Professional Documents

Culture Documents

Ciclos de Vapor

Ciclos de Vapor

Uploaded by

Documentos ImportantesCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

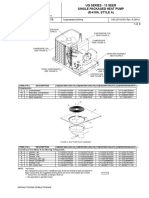

- O & M Manual For BoilerDocument146 pagesO & M Manual For BoilerAshwani Dogra100% (15)

- Explaining The Working Principle of Photovoltaic CellsDocument4 pagesExplaining The Working Principle of Photovoltaic CellsAneek Islam50% (2)

- ME 6404 Thermal Engineering UNIT I Question BankDocument8 pagesME 6404 Thermal Engineering UNIT I Question BankRiyaz haja MohideenNo ratings yet

- Pump Care ManualDocument3 pagesPump Care ManualGerencia Rigar Colombia SASNo ratings yet

- Surface Condenser Configurations: 40 Journal of Energy in Southern Africa - Vol 19 No 3 - August 2008Document1 pageSurface Condenser Configurations: 40 Journal of Energy in Southern Africa - Vol 19 No 3 - August 2008aliscribd46No ratings yet

- Exp. UQ (Style A)Document8 pagesExp. UQ (Style A)missael.alvramNo ratings yet

- Refrigeration Research Receivers EasternDocument2 pagesRefrigeration Research Receivers EasternArnulfoNo ratings yet

- Exergetic and Thermoeconomic Analyses of The Rice-Husk Power Plant in ThailandDocument6 pagesExergetic and Thermoeconomic Analyses of The Rice-Husk Power Plant in ThailandbarmarwanNo ratings yet

- HP 101 STD Hand Pump July 2010Document1 pageHP 101 STD Hand Pump July 2010Forum PompieriiNo ratings yet

- Matrial Balance ReportDocument14 pagesMatrial Balance ReportShah Ali NaqviNo ratings yet

- Simulation of Methanol Production From Biomass Gasification in Interconnected Fluidized BedsDocument9 pagesSimulation of Methanol Production From Biomass Gasification in Interconnected Fluidized BedsKelly TorresNo ratings yet

- WB March 2004Document8 pagesWB March 2004Caterine Jara CeaNo ratings yet

- Ml21256a297 Nei 10CFR53Document59 pagesMl21256a297 Nei 10CFR53오덕환Oh DuckhwanNo ratings yet

- Industrial Training Report-IPGCL& PPCLDocument92 pagesIndustrial Training Report-IPGCL& PPCLSaurav Kumar100% (2)

- Field Instrument ListDocument15 pagesField Instrument Listmohamedsaib438No ratings yet

- GGCP 00 p0 Es 009 PP Shutdown Philosophy Rev 1Document12 pagesGGCP 00 p0 Es 009 PP Shutdown Philosophy Rev 1wahyuNo ratings yet

- Giraldo Legra ResumeDocument2 pagesGiraldo Legra ResumeAwo Orumila GiraldolegraNo ratings yet

- 1 MCQDocument40 pages1 MCQRohit KaleNo ratings yet

- Hydrogen Generator: Low Capacities To 300cc/minDocument2 pagesHydrogen Generator: Low Capacities To 300cc/minNheanvatnak AukNo ratings yet

- Kseries Datasheets Merged PDFDocument22 pagesKseries Datasheets Merged PDFJose VelasquezNo ratings yet

- EC Urvan 2016Document905 pagesEC Urvan 2016Gato Valenz TorresNo ratings yet

- Pilot Operated RegulatorDocument2 pagesPilot Operated RegulatorPengurus Blok BNo ratings yet

- Boliers and Pressure VesselsDocument33 pagesBoliers and Pressure VesselsMarcelo Chaves RestrepoNo ratings yet

- Ch.2 Case and Duct SystemDocument11 pagesCh.2 Case and Duct Systemcpt.ghostNo ratings yet

- Alfa Laval Energy Balance Casestory enDocument2 pagesAlfa Laval Energy Balance Casestory enHélder FernandoNo ratings yet

- SE Zorya-Mashproekt - Gas Turbine Engines For Gas Pipelines PDFDocument12 pagesSE Zorya-Mashproekt - Gas Turbine Engines For Gas Pipelines PDFMohammad Bahreini100% (1)

- Sero Prospekt SRZ eDocument8 pagesSero Prospekt SRZ esdafas dfNo ratings yet

- 5 Star Rated ACDocument3 pages5 Star Rated ACavr8784No ratings yet

- DC Charger and Battery Sizing Calculation ReportDocument8 pagesDC Charger and Battery Sizing Calculation ReportJohn Philip BuntalesNo ratings yet

- Converting Coal To Electricity: Chemical, Biological and Environmental EngineeringDocument28 pagesConverting Coal To Electricity: Chemical, Biological and Environmental EngineeringOanh NguyenNo ratings yet

Ciclos de Vapor

Ciclos de Vapor

Uploaded by

Documentos ImportantesOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ciclos de Vapor

Ciclos de Vapor

Uploaded by

Documentos ImportantesCopyright:

Available Formats

2

We consider power cycles where the working fluid undergoes a phase change. The

best example of this cycle is the steam power cycle where water (steam) is the

working fluid.

Carnot Vapor Cycle

3

The heat engine may be composed of the following components.

The working fluid, steam (water), undergoes a thermodynamic cycle from 1-2-3-4-1.

The cycle is shown on the following T-s diagram.

4

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

0

100

200

300

400

500

600

700 700

s [kJ/kg-K]

T

[

C

]

6000 kPa

100 kPa

Carnot Vapor Cycle Using Steam

1

2

3

4

The thermal efficiency of this cycle is given as

th Carnot

net

in

out

in

L

H

W

Q

Q

Q

T

T

,

= =

=

1

1

Note the effect of T

H

and T

L

on q

th, Carnot

.

The larger the T

H

the larger the q

th, Carnot

The smaller the T

L

the larger the q

th, Carnot

5

To increase the thermal efficiency in any power cycle, we try to increase the

maximum temperature at which heat is added.

Reasons why the Carnot cycle is not used:

Pumping process 1-2 requires the pumping of a mixture of saturated liquid and

saturated vapor at state 1 and the delivery of a saturated liquid at state 2.

To superheat the steam to take advantage of a higher temperature, elaborate

controls are required to keep T

H

constant while the steam expands and does work.

To resolve the difficulties associated with the Carnot cycle, the Rankine cycle was

devised.

Rankine Cycle

The simple Rankine cycle has the same component layout as the Carnot cycle

shown above. The simple Rankine cycle continues the condensation process 4-1

until the saturated liquid line is reached.

Ideal Rankine Cycle Processes

Process Description

1-2 Isentropic compression in pump

2-3 Constant pressure heat addition in boiler

3-4 Isentropic expansion in turbine

4-1 Constant pressure heat rejection in condenser

6

The T-s diagram for the Rankine cycle is given below. Locate the processes for heat

transfer and work on the diagram.

0 2 4 6 8 10 12 12

0

100

200

300

400

500

s [kJ/kg-K]

T

[

C

]

6000 kPa

10 kPa

Rankine Vapor Power Cycle

1

2

3

4

Example 10-1

Compute the thermal efficiency of an ideal Rankine cycle for which steam leaves

the boiler as superheated vapor at 6 MPa, 350

o

C, and is condensed at 10 kPa.

We use the power system and T-s diagram shown above.

P

2

= P

3

= 6 MPa = 6000 kPa

T

3

= 350

o

C

P

1

= P

4

= 10 kPa

7

Pump

The pump work is obtained from the conservation of mass and energy for steady-flow

but neglecting potential and kinetic energy changes and assuming the pump is

adiabatic and reversible.

( )

m m m

mh W m h

W m h h

pump

pump

1 2

1 1 2 2

2 1

= =

+ =

=

Since the pumping process involves an incompressible liquid, state 2 is in the

compressed liquid region, we use a second method to find the pump work or the Ah

across the pump.

Recall the property relation:

dh = T ds + v dP

Since the ideal pumping process 1-2 is isentropic, ds = 0.

8

The incompressible liquid assumption allows

v v const

h h v P P

~ =

~

1

2 1 1 2 1

.

( )

The pump work is calculated from

( ) ( )

( )

W m h h mv P P

w

W

m

v P P

pump

pump

pump

= ~

= =

2 1 1 2 1

1 2 1

Using the steam tables

1

1

3

1

191.81

10

.

0.00101

f

f

kJ

h h

kg P kPa

Sat liquid m

v v

kg

= =

`

)

= =

w v P P

m

kg

kPa

kJ

m kPa

kJ

kg

pump

=

=

=

1 2 1

3

3

000101 6000 10

605

( )

. ( )

.

9

Now, h

2

is found from

2 1

6.05 191.81

197.86

pump

h w h

kJ kJ

kg kg

kJ

kg

= +

= +

=

Boiler

To find the heat supplied in the boiler, we apply the steady-flow conservation of mass

and energy to the boiler. If we neglect the potential and kinetic energies, and note

that no work is done on the steam in the boiler, then

( )

m m m

m h Q m h

Q m h h

in

in

2 3

2 2 3 3

3 2

= =

+ =

=

10

We find the properties at state 3 from the superheated tables as

3

3

3

3

3043.9

6000

350

6.3357

o

kJ

h

P kPa

kg

kJ T C

s

kg K

`

=

)

=

The heat transfer per unit mass is

3 2

(3043.9 197.86)

2845.1

in

in

Q

q h h

m

kJ

kg

kJ

kg

= =

=

=

11

Turbine

The turbine work is obtained from the application of the conservation of mass and

energy for steady flow. We assume the process is adiabatic and reversible and

neglect changes in kinetic and potential energies.

( )

m m m

m h W m h

W m h h

turb

turb

3 4

3 3 4 4

3 4

= =

= +

=

We find the properties at state 4 from the steam tables by noting s

4

= s

3

= 6.3357

kJ/kg-K and asking three questions.

4

4

4

4

10 : 0.6492 ; 8.1488

?

?

?

f g

f

f g

g

kJ kJ

at P kPa s s

kg K kg K

is s s

is s s s

is s s

= = =

<

< <

<

12

4 4

4

4

6.3357 0.6492

0.758

7.4996

f fg

f

fg

s s x s

s s

x

s

= +

= = =

4 4

191.81 0.758(2392.1)

2005.0

f fg

h h x h

kJ kJ

kg kg

kJ

kg

= +

= +

=

The turbine work per unit mass is

3 4

(3043.9 2005.0)

1038.9

turb

w h h

kJ

kg

kJ

kg

=

=

=

13

The net work done by the cycle is

(1038.9 6.05)

1032.8

net turb pump

w w w

kJ

kg

kJ

kg

=

=

=

The thermal efficiency is

1032.8

2845.1

0.363 36.3%

net

th

in

kJ

w kg

kJ

q

kg

or

= =

=

14

Ways to improve the simple Rankine cycle efficiency:

Superheat the vapor

Average temperature is higher during heat addition.

Moisture is reduced at turbine exit (we want x

4

in the above example > 85

percent).

Increase boiler pressure (for fixed maximum temperature)

Availability of steam is higher at higher pressures.

Moisture is increased at turbine exit.

Lower condenser pressure

Less energy is lost to surroundings.

Moisture is increased at turbine exit.

Extra Assignment

For the above example, find the heat rejected by the cycle and evaluate the thermal

efficiency from

th

net

in

out

in

w

q

q

q

= = 1

15

Reheat Cycle

As the boiler pressure is increased in the simple Rankine cycle, not only does the

thermal efficiency increase, but also the turbine exit moisture increases. The reheat

cycle allows the use of higher boiler pressures and provides a means to keep the

turbine exit moisture (x > 0.85 to 0.90) at an acceptable level.

Lets sketch the T-s diagram for the reheat cycle.

T

s

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- O & M Manual For BoilerDocument146 pagesO & M Manual For BoilerAshwani Dogra100% (15)

- Explaining The Working Principle of Photovoltaic CellsDocument4 pagesExplaining The Working Principle of Photovoltaic CellsAneek Islam50% (2)

- ME 6404 Thermal Engineering UNIT I Question BankDocument8 pagesME 6404 Thermal Engineering UNIT I Question BankRiyaz haja MohideenNo ratings yet

- Pump Care ManualDocument3 pagesPump Care ManualGerencia Rigar Colombia SASNo ratings yet

- Surface Condenser Configurations: 40 Journal of Energy in Southern Africa - Vol 19 No 3 - August 2008Document1 pageSurface Condenser Configurations: 40 Journal of Energy in Southern Africa - Vol 19 No 3 - August 2008aliscribd46No ratings yet

- Exp. UQ (Style A)Document8 pagesExp. UQ (Style A)missael.alvramNo ratings yet

- Refrigeration Research Receivers EasternDocument2 pagesRefrigeration Research Receivers EasternArnulfoNo ratings yet

- Exergetic and Thermoeconomic Analyses of The Rice-Husk Power Plant in ThailandDocument6 pagesExergetic and Thermoeconomic Analyses of The Rice-Husk Power Plant in ThailandbarmarwanNo ratings yet

- HP 101 STD Hand Pump July 2010Document1 pageHP 101 STD Hand Pump July 2010Forum PompieriiNo ratings yet

- Matrial Balance ReportDocument14 pagesMatrial Balance ReportShah Ali NaqviNo ratings yet

- Simulation of Methanol Production From Biomass Gasification in Interconnected Fluidized BedsDocument9 pagesSimulation of Methanol Production From Biomass Gasification in Interconnected Fluidized BedsKelly TorresNo ratings yet

- WB March 2004Document8 pagesWB March 2004Caterine Jara CeaNo ratings yet

- Ml21256a297 Nei 10CFR53Document59 pagesMl21256a297 Nei 10CFR53오덕환Oh DuckhwanNo ratings yet

- Industrial Training Report-IPGCL& PPCLDocument92 pagesIndustrial Training Report-IPGCL& PPCLSaurav Kumar100% (2)

- Field Instrument ListDocument15 pagesField Instrument Listmohamedsaib438No ratings yet

- GGCP 00 p0 Es 009 PP Shutdown Philosophy Rev 1Document12 pagesGGCP 00 p0 Es 009 PP Shutdown Philosophy Rev 1wahyuNo ratings yet

- Giraldo Legra ResumeDocument2 pagesGiraldo Legra ResumeAwo Orumila GiraldolegraNo ratings yet

- 1 MCQDocument40 pages1 MCQRohit KaleNo ratings yet

- Hydrogen Generator: Low Capacities To 300cc/minDocument2 pagesHydrogen Generator: Low Capacities To 300cc/minNheanvatnak AukNo ratings yet

- Kseries Datasheets Merged PDFDocument22 pagesKseries Datasheets Merged PDFJose VelasquezNo ratings yet

- EC Urvan 2016Document905 pagesEC Urvan 2016Gato Valenz TorresNo ratings yet

- Pilot Operated RegulatorDocument2 pagesPilot Operated RegulatorPengurus Blok BNo ratings yet

- Boliers and Pressure VesselsDocument33 pagesBoliers and Pressure VesselsMarcelo Chaves RestrepoNo ratings yet

- Ch.2 Case and Duct SystemDocument11 pagesCh.2 Case and Duct Systemcpt.ghostNo ratings yet

- Alfa Laval Energy Balance Casestory enDocument2 pagesAlfa Laval Energy Balance Casestory enHélder FernandoNo ratings yet

- SE Zorya-Mashproekt - Gas Turbine Engines For Gas Pipelines PDFDocument12 pagesSE Zorya-Mashproekt - Gas Turbine Engines For Gas Pipelines PDFMohammad Bahreini100% (1)

- Sero Prospekt SRZ eDocument8 pagesSero Prospekt SRZ esdafas dfNo ratings yet

- 5 Star Rated ACDocument3 pages5 Star Rated ACavr8784No ratings yet

- DC Charger and Battery Sizing Calculation ReportDocument8 pagesDC Charger and Battery Sizing Calculation ReportJohn Philip BuntalesNo ratings yet

- Converting Coal To Electricity: Chemical, Biological and Environmental EngineeringDocument28 pagesConverting Coal To Electricity: Chemical, Biological and Environmental EngineeringOanh NguyenNo ratings yet