Professional Documents

Culture Documents

Topics Page No

Topics Page No

Uploaded by

Mahathir Mohammad BappyCopyright:

Available Formats

You might also like

- BMC 1100 & 1300 Workshop ManualDocument324 pagesBMC 1100 & 1300 Workshop ManualMichael Carnell94% (17)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Small Block Chevrolet: Stock and High-Performance RebuildsFrom EverandSmall Block Chevrolet: Stock and High-Performance RebuildsRating: 4 out of 5 stars4/5 (14)

- MST Jharna BegumDocument1 pageMST Jharna BegumMd.saydur Rahman100% (1)

- Econex PresentationDocument40 pagesEconex PresentationLucky Singh100% (1)

- Chapter 1-Fundamental Safety Instructions (JT262.12)Document11 pagesChapter 1-Fundamental Safety Instructions (JT262.12)mliugongNo ratings yet

- Report On Workshop Mini ProjectDocument5 pagesReport On Workshop Mini ProjectSajad KhanNo ratings yet

- Harshit Digarse Research Paper On Automatic Paper Cutting Machine Using Genneva MechanismDocument5 pagesHarshit Digarse Research Paper On Automatic Paper Cutting Machine Using Genneva Mechanismmp factNo ratings yet

- Power HacksawDocument30 pagesPower Hacksawbilal shaikh100% (3)

- Lathe Machine 1Document22 pagesLathe Machine 1James UgbesNo ratings yet

- Lab Report Lathe TurningDocument13 pagesLab Report Lathe TurningSohaliaNo ratings yet

- 24 Lathe Machine Parts and Functions PDFDocument8 pages24 Lathe Machine Parts and Functions PDFTackle XINo ratings yet

- Chapter 1Document18 pagesChapter 1YogendraSinghNo ratings yet

- P9736 (1) (1) 000000000000000000000000Document29 pagesP9736 (1) (1) 000000000000000000000000WASEM ANWARNo ratings yet

- Lap Report TemplateDocument7 pagesLap Report TemplateMd Sajib SheikhNo ratings yet

- Design and Analysis of Paper Cutting Machine UsingDocument11 pagesDesign and Analysis of Paper Cutting Machine UsingKunal Singh100% (1)

- Mech Lathe Machine ReportDocument15 pagesMech Lathe Machine ReportHassan TalhaNo ratings yet

- Manufacturing of Spur Gear: Aim of The ExperimentDocument5 pagesManufacturing of Spur Gear: Aim of The ExperimentParameshwara MeenaNo ratings yet

- AMPT (3140204) LAB MANUAL 2022 LNJDocument100 pagesAMPT (3140204) LAB MANUAL 2022 LNJShubham JadavNo ratings yet

- Lathe MachineDocument22 pagesLathe MachineRaghavMaheshwariNo ratings yet

- Manufacturing ProcessDocument11 pagesManufacturing ProcessRimti BhowmikNo ratings yet

- Lathe Operations: Submitted byDocument10 pagesLathe Operations: Submitted byUsama MughalNo ratings yet

- What Is Machining ProcessDocument15 pagesWhat Is Machining ProcessNantha Kumar MurugaiyanNo ratings yet

- Design and Manufacturing of Zig-Zag Bar Bending MachineDocument58 pagesDesign and Manufacturing of Zig-Zag Bar Bending MachineSachin T100% (1)

- All You Need To Know About CNC Lathe Mac PDFDocument4 pagesAll You Need To Know About CNC Lathe Mac PDFKroof KayNo ratings yet

- Mohamed Baksh 1036007 Assignment 6Document11 pagesMohamed Baksh 1036007 Assignment 6Mohamed BakshNo ratings yet

- 4951 6365 1 SMDocument6 pages4951 6365 1 SMbartosznikusNo ratings yet

- Hapter 1Document46 pagesHapter 1SURESHNo ratings yet

- Figure 1: AISI 4140 Round BarsDocument3 pagesFigure 1: AISI 4140 Round BarsMorena MoremoholoNo ratings yet

- 2021 Me 16Document16 pages2021 Me 16Muhammad FurqanNo ratings yet

- AcknowledgementsDocument55 pagesAcknowledgementsFARAZ NOORNo ratings yet

- Workshop Technology: EXPERIMENT 1: Hand and Machine Tools (Making A Pin Hammer)Document17 pagesWorkshop Technology: EXPERIMENT 1: Hand and Machine Tools (Making A Pin Hammer)Tan YikcongNo ratings yet

- Automatic Paper Cutting Machine Using Geneva MechanismDocument33 pagesAutomatic Paper Cutting Machine Using Geneva MechanismSuraj KadamNo ratings yet

- Table of Content: S.no. Content Page No. 1 Chapter 1: Project DefinitionDocument24 pagesTable of Content: S.no. Content Page No. 1 Chapter 1: Project Definitionsanju kumarNo ratings yet

- PDF File of Machine Shop Report PDFDocument8 pagesPDF File of Machine Shop Report PDFNur Akmal100% (1)

- Manual Pruning Shears/scissorDocument12 pagesManual Pruning Shears/scissorFarhanIshtiaqNo ratings yet

- Welding Slag CLEANING MachineDocument5 pagesWelding Slag CLEANING MachineSuganthan IasNo ratings yet

- Lathe MachineDocument12 pagesLathe MachineEmy SyazlindaNo ratings yet

- Mahindra Gears Transmiision Training ReportDocument32 pagesMahindra Gears Transmiision Training Reportbestmadeeasy50% (2)

- B.TECH. (5 Semester) Production and Industrial Engineering Pi-319 Vocational Training ReportDocument10 pagesB.TECH. (5 Semester) Production and Industrial Engineering Pi-319 Vocational Training ReportPraveen UpadhyayNo ratings yet

- Gosa Adrian Vasile TCM 141Document6 pagesGosa Adrian Vasile TCM 141Purdea BogdanNo ratings yet

- Roller Bending MachineDocument7 pagesRoller Bending MachinesankaramarayananNo ratings yet

- Heavy Industries Taxila: Internship ReportDocument31 pagesHeavy Industries Taxila: Internship ReportAnonymous gbP4kU5w3No ratings yet

- A Project Progress Report On " ".: Design and Development of Multi-Tasking Cutting MachineDocument13 pagesA Project Progress Report On " ".: Design and Development of Multi-Tasking Cutting Machineprabhat kumarNo ratings yet

- A Project Progress Report On " ".: Design and Development of Multi-Tasking Cutting MachineDocument13 pagesA Project Progress Report On " ".: Design and Development of Multi-Tasking Cutting Machineprabhat kumarNo ratings yet

- CutterDocument7 pagesCuttertahaNo ratings yet

- 5 Milling MachineDocument4 pages5 Milling Machineмσнαммєd ƒαιz ραтєlNo ratings yet

- Design and Fabrication of Pedal Powered HacksawDocument22 pagesDesign and Fabrication of Pedal Powered HacksawAshish Jindal100% (3)

- Bengkel ReportDocument5 pagesBengkel ReportPaih DtNo ratings yet

- Manufacturing Processes Open Ended Lab ReportDocument15 pagesManufacturing Processes Open Ended Lab ReportDawood KhanNo ratings yet

- Training ReportDocument18 pagesTraining ReportSachin ShikotraNo ratings yet

- ReportDocument4 pagesReportTanjid Al TajimNo ratings yet

- Roll BendingDocument12 pagesRoll Bendingyared befekaduNo ratings yet

- Industrial Project Report: AbstractDocument3 pagesIndustrial Project Report: AbstractMuhammad SanaNo ratings yet

- Study and Operation of An Engine Lathe.: Course No: Ipe-108 Course Title: Workshop PracticeDocument9 pagesStudy and Operation of An Engine Lathe.: Course No: Ipe-108 Course Title: Workshop PracticeSazzadNo ratings yet

- Basics of Milling Machine and Its RigidityDocument9 pagesBasics of Milling Machine and Its RigidityshubhamNo ratings yet

- Arduino 3D Wire Bending MachineDocument46 pagesArduino 3D Wire Bending Machinepuwarin najaNo ratings yet

- Lathe DesignDocument11 pagesLathe DesignShiyas Basheer0% (1)

- Lathe Report 1Document17 pagesLathe Report 1Muhammad AbtaheeNo ratings yet

- Turning and Lathe Basics Training ObjectivesDocument8 pagesTurning and Lathe Basics Training ObjectivesSowjanya VenigallaNo ratings yet

- Ervin MEO (Answers)Document2 pagesErvin MEO (Answers)shulkersheepNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Seven Generations Energy LTD.: Canada ResearchDocument27 pagesSeven Generations Energy LTD.: Canada ResearchAnonymous m3c6M1No ratings yet

- No Email Id DetailsDocument89 pagesNo Email Id DetailsvikrantNo ratings yet

- Lithium Manganese Dioxide: Features & Benefits DimensionsDocument2 pagesLithium Manganese Dioxide: Features & Benefits DimensionsEutério SilvaNo ratings yet

- HydroworldDocument44 pagesHydroworldjaguar13No ratings yet

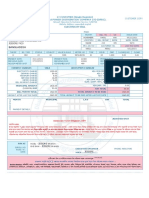

- Bangladesh Power Development Board Electricity Bill: LT Consumer (Si Ngle Register)Document2 pagesBangladesh Power Development Board Electricity Bill: LT Consumer (Si Ngle Register)Junayed Ahammed Tuser.No ratings yet

- Flexible AC Transmission SystemsDocument51 pagesFlexible AC Transmission SystemsPriyanka VedulaNo ratings yet

- Chris Spaulding. TalismanDocument4 pagesChris Spaulding. TalismanMaría Alejandra Gómez CabreraNo ratings yet

- SolarABCs 35 2013 Quality ChecksDocument16 pagesSolarABCs 35 2013 Quality CheckssuperklexNo ratings yet

- Kit Number 15432 Kit Number 15432 Kit Number 15432Document2 pagesKit Number 15432 Kit Number 15432 Kit Number 15432carlosNo ratings yet

- Saf T Gard ActuatorsDocument14 pagesSaf T Gard ActuatorsRicardo FuentesNo ratings yet

- India's Mega KitchenDocument31 pagesIndia's Mega KitchenAnonymous g8PulPTtbSNo ratings yet

- Bill April 21Document1 pageBill April 21Lakshay SharmaNo ratings yet

- Model Solutions: Supplimentary Paper 1 - Set ADocument19 pagesModel Solutions: Supplimentary Paper 1 - Set ACARPE NOCTEMNo ratings yet

- CIPLDocument8 pagesCIPLbountymaniNo ratings yet

- Standard Basic Impulse Insulation Levels: Commrdinatt InsulaetiongorrevisiDocument1 pageStandard Basic Impulse Insulation Levels: Commrdinatt InsulaetiongorrevisiLalo PatoNo ratings yet

- Passenger Boarding Bridges AdelteDocument8 pagesPassenger Boarding Bridges AdelteIsmail SayyedNo ratings yet

- Gabbioneta RDocument6 pagesGabbioneta Rvrider81No ratings yet

- Reference List Nuova FimaDocument51 pagesReference List Nuova FimaAhmedSaadNo ratings yet

- IPFestDocument49 pagesIPFestKaton AntariksaNo ratings yet

- Special Services Presentation - 18 June 2018 Rev 1Document23 pagesSpecial Services Presentation - 18 June 2018 Rev 1Juan CamachoNo ratings yet

- Reducing Dielectric Losses-1Document2 pagesReducing Dielectric Losses-1krcdewanewNo ratings yet

- International Steel Limited SectionsDocument4 pagesInternational Steel Limited SectionsNabeel SheikhNo ratings yet

- Onan ToolDocument42 pagesOnan ToolthanhNo ratings yet

- Multi-V Indoor Unit 0cvp0-02c 09Document309 pagesMulti-V Indoor Unit 0cvp0-02c 09Sasa NackovicNo ratings yet

- CoalDocument18 pagesCoalKishore Kumar KamisettiNo ratings yet

- 18 LCA ConfectioneryDocument20 pages18 LCA ConfectioneryFikrilAzimAbdulSani100% (1)

Topics Page No

Topics Page No

Uploaded by

Mahathir Mohammad BappyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Topics Page No

Topics Page No

Uploaded by

Mahathir Mohammad BappyCopyright:

Available Formats

1

Contents Topics Page No.

1. Objectives..........2

2. Abstract..... 2 3. Keywords.. 3 4. Targeted Customer.......3 5. Product Specification............3 6. Description......... 4 7. Working Procedure....... 8 8. Cost Analysis.... 8 9. Reliability........ 9 10. Additional Features.....9 11. Discussion.....9 12. Gantt Chart....10

13.Conclusion...11

2 TITLE

A Machine (cutting & turning) for carpentry

Objectives

1. To increase the production rate. 2. To reduce the physical labor. 3. To perform cutting and turning in one machine.

Abstract

Nowadays carpentry is an emerging profession in Bangladesh. As a country of third world most of the people here live under the poverty line. They want to do something with low capital like carpentry or furniture manufacturing. Due to the low capital most of the carpenter use the traditional tool for different machining purpose. For this reason the production time and physical labor required for making furniture is high. But using a machine that can perform both cutting and turning operation, which are crucial for furniture manufacturing, can increase the production rate and reduce the physical labor.

Keywords

Carpenter; low-capital; cutter; turner; motor; pulley etc.

Targeted Customer

Fig: A carpenter working with manual hacksaw A carpenter with low capital generally cannot afford more assistants. Without sufficient number of assistants he has to spend more labor in doing various types of operation. But using this type of machine he can perform his job with a small number of assistants and spending less physical labor. So, our targeted customer is this kind of carpenters.

Product Specification

1. 2. 3. 4. Can perform both cutting and turning operation. Machining time is less. Can measure cutting length using the included scale. Adjustable tail stock.

Description

There are two main parts in our machine: one for cutting wood and the other for turning purpose. Different parts of the machine are described below:

Fig: A Machine (cutting & turning) for carpentry

Motor: A motor is an electro-mechanical device which converts the electrical energy into mechanical energy. In that machine we have used an AC motor. It is being used here to produce rotating mechanism in the pulley. The motor we used has the following characteristics: Input voltage 220 V Power- 370 W, HP Current- 4.2 A RPM -1420

Fig: Motor

Head Stock:

5 It is the major component for the turning part of the machine. In head stock we used a pulley and ball- bearing mechanism with a job holder, which gets rotation from motor by belt.

Fig: Head stock

Tail Stock: It is used in the turning part of the machine to support the job on the job on the opposite side of the head stock. It is adjustable on its line. It can be set based on the length of the work piece, in our case it is 36 inch maximum.

Fig: Tail stock Bed: The part on which the operation is being performed is termed as bed. In turning the part on which the head-stock and tail-stock mounted is called bed and here the length of the bed is 45 inch and width is 16 inch. In cutting part the bed carry an adjustable measuring device as a special feature. The length and width is 36x20.5 inch. The bed is in 30.5 inch height from platform.

Fig: Bed Arm:

6 The arm is the most important component in this machine because it carries the cutting tool. It reciprocates longitudinally getting reciprocation from the crank. Here the job is feuded against the tool supported by arm. The length of the arm is 56 inch and the gap is 13 inch at the cutting tool and 9.5 inch at the angle.

Fig: Arm Pulley: It is the circular shaped device used as a medium to convert the rotation of the motor to the reciprocation of the arm and rotation of the small pulley in turner. It remains attached with the motor by belt. The diameter of the driver pulley is 2.5 inch and the driven pulley is 9.5 inch (cutting part) and 2.5 inch (turning part).

Fig: Pulley Crank: In this machine the crank is connected with the pulley. It follows the mechanism of piston. It is also attached with a mill-bearing. Conversion of reciprocation mainly occurs from here.

Fig: Crank Angle:

7 It is used in turner to make a joint between the arms. It is an adjustable type joint which is desirable to make adjustment between the arms.

Fig: Angle Cutting Tool: Cutting tool is very much important for every types of machining. In cutter we have used saw and in turner different types blades are being used for different shape. Normally irons are used to make these types of tools.

Fig: Cutting Tool Belt: It is used for joining motor and the pulley of the machine. Generally rubberized textile belt is being used in the machine. The length of the belt is 50 inch.

Fig: Belt Measuring Mechanism:

8 For the accuracy of measurement and reduction the time consumption of frequent set up time of the job we added a sliding scale on the bed of the cutter machine. We can measure longitudinally up to 30 inch and transversally 36 inch.

Working Procedure

When the machine is switched on the motor starts rotating. The spindle of the motor is attached with the pulley of cutting or turning part by a belt. So the pulley also starts rotating. In case of turning, the pulley rotates the chuck in the head stock. The work piece is held between the chuck and the supporting adjustable tail stock. So the work piece starts rotating and turning operations can be done on it. In case of cutting, the pulley rotates the crank shaft. The crank then causes a reciprocating motion in the arm. So the cutting tool attached at the end of arm also reciprocates and the cutting can be done.

Cost Analysis

Name Motor Crank Wood(Rain tree) Pulley Nut-bolt Rubberized Textile Belt Angle Mill Bearing Steel Rod Ball Bearing Wire Switch Measuring Tape Cutting Tool Total Quantity(pc) 1 1 3 cft 2 2 1 2 2 2 1 3 1 Total Price(tk) 3000 1100 1000 400 200 180 150 150 100 50 40 30 21 7 3428(excluding motor)

Reliability

9 Though it is an electromechanical machine our main concern is with motor. The motor has 5 years warranty. So the lifetime will be long.

Additional Features

Instead of two we used one motor for turning and cutting. The motor we used has one slot for belt. So we cannot run two parts (cutting and turning) at same time. After finishing one operation we have to switch the belt for the other operation. But if we use a motor with two slots for belt we can run both parts simultaneously. In our product we added measuring mechanism. We can adjust a certain length for cutting operation. It will come in handy when cutting many pieces of wood in same size.

Discussion

After generating the concept we set up some specification of the product on the basis of customer needs. When the concept is being selected by testing, we thought about the architecture of the product. We were in a fix that which material and what procedure are suitable for this job. But using the screening method and with the help of an efficient carpenter we find out the suitable materials and procedure of assembling materials. At the time of assembling added some modification to the product. Thus we performed this challenging job as a team based work.

Gantt Chart

10

Concept Generation Concept Selection Set Final Specification Proposal Submission Material search Construction Report Preparation Project Presentation Week 1 2 3 4 5 6 7 8

Conclusion

11 On the shake of necessity any types of products are developed or generated. For this reason we have generated a modified concept of product which is very much crucial for the carpenter with low capital. By using this type of machine a carpenter can easily perform the task of cutting and turning the wood. This machine will be advantageous for a carpenter by reducing the production cost and time. Finally this team based product design and development task performed consciously by following the generic product development process.

You might also like

- BMC 1100 & 1300 Workshop ManualDocument324 pagesBMC 1100 & 1300 Workshop ManualMichael Carnell94% (17)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Small Block Chevrolet: Stock and High-Performance RebuildsFrom EverandSmall Block Chevrolet: Stock and High-Performance RebuildsRating: 4 out of 5 stars4/5 (14)

- MST Jharna BegumDocument1 pageMST Jharna BegumMd.saydur Rahman100% (1)

- Econex PresentationDocument40 pagesEconex PresentationLucky Singh100% (1)

- Chapter 1-Fundamental Safety Instructions (JT262.12)Document11 pagesChapter 1-Fundamental Safety Instructions (JT262.12)mliugongNo ratings yet

- Report On Workshop Mini ProjectDocument5 pagesReport On Workshop Mini ProjectSajad KhanNo ratings yet

- Harshit Digarse Research Paper On Automatic Paper Cutting Machine Using Genneva MechanismDocument5 pagesHarshit Digarse Research Paper On Automatic Paper Cutting Machine Using Genneva Mechanismmp factNo ratings yet

- Power HacksawDocument30 pagesPower Hacksawbilal shaikh100% (3)

- Lathe Machine 1Document22 pagesLathe Machine 1James UgbesNo ratings yet

- Lab Report Lathe TurningDocument13 pagesLab Report Lathe TurningSohaliaNo ratings yet

- 24 Lathe Machine Parts and Functions PDFDocument8 pages24 Lathe Machine Parts and Functions PDFTackle XINo ratings yet

- Chapter 1Document18 pagesChapter 1YogendraSinghNo ratings yet

- P9736 (1) (1) 000000000000000000000000Document29 pagesP9736 (1) (1) 000000000000000000000000WASEM ANWARNo ratings yet

- Lap Report TemplateDocument7 pagesLap Report TemplateMd Sajib SheikhNo ratings yet

- Design and Analysis of Paper Cutting Machine UsingDocument11 pagesDesign and Analysis of Paper Cutting Machine UsingKunal Singh100% (1)

- Mech Lathe Machine ReportDocument15 pagesMech Lathe Machine ReportHassan TalhaNo ratings yet

- Manufacturing of Spur Gear: Aim of The ExperimentDocument5 pagesManufacturing of Spur Gear: Aim of The ExperimentParameshwara MeenaNo ratings yet

- AMPT (3140204) LAB MANUAL 2022 LNJDocument100 pagesAMPT (3140204) LAB MANUAL 2022 LNJShubham JadavNo ratings yet

- Lathe MachineDocument22 pagesLathe MachineRaghavMaheshwariNo ratings yet

- Manufacturing ProcessDocument11 pagesManufacturing ProcessRimti BhowmikNo ratings yet

- Lathe Operations: Submitted byDocument10 pagesLathe Operations: Submitted byUsama MughalNo ratings yet

- What Is Machining ProcessDocument15 pagesWhat Is Machining ProcessNantha Kumar MurugaiyanNo ratings yet

- Design and Manufacturing of Zig-Zag Bar Bending MachineDocument58 pagesDesign and Manufacturing of Zig-Zag Bar Bending MachineSachin T100% (1)

- All You Need To Know About CNC Lathe Mac PDFDocument4 pagesAll You Need To Know About CNC Lathe Mac PDFKroof KayNo ratings yet

- Mohamed Baksh 1036007 Assignment 6Document11 pagesMohamed Baksh 1036007 Assignment 6Mohamed BakshNo ratings yet

- 4951 6365 1 SMDocument6 pages4951 6365 1 SMbartosznikusNo ratings yet

- Hapter 1Document46 pagesHapter 1SURESHNo ratings yet

- Figure 1: AISI 4140 Round BarsDocument3 pagesFigure 1: AISI 4140 Round BarsMorena MoremoholoNo ratings yet

- 2021 Me 16Document16 pages2021 Me 16Muhammad FurqanNo ratings yet

- AcknowledgementsDocument55 pagesAcknowledgementsFARAZ NOORNo ratings yet

- Workshop Technology: EXPERIMENT 1: Hand and Machine Tools (Making A Pin Hammer)Document17 pagesWorkshop Technology: EXPERIMENT 1: Hand and Machine Tools (Making A Pin Hammer)Tan YikcongNo ratings yet

- Automatic Paper Cutting Machine Using Geneva MechanismDocument33 pagesAutomatic Paper Cutting Machine Using Geneva MechanismSuraj KadamNo ratings yet

- Table of Content: S.no. Content Page No. 1 Chapter 1: Project DefinitionDocument24 pagesTable of Content: S.no. Content Page No. 1 Chapter 1: Project Definitionsanju kumarNo ratings yet

- PDF File of Machine Shop Report PDFDocument8 pagesPDF File of Machine Shop Report PDFNur Akmal100% (1)

- Manual Pruning Shears/scissorDocument12 pagesManual Pruning Shears/scissorFarhanIshtiaqNo ratings yet

- Welding Slag CLEANING MachineDocument5 pagesWelding Slag CLEANING MachineSuganthan IasNo ratings yet

- Lathe MachineDocument12 pagesLathe MachineEmy SyazlindaNo ratings yet

- Mahindra Gears Transmiision Training ReportDocument32 pagesMahindra Gears Transmiision Training Reportbestmadeeasy50% (2)

- B.TECH. (5 Semester) Production and Industrial Engineering Pi-319 Vocational Training ReportDocument10 pagesB.TECH. (5 Semester) Production and Industrial Engineering Pi-319 Vocational Training ReportPraveen UpadhyayNo ratings yet

- Gosa Adrian Vasile TCM 141Document6 pagesGosa Adrian Vasile TCM 141Purdea BogdanNo ratings yet

- Roller Bending MachineDocument7 pagesRoller Bending MachinesankaramarayananNo ratings yet

- Heavy Industries Taxila: Internship ReportDocument31 pagesHeavy Industries Taxila: Internship ReportAnonymous gbP4kU5w3No ratings yet

- A Project Progress Report On " ".: Design and Development of Multi-Tasking Cutting MachineDocument13 pagesA Project Progress Report On " ".: Design and Development of Multi-Tasking Cutting Machineprabhat kumarNo ratings yet

- A Project Progress Report On " ".: Design and Development of Multi-Tasking Cutting MachineDocument13 pagesA Project Progress Report On " ".: Design and Development of Multi-Tasking Cutting Machineprabhat kumarNo ratings yet

- CutterDocument7 pagesCuttertahaNo ratings yet

- 5 Milling MachineDocument4 pages5 Milling Machineмσнαммєd ƒαιz ραтєlNo ratings yet

- Design and Fabrication of Pedal Powered HacksawDocument22 pagesDesign and Fabrication of Pedal Powered HacksawAshish Jindal100% (3)

- Bengkel ReportDocument5 pagesBengkel ReportPaih DtNo ratings yet

- Manufacturing Processes Open Ended Lab ReportDocument15 pagesManufacturing Processes Open Ended Lab ReportDawood KhanNo ratings yet

- Training ReportDocument18 pagesTraining ReportSachin ShikotraNo ratings yet

- ReportDocument4 pagesReportTanjid Al TajimNo ratings yet

- Roll BendingDocument12 pagesRoll Bendingyared befekaduNo ratings yet

- Industrial Project Report: AbstractDocument3 pagesIndustrial Project Report: AbstractMuhammad SanaNo ratings yet

- Study and Operation of An Engine Lathe.: Course No: Ipe-108 Course Title: Workshop PracticeDocument9 pagesStudy and Operation of An Engine Lathe.: Course No: Ipe-108 Course Title: Workshop PracticeSazzadNo ratings yet

- Basics of Milling Machine and Its RigidityDocument9 pagesBasics of Milling Machine and Its RigidityshubhamNo ratings yet

- Arduino 3D Wire Bending MachineDocument46 pagesArduino 3D Wire Bending Machinepuwarin najaNo ratings yet

- Lathe DesignDocument11 pagesLathe DesignShiyas Basheer0% (1)

- Lathe Report 1Document17 pagesLathe Report 1Muhammad AbtaheeNo ratings yet

- Turning and Lathe Basics Training ObjectivesDocument8 pagesTurning and Lathe Basics Training ObjectivesSowjanya VenigallaNo ratings yet

- Ervin MEO (Answers)Document2 pagesErvin MEO (Answers)shulkersheepNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Seven Generations Energy LTD.: Canada ResearchDocument27 pagesSeven Generations Energy LTD.: Canada ResearchAnonymous m3c6M1No ratings yet

- No Email Id DetailsDocument89 pagesNo Email Id DetailsvikrantNo ratings yet

- Lithium Manganese Dioxide: Features & Benefits DimensionsDocument2 pagesLithium Manganese Dioxide: Features & Benefits DimensionsEutério SilvaNo ratings yet

- HydroworldDocument44 pagesHydroworldjaguar13No ratings yet

- Bangladesh Power Development Board Electricity Bill: LT Consumer (Si Ngle Register)Document2 pagesBangladesh Power Development Board Electricity Bill: LT Consumer (Si Ngle Register)Junayed Ahammed Tuser.No ratings yet

- Flexible AC Transmission SystemsDocument51 pagesFlexible AC Transmission SystemsPriyanka VedulaNo ratings yet

- Chris Spaulding. TalismanDocument4 pagesChris Spaulding. TalismanMaría Alejandra Gómez CabreraNo ratings yet

- SolarABCs 35 2013 Quality ChecksDocument16 pagesSolarABCs 35 2013 Quality CheckssuperklexNo ratings yet

- Kit Number 15432 Kit Number 15432 Kit Number 15432Document2 pagesKit Number 15432 Kit Number 15432 Kit Number 15432carlosNo ratings yet

- Saf T Gard ActuatorsDocument14 pagesSaf T Gard ActuatorsRicardo FuentesNo ratings yet

- India's Mega KitchenDocument31 pagesIndia's Mega KitchenAnonymous g8PulPTtbSNo ratings yet

- Bill April 21Document1 pageBill April 21Lakshay SharmaNo ratings yet

- Model Solutions: Supplimentary Paper 1 - Set ADocument19 pagesModel Solutions: Supplimentary Paper 1 - Set ACARPE NOCTEMNo ratings yet

- CIPLDocument8 pagesCIPLbountymaniNo ratings yet

- Standard Basic Impulse Insulation Levels: Commrdinatt InsulaetiongorrevisiDocument1 pageStandard Basic Impulse Insulation Levels: Commrdinatt InsulaetiongorrevisiLalo PatoNo ratings yet

- Passenger Boarding Bridges AdelteDocument8 pagesPassenger Boarding Bridges AdelteIsmail SayyedNo ratings yet

- Gabbioneta RDocument6 pagesGabbioneta Rvrider81No ratings yet

- Reference List Nuova FimaDocument51 pagesReference List Nuova FimaAhmedSaadNo ratings yet

- IPFestDocument49 pagesIPFestKaton AntariksaNo ratings yet

- Special Services Presentation - 18 June 2018 Rev 1Document23 pagesSpecial Services Presentation - 18 June 2018 Rev 1Juan CamachoNo ratings yet

- Reducing Dielectric Losses-1Document2 pagesReducing Dielectric Losses-1krcdewanewNo ratings yet

- International Steel Limited SectionsDocument4 pagesInternational Steel Limited SectionsNabeel SheikhNo ratings yet

- Onan ToolDocument42 pagesOnan ToolthanhNo ratings yet

- Multi-V Indoor Unit 0cvp0-02c 09Document309 pagesMulti-V Indoor Unit 0cvp0-02c 09Sasa NackovicNo ratings yet

- CoalDocument18 pagesCoalKishore Kumar KamisettiNo ratings yet

- 18 LCA ConfectioneryDocument20 pages18 LCA ConfectioneryFikrilAzimAbdulSani100% (1)