72 pagesCoal GasificationguymailyNo ratings yet

- Cement Manufacturing Using Alternative Fuels and The Advantages of Process ModellingDocument6 pagesCement Manufacturing Using Alternative Fuels and The Advantages of Process ModellingStefan StrutzNo ratings yet

- Ayush FileDocument9 pagesAyush FileMD Ishteyaque AhmadNo ratings yet

- Large Scale Recycling Process For Scrap Tires and Rubber ProductsDocument11 pagesLarge Scale Recycling Process For Scrap Tires and Rubber ProductsMuhammad Abdul RaufNo ratings yet

- Energy and Energy Analysis On Si Engine by Blend o PDFDocument14 pagesEnergy and Energy Analysis On Si Engine by Blend o PDFJagesh ChauhanNo ratings yet

- Green Engine Seminar ReportDocument11 pagesGreen Engine Seminar ReportSami Zama100% (1)

- Fuels From Plastic WastesDocument10 pagesFuels From Plastic WastesRock onNo ratings yet

- Generations of Crude Oil: March 2019Document6 pagesGenerations of Crude Oil: March 2019Aso SerwanNo ratings yet

- CryogenicDocument19 pagesCryogeniczohaib_farooq100% (1)

- Applied Energy: Orhan Arpa, Recep Yumrutas, Ayhan DemirbasDocument6 pagesApplied Energy: Orhan Arpa, Recep Yumrutas, Ayhan DemirbasKanthan DevanNo ratings yet

- Experiment On Enhancing Heat Transfer - EGT Using Turbulence Promoters and Cross Flow HX With DI/Ag+ Nano ParticlesDocument19 pagesExperiment On Enhancing Heat Transfer - EGT Using Turbulence Promoters and Cross Flow HX With DI/Ag+ Nano ParticlesvinayNo ratings yet

- Wood Gas As Engine FuelDocument86 pagesWood Gas As Engine FuelSv Tinh NguyệnNo ratings yet

- Design of Exhaust Gas Heat ExchangerDocument56 pagesDesign of Exhaust Gas Heat ExchangerAnkit saxena100% (11)

- Fuel Cell PDFDocument18 pagesFuel Cell PDFprsureshauto100% (7)

- 44729538Document95 pages44729538johnlloydNo ratings yet

- SSW#1 Basics of Industrial EcologyDocument8 pagesSSW#1 Basics of Industrial EcologyAisara AmanovaNo ratings yet

- Hong AnalysisDocument38 pagesHong AnalysisleovenuNo ratings yet

- Final Narrative 2013NSDCDocument39 pagesFinal Narrative 2013NSDCMisgatesNo ratings yet

- Module IIlDocument11 pagesModule IIlRudraksh ShivhareNo ratings yet

- Recycling Waste Automotive Engine Oil As Alternative Fuel For Diesel EngineDocument5 pagesRecycling Waste Automotive Engine Oil As Alternative Fuel For Diesel EngineblaNo ratings yet

- Technical and Economic Feasibility Study of Establishing Ethanol Fuel Plant in Kenana Sugar CompanyDocument26 pagesTechnical and Economic Feasibility Study of Establishing Ethanol Fuel Plant in Kenana Sugar CompanyAymen babourNo ratings yet

- Title: Energy Resources and UtilizationDocument6 pagesTitle: Energy Resources and UtilizationMuhammad WaleedNo ratings yet

- Applied Energy: Nimit Nipattummakul, Islam I. Ahmed, Somrat Kerdsuwan, Ashwani K. GuptaDocument5 pagesApplied Energy: Nimit Nipattummakul, Islam I. Ahmed, Somrat Kerdsuwan, Ashwani K. GuptahusseinhshNo ratings yet

- Coal To Methanol p2Document8 pagesCoal To Methanol p2moeeezNo ratings yet

- Simulation Study For Production of Hydrocarbons From WasteDocument9 pagesSimulation Study For Production of Hydrocarbons From WasteeduardoNo ratings yet

- Gas turbine futureDocument3 pagesGas turbine futurefriendforu2121No ratings yet

- Bio DieselDocument9 pagesBio DieselSrini VasanNo ratings yet

- Fuel CellsDocument6 pagesFuel CellsJayan PillaiNo ratings yet

- Fabrication and Testing of A Catalytic ConvertorDocument5 pagesFabrication and Testing of A Catalytic ConvertorInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Afbc Operation of Small: Scale Demonstration For Greenhouse HeatingDocument13 pagesAfbc Operation of Small: Scale Demonstration For Greenhouse HeatingamolsanyoNo ratings yet

- Production of Ethanol From BagasseDocument64 pagesProduction of Ethanol From Bagasseajali1957No ratings yet

- Earth Mortars and Earth-Lime RendersDocument7 pagesEarth Mortars and Earth-Lime RendersMag FhearadhaighNo ratings yet

- Development and Operational Experience With Topless Wood Gasifier Running A 3.75 KW Diesel Engine PumpsetDocument10 pagesDevelopment and Operational Experience With Topless Wood Gasifier Running A 3.75 KW Diesel Engine PumpsetMag FhearadhaighNo ratings yet

- High Definition Infrared: The Truth About What You Thought You KnewDocument10 pagesHigh Definition Infrared: The Truth About What You Thought You KnewMag FhearadhaighNo ratings yet

- Kinetix Diesel Generator Gasifier Data Table 2012Document1 pageKinetix Diesel Generator Gasifier Data Table 2012Mag FhearadhaighNo ratings yet

- Wood Small 5: Gas Generators For Power HP) RequirementsDocument18 pagesWood Small 5: Gas Generators For Power HP) RequirementsMag FhearadhaighNo ratings yet

- Retstruc of Waste TiresDocument2 pagesRetstruc of Waste TiresMag FhearadhaighNo ratings yet

- Table 5. Specifications of The Gasification Plant at Lahti, FinlandDocument28 pagesTable 5. Specifications of The Gasification Plant at Lahti, FinlandMag FhearadhaighNo ratings yet

- EERC Gasifier FactsheetDocument1 pageEERC Gasifier FactsheetMag FhearadhaighNo ratings yet

- Dear JohnDocument3 pagesDear JohnporxchNo ratings yet

- I. Objectives: Computer System ServicingDocument4 pagesI. Objectives: Computer System ServicingCatherine Mae Lammag BuananNo ratings yet

- Legislative Counsel's Digest: Section 1 of This Bill Authorizes A Person Who Is Not Under Arrest or in TheDocument9 pagesLegislative Counsel's Digest: Section 1 of This Bill Authorizes A Person Who Is Not Under Arrest or in TheFOX5 VegasNo ratings yet

- Matrix - An IntroductionDocument10 pagesMatrix - An IntroductionMajid AbNo ratings yet

- Answers For Exercises On Topic 8 1Document7 pagesAnswers For Exercises On Topic 8 1Mark John Paul CablingNo ratings yet

- Strategies Towards Comprehensive Hemophilia Care Services in Uttar Pradesh" SGPGIMS, LucknowDocument4 pagesStrategies Towards Comprehensive Hemophilia Care Services in Uttar Pradesh" SGPGIMS, LucknowsalmanNo ratings yet

- Hanad General Trading Financial Statements 2023Document8 pagesHanad General Trading Financial Statements 2023Nyakwar Leoh NyabayaNo ratings yet

- Persia and The Persian Question Volume IDocument275 pagesPersia and The Persian Question Volume IhbatesNo ratings yet

- Philippines RegionsDocument5 pagesPhilippines RegionsKristine MercadoNo ratings yet

- Upper Gastrointestinal BleedingDocument4 pagesUpper Gastrointestinal BleedingRazi HaiderNo ratings yet

- Hizon, Czarina May CVDocument3 pagesHizon, Czarina May CVnotapernota101No ratings yet

- Secure QR Code System: Raed M. Bani-Hani Yarub A. Wahsheh Mohammad B. Al-SarhanDocument6 pagesSecure QR Code System: Raed M. Bani-Hani Yarub A. Wahsheh Mohammad B. Al-SarhanAnonymous HeroNo ratings yet

- Conviction in Cheque Bounce CaseDocument24 pagesConviction in Cheque Bounce CaseArvind PatilNo ratings yet

- Account Summary: Consolidated StatementDocument7 pagesAccount Summary: Consolidated StatementSrinivasan RamachandranNo ratings yet

- English RevisionDocument3 pagesEnglish RevisionKhanssaa AboutayabNo ratings yet

- Grade 8 Integrated Science Week 2 Lesson 2Document5 pagesGrade 8 Integrated Science Week 2 Lesson 2Balram HaroldNo ratings yet

- Subaru - CHASSISDocument520 pagesSubaru - CHASSISIS52100% (1)

- User Flow DiagramDocument1 pageUser Flow DiagramjimNo ratings yet

- FC GundlachDocument17 pagesFC GundlachRodrigo PeixotoNo ratings yet

- Kalimat Simple Present Tense Aktif Kalimat Simple Past Tense AktifDocument2 pagesKalimat Simple Present Tense Aktif Kalimat Simple Past Tense AktifRestu PamujiNo ratings yet

- Daughtrey v. Fresno City Police Department, Et Al. - Document No. 4Document1 pageDaughtrey v. Fresno City Police Department, Et Al. - Document No. 4Justia.comNo ratings yet

- Main Hydraulic System M315CDocument8 pagesMain Hydraulic System M315CMEULEYENo ratings yet

- Petrochemical Standards (PDFDrive)Document68 pagesPetrochemical Standards (PDFDrive)fatimahNo ratings yet

- The Curious Friendship Between The Sun and The CloudDocument2 pagesThe Curious Friendship Between The Sun and The Cloudfaeza vakarNo ratings yet

- Minimalist Business Slides by SlidesgoDocument55 pagesMinimalist Business Slides by SlidesgoTera Store OsornoNo ratings yet

- Pediatric Vestibular Disorders PDFDocument10 pagesPediatric Vestibular Disorders PDFNati GallardoNo ratings yet

- BELSummer Training ReportDocument33 pagesBELSummer Training ReportPalak MeenaNo ratings yet

- Guide: Daily ReferenceDocument8 pagesGuide: Daily ReferenceGalina TodorovaNo ratings yet

- Chapter 4 - Braking System 4.1 Brake LinesDocument14 pagesChapter 4 - Braking System 4.1 Brake LinesEmanuel VidalNo ratings yet