Professional Documents

Culture Documents

White Paper Pharmaceutical

White Paper Pharmaceutical

Uploaded by

Eric DunnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

White Paper Pharmaceutical

White Paper Pharmaceutical

Uploaded by

Eric DunnCopyright:

Available Formats

White Paper Pharmaceutical Industry

Pharmaceutical plants utilize various toxic gases in the production of their product. Ethylene Oxide is used in sterilization of various pieces of equipment in the industry. Where the hazardous conditions are the greatest, it is necessary to have a plant-wide monitoring system that can constantly monitor the conditions even if humans are not presently in the area so it is necessary to utilize fixed gas detection systems in addition to personal safety monitors. Build up of combustible gases could cause a hazard to the facility in an unoccupied area. Depletion of oxygen would be hazardous to individuals entering the unoccupied area, and even small amounts of toxic gases can cause serious injury or death to workers. The Sentry Gas Detection System is designed for monitoring these hazardous conditions and providing the necessary information efficiently and in a comprehensive manner so that operators can quickly make decisions to protect the plant and personnel. Sentry's unique data communications capabilities enable Sierra Monitor to provide the important hazardous gas information effectively and efficiently to operators who need to make the decisions to protect the plant and the personnel. The IT Series are ideal for this industry with their remote mounting capabilities allowing the sensor element to be located in the best area for monitoring the hazardous gas and the display/transmitter in the best location to read the display and perform calibration. The FieldServer Gateway provides the interface necessary for safety devices, process equipment and facility controls so that these various individual systems and devices can communicate to the distributed control systems found in such Pharmaceutical plants operating on DH+, Profibus, Modbus, ControlNet or EtherNet/IP. Of particular importance in this industry are validation requirements for Building Automation Systems. The U.S. Food and Drug Administration requires documented assessments of all systems serving the pharmaceutical, bio-tech and medical device facility spaces. Thus it is necessary to enable the process control operation of the plant to access data from the building automation and fire safety systems in the facility. The FieldServer Gateway provides the solution to this need, with its ability to provide the interoperability functions needed between building automation and fire alarm panel protocols and process control protocols.

Sierra Monitor Corporation 1991 Tarob Court Milpitas, California 95035 USA Ph: 408-262-6611 800-727-4377 Fax: 408-262-9042 Email: sales@sierramonitor.com

www.sierramonitor.com

You might also like

- READ 180 Daily Lesson Plans - Workshop #1Document11 pagesREAD 180 Daily Lesson Plans - Workshop #1Carrie Cown Collins0% (1)

- N2510 LAS System OverviewDocument34 pagesN2510 LAS System OverviewThanh LeNo ratings yet

- Unit 2-Seven Generation of Iot Sensor To AppearDocument12 pagesUnit 2-Seven Generation of Iot Sensor To AppearKrishna DolasNo ratings yet

- Advancing Automation: Iiot and Industry 4.0Document28 pagesAdvancing Automation: Iiot and Industry 4.0Martina Chila RamirezNo ratings yet

- And Selvamani Palanisamy: Applications of Internet of Things in Pharmaceutical IndustryDocument14 pagesAnd Selvamani Palanisamy: Applications of Internet of Things in Pharmaceutical IndustryJoe Luis Villa MedinaNo ratings yet

- Application of SCADA in RefineriesDocument6 pagesApplication of SCADA in RefineriesInfogain publication100% (3)

- Modern Food ProductionDocument24 pagesModern Food ProductionLaeeq R MalikNo ratings yet

- EPM Products Broucher - IntroductionDocument8 pagesEPM Products Broucher - IntroductionKendra TerryNo ratings yet

- Hart Interfcae SolnsDocument20 pagesHart Interfcae Solnsrenjithv_4No ratings yet

- DS01120_FAAST_Brochure_FLR_8 27 10Document4 pagesDS01120_FAAST_Brochure_FLR_8 27 10Helda MhptNo ratings yet

- MQTT Based Environment Monitoring in Factories For Employee SafetyDocument57 pagesMQTT Based Environment Monitoring in Factories For Employee SafetyPrabhu RNo ratings yet

- Instrumentation and Control EngineeringDocument2 pagesInstrumentation and Control EngineeringIan JadeNo ratings yet

- IntellimineDocument14 pagesIntellimineMarco OlazabalNo ratings yet

- Industry 4.0Document17 pagesIndustry 4.0NPMYS23No ratings yet

- 2K24 - Mrep - Gas Leakage Detection SytsemDocument23 pages2K24 - Mrep - Gas Leakage Detection SytsemRaju'K HalgyeNo ratings yet

- Jumping Into Industry 4.0 With Predictive Maintenance SolutionsDocument26 pagesJumping Into Industry 4.0 With Predictive Maintenance SolutionsNantha Kumara PeriasamyNo ratings yet

- White Paper LandfillsDocument1 pageWhite Paper LandfillsEric DunnNo ratings yet

- iPRSM Brochure 0611Document6 pagesiPRSM Brochure 0611Hardy HendraNo ratings yet

- Advantech - Catalogo Geral - Oil & GasDocument8 pagesAdvantech - Catalogo Geral - Oil & GasMarcelo MarceloNo ratings yet

- Ifm Automotive Industry Catalogue 2013 2014Document353 pagesIfm Automotive Industry Catalogue 2013 20141costin1No ratings yet

- XiltriX Brochure 2022-WebsiteDocument8 pagesXiltriX Brochure 2022-Websitebmesadir14201No ratings yet

- e-CM (Condition Monitoring) : VisionDocument3 pagese-CM (Condition Monitoring) : VisionJHON ANGEL VARGAS HUAHUASONCCONo ratings yet

- ABB Communicator 691HTDocument60 pagesABB Communicator 691HTM Jawad AliNo ratings yet

- Analyzer Houses For Petroleum IndustriesDocument4 pagesAnalyzer Houses For Petroleum IndustriesUmar SaeedNo ratings yet

- ESI Company Profile 2019Document11 pagesESI Company Profile 2019Adrian RuizNo ratings yet

- AN SupremaTouch MSADocument1 pageAN SupremaTouch MSAykresna1631No ratings yet

- 123 NetworkingDocument3 pages123 NetworkingjaechaosNo ratings yet

- Area: Control Systems Title: What Is An Integrated Control System? Author: Healey Date: 10 April 2008Document4 pagesArea: Control Systems Title: What Is An Integrated Control System? Author: Healey Date: 10 April 2008sina20795No ratings yet

- Fire and Gas in Safety SystemsDocument5 pagesFire and Gas in Safety Systemsmostafa_1000100% (1)

- Segregation Sector Wise Patent ListDocument12 pagesSegregation Sector Wise Patent Listananya jainNo ratings yet

- Faast Brochure Asbr252Document12 pagesFaast Brochure Asbr252Zaker AhmedNo ratings yet

- Regulated/Non-Regulated Partitioned Architecture: One System Covers Your Whole Facility!Document6 pagesRegulated/Non-Regulated Partitioned Architecture: One System Covers Your Whole Facility!Keegan GovenderNo ratings yet

- Ifm Technology For Mining Industry Catalogue 2013 GB PDFDocument39 pagesIfm Technology For Mining Industry Catalogue 2013 GB PDFifm electronicNo ratings yet

- DS0276 - Searchpoint Optima Plus - FLR - 3 1 11Document4 pagesDS0276 - Searchpoint Optima Plus - FLR - 3 1 11Temitope VicNo ratings yet

- AMS or AMS Suite - Machinery ManagerDocument6 pagesAMS or AMS Suite - Machinery ManagerJoko IsmiyantoNo ratings yet

- Integritas: More Control of Your Environment, Your Wetstock, Your Business... Different Businesses, Different NeedsDocument6 pagesIntegritas: More Control of Your Environment, Your Wetstock, Your Business... Different Businesses, Different NeedsDaniel Sánchez EscobarNo ratings yet

- Industrial AutomationDocument7 pagesIndustrial AutomationEl LordNo ratings yet

- Industrial SafetyDocument7 pagesIndustrial SafetymuneebNo ratings yet

- Cybersecurity in Operational TechnologyDocument15 pagesCybersecurity in Operational Technologybab_ooNo ratings yet

- HIMA Safe EthernetDocument6 pagesHIMA Safe EthernetchochoroyNo ratings yet

- Bently Nevada 3500 Monitor Regulatory Excellence en Brochure bhcs34373Document4 pagesBently Nevada 3500 Monitor Regulatory Excellence en Brochure bhcs34373Emmanuel CruzNo ratings yet

- Ivib Product Sheet ENGDocument14 pagesIvib Product Sheet ENGJango69No ratings yet

- Communication Protocols in Process ControlDocument45 pagesCommunication Protocols in Process ControlShivani Palekar100% (2)

- Manufacturing Self-Defending NetworksDocument18 pagesManufacturing Self-Defending NetworksLuis Godoy RojasNo ratings yet

- PDF Cisa CatalogueDocument31 pagesPDF Cisa CatalogueANOOPVA0% (1)

- 24 - Metor 6M DatasheetDocument2 pages24 - Metor 6M DatasheetKristanto Riyadi KlatenNo ratings yet

- Automated Test & Alignment System For Telecom ApplicationsDocument4 pagesAutomated Test & Alignment System For Telecom ApplicationsMurali KrishnaNo ratings yet

- PST Controller Brochure 4Document10 pagesPST Controller Brochure 4ferrari.edgardo646No ratings yet

- What's New With FOUNDATION Fieldbus-Part 2 - HP - Dec 2012Document2 pagesWhat's New With FOUNDATION Fieldbus-Part 2 - HP - Dec 2012onizuka-t2263No ratings yet

- Wurldtech Overview Brochure-2Document12 pagesWurldtech Overview Brochure-2Tarek KhafagaNo ratings yet

- Ifm As-Interface Catalogue GB 08Document283 pagesIfm As-Interface Catalogue GB 08Irfan KhanNo ratings yet

- 3 Sirius DatasheetDocument468 pages3 Sirius Datasheetteddy_joNo ratings yet

- Introduction To Industrial Automation and Robotics Session-4Document6 pagesIntroduction To Industrial Automation and Robotics Session-4gonegone044No ratings yet

- HSE Brazil ArticlefinalDocument13 pagesHSE Brazil ArticlefinalAkoKhalediNo ratings yet

- Computerized Systems in Drug Establishments (Feb - 1983) - FDADocument26 pagesComputerized Systems in Drug Establishments (Feb - 1983) - FDAcoimbrarojasipn9No ratings yet

- Centum CS 3000 R3Document11 pagesCentum CS 3000 R3Enas Al-khawaldehNo ratings yet

- Plagiarism Checker X Originality Report: Similarity Found: 18%Document12 pagesPlagiarism Checker X Originality Report: Similarity Found: 18%Saket Sukhwant SinghNo ratings yet

- Role of Operator Training Simulator OTS in CapabilDocument11 pagesRole of Operator Training Simulator OTS in CapabilMurtaza LaxmidharNo ratings yet

- CBM ManualDocument88 pagesCBM ManualZdenko SemanNo ratings yet

- Medical Device Manufacturer Trixell Improves Production VisibilityDocument3 pagesMedical Device Manufacturer Trixell Improves Production VisibilityrazaalvNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- LMProductGuide 2011 PDFDocument41 pagesLMProductGuide 2011 PDFEric DunnNo ratings yet

- EBI System Architecture 77-2148 PDFDocument1 pageEBI System Architecture 77-2148 PDFEric DunnNo ratings yet

- Ansul IQ-636X Control Panel IOMDocument6 pagesAnsul IQ-636X Control Panel IOMEric DunnNo ratings yet

- Central Plant Optimization - WhitePaper PDFDocument8 pagesCentral Plant Optimization - WhitePaper PDFEric DunnNo ratings yet

- Epa Bum FullDocument265 pagesEpa Bum FullAutif SayyedNo ratings yet

- Energy Star Quick Reference Guide PDFDocument4 pagesEnergy Star Quick Reference Guide PDFEric DunnNo ratings yet

- MFG Lighting - CS1 PDFDocument1 pageMFG Lighting - CS1 PDFEric DunnNo ratings yet

- HVAC Products Line Card PDFDocument2 pagesHVAC Products Line Card PDFEric DunnNo ratings yet

- Ademco Alarm Output CodesDocument8 pagesAdemco Alarm Output CodesEric DunnNo ratings yet

- White Paper LandfillsDocument1 pageWhite Paper LandfillsEric DunnNo ratings yet

- White Paper MilitaryDocument1 pageWhite Paper MilitaryEric DunnNo ratings yet

- White Paper Building AutomationDocument1 pageWhite Paper Building AutomationEric DunnNo ratings yet

- White Paper WWTPDocument1 pageWhite Paper WWTPEric DunnNo ratings yet

- White Paper TelecommuinicationsDocument1 pageWhite Paper TelecommuinicationsEric DunnNo ratings yet

- White Paper Boiler RoomsDocument1 pageWhite Paper Boiler RoomsEric DunnNo ratings yet

- White Paper Educational CampusesDocument1 pageWhite Paper Educational CampusesEric DunnNo ratings yet

- White Paper SemiconductorDocument1 pageWhite Paper SemiconductorEric DunnNo ratings yet

- White Paper Remote Mount WWTPDocument1 pageWhite Paper Remote Mount WWTPEric DunnNo ratings yet

- White Paper Facilities Management GatewayDocument1 pageWhite Paper Facilities Management GatewayEric DunnNo ratings yet

- Telecom Site Management White PaperDocument1 pageTelecom Site Management White PaperEric DunnNo ratings yet

- Gerhardt Vapodest 30sDocument40 pagesGerhardt Vapodest 30sAnonymous YwFJrk0yC100% (3)

- Power ToolsDocument5 pagesPower ToolsAhmed MoniemNo ratings yet

- 8 Essential Inventory Management TechniquesDocument6 pages8 Essential Inventory Management TechniquesSubashNo ratings yet

- Zika Virus Disease by SlidesgoDocument56 pagesZika Virus Disease by SlidesgoCaca Nur Salsa BilaNo ratings yet

- IITMandixMasai BrochureDocument12 pagesIITMandixMasai Brochureani.tubai022No ratings yet

- QA TestCases TemplateDocument29 pagesQA TestCases TemplateRafi Uddin Shaik100% (2)

- HIGHEST 47.5 Individual Project Report ASM501 (AMIR ISKANDAR)Document14 pagesHIGHEST 47.5 Individual Project Report ASM501 (AMIR ISKANDAR)Zahratul FauziyyahNo ratings yet

- Samsung d6000 Series Ue32d6000 Ue37d6000 Ue40d6000 Ue46d6000tw Ua32d6000 Ua46d6000 Ua55d6000 Led TrainingDocument31 pagesSamsung d6000 Series Ue32d6000 Ue37d6000 Ue40d6000 Ue46d6000tw Ua32d6000 Ua46d6000 Ua55d6000 Led TrainingMd BahraouiNo ratings yet

- Computer Science SyllabusDocument15 pagesComputer Science SyllabussatanNo ratings yet

- Simulasi Boiler SpreadsheetDocument5 pagesSimulasi Boiler SpreadsheetNHSNo ratings yet

- A2 - Case StudyDocument4 pagesA2 - Case StudyQerter AsphaltNo ratings yet

- Datasheet4u (4) lf411Document4 pagesDatasheet4u (4) lf411JaviNo ratings yet

- Globe TelecomDocument2 pagesGlobe TelecomJoy ShockNo ratings yet

- Nelson Vectors 12 Supplement PDF Force Eucl 3Document17 pagesNelson Vectors 12 Supplement PDF Force Eucl 3Darie MitulescuNo ratings yet

- Extending HCM Redwood Applications Using Visual Builder Studio - Technical BriefDocument25 pagesExtending HCM Redwood Applications Using Visual Builder Studio - Technical Briefjanardhan.kondaveetiNo ratings yet

- Introduction of InheritDocument2 pagesIntroduction of InheritNugroho BagusNo ratings yet

- The Application of Industry 4.0 TechnologiesDocument33 pagesThe Application of Industry 4.0 TechnologiesAchraf adenasNo ratings yet

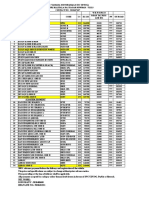

- SL - No Floor Equipment Type Equipment Tag - IDDocument55 pagesSL - No Floor Equipment Type Equipment Tag - IDBaladaru Krishna PrasadNo ratings yet

- Osmobsc Vty ReferenceDocument272 pagesOsmobsc Vty Referencelong leeNo ratings yet

- Terjemahan MBT 726 - 728Document2 pagesTerjemahan MBT 726 - 728Muchammad FauziNo ratings yet

- UntitledDocument1 pageUntitledReplacement AccountNo ratings yet

- 40.00 EnForcer HF Full Line Brochure Page by page-LowResDocument6 pages40.00 EnForcer HF Full Line Brochure Page by page-LowResLuis Alberto Rivas GarciaNo ratings yet

- DD - PlatformEPA10ddc SVC Man 0131Document236 pagesDD - PlatformEPA10ddc SVC Man 0131Cesar Bayes RamosNo ratings yet

- Flat Glass Annealing LehrsDocument7 pagesFlat Glass Annealing LehrsHồng ĐàoNo ratings yet

- Thesis Design and Implementation of A Three Phase Induction Motor Control Scheme PDFDocument93 pagesThesis Design and Implementation of A Three Phase Induction Motor Control Scheme PDFCHRISTIANNo ratings yet

- Elk-3 420 1HC0029799 Aj21 enDocument20 pagesElk-3 420 1HC0029799 Aj21 enaalbaki1No ratings yet

- Team Nand Iot Based Fleet Management System: Round 2 Phase 1 - Ideation PresentsDocument9 pagesTeam Nand Iot Based Fleet Management System: Round 2 Phase 1 - Ideation PresentsMritunjay YadavNo ratings yet

- JCB Tracked Excavator JS 210 LC: Static DimensionsDocument8 pagesJCB Tracked Excavator JS 210 LC: Static DimensionsВолодимир КривкоNo ratings yet