Professional Documents

Culture Documents

Carrier India Supply Chain

Carrier India Supply Chain

Uploaded by

Mano KanthanathanCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Entwistle, K. M.-Basic Principles of The Finite Element Method-Maney Publishing For IOM3, The Institute of Materials, Minerals and Mining (2001)Document187 pagesEntwistle, K. M.-Basic Principles of The Finite Element Method-Maney Publishing For IOM3, The Institute of Materials, Minerals and Mining (2001)Golu PatelNo ratings yet

- Flexsim CT PresentationDocument13 pagesFlexsim CT PresentationMano KanthanathanNo ratings yet

- A320 Aerodynamics StudyDocument7 pagesA320 Aerodynamics StudyGourav DasNo ratings yet

- Wind Asce7 10Document5 pagesWind Asce7 10saravanan4286100% (1)

- Evaluation of Simulation ToolsDocument16 pagesEvaluation of Simulation ToolsAbhishek DubeyNo ratings yet

- Mining Modeling - FlexsimDocument19 pagesMining Modeling - FlexsimMano Kanthanathan100% (1)

- Virtual Commissioning - WarehouseDocument2 pagesVirtual Commissioning - WarehouseMano KanthanathanNo ratings yet

- Bechtel Plant LayoutDocument5 pagesBechtel Plant LayoutMano KanthanathanNo ratings yet

- Hospital Case Study FlexsimDocument2 pagesHospital Case Study FlexsimMano KanthanathanNo ratings yet

- Flexsim Technical SpecsDocument2 pagesFlexsim Technical SpecsMano KanthanathanNo ratings yet

- OptQuest OptimizationDocument28 pagesOptQuest OptimizationMano KanthanathanNo ratings yet

- Flexsim CT BrochureDocument2 pagesFlexsim CT BrochureMano KanthanathanNo ratings yet

- Of Manufacturing, Material Handling, and Logistics Systems: Software For The Visualization, Modeling, and SimulationDocument5 pagesOf Manufacturing, Material Handling, and Logistics Systems: Software For The Visualization, Modeling, and SimulationMano KanthanathanNo ratings yet

- Gjames Glass Handbook PDFDocument106 pagesGjames Glass Handbook PDFJohn Van RooyenNo ratings yet

- Lean Startup Vs Design ThinkingDocument12 pagesLean Startup Vs Design ThinkingJeff WuNo ratings yet

- Ancillary Services in Power SystemsDocument5 pagesAncillary Services in Power SystemsNitakashi87No ratings yet

- Ens 3000Document2 pagesEns 3000Marlon CalixNo ratings yet

- GBE-KPO-2-012-00 JidokaDocument40 pagesGBE-KPO-2-012-00 JidokaEduardo Magana100% (1)

- 06 Clicker Questions PhysicsDocument20 pages06 Clicker Questions PhysicsVerenice Fuentes100% (1)

- E gp10f HPDocument4 pagesE gp10f HPabarry_personalNo ratings yet

- Design and Analysis of A Straight Bladed Vertical Axis Wind Turbine Blade Using Analytical and Numerical Techniques PDFDocument8 pagesDesign and Analysis of A Straight Bladed Vertical Axis Wind Turbine Blade Using Analytical and Numerical Techniques PDFOptimuz TsNo ratings yet

- GOST 9454-78 Translated in EnglishDocument13 pagesGOST 9454-78 Translated in Englishatul.palsaraNo ratings yet

- BI Authentication PDFDocument22 pagesBI Authentication PDFrajibzzamanibcsNo ratings yet

- Properties Value: Ug-23 Maximum Allowable Stress ValuesDocument2 pagesProperties Value: Ug-23 Maximum Allowable Stress ValuesMohamad Faiz ZulkipliNo ratings yet

- API RP 580 Risk Based Inspection 2009Document2 pagesAPI RP 580 Risk Based Inspection 2009faisalNo ratings yet

- 6WE Symbol LS 5800 ReferenceGuideDocument352 pages6WE Symbol LS 5800 ReferenceGuideDavi CavalcanteNo ratings yet

- 300 PR DofollowDocument4 pages300 PR DofollowRalph Vincent FerrarenNo ratings yet

- 2017 MIT Seawater Property Tables R2a PDFDocument53 pages2017 MIT Seawater Property Tables R2a PDFsafar bahariNo ratings yet

- Petersen 262-2040 Hot Tapping Machine Operations ManualDocument8 pagesPetersen 262-2040 Hot Tapping Machine Operations ManualFazly RamlyNo ratings yet

- CMT Electronic Heated ViscometerDocument1 pageCMT Electronic Heated ViscometerIBRAHIM ALMANLANo ratings yet

- Lesson 3 Communication Vis A Vis Mass CommunicationDocument12 pagesLesson 3 Communication Vis A Vis Mass Communicationloiseabejero100% (2)

- 5054 w05 QP 1Document20 pages5054 w05 QP 1mstudy123456No ratings yet

- RTR 1633.30-01-18Document4 pagesRTR 1633.30-01-18LHYT NTUANo ratings yet

- RadDocument35 pagesRadabdellaNo ratings yet

- Magnet ExtensometerDocument12 pagesMagnet ExtensometerMandalay Pioneer Geoengineering Services (MPGS)No ratings yet

- BFSA 2015 03 Hand Chipping On Structures 506792 7Document1 pageBFSA 2015 03 Hand Chipping On Structures 506792 7Solomon AhimbisibweNo ratings yet

- 8200-0859-01-A0 Intlx InstallConfig EN PDFDocument94 pages8200-0859-01-A0 Intlx InstallConfig EN PDFFrancisco Rodriguez MartinezNo ratings yet

- Volca Keys Owner's ManualDocument2 pagesVolca Keys Owner's ManualJimmyPimmyNo ratings yet

- 02-1 Synchronous MachinesDocument54 pages02-1 Synchronous MachinessulemankhalidNo ratings yet

- 23-02-10 Design Problem-2 Storey Residence-R1 - RaniDocument4 pages23-02-10 Design Problem-2 Storey Residence-R1 - RaniROSS JOSEPH FAMARINNo ratings yet

Carrier India Supply Chain

Carrier India Supply Chain

Uploaded by

Mano KanthanathanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carrier India Supply Chain

Carrier India Supply Chain

Uploaded by

Mano KanthanathanCopyright:

Available Formats

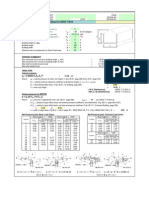

General Purpose Supply Chain Model

Built for Carrier (India)

Purpose:

To make the customer better enabled to schedule future inventories of raw materials and finished goods at their manufacturing plant and distribution centers.

Assumptions:

The following simplifying assumptions were made prior to and during the construction of the model. These assumptions were made to simplify the model in areas where more detail would not have been advantageous and/or cost effective to model. It is important that any user of the model be aware of these assumptions as they may affect the data that is output by the model. Sundays o No work will be done by the manufacturing plants or distribution centers on Sundays o Transportation of raw materials and finished goods will occur on Sundays Orders are placed by the DCs at the beginning of each week Finished goods are shipped at the beginning of each day and arrive at the beginning of the day specified by the lead time o For example if a part has a lead time of 4 days it might ship on Monday at the end of the day and arrive at the beginning of day on Friday Finished goods are built at the end of each day One year is 364 days this evenly divides into 52 weeks

Goals:

The model is designed to achieve the following goals: To allow the customer to calculate an expected service level based on user specified safety stock percents and forecasted sales data To allow the customer to calculate the expected inventory levels at the manufacturing plant and DCs based on the user specified lead times, build time, safety stock percents, and forecasted sales data

Inputs:

To run the model the customer will be required to input the following information into the model: Information supplied through Excel o Actual Sales Data Only if the model is going to be driven by the actual sales data Required for each DC This table contains the number of each type of finished good that was sold each day of the year

o Weekly Minimum and Maximum Sales Forecasts - Only if the model is going to be driven by random data Required for each DC This table specifies the minimum and maximum number of each type of finished good that can be sold during any given week o Weekly Forecasted Sales Required for each DC This table specifies the forecasted number of each finished good that will be sold o Bill of Materials (BOM) Contains all of the required materials for each finished good part This table contains the number of each raw material that is required to build each type of finished good o Raw Materials Lead Time Required for each Manufacturing Plant This table specifies the lead times for each type of raw material o Finished Goods Lead Time Required for each Manufacturing Plant This table specifies the lead times for each type of finished good Information entered directly into Flexsim o Safety Stock Required for all inventory at the Manufacturing Plants and DCs This table specifies the percent above the forecasted sales that the DC should keep in inventory o Suppliers Required for all finished goods at each DC This table specifies what incoming Manufacturing plant supplies what part o Build Time Required for each Manufacturing Plant This number is the number of days required to build any finished good o Maximum Build Required for each Manufacturing Plant This table specifies the maximum number of each type of finished good that can be built in one day o Over Production Limits Required for each Manufacturing Plant This table specifies the maximum amount (in percent) that the manufacturing plant will produce of any type of finished good above the amount specified in the forecast

Outputs:

The model will output the following information: Weekly inventory levels of raw materials and finished goods at the manufacturing plants Weekly inventory levels of the finished goods at the DCs

Weekly service levels at each DC and the min, ave, and max delay times

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Entwistle, K. M.-Basic Principles of The Finite Element Method-Maney Publishing For IOM3, The Institute of Materials, Minerals and Mining (2001)Document187 pagesEntwistle, K. M.-Basic Principles of The Finite Element Method-Maney Publishing For IOM3, The Institute of Materials, Minerals and Mining (2001)Golu PatelNo ratings yet

- Flexsim CT PresentationDocument13 pagesFlexsim CT PresentationMano KanthanathanNo ratings yet

- A320 Aerodynamics StudyDocument7 pagesA320 Aerodynamics StudyGourav DasNo ratings yet

- Wind Asce7 10Document5 pagesWind Asce7 10saravanan4286100% (1)

- Evaluation of Simulation ToolsDocument16 pagesEvaluation of Simulation ToolsAbhishek DubeyNo ratings yet

- Mining Modeling - FlexsimDocument19 pagesMining Modeling - FlexsimMano Kanthanathan100% (1)

- Virtual Commissioning - WarehouseDocument2 pagesVirtual Commissioning - WarehouseMano KanthanathanNo ratings yet

- Bechtel Plant LayoutDocument5 pagesBechtel Plant LayoutMano KanthanathanNo ratings yet

- Hospital Case Study FlexsimDocument2 pagesHospital Case Study FlexsimMano KanthanathanNo ratings yet

- Flexsim Technical SpecsDocument2 pagesFlexsim Technical SpecsMano KanthanathanNo ratings yet

- OptQuest OptimizationDocument28 pagesOptQuest OptimizationMano KanthanathanNo ratings yet

- Flexsim CT BrochureDocument2 pagesFlexsim CT BrochureMano KanthanathanNo ratings yet

- Of Manufacturing, Material Handling, and Logistics Systems: Software For The Visualization, Modeling, and SimulationDocument5 pagesOf Manufacturing, Material Handling, and Logistics Systems: Software For The Visualization, Modeling, and SimulationMano KanthanathanNo ratings yet

- Gjames Glass Handbook PDFDocument106 pagesGjames Glass Handbook PDFJohn Van RooyenNo ratings yet

- Lean Startup Vs Design ThinkingDocument12 pagesLean Startup Vs Design ThinkingJeff WuNo ratings yet

- Ancillary Services in Power SystemsDocument5 pagesAncillary Services in Power SystemsNitakashi87No ratings yet

- Ens 3000Document2 pagesEns 3000Marlon CalixNo ratings yet

- GBE-KPO-2-012-00 JidokaDocument40 pagesGBE-KPO-2-012-00 JidokaEduardo Magana100% (1)

- 06 Clicker Questions PhysicsDocument20 pages06 Clicker Questions PhysicsVerenice Fuentes100% (1)

- E gp10f HPDocument4 pagesE gp10f HPabarry_personalNo ratings yet

- Design and Analysis of A Straight Bladed Vertical Axis Wind Turbine Blade Using Analytical and Numerical Techniques PDFDocument8 pagesDesign and Analysis of A Straight Bladed Vertical Axis Wind Turbine Blade Using Analytical and Numerical Techniques PDFOptimuz TsNo ratings yet

- GOST 9454-78 Translated in EnglishDocument13 pagesGOST 9454-78 Translated in Englishatul.palsaraNo ratings yet

- BI Authentication PDFDocument22 pagesBI Authentication PDFrajibzzamanibcsNo ratings yet

- Properties Value: Ug-23 Maximum Allowable Stress ValuesDocument2 pagesProperties Value: Ug-23 Maximum Allowable Stress ValuesMohamad Faiz ZulkipliNo ratings yet

- API RP 580 Risk Based Inspection 2009Document2 pagesAPI RP 580 Risk Based Inspection 2009faisalNo ratings yet

- 6WE Symbol LS 5800 ReferenceGuideDocument352 pages6WE Symbol LS 5800 ReferenceGuideDavi CavalcanteNo ratings yet

- 300 PR DofollowDocument4 pages300 PR DofollowRalph Vincent FerrarenNo ratings yet

- 2017 MIT Seawater Property Tables R2a PDFDocument53 pages2017 MIT Seawater Property Tables R2a PDFsafar bahariNo ratings yet

- Petersen 262-2040 Hot Tapping Machine Operations ManualDocument8 pagesPetersen 262-2040 Hot Tapping Machine Operations ManualFazly RamlyNo ratings yet

- CMT Electronic Heated ViscometerDocument1 pageCMT Electronic Heated ViscometerIBRAHIM ALMANLANo ratings yet

- Lesson 3 Communication Vis A Vis Mass CommunicationDocument12 pagesLesson 3 Communication Vis A Vis Mass Communicationloiseabejero100% (2)

- 5054 w05 QP 1Document20 pages5054 w05 QP 1mstudy123456No ratings yet

- RTR 1633.30-01-18Document4 pagesRTR 1633.30-01-18LHYT NTUANo ratings yet

- RadDocument35 pagesRadabdellaNo ratings yet

- Magnet ExtensometerDocument12 pagesMagnet ExtensometerMandalay Pioneer Geoengineering Services (MPGS)No ratings yet

- BFSA 2015 03 Hand Chipping On Structures 506792 7Document1 pageBFSA 2015 03 Hand Chipping On Structures 506792 7Solomon AhimbisibweNo ratings yet

- 8200-0859-01-A0 Intlx InstallConfig EN PDFDocument94 pages8200-0859-01-A0 Intlx InstallConfig EN PDFFrancisco Rodriguez MartinezNo ratings yet

- Volca Keys Owner's ManualDocument2 pagesVolca Keys Owner's ManualJimmyPimmyNo ratings yet

- 02-1 Synchronous MachinesDocument54 pages02-1 Synchronous MachinessulemankhalidNo ratings yet

- 23-02-10 Design Problem-2 Storey Residence-R1 - RaniDocument4 pages23-02-10 Design Problem-2 Storey Residence-R1 - RaniROSS JOSEPH FAMARINNo ratings yet