Professional Documents

Culture Documents

QP Cutting JSA

QP Cutting JSA

Uploaded by

Mohammed MujahidOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QP Cutting JSA

QP Cutting JSA

Uploaded by

Mohammed MujahidCopyright:

Available Formats

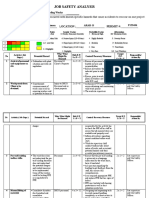

QFM-DKN-25-01 JOB SAFETY ANALYSIS Rev: 0 Date: 19.11.

2012 Page : 1 of 6

PETROSERV LIMITED

RISK MATRIX

PROJECT/JOB DETAILS

Project Ref./ Job Title / Work Order:

E Occurs several times a year at this site Low 3475 / GC 12104700

DATE: 19/11/2012

JSA No: REVISION:

INCREASING PROBABILITY

Potential Severity People Asset / Production Environment Reputation A Never heard of in industry B Has Occurred in Industry C Has Occurred in QP D Occurs several times a year in QP Low

Brief Description of job: Cutting Job Location : Dukhan Hazard Area Classification: Permit Requirements: Hot/cold/Radiography Participants(parties involved in JSA)

No Injury

No damage

No affect

No Impact

No Risk

Low

Low

Sponsoring Department: Performing Department: Permit Authority JSAApproved by

Slight injury or health effects Minor injury or health effects Major Fatality or permanent total disability Single fatality or permanent total disability Multiple fatalities

Slight damage, No disruption to operation

Slight effect

Slight impact

Low

Low

Low

Low

Low

Minor damage (=QR 250,000)

Minor effect

Limited impact

Low

Low

Medium

Medium

Medium

Major damage (=QR 1,300,000)

Localized Effect

National impact

Low

Medium

Medium

Medium

High

All the mitigation measures identified in JSA are in place before starting the activates

Major damage (=25,000,000)

Major effect

Regional Impact

Low

Medium

Medium

High

High

Work site supervisor

Extensive damage(=25,000,000)

Massive Effect

International Impact

Medium

Medium

High

High

High

Probability Factor

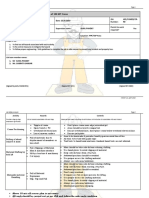

QFM-DKN-25-01 JOB SAFETY ANALYSIS Rev: 0 Date: 19.11.2012 Page : 2 of 6

PETROSERV LIMITED

Sl. No. 1

Activity (Job Steps )

Potential Hazards

Severity Before Mitigation

P= 3C(M) A=2B (M) E= 2B(M) R= 2C(M)

Required Control/Mitigation Measures

Get Authorization of work permit Have a clear understanding of work to be performed and location Use all the emergency equipments mentioned in the work permit Attention to be paid on uneven terrain structure. Hold pre-job safety meeting Get Authorization of work permit Site safety rules shall be followed Hold pre-job safety meeting Check with operations Identify potential Plant Hazards i.e. (critical valves that can be knocked or damaged while passing). Appropriate PPE shall be used Get Authorization of work permit Carry out gas test before entry. Use personal H2S monitor in hazardous area If required, go for continuous gas test. Maintain gas leak awareness by location and wind direction. If monitor warning actuates leave area and use a predetermined

Severity After Mitigation

P= 1C(L) A= 1A(L) E= 1A(L) R= 1C(L)

Action Party

Raise relevant permit clearance

Incorrect information on permit/clearance

Supervisor, Safety Officer

Site Preparation

Ground conditions

P= 2C (M) A= 0B (L) E= 0A(NR) R= 1B(L)

P= 1C(L) A= 0A(NR) E= 0A(NR) R= 0B(L)

Site Engineer, Supervisor .

Plant Hazards

P= 2C (M) A= 1B (L) E= 0A(NR) R= 1B(L)

P= 1C(L) A= 0A(NR) E= 0A(NR) R= 0B(L)

Exposure to Hazardous gases

P= 3C(M) A= 0A(NR) E= 0A(NR) R= 2C(M)

P= 1C(L) A= 0A(NR) E= 0A(NR) R= 1C(L)

Site Engineer, Supervisor, Safety Officer, workers

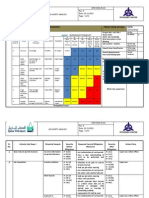

QFM-DKN-25-01 JOB SAFETY ANALYSIS Rev: 0 Date: 19.11.2012 Page : 3 of 6

PETROSERV LIMITED

Transportation

P= 3C (M) A= 3C (M) E= 2C(M) R= 2C(M)

Material Handling (Manual)

P= 3C (M) A= 2C (M) E= 1C(L) R= 1B(L)

escape route across wind Traffic rules & regulations shall be followed Inspection and maintenance of vehicle shall be done periodically All loads transported in a pick-up (or utility) truck or other cargo vehicle shall be securely fastened and shall not exceed the manufacturers load specifications and legal limits for the vehicles Shut off the engine and hand brake shall be applied when leaving the vehicle, the driver must leave his vehicle and not return to it until the loading / unloading activity is complete. Ensure that sub-contractors shall follow traffic Rules & Regulations Ensure fire extinguisher is available in vehicle. Try to use trolleys or wheelbarrows if possible. If required use lifting equipment to unload materials from vehicle. Personnel shall follow proper lifting techniques When lifting a load with another person(s), communicate with the other person(s) before lowering your end of the load. Do not try lifting a load that is too heavy ask for help Do not twist your body while carrying a heavy load

P= 1C (L) A= 1C (L) E= 1C(L) R= 1B(L)

Supervisor, Driver.

P= 1C (L) A= 0B (L) E= 0A(NR) R= 1B(L)

Supervisor, worker.

QFM-DKN-25-01 JOB SAFETY ANALYSIS Rev: 0 Date: 19.11.2012 Page : 4 of 6

PETROSERV LIMITED

Defective Tools / Equipment

P= 3C (M) A= 2C (M) E= 2C(M) R= 2B(M)

Cutting

Harmful fumes

P= 3C (M) A= 0A (NR) E= 2C(M) R= 1C(L)

Fire & Explosion

P= 3C (M) A= 3C (M) E= 3C(M) R= 2C(M)

Appropriate PPE shall be used Ensure the cutting torch, hoses & gas cylinders are free from defect. The equipment and tools are adequately grounded to prevent accumulation of electrostatic charges. Supervisor shall ensure that maintenance is being done regularly. Required PPE shall be used. Work shall be done by certified personnel Wear the required PPE (Long Sleeve Coverall, Apron, Face Shield & suitable respiratory protection etc.). Ensure proper ventilation of the area. Do not leave unattended the cutting torch & Hose with on condition. Isolate the equipment from all source of energy when not in use. Work location shall be shielded Keep the areas clean with no combustible material exists at work site. The entry of non certified tools / equipment / Mobile Plant are to be authorized under appropriate Work Permit. Keep the fire extinguishers & fire hoses in ready condition. Keep trained fire watch as

P= 1C (L) A= 0B (L) E= 1B(L) R= 1B(L)

Supervisor, safety officer

P= 1C (L) A= 0A (NR) E= 1C(L) R= 1A(L)

Supervisor, safety officer

P= 1C (L) A= 1C (L) E= 1B(L) R= 1B(L)

Supervisor, safety officer

QFM-DKN-25-01 JOB SAFETY ANALYSIS Rev: 0 Date: 19.11.2012 Page : 5 of 6

PETROSERV LIMITED

Heat Radiation

P= 3C (M) A= 0A (NR) E= 0A (NR) R= 2C(M) P= 2C (M) A= 2C (M) E= 2C(L) R= 1C(M)

Falling Sparks

Oxy-acetylene Cylinder

P= 2C (M) A= 2C (M) E= 2C(L) R= 1C(M)

Illumination

P= 2C (M) A= 2C (M) E= 0A (NR) R= 1C(M)

standby. Fire fighting & first aid training shall be provided Wear the required PPE (Long Sleeve Coverall, apron, safety Goggle etc.) Periodic Rest shall be provided Keep First Aid Kit at site Work location shall be shielded Ensure no one is working below the location of gas cut. Fire extinguishers shall be maintained at work place. Keep fire watch personnel at work site. Firefighting & first aid training shall be provided Keep Oxy-acetylene Cylinders safely at least 5 meters away from the work location. Close the isolation valve at cylinders when not in use. Do not keep cylinders under direct sunlight. It shall be covered. Keep the fire extinguishers & fire hoses in ready condition. Fire fighting & first aid training shall be provided While working use appropriate PPE Supervisor shall ensure that adequate lighting is available during cutting activity. If required temporary lighting

P= 1C (L) A= 0A(NR) E= 0A(NR) R= 1B(L) P= 1C (L) A= 1A(L) E= 1B(L) R= 1A(L)

Supervisor, Safety Officer

supervisor

P= 1C (L) A= 1A(L) E= 1B(L) R= 1A(L)

Supervisor, safety officer

P= 1C (L) A= 1A(L) E= 0A(NR) R= 1A(L)

Supervisor, Safety Officer

QFM-DKN-25-01 JOB SAFETY ANALYSIS Rev: 0 Date: 19.11.2012 Page : 6 of 6

PETROSERV LIMITED

Windup & Housekeeping

Scattered Material

P= 2C (M) A= 2C (M) E= 2C(L) R= 1C(M)

shall be provided. Ensure proper wind up & housekeeping at worksite. The accessories (torch, hoses & cylinders) not being used must be disconnected and stored separately. Keep walk ways, aisle, and staircases clear of materials, equipments and other items

P= 1C (L) A= 1A(L) E= 1B(L) R= 1A(L)

Supervisor, Safety Officer

JOB SAFETY ANALYSIS Job steps: List the main sequential steps. Each step should be analyzed with the associated risk involved and its severity Alternative Considered: What are the possible means of achieving the job outcome with less risks Now undertake the JAS and record in the table above. Using JSA Hazard Checklist, Critical Question & Risk Assessment tables.

You might also like

- Construction AuditDocument5 pagesConstruction AuditMohammed Mujahid100% (1)

- JSA-020-Safety Watch-Hot WorkDocument2 pagesJSA-020-Safety Watch-Hot WorkNishad MuhammedNo ratings yet

- Site Inspection and Test Plan For Architectural Work Rev-1Document23 pagesSite Inspection and Test Plan For Architectural Work Rev-1Mohammed Mujahid100% (1)

- ITP For ASPHALT CONCRETE PAVINGDocument4 pagesITP For ASPHALT CONCRETE PAVINGMohammed Mujahid100% (1)

- Apple Watch Series 7Document1 pageApple Watch Series 7Mohammed MujahidNo ratings yet

- JSA For Electrical Work TCF3-HaradhDocument6 pagesJSA For Electrical Work TCF3-HaradhShaikh Abu bakarNo ratings yet

- 15.tube Bundle Puller.Document3 pages15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- QP Painting JSADocument6 pagesQP Painting JSAMohammed Mujahid100% (2)

- JsaDocument106 pagesJsaRoy Dwi PrasetyoNo ratings yet

- Trestles and StagingDocument2 pagesTrestles and Stagingdak comeiNo ratings yet

- JHA Valve Leak Test and RepairDocument16 pagesJHA Valve Leak Test and Repairrosevelvet100% (1)

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (2)

- Confined Space Entry For Painting Inside PontoonDocument4 pagesConfined Space Entry For Painting Inside PontoonAchalere Shekhar Kashinath100% (1)

- JHA For Tie-In at PCR14-02Document7 pagesJHA For Tie-In at PCR14-02Francis Enriquez TanNo ratings yet

- QP Painting JSADocument6 pagesQP Painting JSAMohammed Mujahid100% (2)

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- Job Safety Analysis: How To Use This FormDocument4 pagesJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- JSA Formet New Structural Steel FabricationDocument7 pagesJSA Formet New Structural Steel Fabricationsakthi venkatNo ratings yet

- Job Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedDocument2 pagesJob Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedZulfokar FahdawiNo ratings yet

- Jha New - PWHTDocument6 pagesJha New - PWHTSalam AlkataluniNo ratings yet

- Jsa Lifting of PitsDocument8 pagesJsa Lifting of PitseslamNo ratings yet

- JSA 04 Confined Sapce EntryDocument1 pageJSA 04 Confined Sapce EntryalekyaNo ratings yet

- Jsa Loading and Unloading of Pile PipesDocument4 pagesJsa Loading and Unloading of Pile PipesOsiobe Ewomazino100% (1)

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- Appendix A-Job Safety Analysis FormDocument3 pagesAppendix A-Job Safety Analysis Formjiks_i4uNo ratings yet

- Jsa For TIE INS in Accommodation BlockDocument4 pagesJsa For TIE INS in Accommodation BlockAliNo ratings yet

- 3.jsa - Arc Welding-NDocument5 pages3.jsa - Arc Welding-NVivek NaikNo ratings yet

- Petron Bataan Refinery Job Safety Analysis (Jsa)Document2 pagesPetron Bataan Refinery Job Safety Analysis (Jsa)Aldhen Esguerra100% (1)

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- JSA For ExcavationDocument3 pagesJSA For Excavationwahyu nugrohoNo ratings yet

- Nasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetDocument2 pagesNasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetRaza Muhammad SoomroNo ratings yet

- Jsa For Lifting Crane 016Document6 pagesJsa For Lifting Crane 016kiran kumar100% (1)

- Catalyst Filling & SeggregationDocument3 pagesCatalyst Filling & SeggregationMohammed MinhajNo ratings yet

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 pageJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNo ratings yet

- Rig - 1 - Safety Observation Report#75Document1 pageRig - 1 - Safety Observation Report#75Jennifer WangNo ratings yet

- JSA Shut Down and Tie in Work PDFDocument6 pagesJSA Shut Down and Tie in Work PDFpjosesm80% (5)

- Job Safety Analysis (Rolling For MS Plates)Document1 pageJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocument2 pagesAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640No ratings yet

- JSA #19 Grinding, Welding, Gas CuttingDocument2 pagesJSA #19 Grinding, Welding, Gas CuttingSubham Sohal100% (1)

- Jsa Manual ExcavationDocument1 pageJsa Manual ExcavationIan MardiansyahNo ratings yet

- JSA Working in Live AreasDocument1 pageJSA Working in Live Areasyc safetyNo ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- JSA Formet New Structural Steel ErectionDocument11 pagesJSA Formet New Structural Steel Erectionsakthi venkatNo ratings yet

- Jsa For WeldingDocument2 pagesJsa For WeldingMohamed Samir50% (2)

- Job Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job DetailsDocument4 pagesJob Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job Detailsnasar_mahsood100% (1)

- Jsa 035Document10 pagesJsa 035Mohammad Anwar Hossain100% (1)

- Jsa Formats For Hydrotest of AG GRP PIPING Flushing ReinstatementDocument13 pagesJsa Formats For Hydrotest of AG GRP PIPING Flushing ReinstatementKhuda Buksh100% (1)

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- JSA-Using A Type Ladder 2015Document1 pageJSA-Using A Type Ladder 2015nishanthNo ratings yet

- Jsa For Weld and GrindingDocument6 pagesJsa For Weld and GrindingTanzeel LiaqatNo ratings yet

- RoutineJobHazardAnalysis 000Document2 pagesRoutineJobHazardAnalysis 000sugiyanto100% (1)

- Welding and Cutting ProcedureDocument5 pagesWelding and Cutting ProcedureRoger SimbhooNo ratings yet

- JSA 04 Confined Sapce EntryDocument1 pageJSA 04 Confined Sapce Entrywahyu nugrohoNo ratings yet

- 008 JSA - Manual BoringDocument3 pages008 JSA - Manual BoringMohammed MinhajNo ratings yet

- 2 JHA On Shot Grit Blasting1Document3 pages2 JHA On Shot Grit Blasting1Akhilesh KumarNo ratings yet

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRyanNo ratings yet

- Using Hand Drill (WS)Document2 pagesUsing Hand Drill (WS)John KalvinNo ratings yet

- Pha ExcavationDocument13 pagesPha ExcavationirshadNo ratings yet

- Jha Tank Erection NDTDocument3 pagesJha Tank Erection NDTrosevelvet100% (1)

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- JSA 08 Gas WeldingDocument1 pageJSA 08 Gas Weldingmuthuswamy77No ratings yet

- Injury & Illness Prevention Program: Job Safety Analysis FormDocument2 pagesInjury & Illness Prevention Program: Job Safety Analysis FormArif RachmanNo ratings yet

- QP Blasting JSADocument6 pagesQP Blasting JSAMohammed Mujahid100% (1)

- ASP-CSP 14 Noise Study Solutions Rev009Document4 pagesASP-CSP 14 Noise Study Solutions Rev009Mohammed MujahidNo ratings yet

- M6UMTYDocument3 pagesM6UMTYMohammed MujahidNo ratings yet

- FINAL-ITP Earthwork-Rev. 1 13-09-2014Document10 pagesFINAL-ITP Earthwork-Rev. 1 13-09-2014Mohammed Mujahid100% (1)

- Mujahid CVDocument8 pagesMujahid CVMohammed MujahidNo ratings yet

- ITP For Structural Work-1Document5 pagesITP For Structural Work-1Mohammed Mujahid0% (1)

- FINAL-ITP For Concreting Work Rev.2 25-Oct-2014Document12 pagesFINAL-ITP For Concreting Work Rev.2 25-Oct-2014Mohammed MujahidNo ratings yet

- ون مليون ONE MILLION - FLOWER FACTORYDocument1 pageون مليون ONE MILLION - FLOWER FACTORYMohammed MujahidNo ratings yet

- Span Vol2 2015 Part1Document150 pagesSpan Vol2 2015 Part1Mohammed MujahidNo ratings yet

- Guide To Inspecting and Maintaining CranesDocument8 pagesGuide To Inspecting and Maintaining CranesMohammed MujahidNo ratings yet

- International Health and Safety at Work The Handbook For The NEBOSH International General Certificate 2nd Edition Paperback Routledge PDFDocument2 pagesInternational Health and Safety at Work The Handbook For The NEBOSH International General Certificate 2nd Edition Paperback Routledge PDFMohammed Mujahid0% (1)

- QP Blasting JSADocument6 pagesQP Blasting JSAMohammed Mujahid100% (1)

- Cooking Time: 15-20 Minutes Servings: 4: Sprouted Moong KhichdiDocument2 pagesCooking Time: 15-20 Minutes Servings: 4: Sprouted Moong KhichdiMohammed MujahidNo ratings yet

- Sgd-Verger Delporte Uae Switchgear ManufacturingDocument112 pagesSgd-Verger Delporte Uae Switchgear ManufacturingAhmad Yaseen100% (1)

- US Naval Nuclear Propulsion ProgramDocument24 pagesUS Naval Nuclear Propulsion ProgramPablo Pérez DomingoNo ratings yet

- Human Resource ManualDocument15 pagesHuman Resource ManualAzeez Ahmed FirdausNo ratings yet

- Job Safety Analysis: Page 1 of 4Document4 pagesJob Safety Analysis: Page 1 of 4RakeshkasarlaNo ratings yet

- GRDS International ConfrenceDocument13 pagesGRDS International ConfrenceGlobal Research and Development ServicesNo ratings yet

- MSDS Report: According To UN GHS (The 5th Revised Edition)Document9 pagesMSDS Report: According To UN GHS (The 5th Revised Edition)CESAR AUGUSTO MARTINEZ CORTESNo ratings yet

- NWEA Suppliment PDFDocument20 pagesNWEA Suppliment PDFdeepsea74No ratings yet

- D.G.set Loading, Unloading by Hydra and Shifting by Dumper JSA HSE ProfessionalsDocument1 pageD.G.set Loading, Unloading by Hydra and Shifting by Dumper JSA HSE ProfessionalsSamadov 13No ratings yet

- Health and SafetyDocument1 pageHealth and SafetysadeepNo ratings yet

- Manual Del Propietario Motor Honda GX200Document54 pagesManual Del Propietario Motor Honda GX200Aprender20No ratings yet

- NR 10 EnglishDocument18 pagesNR 10 EnglishAbdoEmanuelMalverdiNo ratings yet

- Quiz Bee ReviewerDocument1 pageQuiz Bee Reviewersaquilayan07No ratings yet

- UEENEEE107A - Drawing and Diagrams PDFDocument148 pagesUEENEEE107A - Drawing and Diagrams PDFnellaipaulrajNo ratings yet

- ICAO GAP Analysis Doc.9859.3rd EditionDocument8 pagesICAO GAP Analysis Doc.9859.3rd EditionMik AeilNo ratings yet

- Timpani LabelinfoDocument5 pagesTimpani LabelinfoabufahmyNo ratings yet

- Sa92 03Document1 pageSa92 03Jesus IbañezNo ratings yet

- Organising For Safety - Examples of Roles and ResponsibilitiesDocument7 pagesOrganising For Safety - Examples of Roles and ResponsibilitiesShiju MonNo ratings yet

- 170057-TBO-FIRE - BOQ Calculation - PO - 181210Document49 pages170057-TBO-FIRE - BOQ Calculation - PO - 181210Minh TanNo ratings yet

- 2011 YFBCA Youth Football Coaches Exam: Making Good Coaches, Great Teachers!Document10 pages2011 YFBCA Youth Football Coaches Exam: Making Good Coaches, Great Teachers!Coach Joe BouffardNo ratings yet

- Hsse and Pipe Check ListDocument6 pagesHsse and Pipe Check ListSandip PalNo ratings yet

- Hira - HR Hazard IdentificationDocument4 pagesHira - HR Hazard IdentificationSwati joshiNo ratings yet

- BEUMER Ba-615050001.80-En PDFDocument93 pagesBEUMER Ba-615050001.80-En PDFEwin ApriansyahNo ratings yet

- Tot Lunaria KT 46 MsdsDocument4 pagesTot Lunaria KT 46 Msdsnoar anwarNo ratings yet

- Siremobil Compact MaintenanceDocument22 pagesSiremobil Compact MaintenanceRafael Tejeda100% (1)

- 06 - HSE Inspection ProgramDocument5 pages06 - HSE Inspection ProgramMohammed Affroze100% (1)

- 1 Identification: Safety Data SheetDocument6 pages1 Identification: Safety Data SheetDental OutletNo ratings yet

- 099 - 307 RZ WEB SANY PORT Bro. Telehandler - ENDocument9 pages099 - 307 RZ WEB SANY PORT Bro. Telehandler - EN45xtbrvvjpNo ratings yet

- Precast ConcreteDocument148 pagesPrecast ConcreteSamantha Meril PandithaNo ratings yet

- EC Manual Table of Contents 2021Document13 pagesEC Manual Table of Contents 2021Mohd NajehNo ratings yet

- Hse Inspection ChecklistDocument5 pagesHse Inspection ChecklistCherrycherry BetonioNo ratings yet