Professional Documents

Culture Documents

Seal Assembly Components

Seal Assembly Components

Uploaded by

hadeCopyright:

Available Formats

You might also like

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- 12P Freyssibolt 1Document12 pages12P Freyssibolt 1Ed MateiNo ratings yet

- Valvula Lo TorcDocument16 pagesValvula Lo TorcBelen FernandezNo ratings yet

- Din 15093Document2 pagesDin 15093hadeNo ratings yet

- TPM Concept and Literature Review PDFDocument110 pagesTPM Concept and Literature Review PDFheru984100% (4)

- DHL Logistic Assignment - Supply Chain (YEN's Part)Document13 pagesDHL Logistic Assignment - Supply Chain (YEN's Part)Yen Nguyen100% (2)

- BungeDocument60 pagesBungeManjeet ChoudharyNo ratings yet

- Flange Insulation Brochure Rev3Document10 pagesFlange Insulation Brochure Rev3Gilberto YoshidaNo ratings yet

- WKM Pow R Seal Gate Valves BrochureDocument28 pagesWKM Pow R Seal Gate Valves BrochureKhai Huynh100% (1)

- Destec G RangeBrochureDocument16 pagesDestec G RangeBrochureltrongluanvn100% (2)

- Broady 3500 BrochureDocument12 pagesBroady 3500 Brochureahmedm2020No ratings yet

- PSL CatalogueDocument10 pagesPSL CataloguePhornlert WanaNo ratings yet

- Steel Tank Brochure WDocument8 pagesSteel Tank Brochure Wsegunoyes0% (1)

- Strong Sureseal Shaft Seals: Tides Marine IncDocument2 pagesStrong Sureseal Shaft Seals: Tides Marine IncEdgar Real ViúlaNo ratings yet

- Blast JointDocument1 pageBlast JointRizki MuhamadNo ratings yet

- TC0859 PDFDocument40 pagesTC0859 PDFBoris ZaslichkoNo ratings yet

- WKM HP Butterfly BrochureDocument28 pagesWKM HP Butterfly BrochureAarthi PadmanabhanNo ratings yet

- Tyco Vanessa DatasheetDocument16 pagesTyco Vanessa DatasheetJack ChavanNo ratings yet

- The TBV AdvantageDocument24 pagesThe TBV AdvantageRaushNo ratings yet

- Cera System Catalogue 2011Document36 pagesCera System Catalogue 2011prihartono_diasNo ratings yet

- Perar Trunnion Ball ValvesDocument54 pagesPerar Trunnion Ball ValvesUday GokhaleNo ratings yet

- ProductCatalog Cyrus Shank PSVDocument95 pagesProductCatalog Cyrus Shank PSVmramos4191No ratings yet

- 05 Edge Welded BellowsDocument13 pages05 Edge Welded BellowsAbhishek BasakNo ratings yet

- MaxwellDocument8 pagesMaxwellLassadNo ratings yet

- Válvula de Retención - Clase 600 - CAMERONDocument9 pagesVálvula de Retención - Clase 600 - CAMERONiMaJeniDeasNo ratings yet

- JacketDocument1 pageJacketNirmal SubudhiNo ratings yet

- U L K V: Pper and Ower Elly AlvesDocument1 pageU L K V: Pper and Ower Elly AlvesAnuranjanNo ratings yet

- Head and Well RefDocument5 pagesHead and Well Refmehdi227No ratings yet

- Watlow AccessoriesDocument30 pagesWatlow AccessoriesEliasNo ratings yet

- DeZURIK Eccentric Plug ValveDocument8 pagesDeZURIK Eccentric Plug ValveArikan YuzbasiogullariNo ratings yet

- Cameron Fully Welded Ball Valves PDFDocument36 pagesCameron Fully Welded Ball Valves PDFCARLOSNo ratings yet

- Anchoring of Monolithic Refractories - UkDocument9 pagesAnchoring of Monolithic Refractories - Ukantoniorossini100% (1)

- Conex CompressionDocument32 pagesConex CompressionMike LovisNo ratings yet

- Flange InsulDocument8 pagesFlange InsulAneesh JoseNo ratings yet

- Cameron TK Ball ValvesDocument32 pagesCameron TK Ball ValvesAustin J AlfredNo ratings yet

- (Good) ChemicalResistanceGuide - Many SealsDocument13 pages(Good) ChemicalResistanceGuide - Many SealscrystaltanNo ratings yet

- Temperature Limits of High Temperature SystemsDocument7 pagesTemperature Limits of High Temperature SystemsCarlosAlbertoRibeiroRuyNo ratings yet

- DEMCO Butterfly ValvesDocument36 pagesDEMCO Butterfly ValvesLuis Pol SistiNo ratings yet

- TC1045Document6 pagesTC1045Boris ZaslichkoNo ratings yet

- Rising DiscDocument8 pagesRising DiscwenigmaNo ratings yet

- Applications Guideline-Flashing (Water)Document2 pagesApplications Guideline-Flashing (Water)strahor7492No ratings yet

- Slide Plates General InformationDocument2 pagesSlide Plates General InformationLovebinNo ratings yet

- Garlock Catalogo GasketDocument46 pagesGarlock Catalogo GasketServilab LudicasNo ratings yet

- IRM2200 Lining Systems For Vessels andDocument10 pagesIRM2200 Lining Systems For Vessels andmika cabelloNo ratings yet

- Disc ValvesDocument8 pagesDisc ValvesMahesh KumarNo ratings yet

- Gate Valve Standard FeaturesDocument3 pagesGate Valve Standard Featuresعزت عبد المنعمNo ratings yet

- BellowsTech Ebook 11-15 Vs4Document9 pagesBellowsTech Ebook 11-15 Vs4abs0001No ratings yet

- Gasket RefDocument21 pagesGasket Refjun_bucayuNo ratings yet

- Expension Joints Engineering AppliancesDocument30 pagesExpension Joints Engineering AppliancesAcid BurnsNo ratings yet

- G209 IDocument8 pagesG209 IJaider CamachoNo ratings yet

- Ball ValveDocument10 pagesBall ValveshenkoviNo ratings yet

- FMC Fluid Control Flowline Products - CatalogDocument20 pagesFMC Fluid Control Flowline Products - CatalogVirnando Nainggolan50% (2)

- Metal Face Seals v3Document30 pagesMetal Face Seals v3ntchobanov0% (1)

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocument8 pagesTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4No ratings yet

- Garlock GasketsDocument46 pagesGarlock GasketskfchksdhbvkjhshfNo ratings yet

- Grove T41Document6 pagesGrove T41Den AbbasNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingFrom EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingNo ratings yet

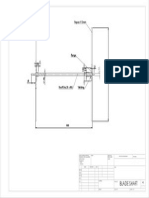

- Potongan B - B: EL +4.50 MAB EL +4.00Document1 pagePotongan B - B: EL +4.50 MAB EL +4.00hadeNo ratings yet

- DWG No. A4 SQ 12/3/2018 Plate / Section: Next ProcessDocument1 pageDWG No. A4 SQ 12/3/2018 Plate / Section: Next ProcesshadeNo ratings yet

- CTP r21Document2 pagesCTP r21hadeNo ratings yet

- Potongan B - B: EL +4.50 MAB EL +4.00Document1 pagePotongan B - B: EL +4.50 MAB EL +4.00hadeNo ratings yet

- Gantrex BumperrsDocument1 pageGantrex BumperrshadeNo ratings yet

- s33 Rail Data Sheet MetricDocument1 pages33 Rail Data Sheet MetrichadeNo ratings yet

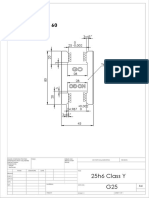

- SKD 11, HRC 60: 25h6 Class Y G25Document1 pageSKD 11, HRC 60: 25h6 Class Y G25hadeNo ratings yet

- KX3300 DataSheetDocument5 pagesKX3300 DataSheethadeNo ratings yet

- Rwin 17Document1 pageRwin 17hadeNo ratings yet

- Blade ShaftDocument1 pageBlade ShafthadeNo ratings yet

- Shaft Assy RWIN-32: 7 15 Flange 1 BushingDocument3 pagesShaft Assy RWIN-32: 7 15 Flange 1 BushinghadeNo ratings yet

- Boiler AhuDocument1 pageBoiler AhuhadeNo ratings yet

- Reamer Ahm Reamer: Material Carbide Coating TialnDocument1 pageReamer Ahm Reamer: Material Carbide Coating TialnhadeNo ratings yet

- Product Design and Development With Reverse EngineeringDocument30 pagesProduct Design and Development With Reverse EngineeringraghavakashyapNo ratings yet

- Catálogo MagnafluxDocument52 pagesCatálogo Magnafluxdaburto2No ratings yet

- Forecasting SpecialityPackagingCorpDocument2 pagesForecasting SpecialityPackagingCorpSunny Raj0% (1)

- ERP-Production Module: Presented To: Ms. Sudha SinghDocument41 pagesERP-Production Module: Presented To: Ms. Sudha SinghsanjibkrjanaNo ratings yet

- Selecting The Proper TEMA TypeDocument3 pagesSelecting The Proper TEMA TypeMubarik AliNo ratings yet

- 022-CEN Steel Tubes and Iron and Steel Fittings - EC ISS TC 110Document2 pages022-CEN Steel Tubes and Iron and Steel Fittings - EC ISS TC 110Mostafa HalawaNo ratings yet

- 1 Understanding The Supply ChainDocument6 pages1 Understanding The Supply ChainswidyartoNo ratings yet

- Strategy and Action Plan: Sector: Food and Drink ManufacturingDocument23 pagesStrategy and Action Plan: Sector: Food and Drink ManufacturingBasilio MaliwangaNo ratings yet

- 3DQStrip PDFDocument2 pages3DQStrip PDFAbdurrahman ÇetinNo ratings yet

- The Lean Lego Game: Francisco Trindade Danilo SatoDocument53 pagesThe Lean Lego Game: Francisco Trindade Danilo SatoAnonymous IcptMgwZlNo ratings yet

- ASTM A159 - Standard Specification For Automotive Gray Iron CastingsDocument2 pagesASTM A159 - Standard Specification For Automotive Gray Iron Castingsjaskaran singhNo ratings yet

- Injection Molding ProcessDocument12 pagesInjection Molding ProcessImane El BouchehatiNo ratings yet

- High Performance Industrial KnivesDocument12 pagesHigh Performance Industrial KnivesborioNo ratings yet

- Metal Cutting and Machine ToolsDocument70 pagesMetal Cutting and Machine ToolsKirankumar Koduru100% (1)

- Bakelite PropertiesDocument6 pagesBakelite PropertiesAlexander PrasetyaNo ratings yet

- Steel Composition - SiliconDocument6 pagesSteel Composition - SiliconjaffliangNo ratings yet

- What Is EDMDocument2 pagesWhat Is EDMNur' AyuniNo ratings yet

- 18-Division 2-Section 02900 PP Pipelines, Materials, Installation & TestingDocument19 pages18-Division 2-Section 02900 PP Pipelines, Materials, Installation & TestingAvaan IvaanNo ratings yet

- Dorma Vloerveren Bts 80 75v 84Document16 pagesDorma Vloerveren Bts 80 75v 84mercab15No ratings yet

- Industrial Management Handouts Lecture Notes 4Document8 pagesIndustrial Management Handouts Lecture Notes 4NicuNo ratings yet

- HTT L1 Hot Tack TesterDocument2 pagesHTT L1 Hot Tack Testerqualityc711No ratings yet

- Prof S K MaitiDocument2 pagesProf S K MaitipankuNo ratings yet

- BS en 13139 PDFDocument10 pagesBS en 13139 PDFanilkumar_bojja97600% (1)

- Bab 8 Costing by Product and Joint ProductDocument5 pagesBab 8 Costing by Product and Joint ProductAntonius Sugi Suhartono100% (1)

- Cold Storage SeminarDocument20 pagesCold Storage SeminarmsshahenterNo ratings yet

- 30GTN CatalogDocument76 pages30GTN CatalogMikeNo ratings yet

- Selective Laser SinteringDocument21 pagesSelective Laser SinteringSreedhar PugalendhiNo ratings yet

Seal Assembly Components

Seal Assembly Components

Uploaded by

hadeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seal Assembly Components

Seal Assembly Components

Uploaded by

hadeCopyright:

Available Formats

SEAL ASSEMBLY COMPONENTS

Techwest Seal Assemblies are designed to provide a dependable, leak proof seal between a Techwest Seal Bore Packer and the production string. The Seal Assemblies feature the field proven Chevron seal design in an opposed seal configuration using metal spacer rings. The Latch Locator Sub is used where it is desirable to latch the Seal Assembly in the packer bore. For example, it is used in cases where upward tubing movement from temperatures or pressure etc. do NOT present a problem. The Locator Sub is used where it is desirable to allow the seals to move up and down within the packer bore. For example, it is used in cases where upward tubing movement from temperature change and/or pressure change can cause the tubing to contract. All type of Seal Assemblies are easily converted from one type to another with interchangeable components. Spacer seal units, spacer tubes etc. can be easily added to or deleted from a seal assembly for maximum versatilitiy.

SEAL ASSEMBLY MATERIALS

Techwest seal assembly components are manufactured from alloy steel meeting N.A.C.E. specification MR-01-75 for H2S Service. When ordered in advance seal assemblies can be supplied in the following materials: High strength Alloy Steel: 9Cr 1Mo Alloy Steel: For high pressure applications Not suitable for H2S exposure as hardness exceed R.C. 22 Used in containing high percentages of H2S and CO2 Material supplied complies with N.A.C.E. specification MR-01-75 for H2S Service Used primarily for very severe corrosion environments

Incoloy 925 High Alloy Steel:

SEAL CONFIGURATIONS AND MATERIALS

STANDARD SEAL STACK Composed of Nitrile Chevron Seals and metal spacer rings. This seal pack is recommended for temperatures up to 175oF in non H2S environments. DEBRIS BARRIER SEAL STACK Similar to the standard seal stack except that Molyglass V Seals are used instead of Nitrile V Seals. This stack is often used as the top two or three stacks on a long KMR Seal Assembly to prevent debris from entering the packer bore. It may also be used as a primary seal stack in environments containing high percentages of oxygen. PREMIUM A SEAL STACK Composed of Viton Chevron Seals backed up by Molyglass Chevron Seals. Recommended for use in sour or hostile environments at temperatures up to 200OC (400o F). PREMIUM B SEAL STACK Similar to the Premium A Stack except that Alfas V Seals are substituted for the Viton V Seals. Good for temperatures up to 175OC (350 OF). KMR SEAL STACK Composed of Kalrez V Seals backed up by Molyglass and Ryton V Seals for use in high temperature hositle environments. Good for temperatures up to 260OC (500 OF). Molyglass Alfas Kalrez Ryton Teflon Trade name for reinforced Teflon Trademark of Ashi Glass Trademark of Dupont Trademark of Phillips Petroleum Co. Trademark of Dupont

3 - 20

You might also like

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- 12P Freyssibolt 1Document12 pages12P Freyssibolt 1Ed MateiNo ratings yet

- Valvula Lo TorcDocument16 pagesValvula Lo TorcBelen FernandezNo ratings yet

- Din 15093Document2 pagesDin 15093hadeNo ratings yet

- TPM Concept and Literature Review PDFDocument110 pagesTPM Concept and Literature Review PDFheru984100% (4)

- DHL Logistic Assignment - Supply Chain (YEN's Part)Document13 pagesDHL Logistic Assignment - Supply Chain (YEN's Part)Yen Nguyen100% (2)

- BungeDocument60 pagesBungeManjeet ChoudharyNo ratings yet

- Flange Insulation Brochure Rev3Document10 pagesFlange Insulation Brochure Rev3Gilberto YoshidaNo ratings yet

- WKM Pow R Seal Gate Valves BrochureDocument28 pagesWKM Pow R Seal Gate Valves BrochureKhai Huynh100% (1)

- Destec G RangeBrochureDocument16 pagesDestec G RangeBrochureltrongluanvn100% (2)

- Broady 3500 BrochureDocument12 pagesBroady 3500 Brochureahmedm2020No ratings yet

- PSL CatalogueDocument10 pagesPSL CataloguePhornlert WanaNo ratings yet

- Steel Tank Brochure WDocument8 pagesSteel Tank Brochure Wsegunoyes0% (1)

- Strong Sureseal Shaft Seals: Tides Marine IncDocument2 pagesStrong Sureseal Shaft Seals: Tides Marine IncEdgar Real ViúlaNo ratings yet

- Blast JointDocument1 pageBlast JointRizki MuhamadNo ratings yet

- TC0859 PDFDocument40 pagesTC0859 PDFBoris ZaslichkoNo ratings yet

- WKM HP Butterfly BrochureDocument28 pagesWKM HP Butterfly BrochureAarthi PadmanabhanNo ratings yet

- Tyco Vanessa DatasheetDocument16 pagesTyco Vanessa DatasheetJack ChavanNo ratings yet

- The TBV AdvantageDocument24 pagesThe TBV AdvantageRaushNo ratings yet

- Cera System Catalogue 2011Document36 pagesCera System Catalogue 2011prihartono_diasNo ratings yet

- Perar Trunnion Ball ValvesDocument54 pagesPerar Trunnion Ball ValvesUday GokhaleNo ratings yet

- ProductCatalog Cyrus Shank PSVDocument95 pagesProductCatalog Cyrus Shank PSVmramos4191No ratings yet

- 05 Edge Welded BellowsDocument13 pages05 Edge Welded BellowsAbhishek BasakNo ratings yet

- MaxwellDocument8 pagesMaxwellLassadNo ratings yet

- Válvula de Retención - Clase 600 - CAMERONDocument9 pagesVálvula de Retención - Clase 600 - CAMERONiMaJeniDeasNo ratings yet

- JacketDocument1 pageJacketNirmal SubudhiNo ratings yet

- U L K V: Pper and Ower Elly AlvesDocument1 pageU L K V: Pper and Ower Elly AlvesAnuranjanNo ratings yet

- Head and Well RefDocument5 pagesHead and Well Refmehdi227No ratings yet

- Watlow AccessoriesDocument30 pagesWatlow AccessoriesEliasNo ratings yet

- DeZURIK Eccentric Plug ValveDocument8 pagesDeZURIK Eccentric Plug ValveArikan YuzbasiogullariNo ratings yet

- Cameron Fully Welded Ball Valves PDFDocument36 pagesCameron Fully Welded Ball Valves PDFCARLOSNo ratings yet

- Anchoring of Monolithic Refractories - UkDocument9 pagesAnchoring of Monolithic Refractories - Ukantoniorossini100% (1)

- Conex CompressionDocument32 pagesConex CompressionMike LovisNo ratings yet

- Flange InsulDocument8 pagesFlange InsulAneesh JoseNo ratings yet

- Cameron TK Ball ValvesDocument32 pagesCameron TK Ball ValvesAustin J AlfredNo ratings yet

- (Good) ChemicalResistanceGuide - Many SealsDocument13 pages(Good) ChemicalResistanceGuide - Many SealscrystaltanNo ratings yet

- Temperature Limits of High Temperature SystemsDocument7 pagesTemperature Limits of High Temperature SystemsCarlosAlbertoRibeiroRuyNo ratings yet

- DEMCO Butterfly ValvesDocument36 pagesDEMCO Butterfly ValvesLuis Pol SistiNo ratings yet

- TC1045Document6 pagesTC1045Boris ZaslichkoNo ratings yet

- Rising DiscDocument8 pagesRising DiscwenigmaNo ratings yet

- Applications Guideline-Flashing (Water)Document2 pagesApplications Guideline-Flashing (Water)strahor7492No ratings yet

- Slide Plates General InformationDocument2 pagesSlide Plates General InformationLovebinNo ratings yet

- Garlock Catalogo GasketDocument46 pagesGarlock Catalogo GasketServilab LudicasNo ratings yet

- IRM2200 Lining Systems For Vessels andDocument10 pagesIRM2200 Lining Systems For Vessels andmika cabelloNo ratings yet

- Disc ValvesDocument8 pagesDisc ValvesMahesh KumarNo ratings yet

- Gate Valve Standard FeaturesDocument3 pagesGate Valve Standard Featuresعزت عبد المنعمNo ratings yet

- BellowsTech Ebook 11-15 Vs4Document9 pagesBellowsTech Ebook 11-15 Vs4abs0001No ratings yet

- Gasket RefDocument21 pagesGasket Refjun_bucayuNo ratings yet

- Expension Joints Engineering AppliancesDocument30 pagesExpension Joints Engineering AppliancesAcid BurnsNo ratings yet

- G209 IDocument8 pagesG209 IJaider CamachoNo ratings yet

- Ball ValveDocument10 pagesBall ValveshenkoviNo ratings yet

- FMC Fluid Control Flowline Products - CatalogDocument20 pagesFMC Fluid Control Flowline Products - CatalogVirnando Nainggolan50% (2)

- Metal Face Seals v3Document30 pagesMetal Face Seals v3ntchobanov0% (1)

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocument8 pagesTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4No ratings yet

- Garlock GasketsDocument46 pagesGarlock GasketskfchksdhbvkjhshfNo ratings yet

- Grove T41Document6 pagesGrove T41Den AbbasNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingFrom EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingNo ratings yet

- Potongan B - B: EL +4.50 MAB EL +4.00Document1 pagePotongan B - B: EL +4.50 MAB EL +4.00hadeNo ratings yet

- DWG No. A4 SQ 12/3/2018 Plate / Section: Next ProcessDocument1 pageDWG No. A4 SQ 12/3/2018 Plate / Section: Next ProcesshadeNo ratings yet

- CTP r21Document2 pagesCTP r21hadeNo ratings yet

- Potongan B - B: EL +4.50 MAB EL +4.00Document1 pagePotongan B - B: EL +4.50 MAB EL +4.00hadeNo ratings yet

- Gantrex BumperrsDocument1 pageGantrex BumperrshadeNo ratings yet

- s33 Rail Data Sheet MetricDocument1 pages33 Rail Data Sheet MetrichadeNo ratings yet

- SKD 11, HRC 60: 25h6 Class Y G25Document1 pageSKD 11, HRC 60: 25h6 Class Y G25hadeNo ratings yet

- KX3300 DataSheetDocument5 pagesKX3300 DataSheethadeNo ratings yet

- Rwin 17Document1 pageRwin 17hadeNo ratings yet

- Blade ShaftDocument1 pageBlade ShafthadeNo ratings yet

- Shaft Assy RWIN-32: 7 15 Flange 1 BushingDocument3 pagesShaft Assy RWIN-32: 7 15 Flange 1 BushinghadeNo ratings yet

- Boiler AhuDocument1 pageBoiler AhuhadeNo ratings yet

- Reamer Ahm Reamer: Material Carbide Coating TialnDocument1 pageReamer Ahm Reamer: Material Carbide Coating TialnhadeNo ratings yet

- Product Design and Development With Reverse EngineeringDocument30 pagesProduct Design and Development With Reverse EngineeringraghavakashyapNo ratings yet

- Catálogo MagnafluxDocument52 pagesCatálogo Magnafluxdaburto2No ratings yet

- Forecasting SpecialityPackagingCorpDocument2 pagesForecasting SpecialityPackagingCorpSunny Raj0% (1)

- ERP-Production Module: Presented To: Ms. Sudha SinghDocument41 pagesERP-Production Module: Presented To: Ms. Sudha SinghsanjibkrjanaNo ratings yet

- Selecting The Proper TEMA TypeDocument3 pagesSelecting The Proper TEMA TypeMubarik AliNo ratings yet

- 022-CEN Steel Tubes and Iron and Steel Fittings - EC ISS TC 110Document2 pages022-CEN Steel Tubes and Iron and Steel Fittings - EC ISS TC 110Mostafa HalawaNo ratings yet

- 1 Understanding The Supply ChainDocument6 pages1 Understanding The Supply ChainswidyartoNo ratings yet

- Strategy and Action Plan: Sector: Food and Drink ManufacturingDocument23 pagesStrategy and Action Plan: Sector: Food and Drink ManufacturingBasilio MaliwangaNo ratings yet

- 3DQStrip PDFDocument2 pages3DQStrip PDFAbdurrahman ÇetinNo ratings yet

- The Lean Lego Game: Francisco Trindade Danilo SatoDocument53 pagesThe Lean Lego Game: Francisco Trindade Danilo SatoAnonymous IcptMgwZlNo ratings yet

- ASTM A159 - Standard Specification For Automotive Gray Iron CastingsDocument2 pagesASTM A159 - Standard Specification For Automotive Gray Iron Castingsjaskaran singhNo ratings yet

- Injection Molding ProcessDocument12 pagesInjection Molding ProcessImane El BouchehatiNo ratings yet

- High Performance Industrial KnivesDocument12 pagesHigh Performance Industrial KnivesborioNo ratings yet

- Metal Cutting and Machine ToolsDocument70 pagesMetal Cutting and Machine ToolsKirankumar Koduru100% (1)

- Bakelite PropertiesDocument6 pagesBakelite PropertiesAlexander PrasetyaNo ratings yet

- Steel Composition - SiliconDocument6 pagesSteel Composition - SiliconjaffliangNo ratings yet

- What Is EDMDocument2 pagesWhat Is EDMNur' AyuniNo ratings yet

- 18-Division 2-Section 02900 PP Pipelines, Materials, Installation & TestingDocument19 pages18-Division 2-Section 02900 PP Pipelines, Materials, Installation & TestingAvaan IvaanNo ratings yet

- Dorma Vloerveren Bts 80 75v 84Document16 pagesDorma Vloerveren Bts 80 75v 84mercab15No ratings yet

- Industrial Management Handouts Lecture Notes 4Document8 pagesIndustrial Management Handouts Lecture Notes 4NicuNo ratings yet

- HTT L1 Hot Tack TesterDocument2 pagesHTT L1 Hot Tack Testerqualityc711No ratings yet

- Prof S K MaitiDocument2 pagesProf S K MaitipankuNo ratings yet

- BS en 13139 PDFDocument10 pagesBS en 13139 PDFanilkumar_bojja97600% (1)

- Bab 8 Costing by Product and Joint ProductDocument5 pagesBab 8 Costing by Product and Joint ProductAntonius Sugi Suhartono100% (1)

- Cold Storage SeminarDocument20 pagesCold Storage SeminarmsshahenterNo ratings yet

- 30GTN CatalogDocument76 pages30GTN CatalogMikeNo ratings yet

- Selective Laser SinteringDocument21 pagesSelective Laser SinteringSreedhar PugalendhiNo ratings yet