Professional Documents

Culture Documents

Coal Journey

Coal Journey

Uploaded by

asnandyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coal Journey

Coal Journey

Uploaded by

asnandyCopyright:

Available Formats

JOURNEY OF A COKING COAL PARTICLE I am a tiny bit of coal. So what!

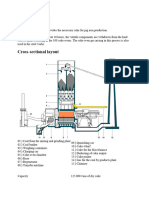

You can hardly imagine the limits to which mankind can go in order to utilize my enormous potential. Let me share my experience in a small place in Bokaro Steel City viz. the Coke Oven & By Product Plant complex of Bokaro Steel Plant. Here I come as the black, sedimentary, rock-like, poorly conducting complex fossil fuel of the bituminous and coke forming variety via ships and railways from such faraway places as Australia, New Zealand & USA and the nearby ones like Chasnalla, Pathardih, Dughda, Sudamdih, Bhojudih, Moonidih, Mahuda, Madhuban, Belatand & Jamadoba which are of the Prime Coking Coal variety and Kathara, Kedla, Mahuda, Rajrappa & Swang which are of the Medium Coking and hence inferior coal type. The wagon tipplers transfer me from the railway box wagons to the tippler bunkers. Subsequently, a number of belt conveyors carry me forward, like a baton in a relay race, to the top of the coal storage bunkers or silos. The tripper cars at the silo top then place me in one particular silo according to the place I come from. There are 81 silos in all, each 38 m high and 12 m in diameter, which can store up to 2,01,750 tons collectively of your truly and friends and relatives and can cater to twenty days demand of the coke oven batteries. I come from different places and am kept separated source-wise in the silos. However, I mix with my other place brethrens shortly afterwards on the belt conveyors placed underneath the silos. These carry us with the help of other conveyors to the hammer crushers. Our mixing is facilitated by the electronic weigh feeders which are placed beneath the silos from which we go to the belt conveyors. The weigh feeders operate in such a fashion that our proportion from the different places tally with the theoretical coal blend. We come in different shapes and sizes and have to be crushed in the hammer crushers, for the sake of uniformity, since the fall down the tippler bunkers, conveyor transfer chutes and silos doesnt help all that much. Somehow, man is unable to assimilate the individuality of each particle and puts forth the excuse that crushing will improve coke strength by providing a homogeneous coke micro-structure. It increases the amount of total suspended particulates in the atmosphere but leaves 80 % of us of a size less than 3.2 mm. The belt conveyors again work in tandem to transport us from the hammer crushers to the Coke Oven Battery coal tower coal bins. These are four in number and each coal bin is attached to two Batteries, one on either side thus making a total of eight Batteries. The cuboidal coal bins, which are 24 m long, 13 m wide and 24 m high, are again sub-divided into four pockets and we are diverted to the more empty pocket by shuttle conveyors. Each pocket has three rows and each row has three openings, which are closed by gates, from which we are fed into the Charging Cars. The Charging Cars then feed us into each of the 69 ovens of a Coke Oven Battery in 5-2 series and within a certain time frame, all the above operations being facilitated by the earths gravitational pull, the pneumatic blow down system in the coal bins and the gate openers and vibrators in the Charging Cars. The 5-2 series of charging and pushing implies that the ovens are filled with coal and the coke is pushed out in the following manner viz. 69, 64, , 9, 4; 67, 62, , 7, 2; 65, 60, , 10, 5; 68, 63, , 8, 3; 66, 61, , 6, 1. Thus, we find that two series are followed at a time alternately and after it is complete the next two series are followed alternately such that there is a difference of two between it and the previous two series. This series facilitates less machine wear and tear compared to the 9-2 series, which we used to follow previously, by minimizing machine movement. Further, refractory jobs can be carried out in the ovens for a longer period of time. We tend to become dry with the passage of time and have to be sprayed with water to have a working moisture content of 7 % which maximizes our bulk density to 850 kg/m 3 and, in turn, helps in maximizing coke strength and, ultimately, coke yield. An excellent case of fattening the

calf before the kill, dont you feel! The average distance that we have to traverse from the wagon tipplers to the coal tower coal bins is roughly 3 km. With our introduction into the trapezoidal slot ovens or coking chambers, which are 15.02 m long, 0.39 m wide on one side and 0.43 m wide on the other, to facilitate pushing out of the coke, and 5 m high, starts our liquidation, as we are roasted in the near absence of air by the glowing heating walls of the ovens at 1200C. 20.11 tons of us, on dry basis, are placed in each oven by the Charging Cars. The irony is that we stew in our own juice as the gas which heats up the oven walls is provided by us. Let me now narrate the story of my pyrolysis or destructive distillation as experimentally found by Prof. D.W.Van-Krevleen of the Netherlands. We start getting hot from the side walls and become soft and plastic in nature, at the same time losing the surface moisture and previously absorbed gases which are water vapour, CO2, O2, N2 and CH4 at a temperature below 200C. Between 200 - 300C, we become slightly rounded. At the first critical temperature level of 350 - 450C, tar and oils evolve and we start sporting spores. At the same time, the reactive macerals in us form an impervious plastic mass. This plastic layer has a thickness varying from 15 40 mm and is characterized by a large temperature drop and high resistance to flow of gases across its width. It moves away from the side walls of the oven as our temperature rises to about 600C and semi-coke, which occupies more space, is formed in its place. The volume increase is due to the formation of an anisotropic ordered mosaic bubble or cellular structure in the semi-coke after the gases have made their way out and upwards through the plastic zone. High molecular weight liquid and gas are evolved between 600 - 700C. The second critical temperature starts from 700 - 1000C when large amounts of H2 is released and the semi-coke shrinks and hardens to the final coke structure, which has a graphite lattice, thus becoming conducting, with secondary cementations and occupying less volume than that which we occupied when initially placed in the oven. The plastic layer moves inwards from both sides of the oven walls and forms a line of median crack where they meet. The rate of carbonization or our transformation into coke which progresses from the side walls and goes inward depends on the oven heating wall temperature and it is 12 mm/hr at 1200C. This means that the coking period or the time it takes for us to transform into coke is roughly 18 hours. The median temperature of the coke is 1050C at the end of coking period. Coke is strongest near the side wall of the ovens and the red hot mass is pushed out from the oven at the end of coking period with the help of the Pusher Car, Guide Car and into the Quenching Car. It weighs 16 tons and is quenched in the Quenching Towers and transported to Coke Sorting Plant for further distribution to Blast Furnace, Sinter Plant, Foundries and other places. Gas, moisture, tar and oils are removed by the Hydraulic Mains and Liquor Pipelines situated at the top of the Batteries and conveyed to the By Product Plant. The gas yield per oven is 6000 m3 at NTP and the gas make is 100 m3/hr approximately. It comprises of 58 % H2, 25 % CH4, 8 % CO, 3.7 % N2, 2.5 % CmHn, 2.5 % CO2 and 0.3 % O2 on dry basis and has a Gross Calorific Value of 4400 kcal/m3 at NTP. The Ammonia yield per oven is roughly 60 kg and the tar yield per oven approximately 600 kg. In _______ 2011, seven Batteries were running and coke was pushed out of the ovens _________times while the gas yield was________ . Now that I have come to the end of my journey and passed away in a blaze, dont you think that my life has been really fulfilling. Some might quip that by dying I have done more for mankind by providing precious coke and gas. No matter what, I have had a rollicking journey and hope you have found my experience most informative and entertaining.

You might also like

- Coke Ovens Vol - 1 PDFDocument312 pagesCoke Ovens Vol - 1 PDFasnandy100% (5)

- Standard Operating Procedure For Sulfuric Acid PlantDocument5 pagesStandard Operating Procedure For Sulfuric Acid PlantasnandyNo ratings yet

- HEALINGDocument10 pagesHEALINGИфашеун Адесаня100% (1)

- Project Report ON Proposed Coal Washing Plant AT Korba AreaDocument23 pagesProject Report ON Proposed Coal Washing Plant AT Korba AreaAmitesh Joseph75% (4)

- MSDS BenzolDocument11 pagesMSDS Benzolasnandy100% (2)

- The Cosmotheoros of Christiaan HuygensDocument65 pagesThe Cosmotheoros of Christiaan HuygensAndres Felipe FernandezNo ratings yet

- CO&CCPDocument23 pagesCO&CCPApoorva RamagiriNo ratings yet

- S K HazraDocument6 pagesS K HazraRicky MenonNo ratings yet

- Saving of Coke Oven Gas by Reduction of Smoke Pushing of Recovery Type Coke PlantDocument7 pagesSaving of Coke Oven Gas by Reduction of Smoke Pushing of Recovery Type Coke PlantPriyatam KumarNo ratings yet

- Coal Combustion TechniquesDocument13 pagesCoal Combustion TechniquesAnup NairNo ratings yet

- Introduction CO & CCDDocument14 pagesIntroduction CO & CCDAaditya Sharma100% (1)

- Coke Preparation in BatteriesDocument22 pagesCoke Preparation in BatteriesRaju Kalintha100% (2)

- Carbonization of Coal For Metallurgical Coke Production - IspatguruDocument7 pagesCarbonization of Coal For Metallurgical Coke Production - IspatguruKadiripuram ArjunNo ratings yet

- CO&CCPDocument43 pagesCO&CCPTHAMMANABOINA SHIVANo ratings yet

- Profitable Calcining of Non-Calcinable Pet CokeDocument4 pagesProfitable Calcining of Non-Calcinable Pet CokeAchyutha SreeniNo ratings yet

- Coal Blending PaperDocument21 pagesCoal Blending PaperPradeep SrikanthNo ratings yet

- 43 Optimization Lime KilnDocument10 pages43 Optimization Lime KilnAris parkerNo ratings yet

- Principles of Fluidized Bed BoilersDocument27 pagesPrinciples of Fluidized Bed BoilersssNo ratings yet

- FK3410041018 PDFDocument15 pagesFK3410041018 PDFFaazil HampaNo ratings yet

- Coke Oven and By-ProductsDocument15 pagesCoke Oven and By-ProductsRitik ChaturvediNo ratings yet

- Cochran and Babcock & Wilcox BoilersDocument3 pagesCochran and Babcock & Wilcox BoilersAshish VermaNo ratings yet

- 25.boiler Water Chemistry R1 26.06.2017Document312 pages25.boiler Water Chemistry R1 26.06.2017VINOTHINI R B.Ed100% (1)

- Pe301, C Tech. CH.4 Melting and CleaningDocument49 pagesPe301, C Tech. CH.4 Melting and Cleaningakshatkumargarg 2K20PE09No ratings yet

- Notes Ppe 16 17Document108 pagesNotes Ppe 16 17rudresh JmNo ratings yet

- Fluidized Bed CombustionDocument23 pagesFluidized Bed CombustionHawk EyeNo ratings yet

- 210 MW PowerplantDocument63 pages210 MW PowerplantPratik Makwana100% (3)

- Steel Mill Internship ReportDocument49 pagesSteel Mill Internship ReportAli RazaNo ratings yet

- The Blast FurnaceDocument6 pagesThe Blast FurnaceJayanta MondalNo ratings yet

- Wa0008.Document19 pagesWa0008.Rksuvendu DashNo ratings yet

- Boiler TypesDocument14 pagesBoiler Typesaecsuresh35No ratings yet

- Coal Handling System: Shaikh SaifDocument30 pagesCoal Handling System: Shaikh SaifKrishna SinghNo ratings yet

- Boiler Construction N19Document16 pagesBoiler Construction N191907nirmal100% (1)

- FBC Boilers in Power PlantDocument20 pagesFBC Boilers in Power PlantVenkatesan SundaramNo ratings yet

- Mini bf3Document5 pagesMini bf3Maheswar SethiNo ratings yet

- Coal Thermal Power Plant REPORTDocument55 pagesCoal Thermal Power Plant REPORTOcampo Amy100% (2)

- Study of Coke Oven BatteryDocument18 pagesStudy of Coke Oven BatteryYeswanth Kumar100% (1)

- Cupola FurnaceDocument9 pagesCupola FurnaceAakanksha RamtekeNo ratings yet

- Apple Industries LTD - Anantapur Dist Exe Sum EngDocument8 pagesApple Industries LTD - Anantapur Dist Exe Sum EngRashmi PatelNo ratings yet

- Presentation On Preparation of Coke in Coke Oven Batteries: Presented By: Anil Kumar KhataiDocument18 pagesPresentation On Preparation of Coke in Coke Oven Batteries: Presented By: Anil Kumar KhataiKhatai Anil KumarNo ratings yet

- MCC v2Document9 pagesMCC v2mauriceNo ratings yet

- Blast Furnace Water Recirculation SystemDocument19 pagesBlast Furnace Water Recirculation SystemDaniel Seixas Breda100% (1)

- Working of Blast FurnaceDocument3 pagesWorking of Blast Furnacehk168No ratings yet

- UNIT VDocument23 pagesUNIT VDhilsanth SLNo ratings yet

- 1technical GuideDocument4 pages1technical GuideLen KahnNo ratings yet

- Session-1-Introduction and Coke MakingDocument51 pagesSession-1-Introduction and Coke MakingHeroNo ratings yet

- Kota Super Thermal Power PlantDocument29 pagesKota Super Thermal Power Plantatul mishra75% (4)

- How Is Crude Coal Tar DerivedDocument8 pagesHow Is Crude Coal Tar DerivedRudy MadianNo ratings yet

- Powerplant Engineering NotesDocument189 pagesPowerplant Engineering NotesMilan LamichhaneNo ratings yet

- Boilers Training Topic Nov 2021Document24 pagesBoilers Training Topic Nov 2021mizharmuisstNo ratings yet

- 4.1 BoilerDocument40 pages4.1 BoilermechgokulNo ratings yet

- Coking PlantDocument7 pagesCoking PlantpdiconpNo ratings yet

- Electric Arc Furnace Steel MakingDocument11 pagesElectric Arc Furnace Steel MakingM. Didik Suryadi100% (2)

- A. Indira National Power Training InstituteDocument80 pagesA. Indira National Power Training InstituteAyan MajiNo ratings yet

- Vebsar: Specific Gravity PorousDocument2 pagesVebsar: Specific Gravity Porousrahul srivastavaNo ratings yet

- Kiln Burning SystemDocument12 pagesKiln Burning SystemMuhammadShoaib100% (1)

- Notes For COALTRANS Presentation2 - ManualDocument15 pagesNotes For COALTRANS Presentation2 - ManualAgus BudiluhurNo ratings yet

- Iron Making PPT 1Document35 pagesIron Making PPT 1SHUBHAM VERMANo ratings yet

- Type of BoilersDocument5 pagesType of Boilersnagraj204No ratings yet

- Tata Steel Report SubmittedDocument32 pagesTata Steel Report SubmittedSnehasisDasNo ratings yet

- Ppe Notes Viii Sem M2Document79 pagesPpe Notes Viii Sem M2anusha meesalaNo ratings yet

- Boiler Steam Generation Distribution 1712008851Document37 pagesBoiler Steam Generation Distribution 1712008851sukhvinderNo ratings yet

- Kiln Burning SystemsDocument30 pagesKiln Burning SystemsNael100% (8)

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Grab Crane Hand SignalsDocument1 pageGrab Crane Hand SignalsasnandyNo ratings yet

- Improving Coke StrengthDocument30 pagesImproving Coke Strengthasnandy100% (1)

- MSDS NaphthaleneDocument6 pagesMSDS NaphthaleneasnandyNo ratings yet

- MSDS Ammonium SulfateDocument7 pagesMSDS Ammonium SulfateasnandyNo ratings yet

- Msds Coal TarDocument8 pagesMsds Coal TarasnandyNo ratings yet

- Msds PitchDocument8 pagesMsds PitchasnandyNo ratings yet

- Material Safety Data Sheet H2SO4Document4 pagesMaterial Safety Data Sheet H2SO4asnandy100% (1)

- CEMA GuidelinesDocument2 pagesCEMA GuidelinesasnandyNo ratings yet

- Equipment History SheetDocument4 pagesEquipment History Sheetasnandy100% (1)

- Check List For Weigh FeedersDocument1 pageCheck List For Weigh FeedersasnandyNo ratings yet

- Shift CalendarDocument58 pagesShift CalendarasnandyNo ratings yet

- Role of Moisture in by Product Coke OvensDocument2 pagesRole of Moisture in by Product Coke OvensasnandyNo ratings yet

- SOP For Empty OvenDocument1 pageSOP For Empty OvenasnandyNo ratings yet

- Water Filtration Using Plant Xylem PDFDocument8 pagesWater Filtration Using Plant Xylem PDFSyukri Abd RahmanNo ratings yet

- Usa 500 FullzDocument26 pagesUsa 500 FullzdaribakewwaNo ratings yet

- tmpECC3 TMPDocument13 pagestmpECC3 TMPFrontiersNo ratings yet

- Hs 4 Genetics Practice Problems 2Document1 pageHs 4 Genetics Practice Problems 2api-366982317No ratings yet

- Nutrition Sensitive AgricultureDocument11 pagesNutrition Sensitive Agricultureioana100% (1)

- Helsinkis Green TreasuresDocument254 pagesHelsinkis Green TreasuresasgljhNo ratings yet

- Siminar Research Since 2017 GDocument43 pagesSiminar Research Since 2017 Gkibrom atsbhaNo ratings yet

- September 20 : Find Out 6! Unit 0. A New School YearDocument6 pagesSeptember 20 : Find Out 6! Unit 0. A New School YearvirinzoNo ratings yet

- CEDD General Specification For Civil Engineering Works (1992 Edition) Volume 1 of 3 (Amendment No. 2003-1)Document281 pagesCEDD General Specification For Civil Engineering Works (1992 Edition) Volume 1 of 3 (Amendment No. 2003-1)Mini ChanNo ratings yet

- Atlas de CactusDocument357 pagesAtlas de CactusSupErmin3No ratings yet

- Aromatherapy, Essential Oils, Remedy Blends, Incense, Scent Therapy, Guidelines For Essential Oils at Peaceful MindDocument15 pagesAromatherapy, Essential Oils, Remedy Blends, Incense, Scent Therapy, Guidelines For Essential Oils at Peaceful MinditzmeaneeshNo ratings yet

- Select Quality SeedsDocument42 pagesSelect Quality SeedsRon EncinasNo ratings yet

- Types of Asexual Reproduction Part 2Document12 pagesTypes of Asexual Reproduction Part 2yashNo ratings yet

- Flora Neotrópica - TrigoniaceaeDocument76 pagesFlora Neotrópica - TrigoniaceaeSergio S. MejíaNo ratings yet

- MyanmarDocument8 pagesMyanmaranon-877302100% (1)

- Tea EstatesDocument3 pagesTea EstatesAbhishek P BenjaminNo ratings yet

- The Legend of Durian Hermit's Three WishesDocument13 pagesThe Legend of Durian Hermit's Three WisheswintermaeNo ratings yet

- Agrifoods Plants PDF BeetsDocument6 pagesAgrifoods Plants PDF BeetsMikhael MisalNo ratings yet

- Parallel StructureDocument3 pagesParallel StructureastridNo ratings yet

- Spring E8 Opis ObrazkaDocument4 pagesSpring E8 Opis ObrazkamichalklucowiczNo ratings yet

- Sacrificial Flower by Hyun Jin GeonDocument5 pagesSacrificial Flower by Hyun Jin GeonHenrie MenaNo ratings yet

- Activity No. 4Document5 pagesActivity No. 4Aroha DongminNo ratings yet

- Computer Masti Level 4Document129 pagesComputer Masti Level 4Rupesh Kumar Shah50% (2)

- Summative Test in Math 7 LifsDocument5 pagesSummative Test in Math 7 LifsMariel PastoleroNo ratings yet

- Draft 1Document6 pagesDraft 1Maverick BeeNo ratings yet

- Using Plants As Natural DyesDocument4 pagesUsing Plants As Natural DyesSanjeet Kumar SharmaNo ratings yet

- J. Agroland 22 (3) : 197 - 204 Desember 2015 ISSN: 0854 - 641X E-ISSN: 2407 - 7607Document8 pagesJ. Agroland 22 (3) : 197 - 204 Desember 2015 ISSN: 0854 - 641X E-ISSN: 2407 - 7607Ria WijayantiNo ratings yet

- 12STEM3 Group5 FINALCHAPTER3Document7 pages12STEM3 Group5 FINALCHAPTER3Josh RoqueNo ratings yet