Professional Documents

Culture Documents

Mav (Atlantis) Washer Installation Instructions

Mav (Atlantis) Washer Installation Instructions

Uploaded by

justinvestCopyright:

Available Formats

You might also like

- Micro Econ 6 Principles of Microeconomics 6Th Edition William A Mceachern Full ChapterDocument67 pagesMicro Econ 6 Principles of Microeconomics 6Th Edition William A Mceachern Full Chapterchristine.parsons231100% (6)

- 66512773K310 KENMORE ELITE DishwasherDocument25 pages66512773K310 KENMORE ELITE Dishwasheraxof50% (2)

- Maytag Neptune StackDocument132 pagesMaytag Neptune StackdanfurlanoNo ratings yet

- Maytag Neptune MAH3000AWW Washing Machine Service ManualDocument157 pagesMaytag Neptune MAH3000AWW Washing Machine Service Manualrhondafos100% (2)

- DU1055XTVS8Document40 pagesDU1055XTVS8mrcmhNo ratings yet

- Manual Elevated Monitor Style 3530 Installation, Operating and Maintenance InstructionsDocument6 pagesManual Elevated Monitor Style 3530 Installation, Operating and Maintenance Instructionshendra saputraNo ratings yet

- Bow 203 Dishwasher ManualDocument12 pagesBow 203 Dishwasher ManualClaudiu Anton VitanNo ratings yet

- Installation Instructions: Full Size Tumble Action WashersDocument12 pagesInstallation Instructions: Full Size Tumble Action WashersGabriel Alexandru GhitaNo ratings yet

- WF250 ImDocument38 pagesWF250 Imins13No ratings yet

- Maytag Mav5000aww PDFDocument9 pagesMaytag Mav5000aww PDFandyvtranNo ratings yet

- Manualn25 35 45 55 70 90 140 - GBDocument24 pagesManualn25 35 45 55 70 90 140 - GBjonathan.gelli5153No ratings yet

- Matrix FF InstallDocument22 pagesMatrix FF Installgcu93No ratings yet

- Indesit Iwb71250Document16 pagesIndesit Iwb71250fullymoonNo ratings yet

- PVC & CPVC Basket Strainers: Installation & Maintenance Service InstructionsDocument2 pagesPVC & CPVC Basket Strainers: Installation & Maintenance Service InstructionsTheresa NguyenNo ratings yet

- Indesit Iwc71251 Manual GB-FR-ARDocument44 pagesIndesit Iwc71251 Manual GB-FR-ARAnonymous aigwY0jgzpNo ratings yet

- Instructions For Use: Washing MachineDocument16 pagesInstructions For Use: Washing MachineAna Maria NeacsuNo ratings yet

- Indesit Manual Wil - 62 PDFDocument16 pagesIndesit Manual Wil - 62 PDFFranceskoNo ratings yet

- Installation Operation Maintenance: HFO Fan CoilsDocument12 pagesInstallation Operation Maintenance: HFO Fan CoilsRd GzNo ratings yet

- Service Manual: Auto WasherDocument33 pagesService Manual: Auto WasheralexNo ratings yet

- ASW-H09A4SAR1DI ASW-H12A4SAR1DI 12000 R410a DC Inverter User Service ManualDocument50 pagesASW-H09A4SAR1DI ASW-H12A4SAR1DI 12000 R410a DC Inverter User Service ManualPedro Dias50% (2)

- Installation Instructions & Owner's Manual: Electronic Steam Unit - Power Humidifier MODELS S2000 AND S2020Document16 pagesInstallation Instructions & Owner's Manual: Electronic Steam Unit - Power Humidifier MODELS S2000 AND S2020Franklin Ergueta100% (1)

- Bosch Washing Machine WAS32461GB 90004608573Document6 pagesBosch Washing Machine WAS32461GB 90004608573David GoldNo ratings yet

- Manual BombaDocument8 pagesManual BombaLuisNo ratings yet

- Rainsoft P-12 ManualDocument9 pagesRainsoft P-12 ManualGreg ReynekeNo ratings yet

- Water Cooled Fcu Piping DetailsDocument14 pagesWater Cooled Fcu Piping Detailsfernandoreyes893No ratings yet

- Hotpoint WTL500Document16 pagesHotpoint WTL500willdoyeahNo ratings yet

- Sanicom & Sanitop Installation GuideDocument9 pagesSanicom & Sanitop Installation GuideSimona Maria PruteanuNo ratings yet

- Hotpoint Dishwasher - Model BFV62 ManualDocument20 pagesHotpoint Dishwasher - Model BFV62 ManualMartin Lee SmithNo ratings yet

- Therma Flow Inst and Oper. Maint. ManualDocument41 pagesTherma Flow Inst and Oper. Maint. ManualJOSUE FERNANDO FERNANDEZNo ratings yet

- SanibestDocument8 pagesSanibesth8banksNo ratings yet

- Washing Mashine Manual To Use W1A101Document16 pagesWashing Mashine Manual To Use W1A101Paula PaulaNo ratings yet

- Triturador de Alimentos Marca HobartDocument8 pagesTriturador de Alimentos Marca HobartErik DominguezNo ratings yet

- Series WDS-E220 and LFWDS-E220 Installation InstructionsDocument12 pagesSeries WDS-E220 and LFWDS-E220 Installation InstructionsWattsNo ratings yet

- LRST-40 Installation Instructions: HiemanDocument16 pagesLRST-40 Installation Instructions: HiemanYoriel GuzmanNo ratings yet

- Poursteady UserManualDocument24 pagesPoursteady UserManualarantsapratamaNo ratings yet

- Maquina Lavar e Secar Roupa INDESIT IWDC6105Document16 pagesMaquina Lavar e Secar Roupa INDESIT IWDC6105Humberto MendesNo ratings yet

- Manual GBDocument18 pagesManual GBReinaldo RosasNo ratings yet

- Equator Combination Washer-Dryer Service Manual 3710Document30 pagesEquator Combination Washer-Dryer Service Manual 3710R Hartman RoemerNo ratings yet

- Power Team PQ120 ManualDocument10 pagesPower Team PQ120 ManualTitanplyNo ratings yet

- Instructions For Use: Washing MachineDocument16 pagesInstructions For Use: Washing MachineHameleo1000No ratings yet

- 2TWR2 Install GuideDocument8 pages2TWR2 Install GuideedwcsdNo ratings yet

- Efdb 7 B 9Document20 pagesEfdb 7 B 9anilr008No ratings yet

- Hotpoint BFV620 Dishwasher Owners ManualDocument20 pagesHotpoint BFV620 Dishwasher Owners Manualmylitter5391No ratings yet

- Instruction Booklet: Washing MachineDocument16 pagesInstruction Booklet: Washing MachineHossam SalehNo ratings yet

- Instructions For Use: Washer-DryerDocument14 pagesInstructions For Use: Washer-DryerMurali Venkat NagNo ratings yet

- Control Panel With Time Switch For Indoor/Outdoor Use: DangerDocument4 pagesControl Panel With Time Switch For Indoor/Outdoor Use: DangerOlga Joy Labajo GerastaNo ratings yet

- 25F-PRCServ PDFDocument38 pages25F-PRCServ PDFsindelu60No ratings yet

- InSinkErator Steaming Hot Water Taps Installation GuideDocument80 pagesInSinkErator Steaming Hot Water Taps Installation Guideliamdixonau100% (1)

- Coleman Generator L0807053Document12 pagesColeman Generator L0807053Jody WoodenNo ratings yet

- Instruction Booklet: Installation, 2-3-4Document12 pagesInstruction Booklet: Installation, 2-3-4Skourasnet TrelosNo ratings yet

- Abovegroundhydrants Dropdownpillar 84-25-27 P7 PDFDocument4 pagesAbovegroundhydrants Dropdownpillar 84-25-27 P7 PDFLimhot SitanggangNo ratings yet

- Dishwasher Hobart AMXDocument20 pagesDishwasher Hobart AMXConcordeus Meyselva Setyaranto Nugroho0% (1)

- Cablemaster CRR-50 - Installation ManualDocument2 pagesCablemaster CRR-50 - Installation ManualGlendinning Products, LLC.0% (1)

- Model UC-2 Installation InstructionsDocument8 pagesModel UC-2 Installation InstructionsWattsNo ratings yet

- DishwasherDocument2 pagesDishwasherAga NowikNo ratings yet

- Instructions For Use: Washer-DryerDocument16 pagesInstructions For Use: Washer-DryerstefanNo ratings yet

- Instructions For Use: Washing MachineDocument72 pagesInstructions For Use: Washing MachineAdriana OlteanuNo ratings yet

- Maintenance and Operation Manual Hydraulic Choke and Control ConsoleDocument42 pagesMaintenance and Operation Manual Hydraulic Choke and Control ConsoleMehdi Hajd KacemNo ratings yet

- Pacific Water - Utah - Series 960 Manual WMDocument24 pagesPacific Water - Utah - Series 960 Manual WMGreg ReynekeNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Chapter 3 Decision TreesDocument12 pagesChapter 3 Decision TreesMark MagumbaNo ratings yet

- ACLU Letter On Riverside County RedistrictingDocument2 pagesACLU Letter On Riverside County RedistrictingThe Press-Enterprise / pressenterprise.comNo ratings yet

- CURRICULUM VITAE DhodhonkDocument1 pageCURRICULUM VITAE DhodhonkVeri MasywandiNo ratings yet

- 20 Preparation Question: Contract: Contract 1 Contract 2 Contract 3 Contract 4Document2 pages20 Preparation Question: Contract: Contract 1 Contract 2 Contract 3 Contract 4SerenaNo ratings yet

- Project Proposal TemplateDocument2 pagesProject Proposal TemplatejorifeberdenuevoespinosaNo ratings yet

- DELL D620 Schematics Document (UMA) - LA-2791Document63 pagesDELL D620 Schematics Document (UMA) - LA-2791Claudiu Petrache33% (3)

- CTW320 Msy 00 El Abd 5002 01Document1 pageCTW320 Msy 00 El Abd 5002 01Jafffar MahasnehNo ratings yet

- Retail Banking ChannelsDocument6 pagesRetail Banking Channelsbeena antuNo ratings yet

- Government of Madhya Pradesh Public Health Engineering DepartmentDocument63 pagesGovernment of Madhya Pradesh Public Health Engineering DepartmentShreyansh SharmaNo ratings yet

- Nix ManualDocument108 pagesNix ManualJérôme AntoineNo ratings yet

- 10 5923 J Ijmee 20120106 04Document5 pages10 5923 J Ijmee 20120106 04SafetyanaNo ratings yet

- Modeling and SimulationDocument11 pagesModeling and SimulationZain MughalNo ratings yet

- WEEK 2 - Safety SignsDocument98 pagesWEEK 2 - Safety SignsDaniel BognotNo ratings yet

- BEKIER Et Al v. COMMONWEALTH CONSTRUCTION COMPANY, INC. Et Al - Document No. 8Document12 pagesBEKIER Et Al v. COMMONWEALTH CONSTRUCTION COMPANY, INC. Et Al - Document No. 8Justia.com100% (1)

- Budget Choux EkondjeDocument4 pagesBudget Choux EkondjePikol WeladjiNo ratings yet

- Inventory - Product Catalogue: Code Description / Location / UOM BarcodeDocument93 pagesInventory - Product Catalogue: Code Description / Location / UOM Barcodefireman100% (1)

- ProjectDocument61 pagesProjectgoodvijay143No ratings yet

- Mechanics L5 PDFDocument52 pagesMechanics L5 PDFCharlie LaiNo ratings yet

- Deutz 2008 SpecsDocument4 pagesDeutz 2008 SpecsaaasNo ratings yet

- 1207 ROBUS AU Sensor Range WebDocument8 pages1207 ROBUS AU Sensor Range WebAlexanderLinaresNo ratings yet

- Office Management Tools (16rsbe7:2) : Sengamalathayaar Educational Trust Women'S CollegeDocument15 pagesOffice Management Tools (16rsbe7:2) : Sengamalathayaar Educational Trust Women'S CollegeKumaran RaniNo ratings yet

- NX Nastran Error ListDocument224 pagesNX Nastran Error ListAdriana Livadariu100% (3)

- Pre TrialDocument6 pagesPre Trialerickson romeroNo ratings yet

- Omori Purple Background - Pesquisa GoogleDocument1 pageOmori Purple Background - Pesquisa Googleataide.leleo11No ratings yet

- Marketing International PDFDocument91 pagesMarketing International PDFDmitrii DurbailovNo ratings yet

- Sliding Mode Controller Design For Controlling The Speed of A DC MotorDocument5 pagesSliding Mode Controller Design For Controlling The Speed of A DC Motorbokic88No ratings yet

- LG 32lg3000 Chassis Ld84a LCD TV SMDocument26 pagesLG 32lg3000 Chassis Ld84a LCD TV SMEmma FrostNo ratings yet

Mav (Atlantis) Washer Installation Instructions

Mav (Atlantis) Washer Installation Instructions

Uploaded by

justinvestOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mav (Atlantis) Washer Installation Instructions

Mav (Atlantis) Washer Installation Instructions

Uploaded by

justinvestCopyright:

Available Formats

MAV (ATLANTIS) WASHER INSTALLATION INSTRUCTIONS

SECTION 1. GENERAL INFORMATION

WASHER PRE-INSTALLATION REQUIREMENTS NOTE: Proper installation sibility of the purchaser, is the respon Do not store or operate washer in tern peratures below freezing. This can aus_ damage to the pump, hoses and othe components. (See page 1-5 for long ten storage.) Water pressure of 20 - 120 P.S.I.is require to fill the washer in the appropriate tim frame. Pressuresof less than 20 P.S.I.m_ cause an extended or exceptionally lot fill time. Refer to the troubleshooting se tion for more information regarding a s lution for slow fill situations. Best performance is obtained with tl washer installed on a solid floor. Wo_ floor constructions may need to be re: forced to minimize vibration from unb anted load situations. Carpets and s tile surfaces are also contributing fact_ in vibration and/or movement during 1 spin cycle, Never install washer on pl form or weak support structure.

Checkpoints for proper installation: Properly grounded electrical cutlet is required. Use 15 amp fuse or comparable circuit breaker for electrical service, Standpipe Drain System must be able to accept 1" O.D. drain hose. In cases where an airtight connectionis required, an anti-siphoning valve, part number 12001586,shouldbeplacedinthe drainhose to prevent siphoningfrom the washer or facilityduringagitation.Standpipeheightof 36" is recommended,

NOTE: If drain standpipe is in excess of 5 feet above floor level, install pump accessory kit, part number]200]58? These units are not equippedwith a siphon break, and the drain hose must be elevated to a minimum height of 36", For installations with short standpipes, the drain hose must be supported by clipping the drain hose into the clip on the back of the washer. Then a coupler and additional hose lenghth is added to the eXisting drain hose. Hot and Cold water faucets should be within four (4) feet of the back of the washer. This allows for quick access for immediate shut off of the water. Water heater should be set to deliver a minimum of 120 (49C) hot water to the washer,

ElectricalRequirements

1. Provide an individual 120 volt, 60 HZ, branch circuit with ground f the washer. This circuit must be rated for 15 amperes or more. 2. Protect the washer's electrical circu with a 15 ampere time delay fuse c circuit breaker. 3. Install in accordance with National Electrical Code and all local codes and ordinances. GROUNDING INSTRUCTIONS

The washer must be grounded. In the event of a malfunction or breakdown,

16009485 @1996 Maytag Corporation

Section1. Generalinformation

grounding will reduce the risk of electrical shock by providing a path of least resistance for electrical current,

The washer is equipped with a power supply cord which has a grounding conductor and three-prong grounding plug. For proper grounding, the threeprong grounding plug must be plugged into an appropriate three-prong grounded receptacle or outlet (see the following figure). The receptacle must be properly installed and grounded in accordance with the National Electrical Code and all local codes and ordinances.

WARNING: Improper connection of the grounding conductor or the three-prong grounding plug of the power supply cord cord may result in an electrical shock hazard, ff there is any doubt as to whetherthe washeris properly grounded, have the installation checked by a qualified electrician. DO NOT MODIFY THE PLUG PROVIDED WITH THE WASHER - If the plug will not fit the outlet, have a proper outlet installed by a qualified technician.

WARNING: For your safety and to protect the test equipment, be sure that the wall polarized and grounded.

/_

outlet is properly

r

I

1_0 VOL'F5 AC

0 VOLTS

AC

120 VOLT8 AO

Figure 1-2

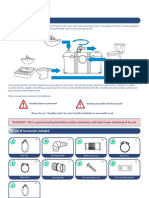

UNCRATING INSTRUCTIONS NOTE: The following steps must be performed in the correct order to ease uncrating. 1. Remove the carton by cutting only marked areas of the carton. CAUTION: Hoses are connected to the washer. 2. Lift the carton and top cap assembly up and clear of the washer. Carefully remove any packaging materials from the outside

of the washer. NOTE: Retain the corner posts for later use. 3. Untape and raise the washer lid; remove the items shipped in the spin basket. Save the literature for future reference. Close and retape lid. 4. Place three (3) corner posts and position them on the floor near the rear base of the washer. Place the remain* ing corner post on the floor approxiSection General 1, Information

16009485

@1998MaytagCorporation

1-2

mately two (2) feet away. Carefully lay the washer on its back on top of the corner posts, DO NOTLOWER OR RAISE THE WASHER B Y THE CONTROL PANEL. 4 Remove the crate bottom from the washer. Pop the plastic loose from the screw located between the back feet, or remove the screw entirely with a screwdriver. (Figure 1-2) Pull the plastic base away from the back feet. Grasping the plastic base on the sides, pulling downward to release the front feet from the slots and toward you to remove the base. Discard the base (it can be recycled). RETURN THEWASHER TO THE UPRIGHT POSITION.

INSTALLATION

PROCEDURE

NOTE: Proper installation is the respon sibility of the purchaser. However,service ca/Is performed as a re suit of improper setup, adjustment ant connection are the responsibility of th_ installer. Proceed as follows: 1. Place the washer as close to its final operating location as possible. 2. Make sure rear feet move up and down freely. 3. Place washer in final location. I I

Front Feet

__-_1_

ir-

Backguard

Figure 1-2

_i_

( ' _-_-_11

feet out of base against the floor until 1 4. When the machine is in place, screw fr,

_"" ' " __: _ i_i_'_!_ i1 _,__1 Popplastic Shipping (3) corne_ awayfromor base Carton corner ._

remove hex posts (stacked

Iocknut clockwise until the nut is tightened firmly against base. (Figure 1-_ 5 washer.machineislevelacrssthetpfrntfi While holding foot still, turn the adjusti, 6. Tilt machine forward until rear of cabin

is approximately 4 inches off the floor, then lower the machine back to the flo, on the rear feet. This operation will cause the rear stabilizing feet to conf to the contour of the floor and seat the solidly. Push washerwith hands on opposite corners to check stability. (Figure 1-3)

headscrew

on eachother)

Figure 1-2

pot

16009485

@t998 MaytagCorporation

Section General 1, Information

(Back Of Control Console) _'_.. _'_., i Beaded Tie

Clip (Rear Wall of Cabinet

_l _

Figure 1-4

Figure 1-3

7. Pull the drain hose up vertically and snap the hose into the retaining clip positioned on the upper rear cabinet wall. (Figure 14) 8. Install gooseneck end of drain hose into drain standpipe. Be sure the connection is not airtight between the drain hose and the standpipe. Standpipe must be at least 36" high. If the hose is twisted after it has been placed into the standpipe, adjust the end of the hose to remove the twist. To remove the twist, turn the short end of the hose while holding the base of the hose stationary. (Figure 1-5) 9 Note: The drain hose should fit loosely in the standpipe to prevent siphoning. (An anti-siphon valve and associated partSpart available12001586).from numberare your dealer, NOTE: BE SURE THE DRAIN HOSE IS NOT TWISTED OR KINKED. / Figure 1-5

__ LAUNDRY :._--"_--_' _TANDPI!:,E _ :_ i_.xz, . "_.r_,-_ q

__---_- _1 _ _)_ U_T Figure 1-6

s_:

_?_x

_:_'_"_" 'L;_!__-_ TU S _,[

_>!II / _!_- -_1 ,\ _.

16009485 @1998 Maytag Corporation

Section1. GeneralInformation

1-4

14. Secure the drain hose to the standptpe or drain facility with the cable strap provided. This will ensure the drain hose will not fall out of the drain facility. (Figure 1-

TOP VIEW OF WASHER

15. Connect inlet hoses to water supply using screenwashers at faucet connections, with the domed screen facing the faucet. (Figure 1-7) Tighten hose connections by hand until snug. Then, turnanother 2/3 of a turn with the pliers.

:. . ,. " ' ----'_..,=_'y _

.. . " :

-_-

<C_

A_ Faucet Connection

Figure 1-8 FINAL INSTALLATION CHECK LIST

A,W_,e,w,veCo,,_o, Figure 1-7 16. With hoses attached to both th_aucets and the water valve, turn on the water and check for leaks. Note the H and C designations on the water valve bracket for the Hot and Coldhoses. 17. Plug the power cord into an outlet. 18. Start the washer in a spin cycle, per operating instructions, to center basket, 19. Startthe washer in awash cycle, as per operating instructions. Allow water to fill in machine until it reaches the level of the bottom row of holes in the wash basket. Then, stop the washer by pushing on timer knob. 12. If the water is not level with the bottom row of holes all around the basket, (Figure 1-9)readjust the leveling feet as required to level. Then remove thewater by selecting a spin cycle,

1. Have all installation requirements been observed? 2. Have Iocknuts on front feet been tightened? 3. Are there any kinks in the hoses? 4. Are any water leaks evident?

UNIQUE INSTALLATIONS

Painted/sloped basement floors - Apply nc slip discs, part number 211692, to the flc directly under the rubber feet of the washe Carpeted Floors - Apply carpet installati discs, part number 204986. Weak Floors - Install rear legs with plas grommets,partnumber12001577,to be insert into baseframeto substitutefor the self adjusti legs. Cold Storage or Installations - Installatic in any location subject to freezing temperatures is not recommended. If the washer must be installed in such a location, it should be thoroughly drained aftE each use as follows:

Section 1, GeneralInformation

16009485

@1998 Maytag Corporation

Turn off hot and cold water faucets. Disconnect both water inlet hoses at the faucets. Lower them to the floor. With the service cord connected to the electrical outlet, rotate the timer to the normal start or fill position and pull timer knob to start washer. Turn water temperature selector switch to warm. When water stops draining from the hoses, disconnect service cord. Lower the drain hose to the floor and allow it to drain into a floor drain or shallow pan. In below-freezing temperatures, ice may form in the "fill" flume and the pump. Raise the room temperature and allow time for the ice to melt before using the washer.

16009485 @1998 Maytag Corporation

Section 1. GeneralInformation

'1-6

SPECIFICATIONS - WASHER (Lower Half Section)

71.8 cm _"

"

68.6em

363/8"1 8_.4 _n

h102err

CAPACITY ELECTRICAL

3.2 Cubic Feet

CN '

120 Volts, 60 Hz; Requires 15 amp circuit breaker or fused electrical supply. Power cord must be connected to a properly grounded and polarized outlet, 1/2 H.P., reversible,2 Speed, 115 volt, 60 cycle A.C. Motor Input: During Agitation* - 480 Watts Max (Fast)370 Watts Max. (Slov During Pump Out* - 760 Watts (Fast) 510 Watts Max. (Slow) Spin - 460 Watts (Fast -Full Tub) 340 Watts (Slow- Full Tub) [*Wattage readings taken with no dethes in spinner.] Rack and pinion type, incorporatingreduction gears Water pressure should be 20- 120 P.S.I. (1.06-8.44 kg/cm) at inlet hose connection, (SEE PAGE 1-8 FOR MORE DETAILS) Four foot inlet hoses with inlet washers attached to water valve. Drain hose attached to pump and will accommodate 36" high drain stand Pil

MOTOR POWER USAGE

TRANSMISSION WATER USAGE HOSE LENGTHS

DIMENSIONS

Cabinet Dimensions: 27" (68.58cm)Wx27 (68.58cm)D x 43 3/8" (110.2cm

WEIGHT (Approx.) FINISH

Uncartoned 160 Ib, (72.6 kg.) Approx.

Crated 185 lb. (84 kg,) Appro

Top Cover- Pome]ain Lid- Porcelain OuterTub - constructedentirely of polypropylene Spin Basket - polypropylene Cabinet - baked enamel Base and other finished parts - baked primer

16009485 @1998 Maytag Corporation

Section1. GeneralInformation

Setting Mini Medium High

Gallons 10.5 14.1 19,5

*Depth Inches 6" 8 1/2" 11" 13 1/2"

*Basket Perforations 3 1/2" 5" 7" 9 1/4"

Super 23.3 *Allowable variations are plus or minus 1/2 inch. AGITATOR SPEED

Regular Cycle Slow (Delicate) Cycle

88 Oscillations per minute 57 Oscillations per minute

! i

155 DegreeArc 155 DegreeArc

SPIN

SPEED

Regular Cycle Slow (Fine Wash) Cycle

620 R.P.M. 410 R.P.M.

I

TABLE 1-3, WATTAGE CHART *WATTAGE CYCLE RANG E Agitate-Regular Full Tub Agitate-Slow Full Tub Agitate-Regular Dry Tub Agitate-Slow Dry Tub 460-470 / 480 (MAX.) 350-360 / 370 (MAX.) 760 510 610-640 / 670 (MAX.) 370400 / 420 (MAX.)

TABLE 1-1. AMPERAGE CHART WATER LEVEL Full Tub Full Tub Dry Tub Dry Tub Dry Tub Full Tub Full Tub

CYCLE Agitate-Regular Agitate-Slow Agitate-Regular Spin-Regular Spin-Slow Pump Out-Regular Pump Out-Slow

i *AMPS 10.4 7.6 7.5 10.2 7.6 10.8 8.0

TABLE 1-2, RESISTANCE CHART COMPONENTS Timer Motor Mixing Valve Cold Solenoid Hot Solenoid Drive Motor High Speed Low Speed Start 1.3 2.3 3.1 *RESISTANCE (OHMS) 2360 500-1000 853 867

Pump Out-Regular Pump Out-Slow Spin-Regular Full Tub Spin-Slow Full Tub

460

340

* These will vary with washer load and line voltag

These values can vary slightly. 16009485 section1. General Information 1-8

@1998MaytagCorporation

You might also like

- Micro Econ 6 Principles of Microeconomics 6Th Edition William A Mceachern Full ChapterDocument67 pagesMicro Econ 6 Principles of Microeconomics 6Th Edition William A Mceachern Full Chapterchristine.parsons231100% (6)

- 66512773K310 KENMORE ELITE DishwasherDocument25 pages66512773K310 KENMORE ELITE Dishwasheraxof50% (2)

- Maytag Neptune StackDocument132 pagesMaytag Neptune StackdanfurlanoNo ratings yet

- Maytag Neptune MAH3000AWW Washing Machine Service ManualDocument157 pagesMaytag Neptune MAH3000AWW Washing Machine Service Manualrhondafos100% (2)

- DU1055XTVS8Document40 pagesDU1055XTVS8mrcmhNo ratings yet

- Manual Elevated Monitor Style 3530 Installation, Operating and Maintenance InstructionsDocument6 pagesManual Elevated Monitor Style 3530 Installation, Operating and Maintenance Instructionshendra saputraNo ratings yet

- Bow 203 Dishwasher ManualDocument12 pagesBow 203 Dishwasher ManualClaudiu Anton VitanNo ratings yet

- Installation Instructions: Full Size Tumble Action WashersDocument12 pagesInstallation Instructions: Full Size Tumble Action WashersGabriel Alexandru GhitaNo ratings yet

- WF250 ImDocument38 pagesWF250 Imins13No ratings yet

- Maytag Mav5000aww PDFDocument9 pagesMaytag Mav5000aww PDFandyvtranNo ratings yet

- Manualn25 35 45 55 70 90 140 - GBDocument24 pagesManualn25 35 45 55 70 90 140 - GBjonathan.gelli5153No ratings yet

- Matrix FF InstallDocument22 pagesMatrix FF Installgcu93No ratings yet

- Indesit Iwb71250Document16 pagesIndesit Iwb71250fullymoonNo ratings yet

- PVC & CPVC Basket Strainers: Installation & Maintenance Service InstructionsDocument2 pagesPVC & CPVC Basket Strainers: Installation & Maintenance Service InstructionsTheresa NguyenNo ratings yet

- Indesit Iwc71251 Manual GB-FR-ARDocument44 pagesIndesit Iwc71251 Manual GB-FR-ARAnonymous aigwY0jgzpNo ratings yet

- Instructions For Use: Washing MachineDocument16 pagesInstructions For Use: Washing MachineAna Maria NeacsuNo ratings yet

- Indesit Manual Wil - 62 PDFDocument16 pagesIndesit Manual Wil - 62 PDFFranceskoNo ratings yet

- Installation Operation Maintenance: HFO Fan CoilsDocument12 pagesInstallation Operation Maintenance: HFO Fan CoilsRd GzNo ratings yet

- Service Manual: Auto WasherDocument33 pagesService Manual: Auto WasheralexNo ratings yet

- ASW-H09A4SAR1DI ASW-H12A4SAR1DI 12000 R410a DC Inverter User Service ManualDocument50 pagesASW-H09A4SAR1DI ASW-H12A4SAR1DI 12000 R410a DC Inverter User Service ManualPedro Dias50% (2)

- Installation Instructions & Owner's Manual: Electronic Steam Unit - Power Humidifier MODELS S2000 AND S2020Document16 pagesInstallation Instructions & Owner's Manual: Electronic Steam Unit - Power Humidifier MODELS S2000 AND S2020Franklin Ergueta100% (1)

- Bosch Washing Machine WAS32461GB 90004608573Document6 pagesBosch Washing Machine WAS32461GB 90004608573David GoldNo ratings yet

- Manual BombaDocument8 pagesManual BombaLuisNo ratings yet

- Rainsoft P-12 ManualDocument9 pagesRainsoft P-12 ManualGreg ReynekeNo ratings yet

- Water Cooled Fcu Piping DetailsDocument14 pagesWater Cooled Fcu Piping Detailsfernandoreyes893No ratings yet

- Hotpoint WTL500Document16 pagesHotpoint WTL500willdoyeahNo ratings yet

- Sanicom & Sanitop Installation GuideDocument9 pagesSanicom & Sanitop Installation GuideSimona Maria PruteanuNo ratings yet

- Hotpoint Dishwasher - Model BFV62 ManualDocument20 pagesHotpoint Dishwasher - Model BFV62 ManualMartin Lee SmithNo ratings yet

- Therma Flow Inst and Oper. Maint. ManualDocument41 pagesTherma Flow Inst and Oper. Maint. ManualJOSUE FERNANDO FERNANDEZNo ratings yet

- SanibestDocument8 pagesSanibesth8banksNo ratings yet

- Washing Mashine Manual To Use W1A101Document16 pagesWashing Mashine Manual To Use W1A101Paula PaulaNo ratings yet

- Triturador de Alimentos Marca HobartDocument8 pagesTriturador de Alimentos Marca HobartErik DominguezNo ratings yet

- Series WDS-E220 and LFWDS-E220 Installation InstructionsDocument12 pagesSeries WDS-E220 and LFWDS-E220 Installation InstructionsWattsNo ratings yet

- LRST-40 Installation Instructions: HiemanDocument16 pagesLRST-40 Installation Instructions: HiemanYoriel GuzmanNo ratings yet

- Poursteady UserManualDocument24 pagesPoursteady UserManualarantsapratamaNo ratings yet

- Maquina Lavar e Secar Roupa INDESIT IWDC6105Document16 pagesMaquina Lavar e Secar Roupa INDESIT IWDC6105Humberto MendesNo ratings yet

- Manual GBDocument18 pagesManual GBReinaldo RosasNo ratings yet

- Equator Combination Washer-Dryer Service Manual 3710Document30 pagesEquator Combination Washer-Dryer Service Manual 3710R Hartman RoemerNo ratings yet

- Power Team PQ120 ManualDocument10 pagesPower Team PQ120 ManualTitanplyNo ratings yet

- Instructions For Use: Washing MachineDocument16 pagesInstructions For Use: Washing MachineHameleo1000No ratings yet

- 2TWR2 Install GuideDocument8 pages2TWR2 Install GuideedwcsdNo ratings yet

- Efdb 7 B 9Document20 pagesEfdb 7 B 9anilr008No ratings yet

- Hotpoint BFV620 Dishwasher Owners ManualDocument20 pagesHotpoint BFV620 Dishwasher Owners Manualmylitter5391No ratings yet

- Instruction Booklet: Washing MachineDocument16 pagesInstruction Booklet: Washing MachineHossam SalehNo ratings yet

- Instructions For Use: Washer-DryerDocument14 pagesInstructions For Use: Washer-DryerMurali Venkat NagNo ratings yet

- Control Panel With Time Switch For Indoor/Outdoor Use: DangerDocument4 pagesControl Panel With Time Switch For Indoor/Outdoor Use: DangerOlga Joy Labajo GerastaNo ratings yet

- 25F-PRCServ PDFDocument38 pages25F-PRCServ PDFsindelu60No ratings yet

- InSinkErator Steaming Hot Water Taps Installation GuideDocument80 pagesInSinkErator Steaming Hot Water Taps Installation Guideliamdixonau100% (1)

- Coleman Generator L0807053Document12 pagesColeman Generator L0807053Jody WoodenNo ratings yet

- Instruction Booklet: Installation, 2-3-4Document12 pagesInstruction Booklet: Installation, 2-3-4Skourasnet TrelosNo ratings yet

- Abovegroundhydrants Dropdownpillar 84-25-27 P7 PDFDocument4 pagesAbovegroundhydrants Dropdownpillar 84-25-27 P7 PDFLimhot SitanggangNo ratings yet

- Dishwasher Hobart AMXDocument20 pagesDishwasher Hobart AMXConcordeus Meyselva Setyaranto Nugroho0% (1)

- Cablemaster CRR-50 - Installation ManualDocument2 pagesCablemaster CRR-50 - Installation ManualGlendinning Products, LLC.0% (1)

- Model UC-2 Installation InstructionsDocument8 pagesModel UC-2 Installation InstructionsWattsNo ratings yet

- DishwasherDocument2 pagesDishwasherAga NowikNo ratings yet

- Instructions For Use: Washer-DryerDocument16 pagesInstructions For Use: Washer-DryerstefanNo ratings yet

- Instructions For Use: Washing MachineDocument72 pagesInstructions For Use: Washing MachineAdriana OlteanuNo ratings yet

- Maintenance and Operation Manual Hydraulic Choke and Control ConsoleDocument42 pagesMaintenance and Operation Manual Hydraulic Choke and Control ConsoleMehdi Hajd KacemNo ratings yet

- Pacific Water - Utah - Series 960 Manual WMDocument24 pagesPacific Water - Utah - Series 960 Manual WMGreg ReynekeNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Chapter 3 Decision TreesDocument12 pagesChapter 3 Decision TreesMark MagumbaNo ratings yet

- ACLU Letter On Riverside County RedistrictingDocument2 pagesACLU Letter On Riverside County RedistrictingThe Press-Enterprise / pressenterprise.comNo ratings yet

- CURRICULUM VITAE DhodhonkDocument1 pageCURRICULUM VITAE DhodhonkVeri MasywandiNo ratings yet

- 20 Preparation Question: Contract: Contract 1 Contract 2 Contract 3 Contract 4Document2 pages20 Preparation Question: Contract: Contract 1 Contract 2 Contract 3 Contract 4SerenaNo ratings yet

- Project Proposal TemplateDocument2 pagesProject Proposal TemplatejorifeberdenuevoespinosaNo ratings yet

- DELL D620 Schematics Document (UMA) - LA-2791Document63 pagesDELL D620 Schematics Document (UMA) - LA-2791Claudiu Petrache33% (3)

- CTW320 Msy 00 El Abd 5002 01Document1 pageCTW320 Msy 00 El Abd 5002 01Jafffar MahasnehNo ratings yet

- Retail Banking ChannelsDocument6 pagesRetail Banking Channelsbeena antuNo ratings yet

- Government of Madhya Pradesh Public Health Engineering DepartmentDocument63 pagesGovernment of Madhya Pradesh Public Health Engineering DepartmentShreyansh SharmaNo ratings yet

- Nix ManualDocument108 pagesNix ManualJérôme AntoineNo ratings yet

- 10 5923 J Ijmee 20120106 04Document5 pages10 5923 J Ijmee 20120106 04SafetyanaNo ratings yet

- Modeling and SimulationDocument11 pagesModeling and SimulationZain MughalNo ratings yet

- WEEK 2 - Safety SignsDocument98 pagesWEEK 2 - Safety SignsDaniel BognotNo ratings yet

- BEKIER Et Al v. COMMONWEALTH CONSTRUCTION COMPANY, INC. Et Al - Document No. 8Document12 pagesBEKIER Et Al v. COMMONWEALTH CONSTRUCTION COMPANY, INC. Et Al - Document No. 8Justia.com100% (1)

- Budget Choux EkondjeDocument4 pagesBudget Choux EkondjePikol WeladjiNo ratings yet

- Inventory - Product Catalogue: Code Description / Location / UOM BarcodeDocument93 pagesInventory - Product Catalogue: Code Description / Location / UOM Barcodefireman100% (1)

- ProjectDocument61 pagesProjectgoodvijay143No ratings yet

- Mechanics L5 PDFDocument52 pagesMechanics L5 PDFCharlie LaiNo ratings yet

- Deutz 2008 SpecsDocument4 pagesDeutz 2008 SpecsaaasNo ratings yet

- 1207 ROBUS AU Sensor Range WebDocument8 pages1207 ROBUS AU Sensor Range WebAlexanderLinaresNo ratings yet

- Office Management Tools (16rsbe7:2) : Sengamalathayaar Educational Trust Women'S CollegeDocument15 pagesOffice Management Tools (16rsbe7:2) : Sengamalathayaar Educational Trust Women'S CollegeKumaran RaniNo ratings yet

- NX Nastran Error ListDocument224 pagesNX Nastran Error ListAdriana Livadariu100% (3)

- Pre TrialDocument6 pagesPre Trialerickson romeroNo ratings yet

- Omori Purple Background - Pesquisa GoogleDocument1 pageOmori Purple Background - Pesquisa Googleataide.leleo11No ratings yet

- Marketing International PDFDocument91 pagesMarketing International PDFDmitrii DurbailovNo ratings yet

- Sliding Mode Controller Design For Controlling The Speed of A DC MotorDocument5 pagesSliding Mode Controller Design For Controlling The Speed of A DC Motorbokic88No ratings yet

- LG 32lg3000 Chassis Ld84a LCD TV SMDocument26 pagesLG 32lg3000 Chassis Ld84a LCD TV SMEmma FrostNo ratings yet