Professional Documents

Culture Documents

Hyd Symbols

Hyd Symbols

Uploaded by

Adi Surya HerysusantoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hyd Symbols

Hyd Symbols

Uploaded by

Adi Surya HerysusantoCopyright:

Available Formats

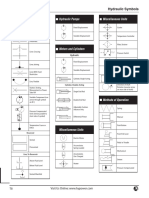

Hydraulic symbols

Energy conversion

Energy transfer

line, supply line, return line, component framing and symbol boxed in internal and external pilot line, leakage oil line, purging line, exhaust line

Actuation Manual actuation

Valves Basic symbols

Valves Directional control valves

A A B

Valves Stop valves

shut-off valve 3-way stop-cock

hydraulic pump with constant delivery rate

by pushing

by pulling

by pulling and pushing Function unit for valves with main ports. The number of ports corresponds to the number of lines shown above and below a square.

frames for several components hydraulic variable displacement pump with alternating direction of delivery at constant direction of rotation tubing line

by turning

by lever

by rocker

T P 3/2-way valve with solenoid coil, directly actuated, reset by spring and manual override with detent A B

T P 4/2-way valve with two solenoid coils, directly actuated, with detent (double solenoid valve)

non-return valve B

non-return valve with spring A2 B2

Mechanical actuation

line connection reversible hydraulic pump/hydraulic motor unit with two directions of flow and variable displacement volume, external leakage oil line and two directions of rotation. crossing line closed exhaust port X1 by plunger A T P 4/3-way proportional valve, directly actuated P T actuated in initial position

G

A X piloted non-return valve with spring X2 A1 shuttle valve (OR function) B A2

A1 B1 double non-return valve, piloted B A1 A2

by roller

pressure supply port, closed

plug within a fluid line

by roller lever, actuation in one direction of travel only

4/3-way valve, hydraulically actuated, spring-centred basic elements with 2, 3, 4 switching positions A B

dual-pressure valve (AND function)

Flow control valves

A flow control valve, fixed B B orifice, fixed B2 flow control valve, adjustable B1

hydraulic motor with constant displacement/ absorption capacity and two directions of rotation

rotary drive/semi-rotary drive with limited angle of rotation and two directions of flow

hydraulic energy source

tank connection, ending below and above the oil level

Pressure actuation

reservoir closed with cover reservoir open to atmosphere pneumatically actuated hydraulically actuated paths and directions of flow through a valve X Y T P 4/3-way servo valve piloted by a control solenoid, with closed-loop position control of main and pilot stage, with integrated electronics, external pilot supply and drain A directional control valve with intermediate positions dynamic control valve by solenoid coil with one winding active direction active direction towards the away from the valving element valving element hydraulic pump and hydraulic motor with shaft coupling A 1M1 X A P T Y A B 1M2 B

function: leak-tight locking, hydraulic seat

electric motor

Electrical actuation

motor shaft points to the right (preferably) or to the left pump shaft points to the left (preferably) or to the right

A one-way flow control valve, adjustable B T

A flow distributor B

T P 4/3-way servo valve, piloted, solenoid coil with two windings, with mechanical feedback of the valve slide position to the pilot stage

A A 3-way flow control valve, adjustable 2-way flow control valve, non-adjustable

compact gear unit (simplified representation)

single-acting cylinder double-acting cylinder with piston rod at one end, with piston rod at one end spring chamber with leakage oil connection

by solenoid coil with two windings, active direction to and from the valving element quick decoupler with two non-return valves, decoupled; i.e. line closed quick decoupler with two non-return valves, coupled by electric motor with by stepper motor continuous rotary motion

double-acting cylinder with through piston rod of different diameters, with adjustable cushioning at both ends

Combined actuation

filter tank ventilation filter by solenoid coil and pilot valve by solenoid coil or manual override and pilot valve

examples for connection identification: A = port B = port T L P = pump T = reservoir X = control oil supply Y = control oil relief 1M1 L = leakage oil M = solenoid coil Connections must be marked on the circuit diagram using the identification marked on the component, sub-base or block (ISO 1219-2).

T P 3/2-way poppet valve with solenoid coil and limit switch

Accessories Measurement and display devices

Pressure control valves

A P pressure gauge temperature gauge (thermometer)

T L P sequence valve, self-actuating, with bypass valve A flow rate display flow meter

single-acting cylinder, plunger cylinder

2/2-way valve with 2 ports, 2 switching positions for 2 flow directions. normally closed normally open position position

directly actuated pressure relief valve, adjustable A

telescope cylinder, single-acting

p1 p2

telescope cylinder, double-acting

filter with bypass valve with optical contamination indicator and switch

fluid level display (sight glass) L pressure switch, electromechanical, adjustable

P

tachometer

by solenoid coil or manual override

by solenoid coil or manual override with detent 3/2-way valve with 3 ports and 2 switching positions, normally closed position 4/2-way valve with 4 ports and 2 switching positions

Mechanical components

pressure booster, single-acting, which converts a pneumatic pressure p1 into a higher hydraulic pressure p2

G G

piloted 2-way pressure directly actuated 2-way pressure regulator regulator with external control oil relief with external control oil relief A A

pressure sensor, analogue output signal

cooler without flow lines for the direction of flow of coolant

heating

5 Detents are to be symmetrically matched with the mechanical connection. With more than three detent positions the number of positions can be displayed above the detent element.

pressure switch, electronically adjustable, output signal switching

G G

P T

3-way pressure regulator accumulator charging valve P T

G

displacement encoder with analogue output signal

displacement encoder with digital output signal

double-acting cylinder double-acting cylinder with displacement with integrated encoder on the piston rod displacement encoder

gas pressure accumulator, separation of media through: diaphragm bladder piston (diaphragm (bladder (piston accumulator) accumulator) accumulator)

1 2 3 1 2 3

X reset by spring spring-centred 4/3-way valve with 4 ports and 3 switching positions various mid-position variants T shut-off/ counterbalancing valve P proportional pressure relief valve, directly actuated with closed-loop position control of solenoid coil and with integrated electronics optical indicator

4

digital display

L

three-way rotary connection

fluid level switch with 4 normally closed contacts

electrical fluid level monitoring with analogue output signal and digital display

053032 en Festo Didactic GmbH & Co. KG

www.festo-didactic.com

You might also like

- GMK Schematic HandbookDocument55 pagesGMK Schematic HandbookYukki Badamgarav100% (10)

- HYDRO 1 - Three Reservoir Problems and Water HammerDocument18 pagesHYDRO 1 - Three Reservoir Problems and Water HammerJohn Paul LiwaliwNo ratings yet

- Dinison High Flow Seat Valve - Ver 7-En 5060-ADocument26 pagesDinison High Flow Seat Valve - Ver 7-En 5060-AKlaus Høj HenriksenNo ratings yet

- RE 00112 - Part 1 Hydraulic Components For Industrial ApplicationsDocument1,008 pagesRE 00112 - Part 1 Hydraulic Components For Industrial Applicationsbee140676100% (2)

- Festo Electrical, Pneumatic and Logic SymbolsDocument1 pageFesto Electrical, Pneumatic and Logic SymbolsAvtomatika Kole Nehtenin67% (3)

- Royu PP R PipesDocument2 pagesRoyu PP R PipesJoseph Valencia100% (2)

- Design - Handbook SEPTIC TANK - New York PDFDocument277 pagesDesign - Handbook SEPTIC TANK - New York PDFJE Ison100% (3)

- Non-Uniform Flows in Open Channel: INTI University CollegeDocument73 pagesNon-Uniform Flows in Open Channel: INTI University CollegeNur SalwaniNo ratings yet

- Simbolo GiaDocument1 pageSimbolo GiaFernando Gutierrez100% (1)

- DCVDocument35 pagesDCVTanoj Patro100% (1)

- Neutral Position in DCVDocument6 pagesNeutral Position in DCVAimee Spears100% (1)

- Parker - General TechnicalDocument34 pagesParker - General TechnicalClarence SmithNo ratings yet

- Servo, Hydraulic - DescriptionDocument6 pagesServo, Hydraulic - DescriptiondodoNiyo100% (1)

- Session 12 en Logic Element-Cartridge Valve NoRestrictionDocument5 pagesSession 12 en Logic Element-Cartridge Valve NoRestrictionahmed elkhoulyNo ratings yet

- Yuken Directional Control ValvesDocument193 pagesYuken Directional Control ValvesphaindikaNo ratings yet

- 3-En2200-B - 4VP01Document15 pages3-En2200-B - 4VP01najafali1No ratings yet

- Overcenter ValvesDocument4 pagesOvercenter ValvesAnonymous jSTkQVC27b100% (1)

- Pneumatic Symbol PDFDocument4 pagesPneumatic Symbol PDFCecep Atmega100% (1)

- Moog New Tb117Document24 pagesMoog New Tb117Hammad Ali Zaman100% (1)

- 4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMDocument8 pages4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMAhmed Abd ElhakeemNo ratings yet

- Short Description Content: 13 Learning Modules, 600 Training Pages, 120 Test QuestionsDocument4 pagesShort Description Content: 13 Learning Modules, 600 Training Pages, 120 Test QuestionsTun Lin NaingNo ratings yet

- Guide To Synchronizing Cylinders PDFDocument8 pagesGuide To Synchronizing Cylinders PDFPhạm Đức ThịnhNo ratings yet

- Introduction To Hydraulics For Industry Professionals: Hydraulic Systems Volume 1Document20 pagesIntroduction To Hydraulics For Industry Professionals: Hydraulic Systems Volume 1Narasimha DNo ratings yet

- Torque Conveter TA22-42E Training TextDocument8 pagesTorque Conveter TA22-42E Training TextPHÁT NGUYỄN THẾNo ratings yet

- T05 CIH Hydrostatic TransmissionsDocument39 pagesT05 CIH Hydrostatic TransmissionsMohamed BakheetNo ratings yet

- Bomba de PistonesDocument38 pagesBomba de PistonesChristian Perez100% (1)

- Hydraulics and PneumaticsDocument20 pagesHydraulics and Pneumaticsharishme028100% (2)

- BruceBesch IntroElectrohydraulicDocument96 pagesBruceBesch IntroElectrohydraulicbabaNo ratings yet

- Goldcup Salescatalog Hy28 2667 01 GC Na, EuDocument88 pagesGoldcup Salescatalog Hy28 2667 01 GC Na, Eugioscorza2100% (2)

- Bosch Rexroth Hydraulic Hybrids - Ra98310 - 2010-08Document8 pagesBosch Rexroth Hydraulic Hybrids - Ra98310 - 2010-08MattH3No ratings yet

- Proportional Reducing ValveDocument8 pagesProportional Reducing ValvediabalziabNo ratings yet

- Me8694 - Hydraulics and Pneumatics: Arulprakasam G Assistant Professor Dept - Of.mech - Engg., Kit-CbeDocument12 pagesMe8694 - Hydraulics and Pneumatics: Arulprakasam G Assistant Professor Dept - Of.mech - Engg., Kit-CbeArul Prakasam GNo ratings yet

- SD 6 eDocument16 pagesSD 6 eseaqu3stNo ratings yet

- Hydraulic System: Dictionary of Pictograph SymbolsDocument7 pagesHydraulic System: Dictionary of Pictograph SymbolsalexarauNo ratings yet

- ME597 Lecture1 11Document33 pagesME597 Lecture1 11Tihomir Markovic100% (1)

- T52WA - Power Board Circuit PDFDocument4 pagesT52WA - Power Board Circuit PDFjose nuñezNo ratings yet

- REXROTH 4wrz 16 5x-6x Series PDFDocument20 pagesREXROTH 4wrz 16 5x-6x Series PDFمحمدلمينابراهيمالموريتاني100% (1)

- Burner - Oilon - GKP 50 To 90 - ManualDocument100 pagesBurner - Oilon - GKP 50 To 90 - ManualMll RaghebNo ratings yet

- Moog Hydraulic Servo Valve Construction Plus Moog PDFDocument13 pagesMoog Hydraulic Servo Valve Construction Plus Moog PDFJean DesingermainNo ratings yet

- Hydraulic Press Machine PartsDocument12 pagesHydraulic Press Machine PartsKereme JulienNo ratings yet

- BOOK 2, CHAPTER 8 - Directional Control Valves - Other Technologies Content From Hydraulics & PneumaticsDocument21 pagesBOOK 2, CHAPTER 8 - Directional Control Valves - Other Technologies Content From Hydraulics & PneumaticssriramNo ratings yet

- Each Component of Air System : Caution: 2 of Air Solenoid Valve Are Used For Different Purpose (Fig. 5 and Fig. 5)Document5 pagesEach Component of Air System : Caution: 2 of Air Solenoid Valve Are Used For Different Purpose (Fig. 5 and Fig. 5)محمد عابدينNo ratings yet

- Hydraulic Components Manufacturing PDFDocument14 pagesHydraulic Components Manufacturing PDFabyzenNo ratings yet

- Parker-Ser - Usadsadasdpravljanje Pumpi 176,183,29oDocument24 pagesParker-Ser - Usadsadasdpravljanje Pumpi 176,183,29oAleksa Milosavljevic AdzaNo ratings yet

- Transparencies Electrohydraulics FestoDocument64 pagesTransparencies Electrohydraulics FestoJosue CarpioNo ratings yet

- Vane Type Double Pump (Bomba de Palheta) Vickers EATON V2200-S214Document5 pagesVane Type Double Pump (Bomba de Palheta) Vickers EATON V2200-S214Lucas CardosoNo ratings yet

- 40Ω -10Ω Series Flow Control and ReliefDocument10 pages40Ω -10Ω Series Flow Control and ReliefMohamed FersiNo ratings yet

- Abu Hanieh Fluid Power Control Ed2 ReducedDocument343 pagesAbu Hanieh Fluid Power Control Ed2 ReducedpcnishantNo ratings yet

- En 60164624-Iso-Din-1219Document20 pagesEn 60164624-Iso-Din-1219MrMsmaxNo ratings yet

- 3 Handout Pilot-Controls enDocument16 pages3 Handout Pilot-Controls enluis100% (1)

- Servo Valve Coloring BookDocument18 pagesServo Valve Coloring BooksaikatmeNo ratings yet

- MHV Proportional Directional Control Valve Series MHV... K: FeaturesDocument28 pagesMHV Proportional Directional Control Valve Series MHV... K: FeaturesthijssilderhuisNo ratings yet

- B1 E-Load-Sensing Tractors enDocument11 pagesB1 E-Load-Sensing Tractors enwalk001No ratings yet

- Transmission Circuit RecommendationsDocument40 pagesTransmission Circuit RecommendationsanandsubbiahNo ratings yet

- A10VO.3X - CANADA - Model A10V0 Piston Pump Manual PDFDocument23 pagesA10VO.3X - CANADA - Model A10V0 Piston Pump Manual PDFbee140676No ratings yet

- Hydraulics and Pnuematics SymbolsDocument9 pagesHydraulics and Pnuematics SymbolsRockingRayGNo ratings yet

- IHP Pneumatic SymbolsDocument4 pagesIHP Pneumatic SymbolsBIPIN SHARMANo ratings yet

- Report: Pneumatic UTMDocument14 pagesReport: Pneumatic UTMadibah ismail50% (2)

- Basic Hydraulic SymbolsDocument14 pagesBasic Hydraulic SymbolsAdi Surya HerysusantoNo ratings yet

- Solenoid SymbolsDocument3 pagesSolenoid Symbolskskr_44No ratings yet

- Symbols in PneumaticDocument5 pagesSymbols in PneumaticOcampo AmyNo ratings yet

- Fluid Power Symbols PDFDocument4 pagesFluid Power Symbols PDFsanisah1245100% (1)

- Plano de Transmision D6TDocument2 pagesPlano de Transmision D6TronaldNo ratings yet

- Basic Symbols (Hydraulic and Pneumatic) : LinesDocument7 pagesBasic Symbols (Hydraulic and Pneumatic) : LinesMansoor AliNo ratings yet

- Simbologia Neumatica Iso 1219 1Document174 pagesSimbologia Neumatica Iso 1219 1Luis Alfredo ContrerasNo ratings yet

- Festo Hydraulics Workbook Basic Level TP501 204Document204 pagesFesto Hydraulics Workbook Basic Level TP501 204Avtomatika Kole NehteninNo ratings yet

- Basic Hydraulic SymbolsDocument14 pagesBasic Hydraulic SymbolsAdi Surya HerysusantoNo ratings yet

- Festo Basic PneumaticDocument274 pagesFesto Basic Pneumaticshellafaye100% (16)

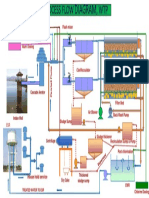

- WTP Process DiagramDocument1 pageWTP Process DiagramKumar AbhishekNo ratings yet

- ItDocument5 pagesItkmsrini@yahoo.comNo ratings yet

- Erw Steel Pipe Api5lb Psl1Document2 pagesErw Steel Pipe Api5lb Psl1hdierkeNo ratings yet

- Final CoTm Curriculum Draft@2nd HarmonizationDocument113 pagesFinal CoTm Curriculum Draft@2nd Harmonizationamare ayeleNo ratings yet

- 3 - Rainwater HarvestingDocument19 pages3 - Rainwater HarvestingBhavin PeshawariaNo ratings yet

- Ce321hw10 12 PDFDocument3 pagesCe321hw10 12 PDFSachinNo ratings yet

- Drinking Water: Does Access To Water Mean Safety?Document3 pagesDrinking Water: Does Access To Water Mean Safety?Priyam MrigNo ratings yet

- Component List V01 PDFDocument9 pagesComponent List V01 PDFshenNo ratings yet

- Sewer Design GuideDocument51 pagesSewer Design GuideDia' M. T. Ghanem100% (2)

- Ganesh Industrial Supplies: Janatha Fish Meal & Oil CompanyDocument1 pageGanesh Industrial Supplies: Janatha Fish Meal & Oil CompanyVikasNo ratings yet

- Trane Tutorial para Diseño Tuberías 1Document2 pagesTrane Tutorial para Diseño Tuberías 1Anabel Hernández DíazNo ratings yet

- Link-Belt LS-108 Hylab 5 Hydraulic Diagram PDFDocument14 pagesLink-Belt LS-108 Hylab 5 Hydraulic Diagram PDFKOK100% (3)

- Water Supply SystemDocument52 pagesWater Supply Systemnyagabona goodluckNo ratings yet

- MEFA - Sprinkler Pipe Loop S"Document2 pagesMEFA - Sprinkler Pipe Loop S"georgecisNo ratings yet

- DPL DripPanElbowDocument1 pageDPL DripPanElbowPartha Sarathi SadhukhanNo ratings yet

- AECB Water Standards Vol 2Document32 pagesAECB Water Standards Vol 2NeedleandMortarNo ratings yet

- Sand Septic SystemDocument5 pagesSand Septic Systemsabiha naazNo ratings yet

- Per Capita DemandDocument14 pagesPer Capita Demandrashmarsv63% (8)

- Sequencing Batch ReactorsDocument7 pagesSequencing Batch ReactorsMar MaslanNo ratings yet

- Sprinkler Calculation - Training Room No 3 - 4Document15 pagesSprinkler Calculation - Training Room No 3 - 4Bukhory Tajudin100% (1)

- Berkley B3ZPL PumpDocument24 pagesBerkley B3ZPL PumpPumpxpertNo ratings yet

- Manila WaterDocument154 pagesManila WaterErwin JasarenoNo ratings yet

- NFPA14Document10 pagesNFPA14kmas1612No ratings yet

- Chapter 10 ReportDocument22 pagesChapter 10 Reporthello whelloNo ratings yet

- Flow Rate MeasurementDocument6 pagesFlow Rate Measurementusebio64No ratings yet

- Hydrology Final PPTX - GRP.5 PDFDocument55 pagesHydrology Final PPTX - GRP.5 PDFAlvin DeliroNo ratings yet