Professional Documents

Culture Documents

Sulzer Catalog

Sulzer Catalog

Uploaded by

Marian CzeszkiewiczCopyright:

Available Formats

You might also like

- Gd-Ha12v Gf-Ha12s Gf-Ha22sDocument983 pagesGd-Ha12v Gf-Ha12s Gf-Ha22sはせがわまだお100% (1)

- Denon-Dra500ae 700ae RecDocument62 pagesDenon-Dra500ae 700ae RecPiotr ZimnyNo ratings yet

- GTL01 CONTROLLER (AN) - E-GB - TL186-Revision 00Document37 pagesGTL01 CONTROLLER (AN) - E-GB - TL186-Revision 00Lucas MaldonadoNo ratings yet

- DPF ContentsDocument19 pagesDPF Contentssilverdollar100% (1)

- Low Speed Engines Handbook 2019Document68 pagesLow Speed Engines Handbook 2019Nadia Novita SariNo ratings yet

- Manual de Instrucciones MP Warsila 6l26 Arc 07 de AgostoDocument509 pagesManual de Instrucciones MP Warsila 6l26 Arc 07 de Agostoma2razor100% (1)

- 60 CC 75 e 0 D 57261714Document508 pages60 CC 75 e 0 D 57261714abdelbagi ibrahimNo ratings yet

- Sulzer Rta58t Cylinder LinerDocument2 pagesSulzer Rta58t Cylinder LinerHarry KharbandaNo ratings yet

- CSL Cse MDocument8 pagesCSL Cse MBoogi Andika TamamiNo ratings yet

- Turbocharger MaintenanceDocument15 pagesTurbocharger MaintenanceAnonymous 7nTvPQVvRNo ratings yet

- Ge .Alco.emd Parts 副本Document4 pagesGe .Alco.emd Parts 副本mingtao liNo ratings yet

- 2CEDocument25 pages2CEfilmonstar100% (1)

- Catalog 1113Document9 pagesCatalog 1113WilberZangaNo ratings yet

- MaK M20 - Spare Parts Catalog - RuDocument204 pagesMaK M20 - Spare Parts Catalog - RuMARINE SOLUTIONSNo ratings yet

- Motor MWM Sprint 4.08 Tcea PDFDocument33 pagesMotor MWM Sprint 4.08 Tcea PDFFelippe DelgadoNo ratings yet

- PC400 450-10Document20 pagesPC400 450-10qrl840927No ratings yet

- ZX300 6 - ZX300LC 6Document13 pagesZX300 6 - ZX300LC 6Calvin ThamNo ratings yet

- Fuel System Diagnostic Test DocumentationDocument10 pagesFuel System Diagnostic Test DocumentationClemente Flores100% (1)

- 燃費・環境性 - ISUZU:フォワード(中型トラック)Document1 page燃費・環境性 - ISUZU:フォワード(中型トラック)Sitichoke SemamonNo ratings yet

- PC300 10Document9 pagesPC300 10William ChangNo ratings yet

- ZX330LC 5B JapaneseDocument22 pagesZX330LC 5B Japanesevicky beastNo ratings yet

- ZX240 6 - ZX240LC 6 - ZX250H 6 - ZX250LCH 6 - ZX250K 6 - ZX250LCK 6Document13 pagesZX240 6 - ZX240LC 6 - ZX250H 6 - ZX250LCH 6 - ZX250K 6 - ZX250LCK 6Calvin ThamNo ratings yet

- HMKB HMKC Series Catalog E 2005Document32 pagesHMKB HMKC Series Catalog E 2005titanwlxNo ratings yet

- ZH200 5B - KS Ja262pDocument13 pagesZH200 5B - KS Ja262pCALVINNo ratings yet

- PC200 210-11Document20 pagesPC200 210-11Nguyen The Phat100% (2)

- 2014 k33 SBP Manual Cbr300 HRCDocument36 pages2014 k33 SBP Manual Cbr300 HRCRed AhmadNo ratings yet

- Motori BrushlessDocument8 pagesMotori BrushlessJack MikeNo ratings yet

- CC Link (MJ0123 28a)Document178 pagesCC Link (MJ0123 28a)Khánh Nguyễn VănNo ratings yet

- Service Training: D8T Track-Type TractorDocument186 pagesService Training: D8T Track-Type TractorLuis GuzmánNo ratings yet

- 1.ion 4-SpeedDocument144 pages1.ion 4-Speedalex generalNo ratings yet

- Benz DTC ADocument76 pagesBenz DTC A笠井 聡No ratings yet

- PT - LUBRAX - TOP - PRO 15W 40 e 10W 30Document3 pagesPT - LUBRAX - TOP - PRO 15W 40 e 10W 30Bruno BarbosaNo ratings yet

- Secomat NewDocument16 pagesSecomat NewYulfre Antonio CarrilloNo ratings yet

- MVM2010 Pesic Ver 3Document8 pagesMVM2010 Pesic Ver 3Радивоје ПешићNo ratings yet

- ZX160LC 6Document11 pagesZX160LC 6Calvin ThamNo ratings yet

- Main Engine Change-Over From Hfo To LsmgoDocument7 pagesMain Engine Change-Over From Hfo To LsmgoHendra SamanthaNo ratings yet

- SK80UR-6E Japan Spec BrochureDocument16 pagesSK80UR-6E Japan Spec BrochurePHÁT NGUYỄN THẾNo ratings yet

- 5 Ncsi sp02 08 1 0Document234 pages5 Ncsi sp02 08 1 0Yongkook KimNo ratings yet

- GAC21 P5213-Kb Web 13.7.24Document8 pagesGAC21 P5213-Kb Web 13.7.24manpreet singhNo ratings yet

- Lubrication SystemDocument64 pagesLubrication Systemmoldovan adrianNo ratings yet

- Sh250 7 CatalogDocument10 pagesSh250 7 CatalogApu debNo ratings yet

- sh75x CatalogDocument6 pagessh75x CatalogHodumi JosefNo ratings yet

- Variable Spindle ThreadingDocument13 pagesVariable Spindle ThreadingihsjwarrenNo ratings yet

- SW20 3sgteDocument7 pagesSW20 3sgteCzarny KotNo ratings yet

- 実際の運航に使用してはならない。 Do not use for real flight: 15-12-(1) Next Page BLANKDocument24 pages実際の運航に使用してはならない。 Do not use for real flight: 15-12-(1) Next Page BLANKBort FortNo ratings yet

- Hydraulics Product GuideDocument28 pagesHydraulics Product GuideCloves KelherNo ratings yet

- Service Manual VLT DanfossDocument56 pagesService Manual VLT Danfossjroyal69100% (3)

- SK45SR SK55SR-7Document20 pagesSK45SR SK55SR-7poiuytrewq85207410No ratings yet

- Power TrainDocument447 pagesPower Trainmoldovan adrianNo ratings yet

- Manual de Operacion de MaquinariaDocument12 pagesManual de Operacion de MaquinariaOogway MasterNo ratings yet

- 231 All PDFDocument82 pages231 All PDFAszrul NizamNo ratings yet

- Rcsft1.users Manual 2 513993Document28 pagesRcsft1.users Manual 2 513993Gerald Leon FloresNo ratings yet

- R01an4674jj0110 rx66t PumpDocument54 pagesR01an4674jj0110 rx66t PumpポケモンマスターNo ratings yet

- 実際の運航に使用してはならない。 Do not use for real flight: 15-17-(1) Next Page BLANKDocument36 pages実際の運航に使用してはならない。 Do not use for real flight: 15-17-(1) Next Page BLANKBort FortNo ratings yet

- Motor LombardiniDocument156 pagesMotor LombardiniManu Barbe Garci100% (1)

- Elecylinder Electricity (Mj3816 4a)Document344 pagesElecylinder Electricity (Mj3816 4a)Khánh Nguyễn VănNo ratings yet

- CDH821C 831C 831CDocument4 pagesCDH821C 831C 831CHodumi JosefNo ratings yet

- 4 Ncsi sp02 07 7 0Document500 pages4 Ncsi sp02 07 7 0Yongkook KimNo ratings yet

- ecoFORCE Folder JAPDocument12 pagesecoFORCE Folder JAPNitinNo ratings yet

- Wind PowerDocument57 pagesWind PowerPergaulan NainggolanNo ratings yet

Sulzer Catalog

Sulzer Catalog

Uploaded by

Marian CzeszkiewiczCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sulzer Catalog

Sulzer Catalog

Uploaded by

Marian CzeszkiewiczCopyright:

Available Formats

Power Range

Power Range for DU-Wrtsil Low-Speed Engines

CONTENTS

3

4

4

ex 59

ex 10

11

12

ex 13

DU-WRTSIL Engines

RT-ex96C 14

RT-ex84T 15

RT-ex82T 16

RT-ex82C 17

RT-ex68-D 18

RT-ex60C 20

RT-ex58T 21

RT-ex50-D 22

RT-ex50-B 23

RT-ex48T 2425

RT-ex40 26

RT-ex35 27

Portable TF-Detector 2829

3031

Humane and Earth-friendly

NOx Emission of IMO Tier- & Tier-

RT-flex Concept and Features of RT-flex engine

2008 10 IMO MEPC Tier-Tier- NOx

MARPOL Annex

Tier-2011 1 1

Tier- 20

Tier-2016 1 1

Tier- 80

Tier-

NOx Tier-

RT-flex (Concept of RT-flex engine)

In October 2008, the Marine Environment Protection Committee (MEPC) of IMO

adopted amendments to the MARPOL Annex regulations.

These specify further NOx emission limits to be known as IMO Tier- and Tier-.

Under IMO Tier-, the NOx emission limits for engines installed in ships constructed on

or after 1 January 2011 will be reduced, according to a speed-dependent function,

about 20% from the presently valid IMO Tier-levels.

Under IMO Tier-, the NOx emission limits for engines installed in ships constructed on

or after 1 January 2016 will be reduced, according to a speed-dependent function,

about 80% from the presently valid IMO Tier-levels, when the ship is operating in a

designated Emission Control Area. Outside designated Emission Control Area IMO

Tier- limits apply.

All engines in this booklet can comply with the new upcoming IMO NOx Tier- emission

regulations.

RT-ex

NOx

Common-rail fuel injection system is adopted for RT-ex engines, and this

system can control freely not only fuel injection pressure but also injection

timing of each injection valves.

Precise combustion control can be achieved by the above, and RT-ex

engines can comply NOx emission with minimum deterioration of BSFC.

RT-flex (Structure of RT-flex engine)

WECS-9520

Electronic Cabinets

FCM20

WECS=Wrtsil Engine

Control System

FCM=Flex Control Module

Exhaust Valve Stroke Sensor

Rail Unit

Fuel oil rail

Servo oil rail

Advantage of Electronically controlled engine

/

Fuel injection/

Exhaust valve control unit

Rail valve

Redundant parts / Monitoring function

Lower fuel consumption & maintenance cost

Smokeless operation

No adjustment of cam shaft & fuel pump

High reliability & safety

High Economy

Gentle to Environment

Easy maintenance

Local Operation

Box

Crank Angle

Sensor

Automatic

Back-wash

Filter

Supply Unit

Fuel pump

Servo oil pump

RT-flex Concept and Features of RT-flex engine

Rail Unit

Fuel Injection

WECS-9520

ICU

Independent fuel injection control

for each fuel valve on each cylinder.

WECS-9520 system controls

fuel valve action by rail valve

on Injection Control Uniit (ICU)

High injection pressure even at

low speed (see the right chart).

ICUInjection Control Unit

The optimum control of fuel injection

and timing of exhaust valve action for

all cylinders materializes both low fuel

consumption and less emission and

thus contributes to environmental

protection.

Exhaust Valve Driving

WECS-9520

EVCU

RTA

Freely adjustable timing of valve

actiion (see the right chart).

WECS-9520 system controls

exhaust valve action by rail

valve on Exhaust Valve Control

Unit (EVCU).

Feedback control of exhaust

valve by stroke sensor.

Reliable valve opening by

hydraulic oil and valve closing

by air spring, same as in proven

RTA engines.

EVCUExhaust Valve Control Unit

RT-flex Concept and Features of RT-flex engine

Supply Unit

Fuel pump

WECS-9520

Driven by crankshaft gear.

High eciency fuel pump.

Fuel oil and servo oil kept at setting

pressure at each speed range.

Sucient capacity of each fuel/servo

pump to allow continuous operation

without interruption even in case of

failure of one fuel/servo pump.

Servo oil pump

Fuel pump

Smokeless Operation at Low Speed

RT-ex

1 /2 /3

R1 10-12

NOx

In RT-ex engine fuel injection of each fuel valve is controlled independently.

Depending on the engine speed one, two or three valves are engaged in fuel

injection for optimum burning thus enabling smooth and smokeless operation

at low speed of 10-12% of R1 rating. This easy burning control is also very

eective to further reduce NOx emission.

WECS-9520 FCM20

FCM20 No.

FCM20

FCM20

FCM20

FCM20

WECS-9520, the core system of RT-ex engine, consists of FCM20 control

modules for cylinders (one FCM module for each cylinder), one on-line spare

of FCM20 and other electronic equipment in the control room. The FCM20

for each cylinder controls the equipment such as servo oil pump and CR

pump actuator assigned to the cylinder. Failure in one of the FCM20s does

not stop the engine.

On-line spare FCM20 automatically downloads the data from all FCM20s for

cylinder and instantly replaces a FCM20 for cylinder if it fails without

resetting of parameters and downloading of program so that continuous

operatin of the engine may not be interrupted.

FCM20 control module is common for all types of RT-ex engines and

supply and stock of spare is easy.

1 OPI Operation Interface

2 CAN Controller Area Network

3 ExVa Exhaust Valve

4 EFIC Electronic Fuel Injection Control

5 SSI Synchronous Serial Interface bus

6 PWM Pulse Width Modulation

RT-flex Performance of RT-flex engine

Engine Rating

Fuel Consumption)

R1, R2, R3 R4

MCR

RT-82T RT-82C R1+ R2+

NOxTier

/ RTA

To cope with 2nd NOx

reguration (Tier ), sequential

fuel injection and optimum

timing control of exhaust and

fuel injection valve ensure

lower fuel consumption

compared with mechanical

RTA engine. Dalta Tuning and

Low Load Tuning lower fuel

consumption at low engine

speed.

The engine layout elds for DU-Wrtsil low-speed engines are dened by the

power/speed rating points R1, R2, R3 and R4.

In RT-82T and RT-82C engines, the layout eld is extended to the points R1+

and R2+.

RT-flex Performance of RT-flex engine)

42.7MJ/kgISO 15550 and 3046

5

RT-ex

RTA

RT-ex

E x te n d e d

C o n v e n tio n a l

L a yo u t F ie ld

L a you t

F ie ld

All brake specic fuel consumptions (BSFC) are quoted for fuel of lower caloric value

42.7 MJ/kg, and for ISO standard reference conditions (ISO 15550 and 3046).

The BSFC gures for engines are given with a tolerance of +5%. RT-ex engines have a

lower part-load fuel consumption than the corresponding RTA engines by using

sequential fuel injection and optimum timing control of exhaust and fuel valve injection.

RT-ex engines are also available with Delta Tuning and Low-Load Tuning for even lower

part-load fuel consumptions.

ISO Standard Reference Condition

Barometric pressure

Suction air temparature

Relative humidity

Scavenge air cooling water

temperature

10

1,000hPa

25

30%

25

11

Pulse Lubricating System

Pulse Lubricating System, newly developed to lower

lubricating oil consumtion than conventioinal accumulator

system, distributes cylinder lubricating oil on the liner wall with

a timed interval.

RT-ex RT-ex System Arrangement

WRTSIL RT-flex

LOW-SPEED MARINE ENGINES

INTEGRATED ELECTRONIC CONTROL

COMMON RAIL SYSTEMS FOR:

- FUEL INJECTION

- EXHAUST VALVE OPERATION

- AIR STARTING

350-960 MM CYLINDER BORE

3,475 - 80,080 KW

Unique Features

Ecient

lubricating oil distribution.

freely adjustable by electronic control.

Hydraulic power supplied by ex servo-oil system.

No supply unit or accumulator

required.

Timing

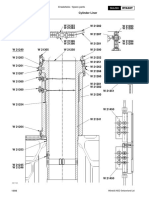

1. Crankshaft

2. Bottom end of

connecting rod

3. Connecting rod

4. Crosshead

5. Crosshead guide

shoes

6. Piston rod

7. Piston

8. Exhaust valve

9. Bedplate

10. Column

11. Cylinder block

12. Tie rods

13. Diaphragm

12

14. Piston rod gland

15. Cylinder liner

16. Scavenge air ports

17. Anti-Polishing Ring

18. Cylinder cover

19. Exhaust valve cage

20. Exhaust manifold

21. Auxiliary scavenge

air blower

22. Flywheel

23. Turning gear

24. RT-flex supply unit

25. High-pressure fuel

supply pumps

26. Servo oil pumps

27. Rail unit

28. Fuel oil rail with

inection control units

29. Servo oil rail with

exhaust valve control

units

30. High-pressure pipes

to fuel injection valves

31. Exhaust valve drive

32. Electronic cabinets

33. Scavenge air receiver

13

DU-

RT-flex96C

RT-flex84T

Main data: Version B, also available as traditional RTA type

Cylinder bore ................................... 960 mm

Piston stroke.................................. 2500 mm

Speed ......................................... 92-102 rpm

Mean effective pressure at R1......... 18.6 bar

Piston speed......................................8.5 m/s

Main data: Version D, also available as traditional RTA type

Fuel specification:

Fuel oil..........................................700 cSt/50C

ISO-F 8217:2005,

category ISO-RMK700

Cylinder bore ................................... 840 mm

Piston stroke.................................. 3150 mm

Speed ........................................... 61-76 rpm

Mean effective pressure at R1......... 19.0 bar

Piston speed......................................8.0 m/s

Rated power, principal dimensions and weights

Output in kW at

Cyl.

6

7

8

9

10

11

12

13

14

Dimensions

mm

102 rpm

R1

R2

34 320

24 000

40 040

28 000

45 760

32 000

51 480

36 000

57 200

40 000

62 920

44 000

68 640

48 000

74 360

52 000

80 080

56 000

B

4 480

C

1 800

92 rpm

R3

R4

30 960

24 000

36 120

28 000

41 280

32 000

46 440

36 000

51 600

40 000

56 760

44 000

61 920

48 000

67 080

52 000

72 240

56 000

D

10 925

Rated power, principal dimensions and weights

Length A

mm

Weight

tonnes

12 240

13 920

16 510

18 190

19 870

21 550

23 230

24 910

26 590

1 160

1 290

1 470

1 620

1 760

1 910

2 050

2 160

2 300

F*

12 950

G

2 594

E

5 380

Brake specific fuel consumption (BSFC) in g/kWh

Full load

Rating point

BMEP, bar

IMO Tier ll

RTA

RT-flex

Part load, % of R1

RT-flex tuning variant

IMO Tier ll

R1

18.6

177

173

Standard Tuning

85

Standard

169.8

70

Standard

169.0

R2

13.0

171

167

R3

18.6

177

173

85

Delta

169.1

70

Delta

167.5

R4

14.4

171

167

60

Low-Load

166.5

* Standard piston dismanting height can be reduced with tilted piston withdrawal.

13 and 14-cylinder engines are only available in RT-flex versions, and not in RTA versions.

Fuel specification:

Fuel oil..........................................700 cSt/50C

ISO-F 8217:2005,

category ISO-RMK700

Output in kW at

Cyl.

76 rpm

Length A

mm

Weight

tonnes

14 700

17 640

20 580

23 520

26 460

9 695

11 195

12 695

15 195

16 695

740

870

990

1 140

1 260

E

5 105

F*

14 500

61 rpm

R1

R2

R3

R4

5

6

7

8

9

21 000

25 200

29 400

33 600

37 800

14 700

17 640

20 580

23 520

26 460

16 850

20 220

23 590

26 960

30 330

Dimensions

mm

B

5 000

C

1 800

D

12 150

Brake specific fuel consumption (BSFC) in g/kWh

Full load

Rating point

BMEP, bar

IMO Tier ll

RTA

RT-flex

Part load, % of R1

RT-flex tuning variant

IMO Tier ll

Standard Tuning

85

Standard

167.8

70

Standard

167.0

R1

19.0

173

171

R2

13.3

167

165

70

Delta

165.5

60

Low-Load

164.5

14

R4

16.6

169

167

* Standard piston dismantling height can be reduced with tilted piston withdrawal.

R3

19.0

173

171

85

Delta

167.1

G

2 700

G

A

15

RT-flex96C, 84T

Engines

DU-

Engines

RT-flex82T

RT-flex82C

Cylinder bore .....................................820 mm

Piston stroke....................................3375 mm

Speed ............................................ 68-80 rpm

Mean effective pressure

at R1/R1+ ................................. 20.0/19.0 bar

Piston speed at R1/R1+ ...............8.6/9.0 m/s

Main data: also available as traditional RTA type

Fuel specification:

Fuel oil.......................................700 cSt/50C

ISO-F 8217:2005,

category ISO-RMK700

Cylinder bore .....................................820 mm

Piston stroke....................................2646 mm

Speed .......................................... 87-102 rpm

Mean effective pressure

at R1/R1+ ................................. 20.0/19.0 bar

Piston speed at R1/R1+ ...............8.6/9.0 m/s

Rated power, principal dimensions and weights

Rated power, principal dimensions and weights

Output in kW at

Cyl.

76/80 rpm

R1/R1+

R2/R2+

68 rpm

Length A

mm

Weight

tonnes

R3

R4

6

7

8

9

27 120

31 640

36 160

40 680

21 720

25 340

28 960

32 580

24 300

28 350

32 400

36 450

21 720

25 340

28 960

32 580

11 045

12 550

14 055

16 500

785

880

975

1 090

Dimensions

mm

B

5 320

C

1 800

D

12 250

E

5 400

F*

14 750

G

2 700

Brake specific fuel consumption (BSFC) in g/kWh

Full load

Rating point

BMEP, bar

IMO Tier ll

R1/R1+ R2/R2+

20.0/19.0 16.0/15.2

173/171

167

Standard Tuning 168/166

162

RTA

RT-flex

R3

20.0

173

168

R4

17.9

170

165

Part load, % of R1/R1+

85

70

85

70

60

RT-flex tuning variant

Standard

Standard

Delta

Delta

Low-Load

IMO Tier ll

164.8/162.8 164.0/162.0 164.1/162.1 162.5/160.5 161.5/159.5

* Standard piston dismantling height can be reduced with tilted piston withdrawal.

Fuel specification:

Fuel oil.......................................700 cSt/50C

ISO-F 8217:2005,

category ISO-RMK700

Cyl.

6

7

8

9

10

11

12

Dimensions

mm

Output in kW at

97/102 rpm

87 rpm

R1/R1+

R2/R2+

R3

R4

27 120

21 720

24 300

21 720

31 640

25 340

28 350

25 340

36 160

28 960

32 400

28 960

40 680

32 580

36 450

32 580

45 200

36 200

40 500

36 200

49 720

39 820

44 550

39 820

54 240

43 440

48 600

43 440

B

4 570

C

1 600

D

10 930

E

5 400

11 045

12 550

14 055

16 500

18 005

19 510

21 015

745

840

935

1 005

1 145

1 230

1 335

F*

12 700

G

2 310

IMO Tier ll

RTA

RT-flex

R1/R1+ R2/R2+

20.0/19.0 16.0/15.2

177/175

171

Standard Tuning 173/171

167

R3

20.0

177

173

R4

17.9

174

170

Part load, % of R1/R1+

85

70

85

70

60

RT-flex tuning variant

Standard

Standard

Delta

Delta

Low-Load

IMO Tier ll

169.8/167.8 169.0/167.0 169.1/167.1 167.5/165.5 166.5/164.5

* Standard piston dismantling height can be reduced with tilted piston withdrawal.

F

D

16

Weight

tonnes

Brake specific fuel consumption (BSFC) in g/kWh

Full load

Rating point

BMEP, bar

Length A

mm

G

A

17

RT-flex82T, 82C

Main data: also available as traditional RTA type

DU-

Engines

RT-flex68

6RT-flex58T-B

Main data: Version D, also available as traditional RTA type

Cylinder bore ................................... 680 mm

Piston stroke.................................. 2720 mm

Speed ........................................... 76-95 rpm

Mean effective pressure at R1......... 20.0 bar

Piston speed......................................8.6 m/s

Fuel specification:

Fuel oil..........................................700 cSt/50C

ISO-F 8217:2005,

category ISO-RMK700

Rated power, principal dimensions and weights

95 rpm

Length A

mm

76 rpm

Weight

tonnes

R1

R2

R3

R4

5

6

7

8

15 650

18 780

21 910

25 040

10 950

13 140

15 330

17 520

12 500

15 000

17 500

20 000

10 950

13 140

15 330

17 520

7 530

8 710

9 890

11 070

412

472

533

593

Dimensions

mm

B

4 300

C

1 520

D

10 400

E

4 490

F*

12 545

G

2 340

RT-flex68

Output in kW at

Cyl.

Brake specific fuel consumption (BSFC) in g/kWh

Full load

Rating point

BMEP, bar

IMO Tier ll

RTA

RT-flex

Part load, % of R1

RT-flex tuning variant

IMO Tier ll

Standard Tuning

85

Standard

166.8

70

Standard

166.0

R1

20.0

174

170

R2

14.0

168

164

R3

20.0

174

170

85

Delta

166.1

70

Delta

164.5

R4

17.5

170

166

12RT-flex96C

60

Low-Load

163.5

* Standard piston dismantling height can be reduced with tilted piston withdrawal.

F

D

C

A

18

19

DU-

Engines

RT-flex60C

RT-flex58T

Main data: Version B

Main data: Version D, also available as traditional RTA type

Fuel specification:

Fuel oil..........................................700 cSt/50C

ISO-F 8217:2005,

category ISO-RMK700

Cylinder bore ................................... 580 mm

Piston stroke.................................. 2416 mm

Speed ......................................... 84-105 rpm

Mean effective pressure at R1......... 20.2 bar

Piston speed......................................8.5 m/s

Rated power, principal dimensions and weights

Output in kW at

Cyl.

114 rpm

91 rpm

Rated power, principal dimensions and weights

Length A

mm

Weight

tonnes

R1

R2

R3

R4

5

6

7

8

9

12 100

14 520

16 940

19 360

21 780

8 450

10 140

11 830

13 520

15 210

9 650

11 580

13 510

15 440

17 370

8 450

10 140

11 830

13 520

15 210

6 638

7 678

8 718

9 758

10 798

268

322

377

428

480

Dimensions

mm

B

3 700

C

1 300

D

8 570

E

3 660

F*

10 500

G

1 955

Brake specific fuel consumption (BSFC) in g/kWh

Full load

Rating point

BMEP, bar

IMO Tier ll

RT-flex

Part load, % of R1

RT-flex tuning variant

IMO Tier ll

Standard Tuning

85

Standard

167.8

70

Standard

167.0

R1

20.0

171

R2

14.0

165

R3

20.0

171

85

Delta

167.1

70

Delta

165.5

* Standard piston dismantling height can be reduced with tilted piston withdrawal.

Fuel specification:

Fuel oil..........................................700 cSt/50C

ISO-F 8217:2005,

category ISO-RMK700

R4

17.5

167

60

Low-Load

164.5

Output in kW at

Cyl.

105 rpm

Length A

mm

Weight

tonnes

7 900

9 480

11 060

12 640

6 381

7 387

8 393

9 399

281

322

377

418

E

3 475

F*

10 880

G

2 000

84 rpm

R1

R2

R3

R4

5

6

7

8

11 300

13 560

15 820

18 080

7 900

9 480

11 060

12 640

9 050

10 860

12 670

14 480

Dimensions

mm

B

3 820

C

1 300

D

8 822

Brake specific fuel consumption (BSFC) in g/kWh

Full load

Rating point

BMEP, bar

IMO Tier ll

RTA

RT-flex

Part load, % of R1

RT-flex tuning variant

IMO Tier ll

Standard Tuning

85

Standard

167.8

70

Standard

167.0

R1

20.2

174

171

R2

14.1

168

165

85

Delta

167.1

60

Low-Load

164.5

F

D

20

70

Delta

165.5

R4

17.7

170

167

* Standard piston dismantling height can be reduced with tilted piston withdrawal.

R3

20.2

174

171

G

A

21

RT-flex60C, 58T

Cylinder bore ................................... 600 mm

Piston stroke.................................. 2250 mm

Speed ......................................... 91-114 rpm

Mean effective pressure at R1......... 20.0 bar

Piston speed......................................8.6 m/s

DU-

Engines

RT-flex50

RT-flex50

Main data: Version D

Main data: Version B

Fuel specification:

Fuel oil..........................................700 cSt/50C

ISO-F 8217:2005,

category ISO-RMK700

Cylinder bore ................................... 500 mm

Piston stroke.................................. 2050 mm

Speed ......................................... 99-124 rpm

Mean effective pressure at R1......... 20.0 bar

Piston speed......................................8.5 m/s

Rated power, principal dimensions and weights

Output in kW at

Cyl.

124 rpm

Length A

mm

99 rpm

Rated power, principal dimensions and weights

Weight

tonnes

R1

R2

R3

R4

5

6

7

8

8 725

10 470

12 215

13 960

6 100

7 320

8 540

9 760

6 975

8 370

9 765

11 160

6 100

7 320

8 540

9 760

5 582

6 462

7 342

8 222

200

225

255

280

Dimensions

mm

B

3 150

C

1 088

D

7 646

E

3 300

F*

9 270

Output in kW at

Cyl.

RT-flex

Part load, % of R1

RT-flex tuning variant

IMO Tier ll

Standard Tuning

85

Standard

167.8

70

Standard

167.0

R1

21.0

171

R2

14.7

165

85

Delta

167.1

R3

21.0

171

70

Delta

165.5

* Standard piston dismantling height can be reduced with tilted piston withdrawal.

124 rpm

Length A

mm

99 rpm

R2

R3

R4

5

6

7

8

8 300

9 960

11 620

13 280

5 800

6 960

8 120

9 280

6 650

7 980

9 310

10 640

5 800

6 960

8 120

9 280

5 582

6 462

7 342

8 222

200

225

255

280

G

1 636

Dimensions

mm

B

3 150

C

1 088

D

7 646

E

3 300

F*

9 270

G

1 636

R4

18.4

167

Full load

Rating point

BMEP, bar

IMO Tier ll

Brake specific fuel consumption (BSFC) in g/kWh

60

Low-Load

164.5

RT-flex

Part load, % of R1

RT-flex tuning variant

IMO Tier ll

Standard Tuning

85

Standard

169.8

70

Standard

169.0

R1

20.0

173

R2

13.9

167

70

Delta

167.5

R4

17.5

169

60

Low-Load

166.5

* Standard piston dismantling height can be reduced with tilted piston withdrawal.

F

D

22

R3

20.0

173

85

Delta

169.1

Weight

tonnes

R1

Brake specific fuel consumption (BSFC) in g/kWh

Full load

Rating point

BMEP, bar

IMO Tier ll

Fuel specification:

Fuel oil..........................................700 cSt/50C

ISO-F 8217:2005,

category ISO-RMK700

G

A

23

RT-flex50

Cylinder bore ................................... 500 mm

Piston stroke.................................. 2050 mm

Speed ......................................... 99-124 rpm

Mean effective pressure at R1......... 21.0 bar

Piston speed......................................8.5 m/s

DU-

Engines

RT-flex48T

RT-flex48T

Main data: Version D, also available as traditional RTA type

Cylinder bore ................................... 480 mm

Piston stroke.................................. 2000 mm

Speed ....................................... 102-127 rpm

Mean effective pressure at R1......... 19.0 bar

Piston speed......................................8.5 m/s

Main data: Version D, also available as traditional RTA type

Fuel specification:

Fuel oil..........................................700 cSt/50C

ISO-F 8217:2005,

category ISO-RMK700

Economy Ratings

Rated power, principal dimensions and weights

Cyl.

127 rpm

Length A

mm

102 rpm

R1

R2

5

6

7

8

7 275

8 730

10 185

11 640

5 100

6 120

7 140

8 160

Dimensions

mm

B

3 170

C

1 085

R3

5 825

6 990

8 155

9 320

R4

Rated power, principal dimensions and weights

Weight

tonnes

5 100

6 120

7 140

8 160

5 314

6 148

6 982

7 816

171

205

225

250

E

3 253

F*

9 030

G

1 700

D

7 334

Cyl.

5

6

7

8

Dimensions

mm

Brake specific fuel consumption (BSFC) in g/kWh

Full load

Rating point

BMEP, bar

IMO Tier ll

RTA

RT-flex

Part load, % of R1

RT-flex tuning variant

IMO Tier ll

Standard Tuning

85

Standard

167.8

70

Standard

167.0

R1

19.0

173

171

R2

13.3

167

165

85

Delta

167.1

R3

19.0

173

171

70

Delta

165.5

* Standard piston dismantling height can be reduced with tilted piston withdrawal.

Output in kW at 127 rpm

ER1

ER2

6 900

8 280

9 660

11 040

6 550

7 860

13 125

10 480

B

3 170

C

1 085

D

7 334

171

205

225

250

R4

16.6

169

167

60

Low-Load

164.5

IMO Tier ll

RTA

RT-flex

RT-flex

RT-flex

RT-flex

RT-flex

RT-flex

Tuning variant

Load

Standard Tuning

Standard Tuning

Standard Tuning

Delta Tuning

Delta Tuning

Low-Load Tuning

100%

100%

85%

70%

85%

70%

60%

Power

F*

9 030

G

1 700

ER1

18.0

171.5

169.5

166.3

165.5

165.8

164.4

163.4

ER2

17.1

170.0

168.0

164.8

164.0

164.5

163.3

162.5

Engine-MCR

Engine

layout field

24

5 314

6 148

6 982

7 816

E

3 253

Weight tonnes

Brake specific fuel consumption (BSFC) in g/kWh

Rating point

BMEP, bar

* Standard piston dismantling height can be

reduced with tilted piston withdrawal.

Length A mm

R3

R4

RT-flex48T

Output in kW at

R1

ER1

ER2

R2

Speed

25

DU-

Engines

RT-flex40

RT-flex35

Fuel specification:

Fuel oil..........................................700 cSt/50C

ISO-F 8217:2005,

category ISO-RMK700

Cylinder bore ................................... 350 mm

Piston stroke.................................. 1550 mm

Speed ....................................... 142-167 rpm

Mean effective pressure at R1......... 21.0 bar

Piston speed......................................8.6 m/s

Rated power, principal dimensions and weights

Output in kW at

Cyl.

146 rpm

R1

R2

5

6

7

8

5 675

6 810

7 945

9 080

4 550

5 460

6 370

7 280

Dimensions

mm

B

2 590

C

950

Output in kW at

Weight

tonnes

Cyl.

4 550

5 460

6 370

7 280

5 050

5 750

6 450

7 150

109

125

140

153

E

1 660

F*

7 700

R3

4 825

5 790

6 755

7 720

Rated power, principal dimensions and weights

Length A

mm

124 rpm

R4

D

6 335

RT-flex

Part load, % of R1

RT-flex tuning variant

IMO Tier ll

Standard Tuning

85

Standard

171.8

70

Standard

171.0

R1

21.0

175

R2

16.8

169

R3

21.0

175

85

Delta

171.1

70

Delta

169.5

* Standard piston dismantling height can be reduced with tilted piston withdrawal.

167 rpm

Length A

mm

Weight

tonnes

3 475

4 170

4 865

5 560

4 434

5 046

5 658

6 270

69

80

90

98

E

1 220

F*

6 850

G

1 326

142 rpm

R1

R2

5

6

7

8

4 350

5 220

6 090

6 960

3 475

4 170

4 865

5 560

G

1 425

Dimensions

mm

B

2 264

C

830

R4

19.8

173

Full load

Rating point

BMEP, bar

IMO Tier ll

Brake specific fuel consumption (BSFC) in g/kWh

Full load

Rating point

BMEP, bar

IMO Tier ll

Fuel specification:

Fuel oil..........................................700 cSt/50C

ISO-F 8217:2005,

category ISO-RMK700

R3

3 700

4 440

5 180

5 920

R4

D

5 556

Brake specific fuel consumption (BSFC) in g/kWh

60

Low-Load

169.5

RT-flex

Part load, % of R1

RT-flex tuning variant

IMO Tier ll

Standard Tuning

85

Standard

172.8

70

Standard

172.0

R1

21.0

176

R2

16.8

170

85

Delta

172.1

70

Delta

170.5

60

Low-Load

169.5

F

D

26

R4

19.8

174

* Standard piston dismantling height can be reduced with tilted piston withdrawal.

R3

21.0

176

G

A

RT-flex40,35

Cylinder bore ................................... 400 mm

Piston stroke.................................. 1770 mm

Speed ....................................... 124-146 rpm

Mean effective pressure at R1......... 21.0 bar

Piston speed......................................8.6 m/s

27

Portable TF-DetectorTrace of Ferrous powder Detector

Very sensitive magnetic

particle detector with

high resolution.

Easy operation as 1-2-3

1. Sample small amount of oil in a glass tube.

2. Set a glass tube to TF-Detector.

3. Press button, then TF-Detector shows the magnetic particle

density in 'ppm' within 20 seconds.

If you want, you can save the measurement data with date and time by

pressing [SAVE] button. Portable TF-Detector has memory for 480 data

(24 unit x 20 data), and you can copy the data to SD-card for PC.

High sensitivity and resolution

TF-Detector examines magnetic particles of a size down to a few

micro-meters with resolution of less than 5ppm. So, you can nd out

abnormal wear at very early stage.

Typical application to two stroke low speed engine

You can monitor piston running condition through periodical

measurement of friction powder content in cylinder drain oil by

TF-Detector, and then,

- You can save cylinder oil consumption by optimized

feed rate setting according to piston running

condition.

- You can catch a foretaste of abnormal piston running

condition, and then you can take actions to avoid

serious damage at very early stage.

Measurement

Measured data

TF-Detector

SD

You can store the data in

TF-Detector and copy to

SD-card, and then you can see

accumulated data and trend

easily by PC.

On-line type is also available.

You can remotely monitor

the magnetic particle density

in the oil, continuously.

1.

2. TF-Detector

3. 20

[SAVE]

480 24 20 SD

28

TF-Detector

DU and MEIYO led an application

of patent for new technologies of

TF-Detector.

29

Global Service Network

Global Service Network

DU and Wrtsil cover all over the world

using Wrtsil world-wide service network.

Network

Workshop

Newest locations

30

70

>

countries

160 locations

31

http://www.ihi.co.jp/du/ E-mail info@du.ihi.co.jp

(Head Office)

101-0041 2-8TEL:03-3257-8222 FAX:03-3257-8220

Prime Kanda Building

2-8 Kanda Suda-cho,Chiyoda-ku,Tokyo, 101-0041,JAPAN TEL:+81-3-3257-8222 FAX:+81-3-3257-8220

(Aioi Works)

678-0041 5292 TEL:0791-24-2608 FAX:0791-24-2648

5292 Aioi,Aioi-shi,Hyogo-ken, 678-0041,JAPAN TEL:+81-791-24-2608 FAX:+81-791-24-2648

(Kobe Sales Office)

650-0022 1-1-1 TEL:078-321-3881 FAX:078-391-2050

Shin-Motomachi,Building

1-1-1 Motomachi-dori,Chuou-ku,Kobe-shi,Hyogo-ken, 650-0022,JAPAN TEL:+81-78-321-3881 FAX:+81-78-391-2050

1003-5000(Fxcw) Printed in Japan

You might also like

- Gd-Ha12v Gf-Ha12s Gf-Ha22sDocument983 pagesGd-Ha12v Gf-Ha12s Gf-Ha22sはせがわまだお100% (1)

- Denon-Dra500ae 700ae RecDocument62 pagesDenon-Dra500ae 700ae RecPiotr ZimnyNo ratings yet

- GTL01 CONTROLLER (AN) - E-GB - TL186-Revision 00Document37 pagesGTL01 CONTROLLER (AN) - E-GB - TL186-Revision 00Lucas MaldonadoNo ratings yet

- DPF ContentsDocument19 pagesDPF Contentssilverdollar100% (1)

- Low Speed Engines Handbook 2019Document68 pagesLow Speed Engines Handbook 2019Nadia Novita SariNo ratings yet

- Manual de Instrucciones MP Warsila 6l26 Arc 07 de AgostoDocument509 pagesManual de Instrucciones MP Warsila 6l26 Arc 07 de Agostoma2razor100% (1)

- 60 CC 75 e 0 D 57261714Document508 pages60 CC 75 e 0 D 57261714abdelbagi ibrahimNo ratings yet

- Sulzer Rta58t Cylinder LinerDocument2 pagesSulzer Rta58t Cylinder LinerHarry KharbandaNo ratings yet

- CSL Cse MDocument8 pagesCSL Cse MBoogi Andika TamamiNo ratings yet

- Turbocharger MaintenanceDocument15 pagesTurbocharger MaintenanceAnonymous 7nTvPQVvRNo ratings yet

- Ge .Alco.emd Parts 副本Document4 pagesGe .Alco.emd Parts 副本mingtao liNo ratings yet

- 2CEDocument25 pages2CEfilmonstar100% (1)

- Catalog 1113Document9 pagesCatalog 1113WilberZangaNo ratings yet

- MaK M20 - Spare Parts Catalog - RuDocument204 pagesMaK M20 - Spare Parts Catalog - RuMARINE SOLUTIONSNo ratings yet

- Motor MWM Sprint 4.08 Tcea PDFDocument33 pagesMotor MWM Sprint 4.08 Tcea PDFFelippe DelgadoNo ratings yet

- PC400 450-10Document20 pagesPC400 450-10qrl840927No ratings yet

- ZX300 6 - ZX300LC 6Document13 pagesZX300 6 - ZX300LC 6Calvin ThamNo ratings yet

- Fuel System Diagnostic Test DocumentationDocument10 pagesFuel System Diagnostic Test DocumentationClemente Flores100% (1)

- 燃費・環境性 - ISUZU:フォワード(中型トラック)Document1 page燃費・環境性 - ISUZU:フォワード(中型トラック)Sitichoke SemamonNo ratings yet

- PC300 10Document9 pagesPC300 10William ChangNo ratings yet

- ZX330LC 5B JapaneseDocument22 pagesZX330LC 5B Japanesevicky beastNo ratings yet

- ZX240 6 - ZX240LC 6 - ZX250H 6 - ZX250LCH 6 - ZX250K 6 - ZX250LCK 6Document13 pagesZX240 6 - ZX240LC 6 - ZX250H 6 - ZX250LCH 6 - ZX250K 6 - ZX250LCK 6Calvin ThamNo ratings yet

- HMKB HMKC Series Catalog E 2005Document32 pagesHMKB HMKC Series Catalog E 2005titanwlxNo ratings yet

- ZH200 5B - KS Ja262pDocument13 pagesZH200 5B - KS Ja262pCALVINNo ratings yet

- PC200 210-11Document20 pagesPC200 210-11Nguyen The Phat100% (2)

- 2014 k33 SBP Manual Cbr300 HRCDocument36 pages2014 k33 SBP Manual Cbr300 HRCRed AhmadNo ratings yet

- Motori BrushlessDocument8 pagesMotori BrushlessJack MikeNo ratings yet

- CC Link (MJ0123 28a)Document178 pagesCC Link (MJ0123 28a)Khánh Nguyễn VănNo ratings yet

- Service Training: D8T Track-Type TractorDocument186 pagesService Training: D8T Track-Type TractorLuis GuzmánNo ratings yet

- 1.ion 4-SpeedDocument144 pages1.ion 4-Speedalex generalNo ratings yet

- Benz DTC ADocument76 pagesBenz DTC A笠井 聡No ratings yet

- PT - LUBRAX - TOP - PRO 15W 40 e 10W 30Document3 pagesPT - LUBRAX - TOP - PRO 15W 40 e 10W 30Bruno BarbosaNo ratings yet

- Secomat NewDocument16 pagesSecomat NewYulfre Antonio CarrilloNo ratings yet

- MVM2010 Pesic Ver 3Document8 pagesMVM2010 Pesic Ver 3Радивоје ПешићNo ratings yet

- ZX160LC 6Document11 pagesZX160LC 6Calvin ThamNo ratings yet

- Main Engine Change-Over From Hfo To LsmgoDocument7 pagesMain Engine Change-Over From Hfo To LsmgoHendra SamanthaNo ratings yet

- SK80UR-6E Japan Spec BrochureDocument16 pagesSK80UR-6E Japan Spec BrochurePHÁT NGUYỄN THẾNo ratings yet

- 5 Ncsi sp02 08 1 0Document234 pages5 Ncsi sp02 08 1 0Yongkook KimNo ratings yet

- GAC21 P5213-Kb Web 13.7.24Document8 pagesGAC21 P5213-Kb Web 13.7.24manpreet singhNo ratings yet

- Lubrication SystemDocument64 pagesLubrication Systemmoldovan adrianNo ratings yet

- Sh250 7 CatalogDocument10 pagesSh250 7 CatalogApu debNo ratings yet

- sh75x CatalogDocument6 pagessh75x CatalogHodumi JosefNo ratings yet

- Variable Spindle ThreadingDocument13 pagesVariable Spindle ThreadingihsjwarrenNo ratings yet

- SW20 3sgteDocument7 pagesSW20 3sgteCzarny KotNo ratings yet

- 実際の運航に使用してはならない。 Do not use for real flight: 15-12-(1) Next Page BLANKDocument24 pages実際の運航に使用してはならない。 Do not use for real flight: 15-12-(1) Next Page BLANKBort FortNo ratings yet

- Hydraulics Product GuideDocument28 pagesHydraulics Product GuideCloves KelherNo ratings yet

- Service Manual VLT DanfossDocument56 pagesService Manual VLT Danfossjroyal69100% (3)

- SK45SR SK55SR-7Document20 pagesSK45SR SK55SR-7poiuytrewq85207410No ratings yet

- Power TrainDocument447 pagesPower Trainmoldovan adrianNo ratings yet

- Manual de Operacion de MaquinariaDocument12 pagesManual de Operacion de MaquinariaOogway MasterNo ratings yet

- 231 All PDFDocument82 pages231 All PDFAszrul NizamNo ratings yet

- Rcsft1.users Manual 2 513993Document28 pagesRcsft1.users Manual 2 513993Gerald Leon FloresNo ratings yet

- R01an4674jj0110 rx66t PumpDocument54 pagesR01an4674jj0110 rx66t PumpポケモンマスターNo ratings yet

- 実際の運航に使用してはならない。 Do not use for real flight: 15-17-(1) Next Page BLANKDocument36 pages実際の運航に使用してはならない。 Do not use for real flight: 15-17-(1) Next Page BLANKBort FortNo ratings yet

- Motor LombardiniDocument156 pagesMotor LombardiniManu Barbe Garci100% (1)

- Elecylinder Electricity (Mj3816 4a)Document344 pagesElecylinder Electricity (Mj3816 4a)Khánh Nguyễn VănNo ratings yet

- CDH821C 831C 831CDocument4 pagesCDH821C 831C 831CHodumi JosefNo ratings yet

- 4 Ncsi sp02 07 7 0Document500 pages4 Ncsi sp02 07 7 0Yongkook KimNo ratings yet

- ecoFORCE Folder JAPDocument12 pagesecoFORCE Folder JAPNitinNo ratings yet

- Wind PowerDocument57 pagesWind PowerPergaulan NainggolanNo ratings yet