Professional Documents

Culture Documents

Bürkle Press Line

Bürkle Press Line

Uploaded by

Wim VerschaeveOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bürkle Press Line

Bürkle Press Line

Uploaded by

Wim VerschaeveCopyright:

Available Formats

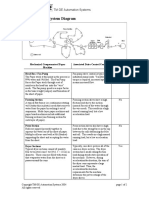

Brkle Short-Cycle Throughfeed Press Line ODW 1433/60 for laminating chipboards with customer-specific material (vinyl) and

balance paper from the roll (good side at top) and laminates cut to size Main data of the plant: Size of heating platens Maximum press surface Specific pressure on the maximum pressing area Total pressure Heating medium Maximum pressing temperature (mylar foil) Heat required with 120 pressings/h Total electric connected load approx. Operating voltage Control voltage Frequency Required suction volume with a speed of the air of 30 m/sec. = Required air pressure minimum 1400 x 3300 mm 3,93 m2 60 N/cm2 2356 kN hot water 130 deg.C. 80 000 kcal/h. .. kW 400 volt 24 volt, DC 50 cycles 5 200 m3/h. 6 bar

The precise connections will be advised on completion of the design works. Paint finish: Machines Switch cabinet Safety devices light gray, light gray, orange, RAL 7035 RAL 7035 RAL 2003

Dimensions of boards: Length **) Width Thickness of boards

2015 - 3050 mm 600 - 1300 mm 8 - 60 mm

Note: Boards of a thickness of more than 30 mm do not pass through the laminating station. The maximum width of boards for laminating is 1270 mm. **) For the manufacture of doors (without laminating station) the hardboards of 3-4 mm thickness are transported up to the core transfer and are then assembled on the acceleration belt transport. They are fed manually.

Substrates: Chipboards Specific weight 650-700 kg/m3

Relative humidity Thickness tolerance Surface

6-8% +/- 0,15 mm sanded

Hardboards which can be laminated, similar to DIN 68750 Specific weight 800 kg/m3 Relative humidity 4-5% Thickness tolerance +/- 0,15 mm Surface free from impurities Fibreboards of medium density (MDF boards) Specific weight Relative humidity Thickness tolerance Surface Cores for doors Laminated on both sides with fibreboards Note: The substrates being used must be heated to room temperature of at least 16 deg.C. prior to their use. Surface material: Customer-specific material (vinyl) To be used from the roll. Weight of foil 200 - 300 g/m2 Note: The quality of the material must allow cutting in the laminating station by means of the swinging knife. The elasticity must be so that the material does not splinter during cutting. Balance papers: Sodium paper with a slight resin coating. Processing from the roll Weight of paper from 650 kg/m3 6-10 % +/- 0,15 mm sanded

70 g/m2

Veneers: Strips of veneer which are joined to the size of the substrate. Relative moisture of the wood 8-12 % Thickness of veneer 0,4-1,2 mm Decorative laminated sheets (DKS): CPL/HPL similar to DIN 16926 Processing in sheets cut to size Thickness

0,6-1 mm

Overhang of foil when laminating: Overhang in lengthwise direction approx. 10 mm per side Overhang in direction of feed: maximum 30 mm per side

Overhang of foil when using the same in sheets cut to size approx. 5 - 10 mm all around Diameter of rolls of foil The maximum diameter of the roll of foils is 500 mm. Glues: Dispersion glue: (PVAC glue) Quantity to be applied Capacity when applying paper foils Handling time with a length of the heating platens of 3300 mm: - Loading and unloading by means of circulating mylar belts - Closing of press - Pressure build-up - Decrease of pressure - Opening of press Handling time per cycle approx. 16 seconds 90 - 130 g/m

The capacity of the plant depends on the materials being used.

Factors which influence the pressing time are: - Thickness of boards - Type of foil and thickness - Type of glue and quantity of application - Temperature of the materials being used as well as the ambient temperatures Usually the pressing times range from 10 to 35 seconds (depending on the above mentioned factors As per the information from the customer a pressing time of approx. 20 seconds and a pressing temperature of approx. 60 - 70 C. are required for pressing vinyl. The normal pressing times for veneering are approx. 30 to 50 seconds. The normal pressing times for pressing laminates are approx. 60 - 120 seconds. Stacking Height Maximum stacking height 1000 mm when loading and unloading with protective boards. Note regarding protective boards: When loading, the protective board must be removed manually.

When unloading, the protective boards must be placed on manually as well. The protective boards must always have the same thickness. Energy Supply: Placing of cables and pneumatic lines in cable ducts which are fitted to the various machines. The connection cables from the various machines to the switch cabinet will be placed in *) floor channels. These floor channels are specified in the foundation drawing. Kind of production: 1) Single or double-sided lamination of substrates with either veneer or laminates (cut to size). 2) Single or double-sided lamination of substrates with paper (from the roll). **) Manufacture of doors Assembly of the doors takes place on the acceleration belt transport. The following sequence of operations is possible: a) Single-sided glue spread and manual turning of each second hardboard (3 layers) b) Double-sided glue spread on the hardboards and assembly of the complete door (5 layers). This requires hardboards which have been sanded on both sides.

Arrangement of the Line: The press will be installed without pit. Switch cabinet at the left-hand side of the alignment roller track, seen in direction of feed. Distance to the centre of the line approx. 3000 mm Control desk at the right-hand side next to the acceleration belt transport. Heating piping at the left-hand side, seen in direction of feed Heating device at the left-hand side of the press , seen in direction of feed The connection lines between the heating device and the press have to be placed and insulated by the customer. Stacking to the right, seen in direction of feed of the line.

Design of the Plant: Item 1 Hydraulic Scissor Lift Table for lifting and lowering the stacks (The stacks are fed on an existing roller track, transfer height approx. 300 mm). Technical Design: - The hydraulic drive as well as the control valves are fitted within the basic frame - Safety devices with foot-contact rails at all four sides and a pipe-break safety valve. Technical Data: Dimensions of platform Useful load Useful stroke Heavy-Duty Roller Track mounted on the scissor lift table Direction of feed: lengthwise Technical Data: Length of transport Useful width Diameter of rollers Roller jacket Spacing of rollers Overall height to top edge of roller track (inclusive scissor lift table), approx. 3200 mm 1400 mm 108 mm zinc-coated 300 mm 650 mm 1500 x 3200 mm 3500 kg 1200 mm

Driving Unit Drive by means of a geared motor and a precision roller chain from roll to roll. Feed speed approx. Item 2 Infeed Device 10 m/min.

Technical Design: - Infeed arm with 2 infeed shoes, driven by a geared motor and a precision roller chain - Infeed arm can be swung up pneumatically for changing the stacks and for manual loading. - Infeed arm arranged at the left-hand side, seen in direction of feed. Technical Data: Adjusting range of the infeed arm steplessly adjustable Thickness of boards Infeed speed Infeed height approx. Item 3

600 mm maximum 8 - 60 mm 3 - 15 m/min. 1060 mm

1 Alignment Roller Track with diagonally arranged rollers Adjustment in width of the guide rail by a handwheel and mechanical digital indication. Transport rollers provided with a rilsan covering. Guiding rail arranged at the right-hand side, seen in direction of feed. Technical Data: Length of transport Width of transport Spacing of rollers Working height Feed speed Diameter of support rollers **) Range of adjustment from 600 to 1300 mm approx. 4000 mm 1400 mm 300 mm 1060 mm 3-15 m/min. 80 mm 350 mm

Supplementary Equipment: Scraper wall at the infeed with a light barrier for the automatic height control of the scissor lift table (light barrier manually adjustable to the thickness of boards). Item 4 Transverse Brushing Machine Model DBM 1400 for double-sided cleaning and dust removal from flat boards. Transverse brush segments which are fitted on a standard chain. Regular wear of the brush segments, thus a considerably longer servicelife. Brushes and feed driven independently of one another. Each brush chain has its own direct drive. Adjustable brush pressure, re-adjustable brush shafts. Feed of the boards by pairs of rubber covered infeed and outfeed rollers. Connection pieces for connecting an available dust exhaust device. Emergency cut-out bar at the infeed side. Technical Data: Maximum working width System of brush chains Covering Speed of brushes Maximum passing height Feed speed Working height Total driving power Number of connection pieces per side Minimum suction power with approx. 28 m/sec. Weight approx. Operating side:

1400 mm Mexican fibre 1 m/sec. 120 mm 3-15 m/min. 1060 mm 2,1 kW 1 x 200 mm diameter 3500 m3/h 700 kg right-hand side

Supplementary Equipment: Machine base to adapt the working height to the infeed height of the press. Item 5 Glue Spreading Machine Model DAK 1400 for single or double-sided application of glue onto flat boards. Technical Design: - Direct drive of the applying rollers by joint couplings - Separate direct drive of the doctor rollers by slip-on gear mechanism - Precise metering of the amount of glue to be applied by a high differential speed between doctor roller and applying roller - Fast and easy cleaning of the machine while the rollers are turning and the protective grate is open due to a safety switching Technical Data: Maximum working width Width of rollers 2 Rubber covered, smooth applying rollers Surface Diameter of applying rollers 2 Hard rubber covered doctor rollers, diameter Maximum passing height Feed speed Working height Operating side Supplementary Equipment: Machine base to adapt the working height to the infeed height of the press. Outfeed with 3 driven knife-edge disk rollers for thin boards. Spraying pipes for cleaning with flat jet nozzles in the gap protection, for automatic cleaning of the doctor roller and applying roller. Minimum required water pressure 3 bar Doctor rollers being coolable with a rotary connection (without cooling device). Infeed table extended by approx. 300 mm. Item 6 1 Disk Transport Track to transport the glued boards Technical Design: 1400 mm 1516 mm 70 shore 20 grooves/ 240 mm 190 mm 80 mm 3 - 15 m/min. 1060 mm right-hand side

- Disks made of stainless steel, turning in a water bath which is provided with foam - Axles made of galvanized steel pipe - Water troughs made of galvanized steel plate which are removable for cleaning Technical Data: Length of transport Width of transport Distance between axles **) Knife-edge disks **) 2 pcs. at a distance of approx. 800 mm 3 pcs. distributed for the smallest workpiece 2 pcs. at a distance of approx. 1100 mm Diameter of disks Feed speed Supplementary Equipment: Double-sided rail which is manually adjustable to the width of the boards. Adjustment in width of the guide rails by a handwheel and mechanical digital indication. One section of 800 mm length each being hinged at infeed and outfeed side to facilitate cleaning of the glue spreading machine and to insert the foil in the subsequent laminating station. Disk transport track displaceable in direction of feed. Pallet Rack mounted on the disk transport track, of two openings, for preparing the surface material. Consisting of: 1 Basic frame with platform 1 Removable platform for a second stack of surface material When the laminating station is withdrawn, one section each can be retracted. Item 7 Laminating Station Model EKM 1300 Height adjustment for all rollers with a handwheel and digital indication Uncoiling Station Fast introduction of the foil thanks to the good accessibility and simple guiding of the foil. One uncoiling device each at top and bottom (suspension). *) The bottom foil spool bearing can be withdrawn laterally towards the right-hand side. Safety chucks with pneumatic disk brake. The foil is adjusted by a cross adjustment. Scales at the guide rollers to align the foil. 1 Clamping roller to draw tight the foil when starting. 2 Pcs. spool shafts with clamping cones for cardboard sleeves of 60 - 100 mm and 140 - 155 mm (3 and 6). 2400 mm 1400 mm 300 mm 7 pcs. per axle

100 mm 3 - 15 m/min.

Foil breakage control at top and bottom To stop the plant when the foil breaks and to reduce cleaning times and a loss of production. Waiting device The feed stops when no boards are fed any more, thus the loss of foil is reduced. The waiting position of the last board can be preselected. 1 Control for discharge The last board is evacuated from the plant after the manual trimming of the foil and without using any further foil. However, the foil rests prepared for the next charge. Automatic trimming device Swinging knife driven by compressed air to cut paper and foils between the boards. The boards are fed edge to edge. The gap for trimming is generated by a difference in speed. To avoid the overriding of boards of less than 8 mm thickness, the same must be fed with a space in between. Inclusive 1 spare trimming knife. Technical Data: 2 Rubber covered laminating rollers Direct drive Pneumatic pressure 2 Rubber covered pressing rollers in front of the trimming knife 2 Rubber covered pressing rollers behind the trimming knife Feed speed Working height approx. Operating side: 290 mm diameter 9000 N 130 mm diameter 130 mm diameter 3 - 15 m/min. 1060 mm right-hand side

Supplementary Equipment: 2 Wide stretching rollers (banana rollers) adjustable in bend, swivelling, with an adjusting slide to adjust contact of the foil with the roller. The laminating station can manually be withdrawn towards the left-hand side on rails and wheel-flange rollers when using veneer. Top foil roll suspension arranged at the post of the laminating station. Item 8 Acceleration Belt Transport System to accelerate the boards after trimming in the laminating station. This produces the distance of time required for the continuous short-cycle process between the continuously working laminating machine and the press working in cycles.

Technical Design: - Basic frame made of structural steel with belt and core transport arranged in between - Feed speed steplessly adjustable - Belts with non-skidding PVC coating Technical Data: Width of transport Length of transport approx. Divided in Width of belts Spacing of belts Feed speed Loading speed approx. 1400 mm 5000 mm 2 sections 50 mm 150 mm 3 - 15 m/min. 45 m/min.

Core Transfer for transport of the substrate on the bottom surface material which is already laid-on and for subsequently depositing the board. Technical Design: - Transport of the substrates on disk rollers made of special steel - The disk rollers are laterally fitted to two circulating transport chains. Technical Data: Width of conveyor belt Length of conveyor belt Feed speed Speed of depositing Height of depositing Supplementary Equipment: Stops which swing-in pneumatically, to hold the boards during depositing. The complete unit can be lifted and lowered pneumatically for either the coating of paper or for using the core transfer (veneering). Item 9 Hydraulic Short-Cycle Press Model ODW 1433/60 Technical Design: Press of the downstroke type of frame construction. Optimal pressure distribution thanks to the arrangement of the cylinders between the frames. Frames burned out of solid steel plates. Bearing surfaces for the bottom heating platen and the press cylinders mechanically machined. Press tables are solid steel platens with a sanded surface. Drilled heating channels. Press cylinders made of steel with built-in guide rings made of Teflon bronze compound material. Special 1400 mm 3200 mm 15 m/min. 30 m/min. 110 mm

grooved ring packings of polyurethane with reinforced profile at the motional side. Dust removal lip in the supporting ring of the packing. Pistons hard chromium-plated Parallel guiding of the mobile press table by lever compensating rods with large-sized connection shafts. Bearings maintenance-free. Roller guiding independent of temperature. Insulation between frame and bottom heating platen by a means of plastic compound boards on mineral basis. Post-suction hydraulics with oil storage reservoir and large-sized connection lines and filling valves for each press cylinder. Opening of the press by means of separate pull-back cylinders. Control by electro-magnetically operated valves. Assembly of the valves on a common hydraulic block for ease of servicing. The hydraulic unit is fitted to the press frame. The hydraulic oil does not belong to our scope of supply. Loading of the press by temperature-resistant, circulating plastic foils equipped with a fast exchange system. Drive of the foils by A.C. geared motor allowing smooth starting, smooth slowing-down and creep speed to the final position. Guide rollers without paint finish. Heating Heating of the press is done by hot water. The heating medium is fed to the heating platens by high pressure metal hoses with stainless steel armouring and by collecting pipes. Each heating platen is heated separately. Technical Data: Dimensions of heating platens Loading side Total pressure Specific pressure Cylinders, 2 rows Hydraulic operating pressure Thickness of heating platens Daylight between platens Maximum operating temperature with mylar foil Electric connected load approx. Specific load on foundation Weight of the press 1400 x 3300 mm 1400 mm 2356 kN 60 N/cm2 6 x 140 mm diameter 255 bar 100 mm 150 mm 130 C 18 kW 25 N/cm2 17 000 kg

Supplementary Equipment: Shaking device to remove the boards which stick to the top protective foil after opening of the press. Pneumatic cylinders release the tension of the foil after closing of the press and tension the same again after opening. Cleaning device for the circulating plastic foil. Consisting of suction nozzles at the infeed side and outfeed side of the bottom heating platen. Safety device to prevent faulty loading to avoid damages to the mobile heating platen in case of incorrect loading of the press. Function: Limit switches of a high switching accuracy monitor the flatness of the mobile press table. In case of a minimum deviation, there is no high pressure build-up and the press opens. Each time when the press opens, the performance of the limit switches is controlled. Air nozzles in the heating platens to detach the conveyor belt after pressing. Multicircuit hydraulics for the separate pressure control of groups of cylinders in case the press is not fully loaded. In addition each circuit can be disconnected separately. Forming of groups: 1. circuit: 2nd and 3rd transverse row of cylinders 2. circuit: 1st transverse row of cylinders Item 10 2 Heating Devices For the separate heating of the top and bottom heating platen with hot water. Technical Design: - Water circuit designed as closed system - Heating by means of electric resistances - Automatic regulation of the water temperature by microprocessor control Technical Data: Heating power 2 x 54 kW Admissible operating temperature 140 C. Connected load of the pump approx. 2 kW Heating medium water Water quality clean, not aggressive, pH value 7,5 to 8,5 Dimensions: length 990 mm width 400 mm height 1050 mm Note: The connection lines between the heating device and the press have to be placed and insulated by the customer.

Item 11 Outfeed Roller Track to take over the pressed boards from the press and to make them available for the vacuum stacker. Technical Design: *) Transport rollers covered with a felt jacket. Central pneumatic alignment. Fixed final stop Technical Data: Length of transport Width of transport Diameter of rollers Spacing of rollers *) Height of transport approx. *) Feed speed 4200 mm 1400 mm 80 mm 300 mm 950 mm 12/48 m/min.

*) Note: To take up the boards the clamping transverse beam goes into the roller track. This has been taken note of in the design. Item 12 *) Stacking Equipment without Swivelling Device for the continuous stacking of boards with a sensitive surface by means of *) clamps (without vacuum). Technical Design: - Portal design - Drive of the vacuum suction carriage by *) a frequency-controlled geared brake motor - Precise positioning of the pick-up and depositing position - Without pit

Technical Data: Maximum load Number of cycles maximum **) Travel approx. **) Number of stacking places **) Number of stopping places Required air pressure *) Design Clamping stroke Operation **)

100 kg 3 cycles/min. 2500 mm 1 2 6 bar retractable rollers, gripping from the bottom, 4 pcs. per side depending on the size of the boards centrical

Item 12.1 Protective Fencing to protect the working zone of the stacker Consisting of: **) Protective fence and 1 safety light barrier at the outfeed of the stacks. **) Light barriers with muting function Item 13 **) 2 Heavy-Duty Roller Tracks for depositing and transporting the finished boards and for making the stack available for the fork lift truck. Direction of transport lengthwise Overall height approx. 300 mm **) 1 Roller track for depositing the protective board and for stacking the boards; length approx. 7600 mm **) 1 Roller track for removing the stack of finished boards; length approx. 4000 mm **) Control of the roller tracks by the customer Item 14 Electric Control for the central control of the plant. (without the existing elements) Technical Design: Technical design as per DIN/VDE (EN 60204/1) - Switch cabinet with all switches, control and adjusting devices - Control of the plant by a microprocessor based programmable control (PLC) make Siemens - Operating elements, light barriers and limit switches at the different plant elements - Connection lines between switch cabinet and the different plant elements of plug type. - Automatic adjustment of pressure according to the prespecified dimensions of the boards - Telephone modem for the fast localization of errors Control desk installed separately, with a sloping control area to house all operating and control elements. Supplementary Equipment: **) Potential-free locking contacts for the control which is available with the customer for the heavy-duty roller tracks item 13. by the customer

You might also like

- The Lease Pumper HandbookDocument548 pagesThe Lease Pumper HandbookellsworsNo ratings yet

- VOLVO EC140 LC EC140LC EXCAVATOR Service Repair Manual PDFDocument20 pagesVOLVO EC140 LC EC140LC EXCAVATOR Service Repair Manual PDFsekfsekmddde60% (5)

- MF 6130Document803 pagesMF 6130Gracjan Łochowicz100% (1)

- Electrical System Os030ec (c801)Document48 pagesElectrical System Os030ec (c801)Hector Puac100% (1)

- PP Pulp Screw Press Brochure PDFDocument3 pagesPP Pulp Screw Press Brochure PDFEverton CarpaneziNo ratings yet

- Siempelkamp ContiRoll Forming and Press Lines-EngDocument16 pagesSiempelkamp ContiRoll Forming and Press Lines-Engxavier668No ratings yet

- Critical Attributes of Folding Cartons 2Document8 pagesCritical Attributes of Folding Cartons 2Wanda Yee100% (1)

- Calendering Is Still King For High Volume PVCDocument9 pagesCalendering Is Still King For High Volume PVCOSIIQPGRISNo ratings yet

- Bruckener StenterDocument52 pagesBruckener StenterHimanshuSingh89% (9)

- TK-50 Installation Manual Rev 1.1 - EVO1 PDFDocument147 pagesTK-50 Installation Manual Rev 1.1 - EVO1 PDFanh trong100% (7)

- Operation 31200354 09-19-11 ANSI EnglishDocument150 pagesOperation 31200354 09-19-11 ANSI EnglishWilliam RoarkNo ratings yet

- CompleteDocument12 pagesCompletemantascitaNo ratings yet

- 30 High Speed Extrusion Coating LinesDocument2 pages30 High Speed Extrusion Coating LinesWs LimNo ratings yet

- Paper Fan PumpsDocument8 pagesPaper Fan PumpsnazeerNo ratings yet

- 1461 e 2015-07-14 Brochure Compact-Dispersion-System en InteraktivDocument8 pages1461 e 2015-07-14 Brochure Compact-Dispersion-System en InteraktivelcarpaneziNo ratings yet

- Production of Conveyor BeltsDocument2 pagesProduction of Conveyor Beltssuraia100% (1)

- Sealencer The Silent Suction Roll Design: Voith PaperDocument2 pagesSealencer The Silent Suction Roll Design: Voith PapersakarisoNo ratings yet

- 1998 Lumiainen Ch4 PDFDocument59 pages1998 Lumiainen Ch4 PDFAnonymous K3FaYFlNo ratings yet

- Krima Screw Press Type RR: Cellwood Machinery AbDocument3 pagesKrima Screw Press Type RR: Cellwood Machinery AbelcarpaneziNo ratings yet

- Century Pul112Document48 pagesCentury Pul112Shubh Prakash TiwariNo ratings yet

- Fiber and Chemical Division: Global Business Unit FiberlineDocument4 pagesFiber and Chemical Division: Global Business Unit FiberlineHilda GzaNo ratings yet

- Cutes CVP SeriesDocument28 pagesCutes CVP SeriesGabenkNo ratings yet

- StickiesDocument9 pagesStickiesMarceloNo ratings yet

- Winding Force PDFDocument9 pagesWinding Force PDFandy981No ratings yet

- Doctor and Roll Cleaning Blade Holders BrochureDocument2 pagesDoctor and Roll Cleaning Blade Holders BrochuregustirizkiawanNo ratings yet

- New Additive With Low Environmental Impact: Improves SoftnessDocument4 pagesNew Additive With Low Environmental Impact: Improves SoftnessJasmainiNo ratings yet

- Twogether Article 22 en 24 TranbyDocument4 pagesTwogether Article 22 en 24 TranbyelcarpaneziNo ratings yet

- Sulzer Pumps For Paper IndustryDocument4 pagesSulzer Pumps For Paper IndustryBapu612345No ratings yet

- Core Handling EquipmentDocument20 pagesCore Handling EquipmentAnjas HardiansyahNo ratings yet

- High Performance Foil Rotor Improves De-Ink Pulp ScreeningDocument9 pagesHigh Performance Foil Rotor Improves De-Ink Pulp ScreeningAliNo ratings yet

- The Fabric of Paper Machine PerformanceDocument4 pagesThe Fabric of Paper Machine Performancest7167No ratings yet

- Belt Selection Procedure-FENNERDocument12 pagesBelt Selection Procedure-FENNERkmambiNo ratings yet

- Mike Coster Mike Coster James Coffey James Coffey Carly Snyder Carly SnyderDocument19 pagesMike Coster Mike Coster James Coffey James Coffey Carly Snyder Carly SnyderAlisha KiranNo ratings yet

- BR81487 - EN - 01 - Valmet IQ Quality Measurement Maintenance enDocument2 pagesBR81487 - EN - 01 - Valmet IQ Quality Measurement Maintenance ennotengofffNo ratings yet

- Hannecard Roll Covers Services Paper Industry en v2Document16 pagesHannecard Roll Covers Services Paper Industry en v2Phu, Le HuuNo ratings yet

- Varioline PLUS-Flexible VF-System Century Paper Pvt. - PakistanDocument11 pagesVarioline PLUS-Flexible VF-System Century Paper Pvt. - PakistansakarisoNo ratings yet

- Siempelkamp Metalforming Presses-EngDocument9 pagesSiempelkamp Metalforming Presses-EngAbdulsalamNo ratings yet

- The Basic of Crowning Industrial RollersDocument8 pagesThe Basic of Crowning Industrial RollersJuan Carlos CárdenasNo ratings yet

- FRIM Centrifugal CleanersDocument12 pagesFRIM Centrifugal CleanersKristin WeberNo ratings yet

- Fiber Paper No LowDocument60 pagesFiber Paper No Low120984No ratings yet

- IE Catalogue 2007Document38 pagesIE Catalogue 2007Вадим НикитенкоNo ratings yet

- Commercial Paper Making With KenafDocument7 pagesCommercial Paper Making With KenafSang Ka KalaNo ratings yet

- Metering Size PressDocument22 pagesMetering Size PressDaud ZamanNo ratings yet

- t580 D 3 Sarg With Editorial Corrections IncorporatedDocument8 pagest580 D 3 Sarg With Editorial Corrections IncorporatedRaNo ratings yet

- Paper Making ProcessDocument13 pagesPaper Making ProcessSamin MaharjanNo ratings yet

- Paper DictionaryDocument88 pagesPaper DictionaryjmobrNo ratings yet

- Calender IngDocument12 pagesCalender IngAditi ChakrabortyNo ratings yet

- VoithDrive-624 e VP Voithdrive enDocument6 pagesVoithDrive-624 e VP Voithdrive enMarcWorldNo ratings yet

- WPP FabricsdryerDocument17 pagesWPP FabricsdryernotengofffNo ratings yet

- Introduction:-: Lars Nilsson.Document18 pagesIntroduction:-: Lars Nilsson.Bharat PatilNo ratings yet

- Andritz NonwovensDocument8 pagesAndritz NonwovensJoe SparrowNo ratings yet

- Technology, Energy Efficiency and Environmental Externalities in The Pulp and Paper Industry - AIT, ThailandDocument140 pagesTechnology, Energy Efficiency and Environmental Externalities in The Pulp and Paper Industry - AIT, ThailandVishal Duggal100% (1)

- Machinery SafetyDocument12 pagesMachinery SafetyAlexius KelupuNo ratings yet

- Voith-Paper Twogether24 enDocument76 pagesVoith-Paper Twogether24 enPhi TiêuNo ratings yet

- Paper Machine System Diagram: TM GE Automation SystemsDocument2 pagesPaper Machine System Diagram: TM GE Automation SystemsWudassie AyeleNo ratings yet

- Cleaning GuidelinesDocument10 pagesCleaning GuidelinesMr. JahirNo ratings yet

- Precision Doctor Blade LRDocument8 pagesPrecision Doctor Blade LRjohnb2bNo ratings yet

- Refining Mechanisms and Development of TMP Propert1Document15 pagesRefining Mechanisms and Development of TMP Propert1Laboratorio PapelesRegionales100% (1)

- Topic 16 Papermaking Calendering TextDocument11 pagesTopic 16 Papermaking Calendering TextranjithNo ratings yet

- PaperGrades VendittiDocument33 pagesPaperGrades VendittiArif Hasan100% (1)

- Paper MakingDocument2 pagesPaper Makinghappy meNo ratings yet

- TB - T 2843-2007Document21 pagesTB - T 2843-2007erdemNo ratings yet

- Expertip 1 Cleaning and Conditioning of Dryer FabricsDocument4 pagesExpertip 1 Cleaning and Conditioning of Dryer FabricsnotengofffNo ratings yet

- SKF in Paper MachinesDocument0 pagesSKF in Paper Machinesgrupa2903No ratings yet

- Komfi - Delta Sinfgmbmgle SidedDocument2 pagesKomfi - Delta Sinfgmbmgle SidedKabil RajNo ratings yet

- Astra V Astra V1.2 1.2: User'S ManualDocument38 pagesAstra V Astra V1.2 1.2: User'S ManualMalik Asif100% (1)

- 330a Installation ChecklistDocument4 pages330a Installation Checklistjimmy pNo ratings yet

- GTH-4017 ManualDocument2 pagesGTH-4017 ManualMark CarterNo ratings yet

- Drilling. and Casing. Check List.Document24 pagesDrilling. and Casing. Check List.Aderobaki GbengaNo ratings yet

- Presentation On MBD Present StatusDocument55 pagesPresentation On MBD Present StatusMiDdin818No ratings yet

- Lift Truck Weight Indicator: Technical Manual GA1035A SeriesDocument36 pagesLift Truck Weight Indicator: Technical Manual GA1035A SeriesAndres NavarroNo ratings yet

- EP16NTDocument4 pagesEP16NTMichael100% (1)

- Primavera WorkshopDocument14 pagesPrimavera WorkshopGerry TriazNo ratings yet

- Is Iso 20474 5 2008Document19 pagesIs Iso 20474 5 2008alamimohamedNo ratings yet

- Elevator Design CalculationsDocument2 pagesElevator Design CalculationsJOSEPH APPIAHNo ratings yet

- FCU Safescreen: Installation ManualDocument13 pagesFCU Safescreen: Installation ManualChien liang LiuNo ratings yet

- Monorail SystemDocument62 pagesMonorail SystemHà Tiến ĐôngNo ratings yet

- A NICE3000new 2018Document203 pagesA NICE3000new 2018Bahodur ToshevNo ratings yet

- Installation Manual: Truck Edition (TSA and AP) Single Temperature SystemsDocument74 pagesInstallation Manual: Truck Edition (TSA and AP) Single Temperature SystemsRicardo CristalinasNo ratings yet

- IONE-AA00-MS-MS-0013 WMS For Air Cooler InstallationDocument18 pagesIONE-AA00-MS-MS-0013 WMS For Air Cooler InstallationYusufNo ratings yet

- Spec New Project V300Document4 pagesSpec New Project V300Robert Oconer AguilarNo ratings yet

- Design of Automatic Parking System For Two-WheelerDocument5 pagesDesign of Automatic Parking System For Two-WheelerSandeep DhimanNo ratings yet

- Parts Book THI056C: Terex HandlersDocument190 pagesParts Book THI056C: Terex HandlersMiguel PicadoNo ratings yet

- NMRV enDocument336 pagesNMRV engbys456jqcNo ratings yet

- LiftsDocument30 pagesLiftsIreneNo ratings yet

- Modular Mill With Modular DriveDocument6 pagesModular Mill With Modular DriveFran JimenezNo ratings yet

- Steering System For Electric Lift Trucks: MaintenanceDocument28 pagesSteering System For Electric Lift Trucks: MaintenanceNgo Ngoc Tu100% (1)

- Observations On TerragniDocument13 pagesObservations On TerragnidamianplouganouNo ratings yet