Professional Documents

Culture Documents

Computer Simulation For Large Scale Bioprocess Design: S.A. Rouf, P.L. Douglas, M. Moo-Young, J.M. Scharer

Computer Simulation For Large Scale Bioprocess Design: S.A. Rouf, P.L. Douglas, M. Moo-Young, J.M. Scharer

Uploaded by

daimon_pOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Computer Simulation For Large Scale Bioprocess Design: S.A. Rouf, P.L. Douglas, M. Moo-Young, J.M. Scharer

Computer Simulation For Large Scale Bioprocess Design: S.A. Rouf, P.L. Douglas, M. Moo-Young, J.M. Scharer

Uploaded by

daimon_pCopyright:

Available Formats

Biochemical Engineering Journal 8 (2001) 229234

Computer simulation for large scale bioprocess design

S.A. Rouf, P.L. Douglas , M. Moo-Young, J.M. Scharer

Department of Chemical Engineering, University of Waterloo, Waterloo, Ont., Canada N2L 3G1 Received 15 February 2000; accepted 19 March 2001

Abstract Two bioprocess simulators, Aspen BPSTM and SuperPro Designer , were used to simulate and compare two owsheets for production of tissue plasminogen activator (t-PA) from Chinese hamster ovary (CHO) cells. The owsheets were designed to compare the economics of using serum and serum-free medium in the bioreactor. The base case owsheet used a medium with 10% serum while the alternative owsheet used a serum-free medium. Afnity chromatography was the major step in the downstream processing of the base case owsheet. The alternate owsheet was designed for two-step cell culture growth and production. Ion-exchange chromatography was considered sufcient for purication of the low protein medium for this case. At a price of US$ 25/l for serum-free medium, the alternate owsheet was found to have an return on investment (ROI), of 115% compared to 65% for the base case owsheet. 2001 Elsevier Science B.V. All rights reserved.

Keywords: Process simulation; Bioprocess design; Aspen BPSTM ; SuperPro designer

1. Introduction The advantages of process simulation for development, evaluation and scale up of bioprocesses have long been realised [13]. Process simulators offer the opportunity to shorten the time required for process development. They allow comparison of process alternatives on a consistent basis so that a large number of process ideas can be synthesised and analysed interactively in a short time. Simulation of integrated processes also enables the study of interactions that exist between upstream and downstream processes. In this study, two commercial bioprocess simulators, BioProcess SimulatorTM (BPS, [4]) and SuperPro Designer (SPD, [5]), were assessed for evaluation of large-scale production processes of a biopharmaceutical from a recombinant mammalian cell culture. Serum, which is a major component of most cell culture medium, has the disadvantage of introducing variability to the different batches of medium. It also increases the possibility of medium contamination with viruses, mycoplasma, bacteria, fungi, endotoxin, etc. [26]. The presence of other proteins in the serum complicates purication of the desired protein and the high cost of quality serum increases the price of the medium. Therefore, efforts have been directed

Corresponding author. Tel.: +1-519-888-4567/2913; fax: +1-519-746-4979. E-mail address: pdouglas@cape.uwaterloo.ca (P.L. Douglas).

towards the formulation of a serum-free medium supplemented with growth factors and other essentials. The most important advantage of a process using serum-free medium is the simplication of the downstream processing, which can account for 7080% of the overall cost for high value products [26]. The economics of using serum-free medium was investigated by simulating alternate owsheets. 2. Process description Production of recombinant tissue plasminogen activator (t-PA) from CHO cells represents one of the largest scale productions of a bio product from cell culture [6]. A proteolytic enzyme, t-PA nds application in the treatment of cardiovascular and cerebrovascular obstructions (i.e. heart attack and stroke). Commercial production of t-PA is currently carried out by Genentech [7], who developed and obtained FDA approval for its large-scale production in 1987. Information on the patented large scale production process for t-PA is not available so the proposed owsheets are based on bits of information scattered in the technical literature combined with engineering judgement and experience with other recombinant products [8]. The generation of the owsheets for simulation was also largely based on the laboratory scale production methods. The process information and operating conditions required for simulation were gathered from the literature. The simulated bioreactors were stirred tank type with the CHO

1369-703X/01/$ see front matter 2001 Elsevier Science B.V. All rights reserved. PII: S 1 3 6 9 - 7 0 3 X ( 0 1 ) 0 0 1 1 2 - 7

230

S.A. Rouf et al. / Biochemical Engineering Journal 8 (2001) 229234

Fig. 1. (a) Process owsheet for t-Pa production from CHO Cells. (b) Alternate owsheet for t-Pa production from CHO Cells.

cells grown in suspension culture, [9]. The batch charge consisted of 10% Fetal Bovine Serum (FBS), 90% Hams F-12 medium and 4 mM Glutamine for the base case. The bioreactor was inoculated with 1000 l of inoculum having a concentration of 2 105 cells/ml. The contents of the bioreactor were aerated with 0.02 VVM sterile air. The base case owsheet is shown in Fig. 1a and the alternate owsheet, Fig. 1b, uses separate bioreactors for growth and production. Hams F-12 medium was replaced with HB-CHO basal mixture and a proprietary supplement (Immucor Canada Inc.) in the serum-free medium for the production bioreactor of this owsheet. Since, the actual composition of the serum-free medium is not known, the concentration of BSA-like protein in this medium was assumed to be 10% of that in the serum-containing medium, [9]. Because of this low background protein concentration, purication with ion-exchange chromatography was assumed to be sufcient to reach the desired purity. In the laboratory, purication of t-PA from serum-free medium using a single ion-exchange column followed by gel ltration has resulted in a purication factor of 58 and an overall yield of 61% [10].

The permeate and retentate pressure for the membrane ltration units were chosen to yield a transmembrane pressure of <1 psi, as recommended by Rudolph [11] and Maiorella et al. [12] for animal cell harvesting. A resistance-in-series model was chosen as the ux model for the system. Membrane resistance and gel resistance parameters were obtained from [13,14,27,28]. The afnity ligand recommended for purication of t-PA is Lysine Sepharose, which has a capacity of >0.6 mg plasminogen/ml gel (Pharmacia LKB Biotechnology). It is widely used in laboratory scale purication of t-PA because of it biospecicity [15]. A Langmuir type equilibrium relationship was assumed for the system since, this relationship has been found satisfactory for many ligand-protein combinations [16]. The Langmuir adsorption isotherm constant was assumed to be 120 103 cm3 /g. This value seems reasonable when compared to the reported value of 162 103 cm3 /g for antibenzenearsonate monoclonal antibody on Sepharose 4B [16]. Simulation was carried out for a 200 l column having a height to diameter ratio of 0.5 and a supercial loading velocity of about 40 cm/h. The ion-exchange column in the alternate owsheet was simulated under similar conditions. The ion-exchange resins used in the laboratory scale purication of t-PA are strong cations such as SP Sephadex C-SO and Mono S [10,17]. The total ionic capacity of SP Sephadex C-SO is found to be between 2.0 and 2.6 mmol/g (Pharmacia LKB Biotechnology). An estimated surface area of 1 cm2 /cm3 was used in the simulation. The operation was simulated at a pH of 4.5, close to the isoelectric point of BSA (5.0) as described in the laboratory scale purication methods. Sephadex G-100, G-150 and G-200 are the gel ltration media used in the laboratory scale purication techniques for t-PA, with Sephadex G-150 being most popular. Gel ltration was simulated in a 147 l column with a length to diameter ratio of 1.5. The sample volume was taken as 5% of column volume as recommended [18] and the ow velocity was 16 cm/h.

3. Simulation and results The process was designed to produce 11,000 g of puried t-PA per year [19]. To meet this production level, ve 6000 l bioreactors are required (Table 1). One of these ve bioreactors with its associated downstream processing units was simulated using Aspen BPSTM . The purity requirement of therapeutic pharmaceuticals like t-PA is very stringent. Downstream processing, therefore, is an important part and represents a dominant cost element (between 70 and 80%). In general, the nal product should be free of infectious agents and should meet the limits specied for other contaminants such as DNA, cell and media proteins, endotoxin, etc. [20]. In this simulation, clearance of only foreign proteins was investigated. Among these contaminating proteins, the clearance of bovine serum

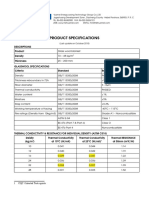

S.A. Rouf et al. / Biochemical Engineering Journal 8 (2001) 229234 Table 1 Design basis World-wide cases (per year) Treatable cases (40%) (per year) Market penetration (10%) (g/year) Amount oft-PA per dose (mg) Production of puried t-PA (g/year) Recovery yield (%) Product titer before purication (mg/l) Plant capacity (l/year) Over design (%) Plant capacity (l/year) Time/one batch (days) No. of batches/year Batch volume (l) 2.8 106 1.1 106 110000 100 11000 40 33.5 820000 20 1025000 10 35 5 6000 Table 2 Simulation results for base case owsheet and alternate owsheet Block Base case owsheet Bioreactor Micro lter Ultra lter Afnity Chrom. Ultra lter Afnity Chrom. Ultra lter Gel ltration Alternate owsheet Growth Bioreactor Micro lter Production Bioreactor Micro lter Ultra lter Ion-exchange Ultra lter Ion-exchange Ultra lter Gel ltration Size 6000 l 80 m2 60 m2 200 l 3 10 m2 85 l 2.5 m2 147 l 6 6000 l 80 m2 5000 l 7 Gm2 50 m2 200 l 2 15 m2 113 l 5 m2 147 l 5 Recovery (%) 93.3 83 73.6 94 90.687 94.13 99.997 84.5 84.76 83.45 92.37 87.16 96.26 99.997

231

Purity (%) 0.55 0.55 7.65 99.98 99.9977 99.9998 6.86 6.86 99.93 99.999 99.9998

albumin (BSA) was considered to be critical, since, t-PA and BSA have very similar molecular weights (about 68,000 and 65,000, respectively). The desired level of retrovirus and DNA removal were assumed to be achieved by the processes, because validated processes have shown that a combination of two chromatographic steps normally results in the desired reduced level of these contaminants [21]. For simulation, required process information about the owsheet and streams, composition of each stream, properties and values of operating variables and parameters of the different unit operation blocks, were supplied through input les written according to the specications outlined in the BPSTM manual. The BPSTM has a built-in data bank for components and properties. It allows three types of components; (conventional, non-conventional and biocomponents). Components such as CHO cells are handled as non-conventional, and macromolecules such as t-PA and other proteins as biocomponents. The built-in property estimator BIOENTE calculates enthalpy from heat of formation and a temperature dependent heat capacity term. BIODEN calculates density as a second-order polynomial of temperature. The BPSTM also allows addition of user supplied properties. The simulator carries out mass and energy balances for the different blocks when necessary information is provided by the user. There are built-in correlations for estimation of different coefcients. It accepts userdened kinetics and correlations in the form of FORTRAN subroutines. Input information required to carry out simulation with Aspen BPSTM and SuperPro Designer are different because they use different unit operation models (rigorous and shortcut models). Most of the information required by BPSTM was available in the literature or could be estimated from the built-in correlations. However, some information required by some of the unit operation blocks in SuperPro needed to be obtained from experiment. For example, simulation of the chromatographic column requires the knowledge of binding percentage and recovery of each component. For these situations, results from BPSTM simulation were used as input to SuperPro .

It was assumed with the two-step fermentation owsheet, that the cell concentration in a growth-inducing environment [22,23] reaches almost twice the concentration reached in the single step growth-production bioreactor of the base case. Therefore, the number of production bioreactors was half the number of growth bioreactors [19] and the number of associated downstream units was half of that required by the base process. Comparison of the simulated owsheets will therefore demonstrate the economic effect of using serum-free medium under these conditions. From the results it is found that both the owsheets are capable of producing t-PA of required purity (99.9998%). The overall recoveries for the two owsheets are 45.7 and 46.3%, respectively. These are well above the recovery yield (40%) assumed in the basis. The batch time for the base case is 218 h or about 9.08 days. For the alternate owsheet the total time required is 221 h or about 9.2 days. These are also within the batch time of 10 days, assumed in the basis. Table 2 shows simulation results for the two owsheets. The base case requires ve sets of the equipment (Table 2) to meet the total production of 30,000 l. The alternate owsheet, on the other hand, requires ve sets for the rst two steps and then only three sets afterwards because of the assumption stated in the previous section.

4. Economic evaluation Aspen BPSTM and SuperPro Designer are both equipped with economic evaluators. However, the economic evaluator of Aspen BPSTM , which has been derived from the chemical process simulator AspenPlusTM , is geared more towards chemical processes. Its calculation mode is

232

S.A. Rouf et al. / Biochemical Engineering Journal 8 (2001) 229234 Table 3 Comparative economic analysis (in millions of dollars) Base case CPE CFC = 4.6 CPE CTC = 5.5 CPE Revenue, R AOC Gross prot, GP = R AOC Net prot, NP (40% tax) Net cash ow = NP + Dep. ROI (%) GM = (GP/R) (%) 14.2 65.32 78.1 176 101 75 45 51 65 43 Alternate 8.8 40.48 48.4 176 92.9 83 49.86 55.86 115 47

rigorous and requires a lot of data from a real project to make appropriate use of the available options. SuperPro Designer on the other hand, has an economic evaluator that is specically developed for bioprocesses. It is simple and easy to use. For preliminary screening of these conceptual owsheets and in the absence of detailed information, economic evaluation with SuperPro was thought to be sufcient in this study. SuperPro generates an equipment list along with the size and number of each item as a part of economic evaluation. Then it uses the built-in power law model to calculate the purchase cost of the equipment (CPE ). The total (CTC ) and xed capital (CFC ) costs are then calculated by multiplying the purchase equipment cost by appropriate cost factors. For the calculation of the annual operating cost, SuperPro calculates the utility requirement and the number of labour-hours. It also calculates the amount of different input streams required from material balances. If the treatment cost of the output streams is supplied, it will also calculate the waste treatment cost for the process. The owsheets were compared on the basis of return on investment (ROI) and Gross Margin (GM). The annual operating cost (AOC) was calculated following the procedure outlined by Datar and Rosen [24]. Table 3 shows the calculation of the economic parameters. The alternate owsheet uses fewer (three) sets of equipment following cell separation compared to the base case (ve). Cell culture equipment accounts for 29% of the total equipment purchase cost for this owsheet compared to 14% for the base case (Fig. 2a and b). This results in significant saving (US$ 5.5 million) in the equipment purchase cost and consequently lowers the capital investment. The expensive afnity columns of the base case are also replaced with cheaper ion-exchange columns. However, the purchase

Fig. 2. (a) Breakdown of equipment purchase cost for the base case owsheet; (b) breakdown of equipment purchase cost for the alternate owsheet.

Fig. 3. (a) Sensitivity to serum-free medium Price; (b) sensitivity to replacement frequency.

S.A. Rouf et al. / Biochemical Engineering Journal 8 (2001) 229234

233

Fig. 4. Sensitivity to serum price.

cost obtained from SuperPro for these columns is almost the same and no savings in purchase cost were realised from this source. The operating cost for the alternate owsheet is found to be signicantly higher which is mainly due to the cost of the media required for its eight bioreactors (ve growth bioreactors and three production bioreactors). Media cost accounts for over 94% of the total process chemicals and media cost and cost of serum-free media accounts for 62% of the total media cost. The cost of serum-free medium is estimated to be US$ 25/l. It is clear that the protability of this owsheet is very sensitive to this price. The replacement cost of the chromatographic resin for the ion-exchange column, however, is much cheaper (Fig. 3a and b). The higher media cost and lower resin replacement cost tend to balance out the raw material and media cost for this owsheet. A sensitivity analysis of the economics of the alternate owsheet with respect to serum-free medium cost showed that, a 50% reduction in this price will improve the ROI of the process by about 9% (Fig. 4). Therefore, with the on-going efforts to formulate low cost serum-free medium, this process can become an even more attractive alternative to the base case. However, the economics of the process is also based on the assumption that resulted in fewer sets of equipment for this owsheet. The process economics is found to be a much stronger function of equipment purchase cost than raw material cost [25] and this limitation should be emphasised while reaching conclusions about the economics of these processes.

ion-exchange columns in the absence of background protein also economises the downstream purication of the product. Simulation helped to quantify the anticipated gain of the process. References

[1] L.B. Evans, R.P. Field, Requirements of a biotechnology process simulator, in: Proceedings of the World Congress II of Chemical Engineers, 1986, pp. 890893. [2] C.L. Cooney, D. Petrides, M. Barrera, L. Evans, Computer-aided design of a biochemical process, ACS Symp. Ser. 39 (1988) 3961. [3] D. Petrides, Biopro designer: an advanced computing environment for modeling and design of integrated biochemical processes, Comp. Chem. Eng. 18 (1994) S621S625. [4] Aspen Technology Inc., ASPEN BPS Reference Manual, Unit Operation Models, Vol. 1, Release 9.2, Cambridge, Massachusetts, 1995. [5] Intelligen, Inc., 1995. SuperPro Designer-Users Guide, Scotch Plains, New Jersey. [6] A.A. Lin, R. Kimura, W.M. Miller, Production of t-Pa in recombinant CHO cells under oxygen-limited conditions, Biotechnol. Bioeng. 42 (1993) 339350. [7] A.D. Levinson, D. Pennica, W.J. Kohr, G.A. Vehar, D.V. Goeddel, C.C. Simonsen, Human TPA Production Using Vectors for DHFR, US Patent 5,268,291, Genentech Inc., San Francisco, CA, 1993. [8] D. Petrides, E. Sapidou, J. Calandranis, Computer-aided process analysis and economic evaluation for biosynthetic human insulin production a case study, Biotechnol. Bioeng. 48 (1995) 529541. [9] R.L. Dutton, J.M. Scharer, M. Moo-Young, Descriptive parameter estimation in mammalian cell culture, Cytotechnol 26 (1998) 139 152. [10] E.K.O. Kruithof, W.-D. Schleuning, F. Bachmann, Human tissue-type plasminogen activator production in continuous serum-free cell culture and rapid purication, Biochem. J. 226 (1985) 631. [11] E.A. Rudolph, et al., Tangential ow ltration systems for clarication and concentration, in: B.K. Lydersen, N.A. Delia, K.L. Nelson (Eds.), Bioprocess Engineering Systems, Equipment and Facilities, Wiley, New York, 1994. [12] B.L. Maiorella, G. Dorm, A. Canon, D. Harano, Cross-ow microltration of animal cells, Biotechnol. Bioeng. 37 (1990) 121 126. [13] D.W. Lee, Hollow-bre cross-ow microltration of E. coli suspensions, MSc Thesis, University of Waterloo, Waterloo, Canada, 1989. [14] D.N. Wood, Harvesting of E. coli cells using cross-ow membrane ltration, MSc Thesis, University of Waterloo, Waterloo, Canada, 1988. [15] Y.D. Clonis, Process afnity chromatography, in: J.A. Asenjo (Ed.), Separation Process in Biotechnology, Marcel Decker, New York, 1990.

5. Conclusion Bioprocess simulators were used to design and evaluate two alternate owsheets for t-PA production. The owsheet employing two-stage cell culture and using serum-free medium in the production bioreactor is found to be an attractive alternative to the base case. This process has both, lower equipment purchase cost and annual operating cost compared to the base case. The economics of this owsheet is sensitive to the assumption of higher cell concentration reached with the two-stage operation. The use of

234

S.A. Rouf et al. / Biochemical Engineering Journal 8 (2001) 229234 [22] R. Kimura, W.M. Miller, Effects of elevated pCO2 and/or osmolability on growth and recombinant t-PA production of CHO cells, Biotechnol. Bioeng. 52 (1996) 152160. [23] G.B. Nyberg, R.R. Balcarcel, B.D. Follstad, G. Stephanopoulos, D.I.C. Wang, Metabolism of peptide hamster ovary cells grown in complex medium, Biotechnol. Bioeng. 62 (1999) 324 335. [24] R.V. Datar, C.G. Rosen, Downstream process economics, in: J.A. Asenjo, (Ed.), Separation Process in Biotechnology, Marcel Dekker, New York, 1990. [25] S.A. Rouf, Evaluation of Process Simulators for an Integrated Bioprocess Design, PhD Thesis, University of Waterloo, Waterloo, Ont., Canada, 1999. [26] T. Cartwright, Animal Cells as Bioreactors, Cambridge University Press, Cambridge, UK, 1994. [27] M. Cheryan, Ultraltration Handbook, Technomic Publishing Co. Inc., Lancaster, Pennsylvania, USA, 1986. [28] M.I. Tamer, Personal communication, 1995.

[16] F.H. Arnold, H.W. Blanch, C.R. Wilke, Analysis of afnity separations I. Predicting the performance of afnity adsorbers, Chem. Eng. J. 30 (1985) B9B23. [17] W.F. Prouty, Process chromatography in production of recombinant products, in: C. Horvath, L.S. Ettre (Eds.), Chromatography in Biotechnology, ACS Symposium Series, 1993, p. 529. [18] S.M. Wheelwright, Protein Purication: Design and Scale up of Downstream Processing, Hanser, New York, 1991. [19] R.V. Datar, T. Cartwright, C. Rosen, Process economics of animal cell and bacterial fermentations: a case study analysis of tissue plasminogen activator, Biotechnology 11 (1993) 349357. [20] V.R. Anicetti, B.A. Keyt, W.S. Hancock, Purity analysis of protein pharmaceuticals produced by recombinant DNA technology, Trends Biotechnol. 7 (12) (1989) 342349. [21] D. Brady, J. Bonnerjea, C.R. Hill, Purication of monoclonal antibodies for human clinical use: validation of DNA and retroviral clearance, in: D.L. Pyle (Ed.), Separations for Biotechnology 2, Elsevier, London, 1990, pp. 472479.

You might also like

- TFS Branching Guide - Scenarios 2.0Document20 pagesTFS Branching Guide - Scenarios 2.0pradeepku.b100% (1)

- Lithium I On IncidentsDocument12 pagesLithium I On IncidentsM8R-fsx9faNo ratings yet

- Computer Simulation For Large Scale Bioprocess Design: S.A. Rouf, P.L. Douglas, M. Moo-Young, J.M. ScharerDocument6 pagesComputer Simulation For Large Scale Bioprocess Design: S.A. Rouf, P.L. Douglas, M. Moo-Young, J.M. ScharerSharat SachinNo ratings yet

- 2782 FTPDocument5 pages2782 FTPJosilene AmaroNo ratings yet

- Email Address: Rsr@kluniversity - in (Srinivasa Reddy Ronda) .: A A A ADocument33 pagesEmail Address: Rsr@kluniversity - in (Srinivasa Reddy Ronda) .: A A A AAsrul M FuadNo ratings yet

- RecomDocument8 pagesRecomDiana Carolina Tenorio SánchezNo ratings yet

- Kim2014 Article ProductionOfRecombinantHumanGrDocument8 pagesKim2014 Article ProductionOfRecombinantHumanGrDiana Carolina Tenorio SánchezNo ratings yet

- Role of Downstream Processes in Purification of BiopharmaceuticalsDocument2 pagesRole of Downstream Processes in Purification of BiopharmaceuticalsManasa UpadhyayaNo ratings yet

- FPD679.pdf Version 1Document6 pagesFPD679.pdf Version 1Ali IrtazaNo ratings yet

- Preparation and Evaluation of PEGylated and Folate-PEGylatedDocument11 pagesPreparation and Evaluation of PEGylated and Folate-PEGylatedAek DjimiNo ratings yet

- Solid Lipid Nanoparticles Optimized by 22 Factorial Design For Skin Administration Cytotoxicity in NIH3T3 FibroblastsDocument5 pagesSolid Lipid Nanoparticles Optimized by 22 Factorial Design For Skin Administration Cytotoxicity in NIH3T3 FibroblastsNor el houda AzizouNo ratings yet

- Biochemical Engineering JournalDocument10 pagesBiochemical Engineering JournalPriyadharshini UlaganathanNo ratings yet

- S Adenosylmethionine and Methylthioadenosine Boost Cellular Productivities of Antibody Forming Chinese Hamster Ovary CellsDocument9 pagesS Adenosylmethionine and Methylthioadenosine Boost Cellular Productivities of Antibody Forming Chinese Hamster Ovary Cellsip87JCNo ratings yet

- Modeling and Performance Prediction of A Conceptual Bio - 2020 - Food and BioproDocument15 pagesModeling and Performance Prediction of A Conceptual Bio - 2020 - Food and BioproJUAN C. OVIEDO LOPERANo ratings yet

- Electronic Journal of Biotechnology: Ying Yu, Xiaoyu Zhou, Sheng Wu, Tiantian Wei, Long YuDocument6 pagesElectronic Journal of Biotechnology: Ying Yu, Xiaoyu Zhou, Sheng Wu, Tiantian Wei, Long YuSadieNo ratings yet

- The Trap Platform. Small-Scale Protein Sample Preparation. Get It Right From The StartDocument8 pagesThe Trap Platform. Small-Scale Protein Sample Preparation. Get It Right From The StartAt ManeNo ratings yet

- Extended AbstractDocument14 pagesExtended AbstractVenkata Suryanarayana GorleNo ratings yet

- Model-Based Fed-Batch Cultivation of R. Eutropha For Enhanced Biopolymer ProductionDocument8 pagesModel-Based Fed-Batch Cultivation of R. Eutropha For Enhanced Biopolymer Productionashuna249396No ratings yet

- Total Antioxidant Capacity Measurement by Colorimetric AssayDocument9 pagesTotal Antioxidant Capacity Measurement by Colorimetric AssayLourdes VictoriaNo ratings yet

- Evaluation of Sample Preparation Methods For The Analysis of Papaya Leaf Proteins Through Two-Dimensional Gel ElectrophoresisDocument9 pagesEvaluation of Sample Preparation Methods For The Analysis of Papaya Leaf Proteins Through Two-Dimensional Gel ElectrophoresisRakesh BasatiaNo ratings yet

- Kim 1995Document8 pagesKim 1995ILAMPARITHI SARVANABAVANNo ratings yet

- Correlation Between Agar Plate Screening and Solid State Fermentation For The Prediction of Cellulase Production by Trichoderma StrainsDocument8 pagesCorrelation Between Agar Plate Screening and Solid State Fermentation For The Prediction of Cellulase Production by Trichoderma StrainsMaruf MuhammadNo ratings yet

- Improvements in Titer, Productivity, and Yield Using Solka-Floc For Cellulase ProductionDocument16 pagesImprovements in Titer, Productivity, and Yield Using Solka-Floc For Cellulase Productionguime27No ratings yet

- Human Lymphocyte Culture and Chromosome Analysis: ProtocolDocument8 pagesHuman Lymphocyte Culture and Chromosome Analysis: ProtocoldsadaNo ratings yet

- Literature Review On Cellulase ActivityDocument9 pagesLiterature Review On Cellulase Activityzgkuqhxgf100% (1)

- Artículo Que Dijo El SocioDocument8 pagesArtículo Que Dijo El SociodyannissNo ratings yet

- Averrmectin B1b Production Optimization From Streptomyces AvermitilisDocument8 pagesAverrmectin B1b Production Optimization From Streptomyces AvermitilisRubina NeloferNo ratings yet

- Pfeffer Et Al. - 2011 - Modeling and Measuring Intracellular Fluxes of SecDocument11 pagesPfeffer Et Al. - 2011 - Modeling and Measuring Intracellular Fluxes of SecAnaNo ratings yet

- Microbial Enzymes and Their ApplicationsDocument4 pagesMicrobial Enzymes and Their Applicationsali abbasNo ratings yet

- Synthetic Pathways and Processes For Effective Production of 5-Hydroxytryptophan and Serotonin From Glucose in Escherichia ColiDocument12 pagesSynthetic Pathways and Processes For Effective Production of 5-Hydroxytryptophan and Serotonin From Glucose in Escherichia ColiBelma TunaNo ratings yet

- Abstract. Fermentation Conditions Were Developed in Order To Achieve Simultaneously A HighDocument9 pagesAbstract. Fermentation Conditions Were Developed in Order To Achieve Simultaneously A HighKarina A.No ratings yet

- Extraction and Purification of Recombinant Intact HPTH From Bacterial CellsDocument10 pagesExtraction and Purification of Recombinant Intact HPTH From Bacterial CellsvenkynmNo ratings yet

- Degradation Behaviour of Methamidophos and Chlorpyrifos in Apple JuiceDocument6 pagesDegradation Behaviour of Methamidophos and Chlorpyrifos in Apple JuiceUgur TucNo ratings yet

- B 0343014018Document5 pagesB 0343014018IOSR Journal of PharmacyNo ratings yet

- Zao, Et Al (2016) Recombinant Production of Medium ToDocument9 pagesZao, Et Al (2016) Recombinant Production of Medium Totantry puspitasariNo ratings yet

- Scale-Up of Protein Purification Downstream Processing Issues PDFDocument13 pagesScale-Up of Protein Purification Downstream Processing Issues PDFCapNo ratings yet

- Andlar Et Al-2017-Journal of Chemical Technology and BiotechnologyDocument10 pagesAndlar Et Al-2017-Journal of Chemical Technology and BiotechnologyGary Kiel Palacios EspinozaNo ratings yet

- Citric Acid Production Stirred TankDocument9 pagesCitric Acid Production Stirred TankKarliiux MedinaNo ratings yet

- Full TextDocument9 pagesFull Text5152251No ratings yet

- Expression of Lignocellulolytic Enzymes in Pichia PastorisDocument11 pagesExpression of Lignocellulolytic Enzymes in Pichia PastorisRoberta B.No ratings yet

- A Facile Microfluidic Method For Production of Liposomes: AbstractDocument5 pagesA Facile Microfluidic Method For Production of Liposomes: AbstractJose Carlos Solis SuarezNo ratings yet

- Preparation of SorbentDocument8 pagesPreparation of SorbentSebastian Genesis ViduyaNo ratings yet

- Cell Engineering and Cultivation of Chinese Hamster OvaryDocument8 pagesCell Engineering and Cultivation of Chinese Hamster OvaryDolce MaternitáNo ratings yet

- Fernandes 2013 April 16 Miniaturization Speeding-Up Bioprocess DevelopmentDocument36 pagesFernandes 2013 April 16 Miniaturization Speeding-Up Bioprocess DevelopmentpedroefeNo ratings yet

- Japonicus URM5620 Using Waste FromDocument13 pagesJaponicus URM5620 Using Waste FrommartivalcgNo ratings yet

- Mello 2019Document10 pagesMello 2019Gabriel De JongNo ratings yet

- 4048-Article Text-18973-1-10-20151222Document9 pages4048-Article Text-18973-1-10-20151222hmossNo ratings yet

- International Journal of EngineeringDocument10 pagesInternational Journal of EngineeringChokri ChakiirNo ratings yet

- Tissue Engineering 2Document11 pagesTissue Engineering 2Vidit NarayanNo ratings yet

- Brazilian Journal of MicrobiologyDocument7 pagesBrazilian Journal of MicrobiologyHimaniNo ratings yet

- Research SampleDocument11 pagesResearch SamplesuryasanNo ratings yet

- J FBP 2017 02 010Document24 pagesJ FBP 2017 02 010Anonymous LSPoghJ5nNo ratings yet

- Pone 0070516Document16 pagesPone 0070516Trân LâmNo ratings yet

- Palm Oil Mill EffluentDocument6 pagesPalm Oil Mill Effluentankitsaxena123100% (2)

- BMC BiotechnologyDocument13 pagesBMC Biotechnologyfather45No ratings yet

- A Possible Link Between Resveratrol and TGF-B: Resveratrol Induction of TGF-B Expression and SignalingDocument5 pagesA Possible Link Between Resveratrol and TGF-B: Resveratrol Induction of TGF-B Expression and SignalingSava1988No ratings yet

- De Filtration Supplement Bioprocess Vol12Document4 pagesDe Filtration Supplement Bioprocess Vol12MilaVargasNo ratings yet

- Effect of Temperature Shift On Levels of Acidic Charge Variants in IgG Monoclonal Antibodies in Chinese Hamster Ovary Cell CultureDocument6 pagesEffect of Temperature Shift On Levels of Acidic Charge Variants in IgG Monoclonal Antibodies in Chinese Hamster Ovary Cell CultureIRFAN AHANGERNo ratings yet

- Sciencedirect: Cupriavidus Necator Using Fructose andDocument10 pagesSciencedirect: Cupriavidus Necator Using Fructose andvalentina tafurNo ratings yet

- Biochemistry New BookDocument17 pagesBiochemistry New BookPritpal SinghNo ratings yet

- Crboue Et Al 2018Document23 pagesCrboue Et Al 2018jicama SEXTO NIVELNo ratings yet

- Black Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.From EverandBlack Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.Rating: 4 out of 5 stars4/5 (1)

- Safety Instrumented Systems: Safety Layers and ProtectionsDocument4 pagesSafety Instrumented Systems: Safety Layers and Protectionsdaimon_pNo ratings yet

- Thermodynamic Analysis of Trinitrotoluene Biodegradation and Mineralization PathwaysDocument8 pagesThermodynamic Analysis of Trinitrotoluene Biodegradation and Mineralization Pathwaysdaimon_pNo ratings yet

- PulscLine Silencer Product GuideDocument12 pagesPulscLine Silencer Product Guidedaimon_pNo ratings yet

- Paraxylene Separation Unit Performances Upgrading: Fabien LUNDYDocument22 pagesParaxylene Separation Unit Performances Upgrading: Fabien LUNDYdaimon_pNo ratings yet

- HT Highland Dike TanksDocument2 pagesHT Highland Dike Tanksdaimon_pNo ratings yet

- Safe Design and Operation of Cryogenic EnclosuresDocument31 pagesSafe Design and Operation of Cryogenic Enclosuresdaimon_pNo ratings yet

- AIGA 075 - 11 Cal Method For Prevention of Overpress - Cryogenic Tanks - Reformated Jan 12 PDFDocument57 pagesAIGA 075 - 11 Cal Method For Prevention of Overpress - Cryogenic Tanks - Reformated Jan 12 PDFdaimon_pNo ratings yet

- AIGA 067 - 10 Safe Location of Oxygen and Inert Gas Vents - Reformated Jan 12 PDFDocument48 pagesAIGA 067 - 10 Safe Location of Oxygen and Inert Gas Vents - Reformated Jan 12 PDFdaimon_pNo ratings yet

- Centrifugal Compressors For Oxygen ServiceDocument53 pagesCentrifugal Compressors For Oxygen Servicedaimon_pNo ratings yet

- Safe Practices Guide For Cryogenic Air Separation PlantsDocument71 pagesSafe Practices Guide For Cryogenic Air Separation Plantsdaimon_p100% (1)

- Model Predictive Control For Integrating Processes: Lou Heavner - Consultant, APCDocument23 pagesModel Predictive Control For Integrating Processes: Lou Heavner - Consultant, APCsamim_khNo ratings yet

- QJAR's Robot CatalogueDocument6 pagesQJAR's Robot CatalogueVioleta Marinkovic Ex SavicicNo ratings yet

- Kuis NPV Vs IRR (CH 5 and 6)Document4 pagesKuis NPV Vs IRR (CH 5 and 6)Imelda HotmariaNo ratings yet

- DD Env 12018-1998Document96 pagesDD Env 12018-1998Виктор ИсакNo ratings yet

- High Volume Armature Testing: Lance Straughn Slaughter CompanyDocument10 pagesHigh Volume Armature Testing: Lance Straughn Slaughter Companyronald allan liviocoNo ratings yet

- ASME Specification For Fastener MaterialsDocument11 pagesASME Specification For Fastener MaterialsAnonymous IwqK1Nl100% (1)

- Sken 4 Dan 5Document27 pagesSken 4 Dan 5Aliza Raudatin SahlyNo ratings yet

- Design and Development of Automatic Wheelchair Cum Patient BedDocument90 pagesDesign and Development of Automatic Wheelchair Cum Patient BedSRL MECHNo ratings yet

- University TechnologyDocument16 pagesUniversity TechnologyAleksandarBukvaNo ratings yet

- Countermeasure For DC Defective Products: DC School Text BookDocument13 pagesCountermeasure For DC Defective Products: DC School Text Bookmike100% (1)

- EMG SIgnal AcquisitionDocument24 pagesEMG SIgnal AcquisitionOpenTsubasaNo ratings yet

- Ye Tu19 Turning IDocument36 pagesYe Tu19 Turning IferNo ratings yet

- Peripheral Launder HydraulicsDocument2 pagesPeripheral Launder HydraulicsahmadNo ratings yet

- A Quick Introduction To Quantum Espresso: Simone Di Cataldo September 27, 2019Document32 pagesA Quick Introduction To Quantum Espresso: Simone Di Cataldo September 27, 2019Jay Bee SharmaNo ratings yet

- Calcium + Vitamin D3Document2 pagesCalcium + Vitamin D3Jai KumarNo ratings yet

- ABX Generic Gateway User Manual 1 - 02UKDocument28 pagesABX Generic Gateway User Manual 1 - 02UKBob YahyaNo ratings yet

- Gnuradio ProgrammingDocument28 pagesGnuradio ProgrammingJavier MelendrezNo ratings yet

- Tetra Pak® Continuous Freezer S700 A 2.0 59717520445Document52 pagesTetra Pak® Continuous Freezer S700 A 2.0 59717520445Carlos Claros RiveraNo ratings yet

- STYLE AG-4911 4# Eva Closed Cell Foam: Typical Properties ofDocument2 pagesSTYLE AG-4911 4# Eva Closed Cell Foam: Typical Properties ofArrow LazarusNo ratings yet

- Oxidizing and Reducing AgentsDocument13 pagesOxidizing and Reducing Agentspallavi guptaNo ratings yet

- Huamei Spec Sheets - 2018Document1 pageHuamei Spec Sheets - 2018Phan LongNo ratings yet

- Assignment Fluid MechanicsDocument8 pagesAssignment Fluid MechanicsPhanna MongNo ratings yet

- Plant Model Matlab: Transfer FunctionDocument11 pagesPlant Model Matlab: Transfer FunctionHussain Bin AliNo ratings yet

- Top Twelve Ways To Speed Up Your Liferay DeploymentDocument48 pagesTop Twelve Ways To Speed Up Your Liferay DeploymentLaci MesterNo ratings yet

- IMOCSEA Infopack 900Document15 pagesIMOCSEA Infopack 900Ely SoemarniNo ratings yet

- Ficha Tecnica GENIE Z-3422NDocument2 pagesFicha Tecnica GENIE Z-3422NChristian Muñoz EquimmatNo ratings yet

- Flyer Powersource Motoweld-Rl350 e 02.2017Document8 pagesFlyer Powersource Motoweld-Rl350 e 02.2017Jorge Martinez PeraltaNo ratings yet

- Number Sense: FactorsDocument38 pagesNumber Sense: FactorsBrian NeisesNo ratings yet