Professional Documents

Culture Documents

5A SystemRepairStandards Handout

5A SystemRepairStandards Handout

Uploaded by

MarsanneOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5A SystemRepairStandards Handout

5A SystemRepairStandards Handout

Uploaded by

MarsanneCopyright:

Available Formats

ONSITE SYSTEM CONSTRUCTION PERMITS AND INSPECTIONS (MASTER CONTRACTOR PART III)

Objectives:

To give a clear understanding of the System Repair and Existing System Modification permitting process. To give a clear understanding of the Septic Tank Contracting Licensing and Enforcement duties and regulations of the DOH.

8:00-9:00 System Repair Standards

System Repair Standards, ACT Day 4 and 5, 2010

Repair Application and Forms (Is it really a Repair?) Original Installation Date (Most recent date system was installed under new system requirements) Existing Tank Certification Site Evaluation Repair Site Plans Sample Forms

Systems in failure require repair in order to prevent or abate a sanitary nuisance. The use of a repair permit assumes:

There will be no change in estimated sewage flow. Change in sewage flow would require and Existing System Evaluation. There has been no unpermitted change in flow since the original system installation. An unpermitted change in the original permit conditions voids the original approval and would require a new system construction permit.

Minor structural adjustments, or replacement of mechanical components do not require a repair permit.

None of this would allow for the continued existence of a sanitary nuisance at the site.

Applications for repairs follow the same general guidelines as for new system construction. There are a few key differences: Site plans do not need to be scaled, and items to be shown are those within proximity to the system, not the property lines.

Floor plans are not required.

Because of this, all pertinent dimensions must be shown.

There is one additional form (DH4015pg4) which gives us information about the existing OSTDS.

Because of this, the existing structure information is verified with other sources, such as the property appraisers information.

System Repair Standards, ACT Day 4 and 5, 2010

DH4015pg4

Tank Size or ATU Capacity (Gallons Per Day) Tank Legend (if present) Tank Material Whether there is a baffle wall present (Additional similar information for Dosing tanks, Grease Interceptors, etc.)

DH4015pg4

Items Documented

Date tanks were pumped (inlet and outlet end if multichambered). Person who pumped the tanks. How the tank capacity was determined. The septic tank contractor, CEHP, or state-licensed plumber who physically inspected and is certifying the tanks. The name of the business certifying the tanks. The date the certification portion was signed.

DH4015pg4

Items Documented

System Repair Standards, ACT Day 4 and 5, 2010

The square-footage of drainfield area present. The number of drainline trenches. The dimensions of each trench or bed. Whether the system is subsurface or other. Whether the drainfield is installed in a bed or trenches. What type of distribution the system uses. Elevation of the bottom surface of the drainfield relative to undisturbed native soil.

DH4015pg4

Items Documented

Date this system was most recently installed under NEW system specifications. Whether the waste is domestic or commercial. Total estimated sewage flow generated by the existing structure. How the total estimated sewage flow was determined. Items Documented

DH4015pg4

Whether conditions are present that may impact the system: Drainage structures: (Ditches, swales, gutters, etc.) Pool (may be leaking, saturating the area). Is the system under a patio or deck? Is the system in an area subject to parking? Does the property slope, or is it flat? Other conditions which may be impacting the system or further reduce the available area. Items Documented

DH4015pg4

System Repair Standards, ACT Day 4 and 5, 2010

What has caused the system to fail?

These items become important when considering what the repair permit must address. There are specific rules to address systems failing due to excessive hydraulic loading and root clogging.

DH4015pg4

Items Documented

What evidence is there of the system failure?

These items serve to help verify the cause of the failure, as well as to further document items that need to be addressed during the repair.

DH4015pg4

Items Documented

Signed and dated by the authorized person submitting the information.

DH4015pg4

Items Documented

System Repair Standards, ACT Day 4 and 5, 2010

Are held to the same standards as for new system construction permits. Require a benchmark that is specific in both location and elevation. Requires careful measurement of the existing setbacks.

These must be referenced to Table V to determine the minimum proposed setbacks.

Table V lists reduced setbacks given for repairs only. These are based on the year of original system installation. If the existing setback is greater than the minimum setback, the existing setback must be maintained.

System Repair Standards, ACT Day 4 and 5, 2010

Is not required to be to scale. Shows all dimensions. Shows the existing OSTDS. Shows the proposed OSTDS. Shows the setbacks for both. Shows the auger boring locations. Shows all features requiring setbacks if they are: In proximity to the system. Will affect system installation. Defers to Table V for setback requirements. Serves to document the existing and the proposed system location and setbacks that will be used for the system permit and inspection.

System Repair Standards, ACT Day 4 and 5, 2010

In order to write the repair permit, we must first determine the following parameters of the existing system, which will be used to determine the repair permit specifications:

What is the existing tank size? Is the tank structurally sound?

The tank must be within 2 tank sizes of that required for the total flow. The tank must be free of observable defects and constructed of approved materials. If one was not present, it must be installed prior to final approval. The permit drainfield size can be no less than the existing size.

Is there an existing outlet device or filter? What is the existing drainfield size?

What are the existing system setbacks to all pertinent features?

The permitted drainfield cannot have lesser setbacks than the existing system. If the existing setbacks are less than the Table V minimums, a variance is required. Items not listed in Table V, have no setback reductions and must meet current rule requirements.

In order to write the repair permit, we must first determine the following parameters of the existing system, which will be used to determine the repair permit specifications:

What is the existing drainfield elevation compared to natural grade? When was the system originally installed? What is the sizing criteria?

The permit drainfield elevation can be no lower, while maintaining the WSWT separation determined via Table V. This information is used to determine the Table V setbacks, and sizing criteria. Determined using the number of bedrooms for pre-83 systems, or Table I for systems installed from 1983 onward. If caused by root clogging or hydraulic overload, there are special provisions.

What is the nature of the failure?

All of this information is obtained from the Application, Site Plan, Site Evaluation, and Existing System and Repair Evaluation forms. It is used to determine the minimum repair system specifications.

Chemical Treatment (any product used must be in compliance with 64E-6.0151, F.A.C.). Air injection/Physical Disruption of the Drainfield. Water Jetting of drain lines. Installation of an Aerobic Bacteria Generator.

The use of these methods requires a repair permit prior to initiating the process and an inspection prior to final approval.

System Repair Standards, ACT Day 4 and 5, 2010

Master ST contractors may schedule inspections within the normal duty schedule of the CHD. If the CHD is not on site within 30 minutes of scheduled time, the master ST contractor on site may document a System Repair Certification on Form DH 4016, Page 3, and cover the system.

If the system has been previously inspected by the CHD, and violations are found in need of correction, the Master Contractor may not inspect and cover the system.

The CHD issues a FINAL APPROVAL based on this certification on form DH4016, Page 4.

The Master Contractor Program does not allow any work without permits or certifications after normal duty hours or on weekends and holidays.

There are no after-the-fact permits.

Form DH4016, Page 4 can only be completed by a DOH employee certified per 381.0101, FS.

Requirements for repair drainfield inspections are the same as for new system construction inspections. If the existing drainfield remains part of the system, its size and configuration must also be verified. If an alternative repair method is employed, the inspection requirements will be method-specific, but must still document compliance with rule requirements.

(see handouts).

System Repair Standards, ACT Day 4 and 5, 2010

9:00- 10:00 Existing System / Modification Standards

System Repair Standards, ACT Day 4 and 5, 2010

10

You might also like

- IATA Airport Codes WorldwideDocument55 pagesIATA Airport Codes WorldwideAl-Harmain AirTravels100% (2)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- CHEVRON Compressors Installation and Pre CommissioningDocument36 pagesCHEVRON Compressors Installation and Pre CommissioningArief Budiman Hermani100% (7)

- AC7108 Rev. F - Audit Criteria For Chemical ProcessingDocument74 pagesAC7108 Rev. F - Audit Criteria For Chemical ProcessingfdsbdfsbhdgndsnNo ratings yet

- Procedure For The Design and Sizing of An Inclined Plate ClarifierDocument10 pagesProcedure For The Design and Sizing of An Inclined Plate ClarifierKelvin Siew33% (3)

- AST ChecklistsDocument16 pagesAST ChecklistsGary WoodsideNo ratings yet

- Smeta Version 4.0 CaprDocument11 pagesSmeta Version 4.0 CaprJuan Carlos0% (1)

- Instagram Creators Handbook - IGTV PDFDocument48 pagesInstagram Creators Handbook - IGTV PDFAndrei Neațu100% (1)

- 000 SAP - SD MM FI QM WM PP TablesDocument12 pages000 SAP - SD MM FI QM WM PP TablessilmarapgNo ratings yet

- Construction, Permitting, Operation, and Maintenance StandardsDocument4 pagesConstruction, Permitting, Operation, and Maintenance StandardsMarsanneNo ratings yet

- Deviation Report Guidance in Pharma in Engineering DepartmentDocument24 pagesDeviation Report Guidance in Pharma in Engineering DepartmentShiva Sai BuraNo ratings yet

- 01-GENERAL Aging AirplanesDocument129 pages01-GENERAL Aging Airplanesherculesp51No ratings yet

- E FinalInspectionsDocument101 pagesE FinalInspectionsWangunNo ratings yet

- Medical Gas - Design Guidance (Categories 1 and 2) : Code Compliant Design CriterionDocument3 pagesMedical Gas - Design Guidance (Categories 1 and 2) : Code Compliant Design CriterionRaydoon SadeqNo ratings yet

- FAT HVAC, Acceptance RequirementsDocument120 pagesFAT HVAC, Acceptance RequirementsSalley Bukhari100% (2)

- Ing Existing EquipmentDocument7 pagesIng Existing EquipmentDave LabbertonNo ratings yet

- Guidelines On Testing DP SystemsDocument28 pagesGuidelines On Testing DP SystemsFrancis ButlerNo ratings yet

- Bob's Planning Blog The Development Permit System in OntarioDocument5 pagesBob's Planning Blog The Development Permit System in Ontarioapi-246006322No ratings yet

- PTT Public Company Limited Ratchaburi World Cogeneration Company LimitedDocument49 pagesPTT Public Company Limited Ratchaburi World Cogeneration Company LimitedzhangjieNo ratings yet

- Generator System Pre-Startup Checklist: PurposeDocument5 pagesGenerator System Pre-Startup Checklist: PurposeFoe AungNo ratings yet

- Cleaning and Flushing Basics For Hydraulic Systems and Similar MachinesDocument8 pagesCleaning and Flushing Basics For Hydraulic Systems and Similar MachinestmtroyoNo ratings yet

- 2 - 2011 570 Closed Book Exam (75Qs)Document15 pages2 - 2011 570 Closed Book Exam (75Qs)Sunny Thundil100% (3)

- EMS - L5 (Air Permits)Document43 pagesEMS - L5 (Air Permits)nitin_nj1No ratings yet

- 4th Edition ChecklistsDocument14 pages4th Edition ChecklistsArdityaTishaVirgianaNo ratings yet

- Testing and Commissioning Procedure For Plumbing and Drainage InstallationDocument76 pagesTesting and Commissioning Procedure For Plumbing and Drainage InstallationSean Chan100% (19)

- Swimming Pool TestingDocument38 pagesSwimming Pool Testingrimi7alNo ratings yet

- Exchange Control PolicyDocument4 pagesExchange Control PolicyScribdTranslationsNo ratings yet

- Ppqa Titan Pneus Do Brasil Rev OriginalDocument60 pagesPpqa Titan Pneus Do Brasil Rev OriginalAnderson TpsNo ratings yet

- ABS Drilling Systems GuideDocument177 pagesABS Drilling Systems GuidemevansmetreelNo ratings yet

- Testing and Commissioning Procedure: 2012 EDITIONDocument76 pagesTesting and Commissioning Procedure: 2012 EDITIONQuerubin R Yolando Jr.No ratings yet

- Precast PCFQA AuditDocument14 pagesPrecast PCFQA AuditNguyễn Thanh Cường100% (2)

- Computerized Accounting SystemDocument12 pagesComputerized Accounting SystemfelixacctNo ratings yet

- Cleaning and Flushing Basics For Hydraulic Systems and Similar MachinesDocument13 pagesCleaning and Flushing Basics For Hydraulic Systems and Similar MachinesSarif IslamNo ratings yet

- Commissioning of Fire PumpsDocument3 pagesCommissioning of Fire Pumpskamranarif4161No ratings yet

- Modusat Pre-Commissioning Checklist MPX 2551428DDocument2 pagesModusat Pre-Commissioning Checklist MPX 2551428DNikolay GeorgievNo ratings yet

- Performance Qualification of A Clean Room From A Quality Perspective PDFDocument7 pagesPerformance Qualification of A Clean Room From A Quality Perspective PDFSirus DevasikamaniNo ratings yet

- Section 8 608 Type 2 Test Part 1Document21 pagesSection 8 608 Type 2 Test Part 1Lê Văn Thế QuangNo ratings yet

- 2011 P&FG Code Amendment # 2 Final Adds-Mods Only PDFDocument29 pages2011 P&FG Code Amendment # 2 Final Adds-Mods Only PDFBrian KrugNo ratings yet

- NFPA Fire PumpDocument12 pagesNFPA Fire PumpSyed Faizan AliNo ratings yet

- WWCollection AssignDocument38 pagesWWCollection AssignGkou DojkuNo ratings yet

- Api 570 NotesDocument3 pagesApi 570 NotesErdi Erdogan100% (1)

- Sti Sp001 Monthly Tank Inspection Checklist: Comments/Corrective ActionDocument1 pageSti Sp001 Monthly Tank Inspection Checklist: Comments/Corrective Actionjkhgvdj mnhsnjkhgNo ratings yet

- Compliance Assurance and Title V MonitoringDocument23 pagesCompliance Assurance and Title V MonitoringstacayNo ratings yet

- Commissioning in The Time of CORONA EDocument12 pagesCommissioning in The Time of CORONA EJoseph PoplingerNo ratings yet

- 2009-10 xAT Tutorial - v5Document33 pages2009-10 xAT Tutorial - v5Alejandro Martín MoninaNo ratings yet

- GTGB - Start Up - Ric8955863 Rev 0.1Document44 pagesGTGB - Start Up - Ric8955863 Rev 0.1Mohamed El Amine BouazzaNo ratings yet

- Condition Assessment Manual: Transformer Inspection Form and ChecklistDocument9 pagesCondition Assessment Manual: Transformer Inspection Form and ChecklistmuhardionoNo ratings yet

- Smeta CaprDocument11 pagesSmeta CaprRashedul IslamNo ratings yet

- 2009 UPC PresentationDocument79 pages2009 UPC Presentationbday23No ratings yet

- Additional Information For Dairy Shed Water Take ApplicationsDocument5 pagesAdditional Information For Dairy Shed Water Take ApplicationsetherbionNo ratings yet

- Perunding Nusajaya SDN BHD WTest (241123)Document29 pagesPerunding Nusajaya SDN BHD WTest (241123)Mohd SyazwanNo ratings yet

- Va259 14 R 0224 002Document53 pagesVa259 14 R 0224 002raulneti1984No ratings yet

- Plant Performance TestDocument10 pagesPlant Performance TestUjang Sonjaya100% (2)

- Factsheet96 PDFDocument9 pagesFactsheet96 PDFdocrafiNo ratings yet

- Critical Installation ElementsDocument10 pagesCritical Installation ElementsmishikhanNo ratings yet

- TSSA Field Approval Information July 29, 2011 PDFDocument5 pagesTSSA Field Approval Information July 29, 2011 PDFpraeinsteinNo ratings yet

- Hydro PlantDocument11 pagesHydro PlantSagar PatilNo ratings yet

- Acceptance Testing & Documentation To Support Validation-PresentationDocument34 pagesAcceptance Testing & Documentation To Support Validation-PresentationpoketupiNo ratings yet

- Testing and Commissioning Procedure: 2007 EDITIONDocument38 pagesTesting and Commissioning Procedure: 2007 EDITIONChokri ChakiirNo ratings yet

- Sofco Nfpa 25 FormDocument5 pagesSofco Nfpa 25 FormVin BdsNo ratings yet

- Textbook of Urgent Care Management: Chapter 5, Business Formation and Entity StructuringFrom EverandTextbook of Urgent Care Management: Chapter 5, Business Formation and Entity StructuringNo ratings yet

- Process System Value and Exergoeconomic Performance of Captive Power PlantsFrom EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsNo ratings yet

- Textbook of Urgent Care Management: Chapter 31, Laboratory OverviewFrom EverandTextbook of Urgent Care Management: Chapter 31, Laboratory OverviewNo ratings yet

- E SitePlan HandoutDocument15 pagesE SitePlan HandoutMarsanneNo ratings yet

- A BasicConcepts HandoutDocument33 pagesA BasicConcepts HandoutMarsanneNo ratings yet

- 7 SoilSurvey LegacyDocument45 pages7 SoilSurvey LegacyMarsanneNo ratings yet

- Construction, Permitting, Operation, and Maintenance StandardsDocument4 pagesConstruction, Permitting, Operation, and Maintenance StandardsMarsanneNo ratings yet

- Ronak KaranpuriaDocument2 pagesRonak Karanpuriarkaran22No ratings yet

- Sunil Hitech Engineers Awarded Road EPC Project Worth Rs. 434 Crores in Arunachal Pradesh (Company Update)Document2 pagesSunil Hitech Engineers Awarded Road EPC Project Worth Rs. 434 Crores in Arunachal Pradesh (Company Update)Shyam SunderNo ratings yet

- ME 208 Materials Science II - 1 - Strengthening MechanismsDocument13 pagesME 208 Materials Science II - 1 - Strengthening Mechanismsyasinakyldz2000No ratings yet

- RF Cavity Simulations For Superconducting Cyclotron c400Document8 pagesRF Cavity Simulations For Superconducting Cyclotron c400Hossein NazemiNo ratings yet

- Pressure Nozzle Distribution UnitDocument16 pagesPressure Nozzle Distribution UnitAlmeghalawyNo ratings yet

- Guidance On Hazard IdentificationDocument20 pagesGuidance On Hazard Identificationmath62210No ratings yet

- Appendix B Study Planner: Practice Test Reading TaskDocument10 pagesAppendix B Study Planner: Practice Test Reading TaskalNo ratings yet

- Gas Cap Drive Reservoirs - PetrowikiDocument8 pagesGas Cap Drive Reservoirs - PetrowikiAdri Coca SuaznabarNo ratings yet

- Trilon C Types TI enDocument11 pagesTrilon C Types TI enjuanfelipehincapieNo ratings yet

- Maruti Suzuki TrainingDocument37 pagesMaruti Suzuki TrainingSanu Singh0% (1)

- LS32 Parts Manual 88298001-624 MNK Tro Bay PDFDocument53 pagesLS32 Parts Manual 88298001-624 MNK Tro Bay PDFAnh Vo0% (1)

- SurajVideoRecordsFB IEIApplicationStatusOctober29,2020Document60 pagesSurajVideoRecordsFB IEIApplicationStatusOctober29,2020P Eng Suraj SinghNo ratings yet

- Earthquake Load Sharing Between Timber Framed and Masonry WallsDocument9 pagesEarthquake Load Sharing Between Timber Framed and Masonry WallsjeccoNo ratings yet

- Law of Friction: Surface Between Two Bodies Oppose Relative MotionDocument11 pagesLaw of Friction: Surface Between Two Bodies Oppose Relative Motionpradeep kumarNo ratings yet

- Chapter 3Document17 pagesChapter 3Huzairee IsmailNo ratings yet

- PL/SQL Raspunsuri Test FinalDocument27 pagesPL/SQL Raspunsuri Test FinalCristina Dinu50% (2)

- 2019 AdjustaStairs BrochureDocument12 pages2019 AdjustaStairs BrochureMauricio P. Romero ChacaltanaNo ratings yet

- EnviroBLASTO: A Calculator For Estimating The Environmental Impacts of Rock BlastingDocument6 pagesEnviroBLASTO: A Calculator For Estimating The Environmental Impacts of Rock BlastinggnpanagiotouNo ratings yet

- 2012 03 19 Ronald H Brookman Nist Foia Shear Studs Lateral Displacement wtc7 Girder A2001 PDFDocument4 pages2012 03 19 Ronald H Brookman Nist Foia Shear Studs Lateral Displacement wtc7 Girder A2001 PDFFight EvildoersNo ratings yet

- Productbrochure SD70D-SD70F VOE22B1004051 2009-05Document4 pagesProductbrochure SD70D-SD70F VOE22B1004051 2009-05t1meNo ratings yet

- Recombinant Therapeutic Protein Production in Cultivated Mammalian Cells: Current Status and Future ProspectsDocument6 pagesRecombinant Therapeutic Protein Production in Cultivated Mammalian Cells: Current Status and Future ProspectsGryseldaNo ratings yet

- No 4 Major SubwaysDocument2 pagesNo 4 Major SubwaysAndiKhaerin0% (1)

- Milspec Cross ReferenceDocument1 pageMilspec Cross ReferenceJesseNo ratings yet

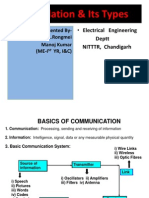

- Modullation PPT NewDocument58 pagesModullation PPT NewMayank TripathiNo ratings yet

- Jalashakti Vol No 13 Year 20 BS2071Document41 pagesJalashakti Vol No 13 Year 20 BS2071raghurmiNo ratings yet

- Microchannel Heat Exchanger: Prepared byDocument18 pagesMicrochannel Heat Exchanger: Prepared byPritam GoleNo ratings yet

- Technical Data SOLO Transfer BIO-GRINDER HUNGRYGIANT2022Document4 pagesTechnical Data SOLO Transfer BIO-GRINDER HUNGRYGIANT2022Oscar AguirreNo ratings yet