Professional Documents

Culture Documents

Lantec LH Series Hoists Catalog

Lantec LH Series Hoists Catalog

Uploaded by

Anonymous 1qAH6CKCCopyright:

Available Formats

You might also like

- A Series 1.3 - 2.0t 3-Pivot Electric Forklift Service Manual (CE) 2019.08Document92 pagesA Series 1.3 - 2.0t 3-Pivot Electric Forklift Service Manual (CE) 2019.08roberto_robledo_6No ratings yet

- 6F35 Boletín TécnicoDocument8 pages6F35 Boletín TécnicoReydeEspa1100% (2)

- Manitowoc 4500 - 4665 - Parts ManualDocument280 pagesManitowoc 4500 - 4665 - Parts ManualalbertoNo ratings yet

- Draw WorkDocument5 pagesDraw WorkriobmNo ratings yet

- Komatsu PW200-7K Hydraulic Excavator Service Repair Manual SNK40001 and Up PDFDocument26 pagesKomatsu PW200-7K Hydraulic Excavator Service Repair Manual SNK40001 and Up PDFfhjskemmd83% (6)

- Wilson GearboxDocument7 pagesWilson GearboxSunil AundhekarNo ratings yet

- At 01M OverhaulDocument48 pagesAt 01M OverhaulValerie Bliss100% (10)

- Lantec Hydraulic Winch - LWS430Document46 pagesLantec Hydraulic Winch - LWS430Shag Shaggy100% (1)

- Lantec LW Series Winches Catalog PDFDocument16 pagesLantec LW Series Winches Catalog PDFFareedMohmed100% (1)

- Top Drive 500 TonDocument10 pagesTop Drive 500 TonImanNo ratings yet

- Manual de Panther T8 2013Document347 pagesManual de Panther T8 2013Anonymous Hd32bhqNo ratings yet

- T1689-MV-DELTA-Air-Cooled-Technical Manual Rev-0007Document188 pagesT1689-MV-DELTA-Air-Cooled-Technical Manual Rev-0007MichelleNo ratings yet

- Baby Mait PDFDocument2 pagesBaby Mait PDFChris LuNo ratings yet

- CalibrationDocument2 pagesCalibrationAnonymous 1qAH6CKCNo ratings yet

- Chapter 6 - Johnson Blocks - MetricDocument46 pagesChapter 6 - Johnson Blocks - MetricJc ElectroHidraulicos Sac50% (2)

- TODAS LAS MARCAS Brake BlocksDocument17 pagesTODAS LAS MARCAS Brake BlocksJaime MurilloNo ratings yet

- Mico - Selection Procedures For BrakesDocument4 pagesMico - Selection Procedures For BrakesJenner Volnney Quispe ChataNo ratings yet

- Pump SciDocument78 pagesPump Scieddy ortegaNo ratings yet

- RT 750 - TransmisionDocument21 pagesRT 750 - TransmisionLeydi Martin100% (1)

- RT Drive Device User ManualDocument13 pagesRT Drive Device User ManualJohn SimancaNo ratings yet

- C330 Torque Converter SpecDocument2 pagesC330 Torque Converter SpecTamer Elsebaei EbarhimNo ratings yet

- PGP PGM 500 600 Uk 845Document36 pagesPGP PGM 500 600 Uk 845Jorge Andres PozoNo ratings yet

- 13 - Servo Valve SV 10 - B (Boekwerk)Document36 pages13 - Servo Valve SV 10 - B (Boekwerk)Ivan MaltsevNo ratings yet

- 177 - 178 Vis 40 Vis 45 Char-Lynn Parts Drawing.18162438 PDFDocument59 pages177 - 178 Vis 40 Vis 45 Char-Lynn Parts Drawing.18162438 PDFtrinaNo ratings yet

- 450 Ajp Serie 2Document566 pages450 Ajp Serie 2Edwin CastilloNo ratings yet

- 400HP AC Drilling Motor WL250040 2Document2 pages400HP AC Drilling Motor WL250040 2HayLenLeeNo ratings yet

- Hercules Model 131 Deadline Anchor SpecsDocument2 pagesHercules Model 131 Deadline Anchor SpecsAaron HigginsNo ratings yet

- Parker 2H CylindersDocument26 pagesParker 2H CylindersnitinjainmechNo ratings yet

- Teda Xq140 12a Tubing TongDocument61 pagesTeda Xq140 12a Tubing TongRicardo CabreraNo ratings yet

- TM 10-3950-263-14P-3 140 Ton Crane FMC Link Belt MDL Hc-238a, Mhe-248Document517 pagesTM 10-3950-263-14P-3 140 Ton Crane FMC Link Belt MDL Hc-238a, Mhe-248Advocate100% (2)

- Parts Catalog Cad XM TurkeyDocument202 pagesParts Catalog Cad XM TurkeyNelsonParedesNo ratings yet

- Instruction Sheet: S9800/S9810 Upgrade To S9820Document7 pagesInstruction Sheet: S9800/S9810 Upgrade To S9820fernando2228No ratings yet

- DW402 - Pulidor DewaltDocument3 pagesDW402 - Pulidor DewaltJorge Adalberto Lugo QuinteroNo ratings yet

- Hydraulic Control Valve (W-BICS Valve) - (S-N 5122 20298 & Abv, 5124 40721 & Abv, 5126 12258 & Ab - 763 PDFDocument5 pagesHydraulic Control Valve (W-BICS Valve) - (S-N 5122 20298 & Abv, 5124 40721 & Abv, 5126 12258 & Ab - 763 PDFRomusNo ratings yet

- Grua Terex RT 230-1 XL Datasheet - ImperialDocument22 pagesGrua Terex RT 230-1 XL Datasheet - ImperialjuancarlostNo ratings yet

- DS PF 6000Document2 pagesDS PF 6000Junior Francisco Quijano100% (1)

- Hy11 3302 Uk PDFDocument32 pagesHy11 3302 Uk PDFValbertgNo ratings yet

- Operator Carrier PDFDocument144 pagesOperator Carrier PDFGILMAR NIETONo ratings yet

- Allison Transmission BrochureDocument3 pagesAllison Transmission Brochurem mainNo ratings yet

- H-2 Controlair Valve: Service InformationDocument18 pagesH-2 Controlair Valve: Service InformationRonald LlerenaNo ratings yet

- Cle5500xht Bucd5500 Rev02-08 PDFDocument117 pagesCle5500xht Bucd5500 Rev02-08 PDFedisonabreu89No ratings yet

- Wichita PH D e 0616 PDFDocument92 pagesWichita PH D e 0616 PDFsahidNo ratings yet

- Valvulas GresensvDocument92 pagesValvulas GresensvAnonymous j6WnEH5No ratings yet

- 8487A Oilwell A 1100 PT A 850 PT - 881Document8 pages8487A Oilwell A 1100 PT A 850 PT - 881PSC RFQNo ratings yet

- Каталог системы для подъема ПВО Ingersoll RandDocument44 pagesКаталог системы для подъема ПВО Ingersoll RandSagadat AbdiganiNo ratings yet

- PVG 32 Parts CatalogDocument52 pagesPVG 32 Parts CatalogVipin Gupta75% (4)

- 165T-5 Parts ListDocument26 pages165T-5 Parts ListJorge Luis Galezo MuñozNo ratings yet

- Bomba Denison Serie PremierDocument50 pagesBomba Denison Serie Premiergineslopezruiz100% (1)

- Ball Base 12.0 20.0: Letourneau Technologies™Document1 pageBall Base 12.0 20.0: Letourneau Technologies™Mikel1020No ratings yet

- Axle: 4. AXLE (ZF, Machine Serial No.: #0080-)Document49 pagesAxle: 4. AXLE (ZF, Machine Serial No.: #0080-)mohamed omerNo ratings yet

- Sandwich Valve - Parker PDFDocument91 pagesSandwich Valve - Parker PDFArjed Ali ShaikhNo ratings yet

- 005 Joystick 2Document8 pages005 Joystick 2JonathanDavidDeLosSantosAdornoNo ratings yet

- 04 427Document2 pages04 427Eng-Mohammed Salem100% (1)

- Hydrolink General Product CatalogueDocument17 pagesHydrolink General Product CatalogueMarcoAlbaNo ratings yet

- Bowex enDocument32 pagesBowex enTimon2005No ratings yet

- LIT2103 R6 PD12C 15B 17A Service ManualDocument40 pagesLIT2103 R6 PD12C 15B 17A Service ManualAlex Parampampam100% (2)

- 150 Ton Link Belt LS 238HSpecsDocument6 pages150 Ton Link Belt LS 238HSpecsYosses Sang Nahkoda0% (1)

- Braden Winch CH 230-2Document2 pagesBraden Winch CH 230-2wessamalexNo ratings yet

- Solenoid Valve Mini Catalog PDFDocument255 pagesSolenoid Valve Mini Catalog PDFCh Jameel SidhuNo ratings yet

- NOV Blak Jak RemovalDocument2 pagesNOV Blak Jak RemovalddiazveNo ratings yet

- Filtro Separador de Agua 900fhDocument2 pagesFiltro Separador de Agua 900fhale alvarezNo ratings yet

- Eaton MotorDocument59 pagesEaton MotorVinod Kumar BhargavNo ratings yet

- Steering StabilisationDocument24 pagesSteering StabilisationRooftop Gardener100% (1)

- Muncie Power Product BrochureDocument12 pagesMuncie Power Product Brochurewrath_of_marsNo ratings yet

- Controllable Pitch PropelleDocument12 pagesControllable Pitch PropelleJoshua SanchezNo ratings yet

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Letter For CE ClientsDocument1 pageLetter For CE ClientsAnonymous 1qAH6CKCNo ratings yet

- Program Winch Teardown - 21-9-15Document11 pagesProgram Winch Teardown - 21-9-15Anonymous 1qAH6CKCNo ratings yet

- Service ReportsDocument1 pageService ReportsAnonymous 1qAH6CKCNo ratings yet

- Cpe Post MeetingDocument2 pagesCpe Post MeetingAnonymous 1qAH6CKCNo ratings yet

- Corning Gorilla Glass: Technical MaterialsDocument2 pagesCorning Gorilla Glass: Technical MaterialsAnonymous 1qAH6CKCNo ratings yet

- Schneider ContactorDocument3 pagesSchneider ContactorAnonymous 1qAH6CKCNo ratings yet

- Program - Winch Tear DownDocument11 pagesProgram - Winch Tear DownAnonymous 1qAH6CKCNo ratings yet

- Version - 2.0 Page - 1 - of - 14 Weights - and - Capacities - in - Metric - Tonnes, - Dimensions - in - Meters. - For - Reference - Only.Document14 pagesVersion - 2.0 Page - 1 - of - 14 Weights - and - Capacities - in - Metric - Tonnes, - Dimensions - in - Meters. - For - Reference - Only.Anonymous 1qAH6CKCNo ratings yet

- SKF Composite Plain Bearings - 11004 EN - TCM - 12-107917 PDFDocument60 pagesSKF Composite Plain Bearings - 11004 EN - TCM - 12-107917 PDFAnonymous 1qAH6CKCNo ratings yet

- HoistDocument4 pagesHoistAnonymous 1qAH6CKCNo ratings yet

- Re 07700Document2 pagesRe 07700Ahmed Abd ElhakeemNo ratings yet

- Re 07100Document2 pagesRe 07100Anonymous 1qAH6CKCNo ratings yet

- The Antikythera Mechanism and The Early History of The MoonDocument11 pagesThe Antikythera Mechanism and The Early History of The MoonAtlantisPapersNo ratings yet

- 7495HD Pala Eléctrica de Cable CaterpillarDocument3 pages7495HD Pala Eléctrica de Cable CaterpillarJose Manuel Camacho GallegosNo ratings yet

- Cletrac Controlled Differential Steering SystemDocument10 pagesCletrac Controlled Differential Steering SystemGreggs ShopukNo ratings yet

- Maxon GP 32 HPDocument1 pageMaxon GP 32 HPElectromateNo ratings yet

- Auto Transmission A425e PDFDocument96 pagesAuto Transmission A425e PDFtony100% (1)

- AE2201 2marks PDFDocument30 pagesAE2201 2marks PDFSathis KumarNo ratings yet

- For Full Explanations of All These Questions, and For Many More New and Up-To-Date Questions, With Correct Answers, Full Explanations, Downloadable Material and Tutorial Support, Please VisitDocument43 pagesFor Full Explanations of All These Questions, and For Many More New and Up-To-Date Questions, With Correct Answers, Full Explanations, Downloadable Material and Tutorial Support, Please Visitariesguy_86No ratings yet

- Transmission atDocument47 pagesTransmission atDidier ÁlvarezNo ratings yet

- Final - Chain Drive & TyresDocument11 pagesFinal - Chain Drive & TyresMahmoud MohsenNo ratings yet

- MD31.1 FLENDER SIP Standard Industrie Planetengetriebe enDocument68 pagesMD31.1 FLENDER SIP Standard Industrie Planetengetriebe enJoshua PorterNo ratings yet

- Schaffler FAG Bearings Tpi 008 de enDocument116 pagesSchaffler FAG Bearings Tpi 008 de enjohn kasichNo ratings yet

- Maxon GP 22 MDocument1 pageMaxon GP 22 MElectromateNo ratings yet

- Shimano Nexus Inter-7 - Coaster - BrakeDocument12 pagesShimano Nexus Inter-7 - Coaster - BrakeGeorge OrfanidisNo ratings yet

- Differential Functions Parts Woking Advantages Disadvantages and Applications PDFDocument6 pagesDifferential Functions Parts Woking Advantages Disadvantages and Applications PDFRohan ModhNo ratings yet

- Planetary Gear Box FailureDocument13 pagesPlanetary Gear Box Failuretsrinivasan5083No ratings yet

- Motorreductores SEW-EurodriveDocument110 pagesMotorreductores SEW-EurodriveJavier Carrillo MdezNo ratings yet

- Tourbillon Mechanica Assembly Guide MQ Dec 30Document38 pagesTourbillon Mechanica Assembly Guide MQ Dec 30darkandmellowNo ratings yet

- r3 Forecast Oli Aceh 2021Document31 pagesr3 Forecast Oli Aceh 2021ArifinNo ratings yet

- ODF-2 - Learning MaterialDocument24 pagesODF-2 - Learning MateriallevychafsNo ratings yet

- Dynamic Characteristics of Epicyclic Gear SystemDocument77 pagesDynamic Characteristics of Epicyclic Gear Systemkaajemaina195No ratings yet

- Prabhu T. - Automobile Engineering. Basic Fundamentals. Basic Fundamentals To Advanced Concepts of Automobile Engineering (2021, Nestfame Creations Pvt. LTD.) - Libgen - LiDocument1,377 pagesPrabhu T. - Automobile Engineering. Basic Fundamentals. Basic Fundamentals To Advanced Concepts of Automobile Engineering (2021, Nestfame Creations Pvt. LTD.) - Libgen - Livivek panchalNo ratings yet

- Hyundai Santa Fe 2006 Auto TransaxleDocument194 pagesHyundai Santa Fe 2006 Auto Transaxlebravo6d78% (9)

- Gnanamani College of TechnologyDocument15 pagesGnanamani College of TechnologyRajueswarNo ratings yet

- Final Drive AssemblyDocument118 pagesFinal Drive AssemblyKARTHICKRAJ KANDASAMYNo ratings yet

- AUTOMOBILEDocument14 pagesAUTOMOBILEabhinandsofficialNo ratings yet

Lantec LH Series Hoists Catalog

Lantec LH Series Hoists Catalog

Uploaded by

Anonymous 1qAH6CKCOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lantec LH Series Hoists Catalog

Lantec LH Series Hoists Catalog

Uploaded by

Anonymous 1qAH6CKCCopyright:

Available Formats

LANTEC

LH Series Hoists

A ModuLAr Line of hydrAuLic hoists

Line pulls from 15,000 lb to 72,000 lb

LANTEC

Winch & Gear Inc.

Gear Drives Winches & hoists Brakes & clutches

Driven to Excellence

LANTEC

LH Series Hoists

this catalogue contains detailed sales information on the lantec lh series hoists. A M o duL Ar L i ne of With more than 10 basic models, a modular design and flexible input options, lantec lh series hoists suit many applications.

hydrAuL i c

hoi sts

Experience

lantec. recognized

Reliability

Our low warranty cost is the envy of the hoist industry and is a testament to our rugged, reliable design.

modula

reliability versatility quality

worldwide for providing highly dependable hoists and planetary drives for the most demanding applications. over forty years of technical know-how and application experience are brought together with state-of-the-art manufacturing techniques to produce the ultimate in hoist reliability, versatility and quality.

Fast, dependable delivery with competitive pricing. lantec is responding to our customer needs for minimal inventory and ever shorter lead times.

lantec Winch & Gear is a part of tWG, a global leader in standard and engineered winch, gearbox and load information systems.

construction

lantec lh series hoists

the lantec lh series hoists are a compact modular construction consisting of:

house the planetary reduction gearing and friction brake within the large diameter

technical description

Cable Drum Steel cable drum running on rolling bearings. Drum seals run on corrosion resistant seats. Cable is anchored to the drum using the industry accepted method of a wedge and a tapered pocket. Drum includes a No-Spill oil change feature for clean and fast oil changes without special tools.

drum barrel providing for a very compact design and long cable life. this series is suitable for most crane and

Hoist Base High-strength nodular iron base components designed for maximum rigidity and easy assembly.

lifting applications requiring at least an 18:1 D:d ratio (First layer pitch diameter: cable diameter).

Drive Module Pre-packaged two- or three-stage, high-efficiency planetary drive with hardened internal gears and case carburized sun and planet gears. Planet gears run on rolling bearings which are replaceable independent of the gear itself. Sun gears float to ensure balanced load distribution.

For applications that DO NOT require drums with a large D:d ratio consider the more economical LANTEC LW

Brake Module Multi-disc, wet friction brake is spring force applied, hydraulic pressure released. Overrunning clutch is large diameter, high-capacity, sprag type. Brake module is standard with SAE C or D motor mount. Optional motor mounts are available.

Series Winches available with smaller drum barrels and the planetary reduction gearing and friction brake located external to the drum. A wide

Hydraulic Motor Standard motor is a durable gear motor designed specifically for hoisting applications with improved starting torque characteristics. LH Series Hoists can be fitted with other motor types including 2-speed gear motors, axial and radial piston motors, and motors for low power systems.

range of models and drum sizes are available. Please see separate brochure.

Brake Valve Industrys most stable and reliable counterbalance valve attached directly to the hydraulic motor.

lantec lh series hoists are available with single or dual drives. Dual drives have two motors, two brakes, and two drive modules, for high-horsepower capability.

brake operation

When hoisting, the Multi-disc Brake remains applied with the hydraulic motor driving directly into the gear reduction, through an overrunning clutch. When hoisting stops, the overrunning clutch locks the input shaft to the already applied Multi-disc Brake ensuring no backdrop of the load. When lowering, the hydraulic motor is pressurized for the lowering rotation. This pressure is also applied to the Multi-disc Brake, releasing it fully. The Brake Valve then controls load lowering in response to operator demand. When the operator intends to stop, the main control valve is moved to neutral, the lowering pressure diminishes, the Brake Valve closes to stop the load, and the Multi-disc Brake applies as a parking brake to positively hold the load.

While LANTEC LH Series Hoists are generally NOT intended for personnel handling, special configurations are available for use on offshore cranes operated under the provisions of American Petroleum Institute (API) Specification 2C. Please consult factory. 1

LANTEC

LH Series Hoists

features

typical Lh series hoist

Features

High-strength nodular iron base components Oil level sight gauge for reliable and convenient fluid level monitoring Corrosion resistant seal running surfaces for marine duty dependability High-capacity rolling bearings for long, trouble-free life with minimum maintenance Built-in No-Spill oil drain system for clean and fast oil changes no special tools required Planet gear rolling bearings replaceable independent of the gear itself for lower cost rebuilds High-efficiency planetary gearing for optimum performance Multi-disc Brake spring force applied and hydraulic pressure released for positive load holding Large diameter, high-capacity, sprag type, overrunning clutch for reliable engagement and long life SAE C or D motor mounts to accept a wide variety of motors Standard gear motor for durability Optional 2-speed gear motor for faster light-load speeds Optional high-efficiency piston motors to match high-pressure hydraulic systems and achieve optimum hoist performance Brake Valve for controlled lowering and high energy transfer rate Many models have mounting dimensions directly interchangeable with competitive brands

features

Many Options and Accessories are available to meet your most demanding applications. Refer to page 4.

LANTEC

LH Series Hoists

lantec lh series hoists are available with a wide variety of optional configurations and accessories to create the hoist that meets all your needs.

options & Accessories

options & accessories

4

Drum Configurations Beyond the range of standard drums, LANTEC offers: Alternate drum sizes to match your cable storage requirements Additional cable anchors for multiple cable or On-Off applications Drum divider for multiple cable applications Grooved drums with spiral grooving LeBus parallel groove drum sleeves

Optional Gear Ratios LANTEC offers optional gear ratios to permit the most economical matching of performance requirements with motor performance.

Hydraulic Motor LANTEC supplies the hoist with a hydraulic motor that matches the customers hydraulic system to provide optimum performance. Hoists are also available without motors for customers who prefer to supply their own.

Motor Mounting Configurations LANTEC provides either an SAE C or D motor mount. Other motor mounting configurations are available to support most hydraulic motors including DIN and ISO standards.

Ratchet & Pawl LANTEC offers a spring engaged, hydraulic pressure released ratchet and pawl package. Ratchet and pawl kits for field installation are also available.

Multi-disc Brake LANTEC includes a standard multi-disc, friction brake with a sprag type, overrunning clutch for hoisting applications. The brake is available without the overrunning clutch for applications requiring a brake effective in both directions, such as slewing or positioning.

Drum Brake LANTEC offers a friction brake acting directly on the drum.

Drum Pressure Roller LANTEC provides a roller, forced into contact with the cable on the drum by adjustable springs to assist with proper cable spooling. This option is also available with sensors indicating top and bottom layer conditions.

Encoder Drive LANTEC offers a light duty output shaft for driving a rotary encoder to monitor hoist drum speed and/or position.

Coatings LANTEC provides Marine Epoxy and other special coatings.

personnel handling rating

While LANTEC LH Series Hoists are generally NOT intended for personnel handling, special configurations are available for use on offshore cranes operated under the provisions of American Petroleum Institute (API) Specification 2C. Please consult factory.

LeBus and the Grooved Sleeve design are Registered Trademarks of LeBus International Inc.

LANTEC

LH Series Hoists

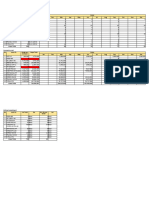

cable drum capacities

This chart shows the estimated gross cable capacity (feet) of the drum, assuming proper spooling. No allowance has been made for dead wraps (mandatory minimum of 5 dead wraps of cable to be left on the drum at all times). Allowance has been made for free flange or free board according to API-2C requiring that the flange extend a minimum of 1/2" over the top layer of rope at all times. LANTEC is pleased to provide a layer-by-layer drum capacity chart upon request.

Model

Drum Dimensions (in)

Drum Number Barrel Diameter Flange Diameter Between Flanges

Nominal Wire Rope Diameter (in)

1/2 1,402 1,897 880 1,113 5/8 866 1,172 613 776 1,407 2,252 645 873 3/4 623 843 426 539 1,038 1,662 427 578 1,894 3,002 763 1,221 376 509 1,458 2,310 1,082 1,728 942 1,504 2,210 1,116 1,769 975 1,557 844 1,348 1,979 975 1,557 844 1,348 1,979 897 2,026 2,619 4,002 4,970 594 1,334 1,725 2,890 3,589 494 944 1,172 2,333 2,896 523 1,007 1,302 2,042 2,536 275 640 795 1,795 2,229 756 1,120 1,923 2,192 3,261 334 750 970 1,626 2,019 244 573 711 1,374 1,707 673 996 1,472 1,678 2,497 1,286 1,917 1,668 1,907 2,857 220 371 461 1,037 1,287 386 571 1,110 1,266 1,883 897 1,338 1,260 1,440 2,158 897 1,440 2,056 3,088 2,738 351 520 816 930 1,384 823 1,227 1,163 1,330 1,993 823 1,330 1,606 2,412 2,217 543 810 863 986 1,478 543 986 1,231 1,849 1,778 505 924 1,157 1,737 1,405 712 1,137 589 941 1,381 712 1,137 589 941 1,381 7/8 1 1 1/8 1 1/4 1 3/8 1 1/2

Lhs100

01 02 01 02 01 02 01 02 01 02 01 02 03 04 05 01 02 03 04 05 01 02 03 04 05 01 02 03 04 05 01 02 03 04 05 01 02 03 04 05 01 02 03 04 05

13.00 13.00 11.50 11.50 16.00 16.00 15.00 15.00 18.00 18.00 20.00 20.00 22.00 22.00 22.00 20.00 20.00 22.00 22.00 22.00 15.00 14.00 14.00 14.00 14.00 17.00 18.00 18.00 18.00 18.00 20.00 20.00 18.00 18.00 18.00 22.00 22.00 22.00 22.00 22.00 22.00 22.00 22.00 22.00 22.00

23.00 23.00 20.00 20.00 27.50 27.50 23.00 23.00 33.00 33.00 33.00 33.00 33.00 33.00 33.00 33.00 33.00 33.00 33.00 33.00 23.00 27.50 27.50 33.00 33.00 23.00 27.50 27.50 33.00 33.00 27.50 27.50 33.00 33.00 33.00 33.00 33.00 38.00 38.00 38.00 33.00 38.00 42.00 42.00 46.00

17.00 23.00 16.00 20.25 20.00 32.00 17.00 23.00 24.38 38.62 23.88 38.13 23.88 38.13 56.00 23.88 38.13 23.88 38.13 56.00 23.63 23.88 30.88 30.00 37.25 24.50 24.88 30.88 30.00 37.25 37.25 55.13 32.13 36.63 54.50 36.38 54.25 31.38 35.88 53.75 36.38 35.88 35.63 53.50 35.38

cable drum capacities

Lhs110 Lhs160 Lhs170 Lhs240

Lhs330

540 862 1,267

Lhs430

540 862 1,267

Lhd200

Lhd310

Lhd450

Lhd670

Lhd840

Important Note: Some drum and cable combinations may not meet an 18:1 D:d requirement.

Estimated Gross Cable Capacity (ft)

Consult Factory

Not Available

LANTEC

LH Series Hoists

Performance

Model

Drum Number

This table shows the basic hoist performance data and limitations based on the standard gear ratio and motor for each model. Considering the wide variety of hoist sizes, gear ratios, hydraulic motor characteristics and hydraulic system performance, the hoist selection process can become complex.

Drum Size

Barrel Diameter in Flange Diameter in 1st Layer lb

Line Pull

(Maximum)

Mid Layer lb

(Maximum Allowable)

Top Layer lb 1st Layer fpm Mid Layer fpm Top Layer fpm

Line Speed

(Maximum with Standard Motor)

1st Layer fpm Mid Layer fpm Top Layer fpm

Line Speed

Single Drive Lhs100 Lhs110 Lhs160 Lhs170 Lhs240 Lhs330 01 & 02 01 & 02 01 & 02 01 & 02 01 & 02 01 & 02 03, 04, 05 01 & 02 03, 04, 05 13.00 11.50 16.00 15.00 18.00 20.00 22.00 20.00 22.00 23.00 20.00 27.50 23.00 33.00 33.00 33.00 33.00 33.00 15,000 16,700 18,700 19,800 24,100 32,000 26,200 40,000 36,500 12,200 13,900 15,500 17,600 19,400 27,300 25,800 33,600 31,800 9,400 11,000 12,300 15,400 14,700 22,600 22,400 27,100 27,100 481 432 387 367 294 222 243 178 194 624 544 489 419 388 269 280 220 228 767 655 591 471 482 315 317 262 262 414 372 332 315 253 190 209 153 167 537 468 420 360 334 230 241 189 196 659 563 507 405 414 270 273 225 225

Lhs430

Dual Drive Lhd200 01 02 & 03 04 & 05 01 02 & 03 04 & 05 01 & 02 03, 04, 05 01 & 02 03, 04, 05 15.00 14.00 14.00 17.00 18.00 18.00 20.00 18.00 22.00 22.00 23.00 27.50 33.00 23.00 27.50 33.00 27.50 33.00 33.00 38.00 25,800 27,500 27,500 34,800 33,000 33,000 43,100 47,700 57,800 57,800 22,900 21,800 20,300 33,300 29,400 26,500 39,700 38,500 51,300 48,400 20,000 16,100 13,000 31,700 25,800 20,000 36,200 29,200 44,700 38,900 562 526 526 416 439 439 329 298 246 246 642 714 821 437 500 582 361 392 282 306 722 901 1,115 457 561 724 392 486 317 365 483 452 452 357 377 377 283 256 211 211 552 613 705 375 430 500 310 337 242 263 621 774 958 392 482 622 337 417 273 314

performance

Lhd310

Lhd450

Lhd670

Lhd840

01 02 03 & 04 05

22.00 22.00 22.00 22.00

33.00 38.00 42.00 46.00

72,200 72,200 72,200 72,200

63,400 59,600 58,100 55,500

54,600 47,000 43,900 38,800

197 197 197 197

229 250 260 282

260 302 323 366

169 169 169 169

196 215 224 242

223 260 278 314

LANTEC reserves the right to revise performance figures without prior notice due to further development and technical improvements.

LANTEC recommends allowing our Sales & Application Engineering professionals to assist in determining the hoist model and options that satisfy your most demanding applications. LANTEC will be pleased to supply a detailed specification sheet specifically for your application.

Basic Output Data

Drum Torque Maximum lb-in Drum Speed Maximum Allowable rpm Drum Speed Maximum with Standard Motor rpm

Basic Input Data

Standard Gear Ratio Input Torque Maximum Allowable lb-in Input Speed Maximum Allowable rpm Standard Motor Maximum Speed rpm

Hydraulic Supply Required with Standard Motor

Standard Motor Displacement in 3 Pressure Required (Run) psi(d) Pressure Required (Start) psi(d) Flow Required at Maximum Speed gpm Minimum Flow Required for Smooth Performance gpm Recommended Minimum Flow gpm

101,500 101,500 155,600 155,600

226,400

136 136 89 89 60 41 41 32 32

117 117 76 76 51 35 35 28 28

23.49 23.49 36.00 36.00 53.46 78.91 78.91 99.10 99.10

4,500 4,500 4,500 4,500 4,500 4,500 4,500 4,500 4,500

3,200 3,200 3,200 3,200 3,200 3,200 3,200 3,200 3,200

2,750 2,750 2,750 2,750 2,750 2,750 2,750 2,750 2,750

12.30 12.30 12.30 12.30 12.30 12.30 12.30 12.30 12.30

2,500 2,500 2,500 2,500 2,500 2,500 2,500 2,500 2,500

2,870 2,870 2,870 2,870 2,870 2,870 2,870 2,870 2,870

150 150 150 150 150 150 150 150 150

28 28 28 28 28 28 28 28 28

50 50 50 50 50 50 50 50 50

334,200 334,200 419,700 419,700

203,000 203,000 203,000 311,200 311,200 311,200 452,800 452,800 668,400 668,400

136 136 136 89 89 89 60 60 41 41

117 117 117 76 76 76 51 51 35 35

23.49 23.49 23.49 36.00 36.00 36.00 53.46 53.46 78.91 78.91

4,500 4,500 4,500 4,500 4,500 4,500 4,500 4,500 4,500 4,500

3,200 3,200 3,200 3,200 3,200 3,200 3,200 3,200 3,200 3,200

2,750 2,750 2,750 2,750 2,750 2,750 2,750 2,750 2,750 2,750

12.30 12.30 12.30 12.30 12.30 12.30 12.30 12.30 12.30 12.30

2,500 2,500 2,500 2,500 2,500 2,500 2,500 2,500 2,500 2,500

2,870 2,870 2,870 2,870 2,870 2,870 2,870 2,870 2,870 2,870

300 300 300 300 300 300 300 300 300 300

56 56 56 56 56 56 56 56 56 56

100 100 100 100 100 100 100 100 100 100

839,400 839,400 839,400 839,400

32 32 32 32

28 28 28 28

99.10 99.10 99.10 99.10

4,500 4,500 4,500 4,500

3,200 3,200 3,200 3,200

2,750 2,750 2,750 2,750

12.30 12.30 12.30 12.30

2,500 2,500 2,500 2,500

2,870 2,870 2,870 2,870

300 300 300 300

56 56 56 56

100 100 100 100

LANTEC

LH Series Hoists

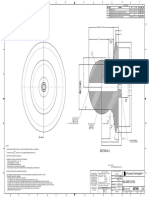

dimensional data LHS Series Single Drive

Barrel Diameter A Flange Diameter B

The dimensions shown are for general information. Only a detailed Certified Installation Drawing, specific to your hoist, should be used for final installation dimensions. Certified Installation Drawings are available from LANTEC upon request.

Many models have mounting dimensions directly interchangeable with competitive brands.

Mounting Hole Diameter L

Model

drum number

Between Flanges C

Mounting Holes D

Length E

Mounting Offest F

Height G

Height to Center H

Mounting Holes J

Width K

LHS Series Single Drive Lhs100 Lhs110 Lhs160 Lhs170 Lhs240 01 02 01 02 01 02 01 02 01 02 01 02 03 04 05 01 02 03 04 05 13.00 13.00 11.50 11.50 16.00 16.00 15.00 15.00 18.00 18.00 20.00 20.00 22.00 22.00 22.00 20.00 20.00 22.00 22.00 22.00 23.00 23.00 20.00 20.00 27.50 27.50 23.00 23.00 33.00 33.00 33.00 33.00 33.00 33.00 33.00 33.00 33.00 33.00 33.00 33.00 17.00 32.00 16.00 20.25 20.00 32.00 17.00 23.00 24.36 38.61 23.88 38.18 23.88 38.13 56.00 23.88 38.18 23.88 38.13 56.00 23.50 29.50 21.50 25.75 26.38 38.38 23.50 29.50 34.29 48.54 34.29 48.54 34.29 48.54 66.41 34.29 48.54 34.29 48.54 66.41 38.26 44.26 36.50 40.75 40.83 52.83 38.26 44.26 47.72 62.00 47.72 62.00 47.72 62.00 79.84 47.72 62.00 47.72 62.00 79.84

All dimensions are in inches.

13.51 13.51 13.81 13.81 13.14 13.14 13.51 13.51 11.93 11.93 11.93 11.93 11.93 11.93 11.93 11.93 11.93 11.93 11.93 11.93

23.50 23.50 20.50 20.50 28.00 28.00 23.50 23.50 33.50 33.50 33.50 33.50 33.50 33.50 33.50 33.50 33.50 33.50 33.50 33.50

12.00 12.00 10.50 10.50 14.25 14.25 12.00 12.00 17.00 17.00 17.00 17.00 17.00 17.00 17.00 17.00 17.00 17.00 17.00 17.00

14.75 14.75 13.25 13.25 21.00 21.00 14.75 14.75 20.00 20.00 20.00 20.00 20.00 20.00 20.00 20.00 20.00 20.00 20.00 20.00

27.00 27.00 24.00 24.00 31.50 31.50 27.00 27.00 37.00 37.00 37.00 37.00 37.00 37.00 37.00 37.00 37.00 37.00 37.00 37.00

1.31 1.31 1.06 1.06 1.06 1.06 1.31 1.31 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38

Lhs330

Lhs430

single drive

C A B G

diagram LHS Series

D E

L MOUNTING HOLES (4 PLACES)

J K

Specifications subject to change without notice and without incurring obligation. Rely only on a Certified Installation Drawing for accurate and current dimensions.

Dimensions E and F are based on the Standard Motor. Length will vary with optional motors.

LANTEC

LH Series Hoists

dimensional data LHD Series Dual Drive

Barrel Diameter A Flange Diameter B

The dimensions shown are for general information. Only a detailed Certified Installation Drawing, specific to your hoist, should be used for final installation dimensions. Certified Installation Drawings are available from LANTEC upon request.

Model

drum number

Between Flanges C

Mounting Holes D

Length E

Mounting Offest F

Height G

Height to Center H

Mounting Holes J

Width K

Mounting Hole Diameter L

LHS Series Dual Drive Lhs200 01 02 03 04 05 01 02 03 04 05 01 02 03 04 05 01 02 03 04 05 01 02 03 04 05 15.00 14.00 14.00 14.00 14.00 17.00 18.00 18.00 18.00 18.00 20.00 20.00 18.00 18.00 18.00 22.00 22.00 22.00 22.00 22.00 22.00 22.00 22.00 22.00 22.00 23.00 27.50 27.50 33.00 33.00 23.00 27.50 27.50 33.00 33.00 27.50 27.50 33.00 33.00 33.00 33.00 33.00 38.00 38.00 38.00 33.00 38.00 42.00 42.00 46.00 23.63 23.88 30.88 30.00 37.25 24.50 24.88 30.88 30.00 37.25 37.25 55.13 32.13 36.63 54.50 36.38 54.25 31.38 35.88 53.75 36.38 35.88 35.63 53.50 35.38 33.13 32.75 39.75 37.40 44.65 33.88 34.25 40.25 41.79 49.04 51.75 69.63 46.63 51.13 69.00 50.88 68.75 45.88 50.38 68.25 50.41 50.88 51.63 69.50 51.38 57.85 56.97 63.97 59.20 66.45 58.10 58.47 64.47 63.59 70.84 77.61 95.49 72.49 76.99 94.86 76.74 94.61 71.74 76.24 94.11 72.21 76.74 77.49 95.36 77.24

All dimensions are in inches.

12.36 12.11 12.11 10.90 10.90 12.11 12.11 12.11 10.90 10.90 12.93 12.93 12.93 12.93 12.93 12.93 12.93 12.93 12.93 12.93 10.90 12.93 12.93 12.93 12.93

23.38 28.00 28.00 33.50 33.50 25.75 28.00 28.00 33.50 33.50 29.75 29.75 35.25 35.25 35.25 35.25 35.25 40.25 40.25 40.25 33.50 40.25 46.25 46.25 52.25

11.88 14.25 14.25 17.00 17.00 14.25 14.25 14.25 17.00 17.00 16.00 16.00 18.75 18.75 18.75 18.75 18.75 21.25 21.25 21.25 17.00 21.25 25.25 25.25 29.25

14.75 21.00 21.00 20.00 20.00 21.00 21.00 21.00 20.00 20.00 8 Bolts Consult Factory

27.00 31.25 31.25 36.75 36.75 31.25 31.25 31.25 36.75 36.75 34.50 34.50 40.00 40.00 40.00 40.00 40.00 45.00 45.00 45.00 36.75 45.00 49.00 49.00 53.00

1.06 1.06 1.06 1.38 1.38 1.06 1.31 1.06 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38 1.38

Lhs310

Lhs450

Lhs670

8 Bolts Consult Factory 20.00 8 Bolts Consult Factory

Lhs840

dual drive

C A B

diagram LHS Series

H

F

D E

L MOUNTING HOLES (4 PLACES)

J K

Specifications subject to change without notice and without incurring obligation. Rely only on a Certified Installation Drawing for accurate and current dimensions.

Dimensions E and F are based on the Standard Motor. Length will vary with optional motors.

LANTEC

LH Series Hoists

Motor selection

standard Motor

lantec lh series hoists utilize a gear motor designed for performance characteristics specifically suited to hoist applications. this is a time-proven and very durable hydraulic motor suited to most applications.

For high-pressure hydraulic systems on mobile or offshore cranes and equipment employing piston pumps and high-grade system 2-speed Motor components, we offer lh series hoists with sae c or D motor mounting configurations.

lantec can supply the hoist with a variety

motor selection

of motor types and sizes to best match your system configuration and performance needs. Piston fixed displacement

some crane and equipment manufacturers prefer to retain complete system responsibility. therefore, we also offer the lh series hoist shipped from the factory without a motor. this allows the customer to supply the Motor and Brake valve that best suits the application.

Piston Variable displacement

LANTEC Sales & Application Engineering professionals are pleased to assist customers with appropriate motor selection.

10

LANTEC

LH Series Hoists

Model Code Example

Model code description

Basic

ModeL code eXAMPLe

Lhs160A - 36.00 - 01 - 16.00 - 27.50 - 20.00 - cc - c4 - 14c - G - 12.30 - B - X

The above code is an example of the alpha-numeric designation given to an LH Series Hoist that has certain specifications. This is broken down below to explain the meaning of each designation and to describe the various possible specifications for the LH Series Hoist.

Drum A 36.00

Motor

Options X

160

- 01 - 16.00 - 27.50 - 20.00 - cc - c4 - 14c - G - 12.30 - B -

L series hoist

L h s 100 110 160 170 240

Gears internal to drum

drum rotation hoisting Counter Clockwise as Viewed from Motor End Clockwise as Viewed from Motor End

cc Std cW

single Motor input

Basic size

330

430

Gear ratio 23.49 Std 23.49 Std 36.00 Std 30.38 Opt 36.00 Std 30.38 Opt 53.46 Std 60.60 Opt 48.17 Opt 78.91 Std 99.10 Opt 87.49 Opt 69.64 Opt 62.79 Opt 99.10 Std 87.49 Opt 78.91 Opt 69.64 Opt 62.79 Opt

Motor flange type SAE B 2-Bolt (SAE J744 ID 101-2) SAE B 4-Bolt (SAE J744 ID 101-4) SAE C 2-Bolt (SAE J744 ID 127-2) SAE C 4-Bolt (SAE J744 ID 127-4) SAE D 2-Bolt (SAE J744 ID 152-2) SAE D 4-Bolt (SAE J744 ID 152-4)

B2 B4 c2 c4 d2 d4

Motor shaft type 13 Tooth 16/32 (SAE J744 ID 22-4) 15 Tooth 16/32 (SAE J744 ID 25-4) 14 Tooth 12/24 (SAE J744 ID 32-4) 17 Tooth 12/24 (SAE J744 ID 38-4) 13 Tooth 8/16 (SAE J744 ID 44-4)

13B 15B 14c 17c 13d

Motor type No Motor Gear Motor 2-Speed Gear Motor Piston Motor Vane Motor Geroter/Geroler Motor

X G M P V r

dual Motor input

d 200 310 450 Gear ratio 23.49 Std 36.00 Std 30.38 Opt 53.46 Std 60.60 Opt 48.17 Opt 78.91 Std 99.10 Opt 87.49 Opt 69.64 Opt 62.79 Opt 99.10 Std 87.49 Opt 78.91 Opt 69.64 Opt 62.79 Opt Motor displacement No Motor Motor Displacement (cu in) X 00.00

Basic size

model code

670

Brake Valve No Brake Valve 1.50" Port Special

X B s

optional equipment Separate each entry by dash No Options Grooved Drum Ratchet & Pawl Drum Brake Spring Applied / Hyd Release Drum Pressure Roller Encoder Drive LANTEC Standard Coating Enamel Machinery Primer Only Marine Epoxy X 00.00 in 00.00 in 00.00 in Personnel Handling Offshore Crane Applications ONLY

Includes configuration for testing and inspection per API-2C

X Gd rP dB dr ed <Blank> cP cM APi

840

design Version designator Original

drum number Drum Number if Designated No Drum Number Designated

drum Barrel diameter

drum flange diameter

Between flanges

11

LANTEC

LH Series Hoists

parts

lantec stocks all wear parts for quick shipment to any location world wide. expedited parts service is available for same day shipment if ordered by 11:00 am (Pst). our Parts professionals work hard to ensure you receive the correct parts for your hoist. When a hoist serial number is provided with your order, we cross-check to ensure you have ordered the right parts for the job.

Parts service installation

service

lantec provides in-factory service of your hoist including visual inspection, magnetic particle inspection, re-certification, rebuild, testing and re-coating. Factory authorized service centers are conveniently located with factory-trained service personnel to perform troubleshooting, inspection and service.

LANTEC LH Series Hoists must be installed in strict accordance with our written installation instructions. The hoist must be connected to a suitable hydraulic power supply. Caution: these circuits are for illustration purposes only and may not contain all components required for full system function.

Hoist Assembly (Supplied by LANTEC) (Supplied by LANTEC) Hoist Assembly Hoist Assembly (Supplied by LANTEC) (Supplied by LANTEC) Hoist Assembly Hoist Friction Brake Hoist Friction Brake

installation

Typical Hydraulic Circuit for Standard Motor

Hoist Friction Brake

Hoist Friction Brake

Hoist Motor

Hoist Motor

Hoist Brake Valve

Hoist Brake Valve

Typical Hydraulic Circuit for 2-Speed Motor

Hoist Motor

Hoist Motor

Hoist Brake Valve

Hoist Brake Valve

Control Valve

Control Valve

Control Valve

Control Valve

Pump

Pump Relief Valve Relief Valve

Pump

Pump Relief Valve Relief Valve

12

Application data sheet

Maximum Line Pull Required Condition for Maximum Pull Requirement Line Speed Required Condition for Line Speed Requirement Cable (Wire Rope) Size Length of Cable on Drum What is the maximum line pull required at the drum for the application? This should take into account the basic payload weight, cable weight, tackle weight, parts of line, sheave efficiency, load dynamics, load acceleration/deceleration time, etc. Is this maximum line pull required on the top layer, mid (mean) layer, or first layer? This varies between applications, however most crane hoists require the maximum pull capability on all layers, thus the top layer is specified in that case. What is the line speed required at the drum for the application? This should take into account the parts of line. 1st Layer Mid Layer Top Layer 1st Layer Mid Layer Top Layer

lb ton kg tonne

Check One

fpm m/min

Is this line speed required on the top layer, mid (mean) layer, or first layer?

Check One

Select the appropriate cable size for the application. This selection should consider the maximum load and the factor of safety, which may be dictated by codes or rules relevant to the application. Determine the total length of cable to be held on the drum. This should take into account the parts of line in the cable system, the total load travel requirement and over-travel margin. In addition, the cable length on the drum must include the mandatory minimum 5 dead wraps of cable to be left on the drum at all times (to supplement the cable termination system and minimize the possibility of reverse wrapping the cable on the drum). Determine the minimum allowable drum barrel diameter. This is often dictated by codes or rules relevant to the application and often expressed as a Minimum D:d Ratio, that is, the ratio of first layer pitch diameter to cable diameter. This ratio affects cable bending stress and wear; generally the larger the D:d ratio the longer the cable life will be. A ratio of 18:1 is typical for crane applications. If the hydraulic system is predetermined, we will use this data to help select the gear ratio and motor size to best suit the performance requirements. If the hydraulic system is not predetermined, then we will advise the requirements based upon optimized selection of gear ratio and motor size. Gear Piston

in mm

ft m

Minimum Drum Barrel Diameter

in mm

Hydraulic Power Supply

gpm lpm psi bar

Preferred Hydraulic Motor Type Distance to Fixed Sheave

To be indicated if there is a preference.

Check One

The distance from the cable drum axis to the axis of the first, non-floating sheave. This distance will be used to determine the cable drum width that will ensure proper cable spooling. The shorter the distance the narrower the drum must be.

ft m

Application Type

Describe General Application

considering the wide variety of hoist sizes, gear ratios, hydraulic motor characteristics and hydraulic system performance, the hoist selection process can become complex. lantec recommends allowing our sales & application engineering professionals to assist in determining the hoist model and options that satisfy your most demanding applications. For assistance in determining a hoist for your application, please copy and fill out this Application Data Sheet and fax to LANTEC at 604-530-2889.

LANTEC

LW Series Winches

lantec lW series Winches are a family of winches specifically designed with flexibility in mind. With line Pulls from 15,000 to 300,000 lbs, there's an lW Winch tailored to suit the most demanding application. virtually any line Pull, line speed and cable Drum can be offered to meet your specifications or application requirements. Please contact LANTEC for more information.

LANTEC

Planetary Drives

lantec Planetary Drives are manufactured to meet your application. current designs include output torques from 10,000 to 500,000 lb-ft. a long history of successful projects assures you of high quality and dependability. Please contact LANTEC for more information.

LANTEC

Electric Winches

Many of our winch models readily accept electric motors. today's modern electric drives are well suited for use on winches. if your application requires electric drives, let lantec show you our economical solutions. Please contact LANTEC for more information.

LANTEC

Custom Winches

lantec has been designing custom winches for over 40 years. this tremendous experience allows us to assist you in designing and manufacturing the ideal winch for your most demanding projects. Please contact LANTEC for more information.

LANTEC

Winch & Gear Inc.

P r o u d Ly d i s t r i B u t e d B y

5827 Production Way Langley, BC V3A 4N5 Canada Tel (604) 530-0737 Fax (604) 530-2889 sales@lantecgear.com www.lantecgear.com

2002 Copyright LANTEC. All rights reserved.

20010 1102

You might also like

- A Series 1.3 - 2.0t 3-Pivot Electric Forklift Service Manual (CE) 2019.08Document92 pagesA Series 1.3 - 2.0t 3-Pivot Electric Forklift Service Manual (CE) 2019.08roberto_robledo_6No ratings yet

- 6F35 Boletín TécnicoDocument8 pages6F35 Boletín TécnicoReydeEspa1100% (2)

- Manitowoc 4500 - 4665 - Parts ManualDocument280 pagesManitowoc 4500 - 4665 - Parts ManualalbertoNo ratings yet

- Draw WorkDocument5 pagesDraw WorkriobmNo ratings yet

- Komatsu PW200-7K Hydraulic Excavator Service Repair Manual SNK40001 and Up PDFDocument26 pagesKomatsu PW200-7K Hydraulic Excavator Service Repair Manual SNK40001 and Up PDFfhjskemmd83% (6)

- Wilson GearboxDocument7 pagesWilson GearboxSunil AundhekarNo ratings yet

- At 01M OverhaulDocument48 pagesAt 01M OverhaulValerie Bliss100% (10)

- Lantec Hydraulic Winch - LWS430Document46 pagesLantec Hydraulic Winch - LWS430Shag Shaggy100% (1)

- Lantec LW Series Winches Catalog PDFDocument16 pagesLantec LW Series Winches Catalog PDFFareedMohmed100% (1)

- Top Drive 500 TonDocument10 pagesTop Drive 500 TonImanNo ratings yet

- Manual de Panther T8 2013Document347 pagesManual de Panther T8 2013Anonymous Hd32bhqNo ratings yet

- T1689-MV-DELTA-Air-Cooled-Technical Manual Rev-0007Document188 pagesT1689-MV-DELTA-Air-Cooled-Technical Manual Rev-0007MichelleNo ratings yet

- Baby Mait PDFDocument2 pagesBaby Mait PDFChris LuNo ratings yet

- CalibrationDocument2 pagesCalibrationAnonymous 1qAH6CKCNo ratings yet

- Chapter 6 - Johnson Blocks - MetricDocument46 pagesChapter 6 - Johnson Blocks - MetricJc ElectroHidraulicos Sac50% (2)

- TODAS LAS MARCAS Brake BlocksDocument17 pagesTODAS LAS MARCAS Brake BlocksJaime MurilloNo ratings yet

- Mico - Selection Procedures For BrakesDocument4 pagesMico - Selection Procedures For BrakesJenner Volnney Quispe ChataNo ratings yet

- Pump SciDocument78 pagesPump Scieddy ortegaNo ratings yet

- RT 750 - TransmisionDocument21 pagesRT 750 - TransmisionLeydi Martin100% (1)

- RT Drive Device User ManualDocument13 pagesRT Drive Device User ManualJohn SimancaNo ratings yet

- C330 Torque Converter SpecDocument2 pagesC330 Torque Converter SpecTamer Elsebaei EbarhimNo ratings yet

- PGP PGM 500 600 Uk 845Document36 pagesPGP PGM 500 600 Uk 845Jorge Andres PozoNo ratings yet

- 13 - Servo Valve SV 10 - B (Boekwerk)Document36 pages13 - Servo Valve SV 10 - B (Boekwerk)Ivan MaltsevNo ratings yet

- 177 - 178 Vis 40 Vis 45 Char-Lynn Parts Drawing.18162438 PDFDocument59 pages177 - 178 Vis 40 Vis 45 Char-Lynn Parts Drawing.18162438 PDFtrinaNo ratings yet

- 450 Ajp Serie 2Document566 pages450 Ajp Serie 2Edwin CastilloNo ratings yet

- 400HP AC Drilling Motor WL250040 2Document2 pages400HP AC Drilling Motor WL250040 2HayLenLeeNo ratings yet

- Hercules Model 131 Deadline Anchor SpecsDocument2 pagesHercules Model 131 Deadline Anchor SpecsAaron HigginsNo ratings yet

- Parker 2H CylindersDocument26 pagesParker 2H CylindersnitinjainmechNo ratings yet

- Teda Xq140 12a Tubing TongDocument61 pagesTeda Xq140 12a Tubing TongRicardo CabreraNo ratings yet

- TM 10-3950-263-14P-3 140 Ton Crane FMC Link Belt MDL Hc-238a, Mhe-248Document517 pagesTM 10-3950-263-14P-3 140 Ton Crane FMC Link Belt MDL Hc-238a, Mhe-248Advocate100% (2)

- Parts Catalog Cad XM TurkeyDocument202 pagesParts Catalog Cad XM TurkeyNelsonParedesNo ratings yet

- Instruction Sheet: S9800/S9810 Upgrade To S9820Document7 pagesInstruction Sheet: S9800/S9810 Upgrade To S9820fernando2228No ratings yet

- DW402 - Pulidor DewaltDocument3 pagesDW402 - Pulidor DewaltJorge Adalberto Lugo QuinteroNo ratings yet

- Hydraulic Control Valve (W-BICS Valve) - (S-N 5122 20298 & Abv, 5124 40721 & Abv, 5126 12258 & Ab - 763 PDFDocument5 pagesHydraulic Control Valve (W-BICS Valve) - (S-N 5122 20298 & Abv, 5124 40721 & Abv, 5126 12258 & Ab - 763 PDFRomusNo ratings yet

- Grua Terex RT 230-1 XL Datasheet - ImperialDocument22 pagesGrua Terex RT 230-1 XL Datasheet - ImperialjuancarlostNo ratings yet

- DS PF 6000Document2 pagesDS PF 6000Junior Francisco Quijano100% (1)

- Hy11 3302 Uk PDFDocument32 pagesHy11 3302 Uk PDFValbertgNo ratings yet

- Operator Carrier PDFDocument144 pagesOperator Carrier PDFGILMAR NIETONo ratings yet

- Allison Transmission BrochureDocument3 pagesAllison Transmission Brochurem mainNo ratings yet

- H-2 Controlair Valve: Service InformationDocument18 pagesH-2 Controlair Valve: Service InformationRonald LlerenaNo ratings yet

- Cle5500xht Bucd5500 Rev02-08 PDFDocument117 pagesCle5500xht Bucd5500 Rev02-08 PDFedisonabreu89No ratings yet

- Wichita PH D e 0616 PDFDocument92 pagesWichita PH D e 0616 PDFsahidNo ratings yet

- Valvulas GresensvDocument92 pagesValvulas GresensvAnonymous j6WnEH5No ratings yet

- 8487A Oilwell A 1100 PT A 850 PT - 881Document8 pages8487A Oilwell A 1100 PT A 850 PT - 881PSC RFQNo ratings yet

- Каталог системы для подъема ПВО Ingersoll RandDocument44 pagesКаталог системы для подъема ПВО Ingersoll RandSagadat AbdiganiNo ratings yet

- PVG 32 Parts CatalogDocument52 pagesPVG 32 Parts CatalogVipin Gupta75% (4)

- 165T-5 Parts ListDocument26 pages165T-5 Parts ListJorge Luis Galezo MuñozNo ratings yet

- Bomba Denison Serie PremierDocument50 pagesBomba Denison Serie Premiergineslopezruiz100% (1)

- Ball Base 12.0 20.0: Letourneau Technologies™Document1 pageBall Base 12.0 20.0: Letourneau Technologies™Mikel1020No ratings yet

- Axle: 4. AXLE (ZF, Machine Serial No.: #0080-)Document49 pagesAxle: 4. AXLE (ZF, Machine Serial No.: #0080-)mohamed omerNo ratings yet

- Sandwich Valve - Parker PDFDocument91 pagesSandwich Valve - Parker PDFArjed Ali ShaikhNo ratings yet

- 005 Joystick 2Document8 pages005 Joystick 2JonathanDavidDeLosSantosAdornoNo ratings yet

- 04 427Document2 pages04 427Eng-Mohammed Salem100% (1)

- Hydrolink General Product CatalogueDocument17 pagesHydrolink General Product CatalogueMarcoAlbaNo ratings yet

- Bowex enDocument32 pagesBowex enTimon2005No ratings yet

- LIT2103 R6 PD12C 15B 17A Service ManualDocument40 pagesLIT2103 R6 PD12C 15B 17A Service ManualAlex Parampampam100% (2)

- 150 Ton Link Belt LS 238HSpecsDocument6 pages150 Ton Link Belt LS 238HSpecsYosses Sang Nahkoda0% (1)

- Braden Winch CH 230-2Document2 pagesBraden Winch CH 230-2wessamalexNo ratings yet

- Solenoid Valve Mini Catalog PDFDocument255 pagesSolenoid Valve Mini Catalog PDFCh Jameel SidhuNo ratings yet

- NOV Blak Jak RemovalDocument2 pagesNOV Blak Jak RemovalddiazveNo ratings yet

- Filtro Separador de Agua 900fhDocument2 pagesFiltro Separador de Agua 900fhale alvarezNo ratings yet

- Eaton MotorDocument59 pagesEaton MotorVinod Kumar BhargavNo ratings yet

- Steering StabilisationDocument24 pagesSteering StabilisationRooftop Gardener100% (1)

- Muncie Power Product BrochureDocument12 pagesMuncie Power Product Brochurewrath_of_marsNo ratings yet

- Controllable Pitch PropelleDocument12 pagesControllable Pitch PropelleJoshua SanchezNo ratings yet

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Letter For CE ClientsDocument1 pageLetter For CE ClientsAnonymous 1qAH6CKCNo ratings yet

- Program Winch Teardown - 21-9-15Document11 pagesProgram Winch Teardown - 21-9-15Anonymous 1qAH6CKCNo ratings yet

- Service ReportsDocument1 pageService ReportsAnonymous 1qAH6CKCNo ratings yet

- Cpe Post MeetingDocument2 pagesCpe Post MeetingAnonymous 1qAH6CKCNo ratings yet

- Corning Gorilla Glass: Technical MaterialsDocument2 pagesCorning Gorilla Glass: Technical MaterialsAnonymous 1qAH6CKCNo ratings yet

- Schneider ContactorDocument3 pagesSchneider ContactorAnonymous 1qAH6CKCNo ratings yet

- Program - Winch Tear DownDocument11 pagesProgram - Winch Tear DownAnonymous 1qAH6CKCNo ratings yet

- Version - 2.0 Page - 1 - of - 14 Weights - and - Capacities - in - Metric - Tonnes, - Dimensions - in - Meters. - For - Reference - Only.Document14 pagesVersion - 2.0 Page - 1 - of - 14 Weights - and - Capacities - in - Metric - Tonnes, - Dimensions - in - Meters. - For - Reference - Only.Anonymous 1qAH6CKCNo ratings yet

- SKF Composite Plain Bearings - 11004 EN - TCM - 12-107917 PDFDocument60 pagesSKF Composite Plain Bearings - 11004 EN - TCM - 12-107917 PDFAnonymous 1qAH6CKCNo ratings yet

- HoistDocument4 pagesHoistAnonymous 1qAH6CKCNo ratings yet

- Re 07700Document2 pagesRe 07700Ahmed Abd ElhakeemNo ratings yet

- Re 07100Document2 pagesRe 07100Anonymous 1qAH6CKCNo ratings yet

- The Antikythera Mechanism and The Early History of The MoonDocument11 pagesThe Antikythera Mechanism and The Early History of The MoonAtlantisPapersNo ratings yet

- 7495HD Pala Eléctrica de Cable CaterpillarDocument3 pages7495HD Pala Eléctrica de Cable CaterpillarJose Manuel Camacho GallegosNo ratings yet

- Cletrac Controlled Differential Steering SystemDocument10 pagesCletrac Controlled Differential Steering SystemGreggs ShopukNo ratings yet

- Maxon GP 32 HPDocument1 pageMaxon GP 32 HPElectromateNo ratings yet

- Auto Transmission A425e PDFDocument96 pagesAuto Transmission A425e PDFtony100% (1)

- AE2201 2marks PDFDocument30 pagesAE2201 2marks PDFSathis KumarNo ratings yet

- For Full Explanations of All These Questions, and For Many More New and Up-To-Date Questions, With Correct Answers, Full Explanations, Downloadable Material and Tutorial Support, Please VisitDocument43 pagesFor Full Explanations of All These Questions, and For Many More New and Up-To-Date Questions, With Correct Answers, Full Explanations, Downloadable Material and Tutorial Support, Please Visitariesguy_86No ratings yet

- Transmission atDocument47 pagesTransmission atDidier ÁlvarezNo ratings yet

- Final - Chain Drive & TyresDocument11 pagesFinal - Chain Drive & TyresMahmoud MohsenNo ratings yet

- MD31.1 FLENDER SIP Standard Industrie Planetengetriebe enDocument68 pagesMD31.1 FLENDER SIP Standard Industrie Planetengetriebe enJoshua PorterNo ratings yet

- Schaffler FAG Bearings Tpi 008 de enDocument116 pagesSchaffler FAG Bearings Tpi 008 de enjohn kasichNo ratings yet

- Maxon GP 22 MDocument1 pageMaxon GP 22 MElectromateNo ratings yet

- Shimano Nexus Inter-7 - Coaster - BrakeDocument12 pagesShimano Nexus Inter-7 - Coaster - BrakeGeorge OrfanidisNo ratings yet

- Differential Functions Parts Woking Advantages Disadvantages and Applications PDFDocument6 pagesDifferential Functions Parts Woking Advantages Disadvantages and Applications PDFRohan ModhNo ratings yet

- Planetary Gear Box FailureDocument13 pagesPlanetary Gear Box Failuretsrinivasan5083No ratings yet

- Motorreductores SEW-EurodriveDocument110 pagesMotorreductores SEW-EurodriveJavier Carrillo MdezNo ratings yet

- Tourbillon Mechanica Assembly Guide MQ Dec 30Document38 pagesTourbillon Mechanica Assembly Guide MQ Dec 30darkandmellowNo ratings yet

- r3 Forecast Oli Aceh 2021Document31 pagesr3 Forecast Oli Aceh 2021ArifinNo ratings yet

- ODF-2 - Learning MaterialDocument24 pagesODF-2 - Learning MateriallevychafsNo ratings yet

- Dynamic Characteristics of Epicyclic Gear SystemDocument77 pagesDynamic Characteristics of Epicyclic Gear Systemkaajemaina195No ratings yet

- Prabhu T. - Automobile Engineering. Basic Fundamentals. Basic Fundamentals To Advanced Concepts of Automobile Engineering (2021, Nestfame Creations Pvt. LTD.) - Libgen - LiDocument1,377 pagesPrabhu T. - Automobile Engineering. Basic Fundamentals. Basic Fundamentals To Advanced Concepts of Automobile Engineering (2021, Nestfame Creations Pvt. LTD.) - Libgen - Livivek panchalNo ratings yet

- Hyundai Santa Fe 2006 Auto TransaxleDocument194 pagesHyundai Santa Fe 2006 Auto Transaxlebravo6d78% (9)

- Gnanamani College of TechnologyDocument15 pagesGnanamani College of TechnologyRajueswarNo ratings yet

- Final Drive AssemblyDocument118 pagesFinal Drive AssemblyKARTHICKRAJ KANDASAMYNo ratings yet

- AUTOMOBILEDocument14 pagesAUTOMOBILEabhinandsofficialNo ratings yet