Professional Documents

Culture Documents

Friction Vs Speed

Friction Vs Speed

Uploaded by

paperbirds1199Copyright:

Available Formats

You might also like

- Lab 112 ReportDocument3 pagesLab 112 ReportKing100% (3)

- Belt Friction Full ReportDocument8 pagesBelt Friction Full ReportJoshua Reynolds73% (11)

- Senarai Amali Fizik SPM Ting 4Document52 pagesSenarai Amali Fizik SPM Ting 4Hazrina Awang100% (3)

- MarblesDocument3 pagesMarblesLeandro LeandroNo ratings yet

- Solenoid Actuators: Theory and Computational MethodsFrom EverandSolenoid Actuators: Theory and Computational MethodsRating: 3 out of 5 stars3/5 (1)

- Fluids Lab - Experiment 2 - Fluid Properties: ViscosityDocument9 pagesFluids Lab - Experiment 2 - Fluid Properties: ViscosityJordan Hines100% (6)

- Golf-Racht, T. D. Van. - Fundamentals of Fractured Reservoir EngineeringDocument729 pagesGolf-Racht, T. D. Van. - Fundamentals of Fractured Reservoir Engineeringionizedx50% (2)

- BE Tonsil Optimum FFDocument2 pagesBE Tonsil Optimum FFbourtyNo ratings yet

- Rosin-Rammler Paper 1980Document3 pagesRosin-Rammler Paper 1980Metalurgia En Verde100% (1)

- Circ MPYDocument7 pagesCirc MPYsinghmantejveer8No ratings yet

- Phy Report Exp2Document5 pagesPhy Report Exp2audiliciousNo ratings yet

- TheoryDocument12 pagesTheoryAhmad FikriNo ratings yet

- Lab 7: Uniform Circular Motion: Professor Dr. K. H. ChuDocument5 pagesLab 7: Uniform Circular Motion: Professor Dr. K. H. ChuJamkevin SariegoNo ratings yet

- The Bounce of A Ball: Rod CrossDocument6 pagesThe Bounce of A Ball: Rod CrossAhmed MagedNo ratings yet

- Revision Midterm Exam Physics1 NEWDocument17 pagesRevision Midterm Exam Physics1 NEWBaoduy NguyenNo ratings yet

- F4experiments 120222235933 Phpapp02Document52 pagesF4experiments 120222235933 Phpapp02Syafiq HazwanNo ratings yet

- Revision Midterm Exam Physics1 NEWDocument14 pagesRevision Midterm Exam Physics1 NEWBá Phong LêNo ratings yet

- Free Fall LabDocument9 pagesFree Fall Labapi-263210614No ratings yet

- F4 ExperimentsDocument52 pagesF4 ExperimentsKiTTy94% (16)

- Dynamic FREE FALL Lab ReportDocument6 pagesDynamic FREE FALL Lab ReportKevin TanNo ratings yet

- Pulley MechanicsDocument8 pagesPulley MechanicslaestatNo ratings yet

- Centripetal Force Experiment - For PG 63, Q12Document5 pagesCentripetal Force Experiment - For PG 63, Q12lz lzNo ratings yet

- Centripetal ForceDocument8 pagesCentripetal ForceShukor AzNo ratings yet

- Physics DP1 Lab Report William Ivan RealDocument8 pagesPhysics DP1 Lab Report William Ivan RealyfyvddjhpjNo ratings yet

- EGR365 Lab8 - Drag Coefficient of A SphereDocument4 pagesEGR365 Lab8 - Drag Coefficient of A Spherejoeblow4224No ratings yet

- Physics 11 Sample PaperDocument3 pagesPhysics 11 Sample PaperFAISAL GHEYASNo ratings yet

- Topic 1 General PhysicsDocument17 pagesTopic 1 General PhysicsSashideran ThilagesuaryNo ratings yet

- Coefficient of Kinetic Friction and Drag ForceDocument7 pagesCoefficient of Kinetic Friction and Drag ForcejhhjjhNo ratings yet

- High and Low Strain Dynamic Pile Testing - Independent Geoscience Pty LTDDocument5 pagesHigh and Low Strain Dynamic Pile Testing - Independent Geoscience Pty LTDindependentgeoscienceNo ratings yet

- Creep Lab ManualDocument11 pagesCreep Lab ManualapproachtheprobNo ratings yet

- (Physics) AnswersDocument15 pages(Physics) AnswersLoraine Rose EstivaNo ratings yet

- Laws of Motion 1Document7 pagesLaws of Motion 1AdityaNo ratings yet

- Newton's Laws of Motion: AdvnlDocument4 pagesNewton's Laws of Motion: AdvnlRashad AlamNo ratings yet

- PHY 303K - Florin - Exam IV - Fall 2013Document42 pagesPHY 303K - Florin - Exam IV - Fall 2013Roger100% (1)

- Modeling of Rocking of Shallow FoundationDocument14 pagesModeling of Rocking of Shallow FoundationsinisavucibatinaNo ratings yet

- BeltfrictionlabreportfullDocument12 pagesBeltfrictionlabreportfullShasmita LakshmiNo ratings yet

- Physics Week 2Document9 pagesPhysics Week 2gelvirnaNo ratings yet

- Direct Shear TestDocument11 pagesDirect Shear Testshahrolhazrien91% (34)

- Report AlphaalphaalphaDocument3 pagesReport AlphaalphaalphaNik HumphriesNo ratings yet

- Air Over A Two-Dimensional Studies Velocity Speed-Up, Roughness Effects and TurbulenceDocument20 pagesAir Over A Two-Dimensional Studies Velocity Speed-Up, Roughness Effects and TurbulenceGonKilNo ratings yet

- Stokes Law PDFDocument3 pagesStokes Law PDFmartim_martinsNo ratings yet

- Dynamic Deformation of Earth and Motion Effects Caused by Universe's Gravitational FieldFrom EverandDynamic Deformation of Earth and Motion Effects Caused by Universe's Gravitational FieldNo ratings yet

- Selected Problems in Physics with AnswersFrom EverandSelected Problems in Physics with AnswersRating: 3 out of 5 stars3/5 (2)

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Pressure, Resistance, and Stability of Earth American Society of Civil Engineers: Transactions, Paper No. 1174, Volume LXX, December 1910From EverandPressure, Resistance, and Stability of Earth American Society of Civil Engineers: Transactions, Paper No. 1174, Volume LXX, December 1910No ratings yet

- Experiments on the Absence of Mechanical Connexion between Ether and MatterFrom EverandExperiments on the Absence of Mechanical Connexion between Ether and MatterNo ratings yet

- Method of Moments for 2D Scattering Problems: Basic Concepts and ApplicationsFrom EverandMethod of Moments for 2D Scattering Problems: Basic Concepts and ApplicationsNo ratings yet

- Barron's Physics Practice Plus: 400+ Online Questions and Quick Study ReviewFrom EverandBarron's Physics Practice Plus: 400+ Online Questions and Quick Study ReviewNo ratings yet

- Physico-Chemistry of Solid-Gas Interfaces: Concepts and Methodology for Gas Sensor DevelopmentFrom EverandPhysico-Chemistry of Solid-Gas Interfaces: Concepts and Methodology for Gas Sensor DevelopmentNo ratings yet

- Applications of Derivatives Rate of Change (Calculus) Mathematics Question BankFrom EverandApplications of Derivatives Rate of Change (Calculus) Mathematics Question BankNo ratings yet

- The World Factbook: South Asia:: AfghanistanDocument1 pageThe World Factbook: South Asia:: Afghanistanpaperbirds1199No ratings yet

- The World Factbook: Europe:: AlbaniaDocument1 pageThe World Factbook: Europe:: Albaniapaperbirds1199No ratings yet

- The World Factbook: Africa:: AlgeriaDocument1 pageThe World Factbook: Africa:: Algeriapaperbirds1199No ratings yet

- The World Factbook: Europe:: AkrotiriDocument1 pageThe World Factbook: Europe:: Akrotiripaperbirds1199No ratings yet

- BackDocument1 pageBackpaperbirds1199No ratings yet

- Bangladesh AdminDocument1 pageBangladesh Adminpaperbirds1199No ratings yet

- BosniaHerzegovina TransportationDocument1 pageBosniaHerzegovina Transportationpaperbirds1199No ratings yet

- United StatesDocument1 pageUnited Statespaperbirds1199No ratings yet

- Middle EastDocument1 pageMiddle Eastpaperbirds1199No ratings yet

- Centra AmericaDocument1 pageCentra Americapaperbirds1199No ratings yet

- Design of Geocell Reinforced Flexible PavementDocument4 pagesDesign of Geocell Reinforced Flexible Pavementsundra0No ratings yet

- BS 4360 50eeDocument1 pageBS 4360 50eeTimNo ratings yet

- Basics of MechanismsDocument26 pagesBasics of MechanismsAtal KumarNo ratings yet

- Theory of The Streaming Current MonitorDocument10 pagesTheory of The Streaming Current MonitorMirza Quanta Ahady HusainiyNo ratings yet

- Chap10no1 PDFDocument2 pagesChap10no1 PDFTajiriMollel0% (9)

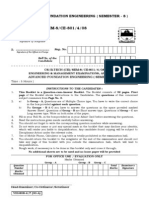

- CS/B.TECH (CE) /SEM-8/CE-801/4/08: Advanced Foundation Engineering (Semester - 8)Document6 pagesCS/B.TECH (CE) /SEM-8/CE-801/4/08: Advanced Foundation Engineering (Semester - 8)Debanjan BanerjeeNo ratings yet

- Motox WormDocument34 pagesMotox WormCristianDuarteNo ratings yet

- Department of Mechanical Engineering Visvesvaraya National Institute of Technology-NagpurDocument6 pagesDepartment of Mechanical Engineering Visvesvaraya National Institute of Technology-NagpurNikhil MulikNo ratings yet

- Assignment b3 MetfisDocument3 pagesAssignment b3 MetfisDewi Lestari Natalia MarpaungNo ratings yet

- Material Science Quiz: AnswersDocument3 pagesMaterial Science Quiz: Answersairbuk doeingNo ratings yet

- Advances in WiresDocument47 pagesAdvances in WiresHarshita DabasNo ratings yet

- Ferrocement AND Fiber Reinforced Concrete: Submitted by - Parth Pranav SaloniDocument18 pagesFerrocement AND Fiber Reinforced Concrete: Submitted by - Parth Pranav Salonisaloni karakNo ratings yet

- 3 BDocument3 pages3 BadnandjNo ratings yet

- Tabla Qw-252.1 - Asme IxDocument1 pageTabla Qw-252.1 - Asme IxAngelTinocoNo ratings yet

- 12 Physics Notes ch05 Magnetism and Matter PDFDocument2 pages12 Physics Notes ch05 Magnetism and Matter PDFAashna JenaNo ratings yet

- Pigments TiO2Document43 pagesPigments TiO2dougNo ratings yet

- Razon Tile Fix A1 Tile & Stone AdhesiveDocument3 pagesRazon Tile Fix A1 Tile & Stone Adhesiveshrikrishna rathodNo ratings yet

- Optimol Longtime PD 1 + 2 eDocument2 pagesOptimol Longtime PD 1 + 2 ericardoruedaNo ratings yet

- Interpreting Carburized Case DepthsDocument4 pagesInterpreting Carburized Case Depthsmp87_ing100% (1)

- Marpol - Coatings - Series - Tech - Specs PDFDocument12 pagesMarpol - Coatings - Series - Tech - Specs PDFYashwant RajeshirkeNo ratings yet

- Soft Soils Improved by Prefabricated Vertical Drains: Performance and PredictionDocument22 pagesSoft Soils Improved by Prefabricated Vertical Drains: Performance and PredictionJunieli Niel MendrofaNo ratings yet

- FEFCO Angle of Slip 104Document4 pagesFEFCO Angle of Slip 104Ml AgarwalNo ratings yet

- Shear Strength in The New Eurocode 2. A Step ForwardDocument10 pagesShear Strength in The New Eurocode 2. A Step ForwardChineseAssassinNo ratings yet

- SKD61-Hot Work Tool SteelDocument2 pagesSKD61-Hot Work Tool SteelAgustine SetiawanNo ratings yet

- Gear HoningDocument2 pagesGear HoningMargam Kiran KumarNo ratings yet

- El Ctrophilic: SolutionDocument41 pagesEl Ctrophilic: SolutionManaswini PNo ratings yet

Friction Vs Speed

Friction Vs Speed

Uploaded by

paperbirds1199Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Friction Vs Speed

Friction Vs Speed

Uploaded by

paperbirds1199Copyright:

Available Formats

Increase in friction force with sliding speed

Rod Crossa)

Physics Department, University of Sydney, Sydney NSW 2006, Australia

Received 19 November 2004; accepted 18 February 2005 A block sliding down an inclined plane normally accelerates. However, if the friction force increases with speed, then the block can slide at a constant terminal speed in a manner similar to the fall of an object through a uid. Measurements of the increase in the coefcient of friction for tennis ball cloth sliding on a smooth surface are described over speeds varying by a factor of 9000. For the low speed measurements, the ball cloth was attached to the bottom of a weighted box and pulled along a horizontal surface by a constant horizontal force. Results at higher speeds were obtained by bouncing a tennis ball off the surface. 2005 American Association of Physics Teachers. DOI: 10.1119/1.1891174

I. INTRODUCTION The coefcient of sliding friction COF between two surfaces is commonly assumed to be independent of surface area, normal reaction force, and sliding speed, as originally determined by da Vinci, Amonton, and Coulomb.1,2 Although these approximations may sometimes be appropriate for metals and other elastically hard materials, they are not generally applicable for elastically soft materials such as rubber or textiles.3,4 Dry, unlubricated metals also have a velocitydependent value of the COF at low sliding speeds, as evidenced by slip-stick phenomena.3 6 Nevertheless, departures from Amontons or Coulombs original laws of friction are still regarded as unusual. An interesting observation of such a departure7 is examined in more detail here. The experiment is easy to set up and may be already done in some undergraduate laboratories. The apparatus consists of a mass M 1 that slides horizontally and a second mass M 2 attached to the rst by a string over a pulley. In this way, a known horizontal force M 2 g is applied to M 1 . The COF between M 1 and the surface on which it slides is determined from a measurement of the acceleration of M 1 . A surprising result is obtained with smooth surfaces if cloth or rubber is attached underneath the sliding mass. For relatively small values of M 2 , M 1 slides at constant speed after a brief initial acceleration. If M 2 is increased, then M 1 slides at a higher constant speed. The explanation is that for any given value of M 2 , the COF increases with sliding speed until the net horizontal force on M 1 is zero. Not all materials exhibit such behavior, but it is common with easily deformable materials, even for paper sliding on paper.6 The effect is examined in this paper for over four orders of magnitude of sliding speed for tennis ball cloth sliding on a smooth table and on a rougher surface. Other materials and surfaces also were tested in an attempt to understand why the COF might increase with sliding speed. Stick-slip phenomena are associated with a decrease in the COF as the sliding speed increases. The transition from static to sliding friction also can be regarded as a case where the COF decreases as sliding speed increases. Measurements of the COF at high sliding speeds were obtained by bouncing a tennis ball obliquely off a surface. The experiments were conducted in part to extend the range of sliding speeds, but also to determine whether the COF for a short impact is the same as that found when sliding is maintained over longer time intervals.

812 Am. J. Phys. 73 9 , September 2005 http://aapt.org/ajp

II. EXPERIMENTAL PROCEDURES A. Measurements of COF at low sliding speeds For sliding speeds from about 0.002 to about 1 m/s, the COF between tennis ball cloth and two different surfaces was measured using the apparatus shown in Fig. 1. This cloth is not much different from other cloth in terms of its frictional properties, but was chosen because it is strongly resistant to abrasion and so that measurements could be made at higher sliding speeds by bouncing a tennis ball off each surface. For the low speed measurements, an aluminum die-cast box was used to support various masses on top of a rectangular piece of ball cloth glued to the bottom of the box. The cloth was 110 mm long in the sliding direction, 57 mm wide, and 3 mm thick. The mass of the box and cloth was 121 g when the box was empty. Masses up to 2.1 kg could be placed inside the box, and measurements also were made with a 3.4 kg lead brick resting on top of the box. The box was pulled horizontally by means of a string attached to the box. The string passed over a 12 g pulley and was hooked at the bottom end to a 10 g plastic bucket used to support various masses. Alternatively, large masses could be attached directly to the hook. The pulley spun freely under light or heavy loads and offered negligible frictional resistance on its own. An unbalanced load of only 0.4 g on either side of the pulley was enough to generate rotation of the pulley. For each surface, the mass M 1 was pulled over a horizontal distance of about 40 cm before coming to rest, either when the mass M 2 hit soft padding on the oor or when the mass M 1 impacted soft padding located near the pulley. The apparatus was mounted on a laminated desk top, which provided a suitably hard and smooth surface on which to conduct low friction measurements. Alternatively, other surfaces such as paper or emery paper could be taped rmly to the desk top. Speed and acceleration measurements were made by lming the motion of M 1 at 25 frames/s with a digital video camera and transferring short clips to a computer for subsequent analysis. Very low sliding speeds were measured more conveniently with a ruler and stopwatch. The desk top was cleaned and dried regularly to ensure that no dust or nger marks inuenced the results. As a result, constant sliding speeds could be maintained for periods up to several minutes at the lowest sliding speeds. The equations describing motion of M 1 and M 2 are given by

2005 American Association of Physics Teachers 812

Fig. 1. Arrangement used to measure the coefcient of friction COF at low sliding speeds.

Fig. 2. Oblique impact of a ball on a horizontal surface. F is the friction force and N is the normal reaction force. N does not necessarily act through the center of the ball, and F is not necessarily equal to N.

T1

M 1g

M 1 a,

1 2

M 2 g T 2 M 2 a,

where T 1 and T 2 are the string tensions, a is the acceleration of M 1 and M 2 , and is the COF. If the pulley has a radius R and a moment of inertia I 0 about an axis through the center of the pulley, the net torque on the pulley is given by T 2R T 1R I 0 /R a, 3 where we have ignored any frictional torque on the pulley axle. For a pulley of mass M p , I 0 M p R 2 /2 to a good approximation. A more precise estimate of I 0 was not warranted in this experiment because M p was much smaller than M 1 M 2 . The equation of motion is therefore given by M 1 M 2 M p /2 a M2 M 1 g. 4 The COF can be determined by measuring a. Alternatively, can be measured by nding the value of M 2 that allows the masses to move at constant speed, in which case M 2 /M 1 . For sufciently small values of M 2 , there is no sliding at all because the horizontal force is too small to overcome the static friction force. For large values of M 2 , both masses accelerate rapidly as soon as the load is applied. For intermediate values of M 2 , the masses moved at a constant low speed after accelerating for a short M 2 /M 1 could be period. The constant speed condition maintained up to a maximum speed of about 0.1 m/s. For was insufcient to larger values of M 2 , the increase in satisfy the condition M 2 /M 1 , in which case M 1 continued to accelerate until it reached the end of its travel. The implication is that increases with speed, but is not proportional to the speed or to the ratio M 2 /M 1 . B. Measurements of COF at high sliding speeds Consider a ball incident at speed v 1 and angle 1 on a horizontal surface, as shown in Fig. 2. The ball rebounds at speed v 2 and angle 2 . If the ball slides throughout the bounce, the horizontal x and vertical y components of the ball speed are given by e v y2 / v y1 and8

v x2 / v x1 1

the ball will stop sliding during the bounce and grip the surface, in which case a measurement of based on Eq. 5 will underestimate the true COF because the friction force reverses direction during the grip phase. The critical angle at which the ball stops sliding depends on and on the spin of the incident ball. If the ball is incident without spin, the critical angle is given by8 tan 1

1

1 e 1 1/

mR 2 , where The parameter, , is dened by the relation I I is the moment of inertia of a ball of mass m and outer 2 2 radius R; 5 for a solid sphere, 3 for a thin spherical shell, 0.55 for a tennis ball. Because e is 0.75 for all and angles of incidence, the critical angle for a tennis ball is 0.75 and if the given by tan 1 0.203/ . For example, if ball is incident without spin, then 1 needs to be less than about 15 to prevent the ball from gripping the surface. A simple indication of whether the ball grips the surface, based on the measured ball spin, is that R 2 v x2 for pure sliding, but R 2 v x2 if the ball grips.8 III. EXPERIMENTAL RESULTS A. Low sliding speeds made by sliding ball cloth on the Measurements of smooth, laminated desk top are shown in Fig. 3. All results in Fig. 3 were obtained using the apparatus shown in Fig. 1. The COF increases with sliding speed, v , over a relatively wide range of v , and decreases as M 1 increases. Under conditions for which M 1 slides at constant speed, could be determined to within 0.5% from the relation M 2 /M 1 . The higher values of were determined to within 3%, the main error arising from the difculty of obtaining accurate acceleration measurements from position versus time data. Because the sliding speed increases while the box accelerates, the velocities plotted in Fig. 3 are time-averaged velocities measured over a xed 20 cm sliding distance. Each data point in Figs. 35 represents the average of three measurements. The nominal surface area of the cloth used to obtain the results in Fig. 3 was 64 cm2. The experiment was repeated using two narrow strips of cloth glued to the bottom of a second die-cast box, with a total surface area of 34 cm2. The two sets of results are compared in Fig. 4, showing that increases with nominal surface area. The small difference in friction coefcients in Figs. 3 and 4, each determined a few days apart, can be attributed to small differences in the alignment of the cloth bers after repeated sliding. A more sigRod Cross 813

1 e tan

1,

where e is the coefcient of restitution and F/N, which is assumed to remain constant throughout the bounce. In fact is likely to vary during the bounce in which case a measurement of the relevant speeds and angles yields a timeaveraged value of . A reliable measurement of is possible only if 1 is relatively small, typically less than 30. At larger values of 1

813 Am. J. Phys., Vol. 73, No. 9, September 2005

Fig. 3. Results at low sliding speeds. The mass values show the mass added to the 121 g box and the straight lines are best linear ts to the experimental data.

Fig. 5. Low speed results for ball cloth sliding on P800 emery paper.

nicant result was obtained a few weeks later after the cloth had been used on rougher surfaces. The rough surfaces acted to align and twist together individual cloth bers in a direction transverse to the sliding direction. In that condition, the COF on the smooth table was essentially independent of the load on the cloth, but it still increased with sliding speed at the same rate as in Fig. 3. In effect the cloth became compacted by repeated sliding under heavy loads so that any subsequent or additional load on the cloth had a negligible effect on . The overall thickness of the cloth was unaffected, but the bottom surface of the cloth was visibly matted by tight twisting of adjacent bers in random, slightly raised patches over the whole surface. Results similar to those in Fig. 3 were obtained using a variety of other materials glued or taped to the bottom of the die-cast box. In general, however, smooth sliding at constant speed was observed only with elastically soft materials such as rubber, a variety of textiles of various thicknesses, nylon or polyester string, and steel wool. A change in thickness or number of layers of a particular textile material had no sig-

nicant effect on the COF. Elastically hard materials tend to slide at variable speed or come to a complete stop at low values of M 2 . At higher values of M 2 , elastically hard materials accelerate uniformly with an essentially constant value of the COF, at least at sliding speeds between about 0.1 and 1.0 m/s. The COF of ne nylon strands on a tennis ball and even the soft nylon strings of a racquet increases with sliding speed, but the COF of hard nylon or steel washers does not. It therefore appears that compliance of the mating surfaces, or possibly the ability of a material to stretch in the sliding direction, contributes to the increase in COF with sliding speed. Using a transparent weight such as glass or lucite and viewing the surface with a magnifying lens, there was no visible sticking of bers to the surface under steady sliding conditions, nor was there any relative movement between adjacent bers. The apparatus shown in Fig. 1 also was used to obtain the results shown in Fig. 5. These results were obtained with ne-grained emery paper P800 taped to the smooth table top to measure the COF between ball cloth and a rough surface. The roughness of P800 is similar to or slightly higher than that of hardcourt and clay tennis courts. Smooth sliding at constant speed was observed under some conditions, but generally the sliding speed was variable at low values of M 2 and even at high values of M 2 , where masses placed in the box tended to rattle as the box accelerated, indicating stick-slip behavior. The COF values shown in Fig. 5 are plotted from measurements of the average speed and acceleration over a xed 20 cm sliding distance. Compared with the results in Fig. 3, the COF on the rougher surface is signicantly higher and relatively independent of sliding as M 1 is inspeed. There also is a smaller decrease in creased, both in a relative and absolute sense, compared with the results in Fig. 3. For heavy loading conditions the friction force was sufciently large to leave yellow tracks consisting of ne particles of polished nylon and even whole strands of broken bers on the emery paper. B. High sliding speeds Results showing an increase in COF with sliding speed at high speeds are shown in Fig. 6. These results were obtained by lming a tennis ball incident obliquely at 1 (17 1)

Rod Cross 814

Fig. 4. Effect of apparent surface area on the COF. 814 Am. J. Phys., Vol. 73, No. 9, September 2005

Fig. 6. High speed results for a tennis ball sliding on a smooth table top.

on the smooth table top. Data at speeds v x1 6 m/s were obtained by dropping the ball without spin from various heights to impact the table top which was inclined at 17 to the vertical. The higher speed data were obtained with the table top horizontal by projecting the ball downward with zero spin from a ball launcher. Measurements of ball spin after each impact conrmed that the ball did not grip the surface. The COF was obtained from Eq. 5 using the measured ball trajectories, correcting for gravitational acceleration before and after each bounce to determine the incident and rebound speeds and angles immediately before and just after each bounce. The main source of error in this experiment was the variability in bounce speed and angle from one bounce to the next, as indicated by the scatter in the data in Fig. 6. Each data point in Fig. 6 corresponds to a separate bounce. The data in Fig. 6 are consistent with the results in Figs. 3 and 4, but a direct comparison cannot be made because the nominal surface area of the cloth was different and because the normal reaction force on the ball cloth also was different. When a 66 mm diameter tennis ball contacts a surface at high speed, the maximum possible contact area is about 35 cm2. For low speed impacts the nominal contact area might be as small as 4 cm2. Given that the impact time8 is about 5 ms and the change in momentum in the y direction is about 1.75m v y1 0.53m v x1 , where m 57 g is the ball mass, the time-averaged normal reaction force on the ball varied from about 9 N to about 109 N for the results in Fig. 6. The effective load on the ball therefore varied from about 0.9 kg at the lowest impact speeds to about 11.0 kg at the highest impact speeds. Over a range of speeds from v x1 1.5 to 18 m/s, the nominal contact surface area would therefore have increased by a factor of about 5 and the load increased by a factor of about 12. If these factors are taken into account, the results in Fig. 6 are not inconsistent with those in Figs. 3 and 4, but the uncertainty in contact area is too large to claim that the two sets of results are in complete agreement. The results in Fig. 3 are plotted on a log(v) scale and the results in Fig. 6 are plotted on a linear v scale. It may therefore appear that the two sets of results are inconsistent. However, the results in Fig. 3 were obtained by keeping the normal load and apparent surface area xed, while the results in Fig. 6 were obtained by allowing the load, surface area, and

815 Am. J. Phys., Vol. 73, No. 9, September 2005

sliding speed to vary simultaneously. We can conclude from the results in Fig. 6 only that the COF increased with sliding speed, despite the increased load on the ball, partly because of the increase in the nominal contact area and partly because the COF increases with sliding speed, even when the load and nominal contact area remain constant. From a practical rather than a physics point of view, these three separate effects are of no particular interest. In a sporting context the main feature of interest is that the speed or COF of a sporting surface is likely to depend on the speed of the ball, given that the balls and/or surfaces used in most ball sports are elastically soft. An increase in COF with speed has previously been described for billiard balls sliding on cloth.9 Measurements of the COF for a ball impacting on P800 emery paper also were attempted, but the required angle of incidence was too low to obtain a reliable value of . According to Eq. 6 and the results in Fig. 5, 1 must be less 1.1. Such low grazing angles of incidence than 10 when are difcult to achieve experimentally and are difcult to measure with appropriate accuracy. Bounce results obtained was at least 0.85 for a 5 ms at 1 10 indicated that impact on P800, as expected from the results in Fig. 5. I note that the ofcial rules of tennis regarding the measurement of court speed should be modied. As they currently stand, the rules specify that court surfaces must be tested by bouncing a ball at an angle of incidence of 16. IV. DISCUSSION Observations of the increase in COF with speed were made using several techniques other than those described so far to establish that the effect depends on the sliding surfaces and not on the technique itself. The simplest method, and one that would be suited to a classroom demonstration, is to slide a blackboard or whiteboard eraser down a smooth incline. The felt side slides at constant speed for a range of incline angles provided dust or chalk is removed rst , but the wood or plastic side accelerates down the incline. Another simple technique is to slide string, tape, or cloth over a xed smooth cylinder with unbalanced masses hanging on each end. If a string is wound n times around the cylinder n can be fractional and slides at constant speed, then it is easy to is the COF between the show that T 2 T 1 e 2 n , where string and the cylinder, and T 1 and T 2 are the tensions at each end of the string. Observations at higher speeds can be made by launching a mass along a long table, by hand or by a spring mechanism, and measuring its deceleration. The latter method is not reliable at large values of the COF, because the torque generated by the friction force tends to ip over the mass. The actual area of contact between any two surfaces is usually much less than the nominal surface area. The friction force is proportional to the actual area of contact, but for polymers the actual area of contact is not directly proportional to the load. Solids normally contact over many individual, microscopic points of contact. At high loads and for smooth surfaces, polymers and rubbers can contact over much larger contact regions, in which case the actual contact area might be almost as large as the nominal surface area. Alternatively, if a polymer sphere contacts a at plate, the area of contact A is not proportional to the load N, but is proportional3 to N 2/3. For these conditions we would expect that would be proportional to A/N or to 1/N 1/3. Note that Amontons laws also can be explained in terms of the relaRod Cross 815

tion F/N, using the fact that F is proportional to the actual contact area A. However, if A is proportional to N, then is independent of N. Tennis ball cloth contains a felted mixture of some wool but mostly nylon bers. As the load increases, the number of bers in contact with a at surface will increase, while the actual contact area of each ber might obey a power law similar to that for a sphere. The results at high v in Fig. 3 indicate that is proportional to N 0.054 for fresh samples of cloth, but it also was found that is essentially independent of N when the cloth bers became tightly twisted. It was found that is essentially independent of N when the ball cloth was replaced by several strands of 1.3 mm diameter nylon tennis string. Consequently, we cannot attribute the with increased load to the theoretically exdecrease in pected 2 power law. Rather, it appears that for a fresh sample 3 of cloth, the number of bers in contact with the surface increases with N in such a way that A/N decreases as N increases where A is the actual contact area. The data indicates that when N is doubled, A increases by a factor of 2 0.946 1.93. with sliding speed has been observed An increase in previously, especially for textiles,10 but the underlying mechanism remains unclear. Rabinowitz5 and also Persson11 indicate that slow creep of one or both sliding surfaces can explain the effect at extremely low speeds, but the rate of creep of nylon is much too slow to account for the fact that increases with speed even at speeds above 1 m/s. In fact, with creep was used in Ref. 6 to explain a decrease in sliding speed that also can be observed at extremely low speeds around 10 6 m/s). Studies of the latter type are commonly undertaken to investigate earthquake or glacier dynamics. In the absence of a well-established mechanism to explain an increase in with sliding speed, we can speculate that the mechanism might be modeled microscopically by a block sliding on a frictionless surface on which many small balls are resting and which hinder the progress of the block. As the block collides with the balls, it experiences an average retarding force that is proportional to the square of the speed of the block, because the momentum transferred to each ball is proportional to the speed of the block and because the collision frequency also is proportional to the speed of the block. Alternatively, if the collision frequency is determined by the speed of the balls rather than the speed of the block, then the average retarding force will be directly proportional to the

speed of the block. The latter situation has been modeled at a much more sophisticated level in terms of lattice vibrations induced by sliding. Provided that the actual contact area is not altered by a change in the sliding speed, it is found that the electronic and photonic contributions to the friction force are both proportional to sliding speed.11,12 These contributions in the present experiment were not investigated directly. V. CONCLUSIONS Experimental results have been presented showing that the coefcient of sliding friction increases with speed, over a wide range of sliding speeds, when elastically soft materials slide on smooth surfaces. A number of different materials and surfaces were examined in coming to this conclusion, but the emphasis in this paper was to measure the COF of tennis ball cloth. It was found that the COF is larger and less dependent on speed if cloth slides on a rough rather than a smooth surface. A decrease in the COF with increasing speed is a well-known cause of stick-slip phenomena, but the increase in COF with speed has not been as extensively studied. The latter effect is likely to play an important role in ball sports, because variations in the COF between a ball and the striking implement or the playing surface will alter the bounce speed and angle and will therefore challenge even the best of players.

Electronic mail: cross@physics.usyd.edu.au J. Ringlein and M. O. Robbins, Understanding and illustrating the atomic origins of friction, Am. J. Phys. 72, 884 891 2004 . 2 J. Krim, Resource Letter: FMMLS1: Friction at macroscopic and microscopic length scales, Am. J. Phys. 70, 890 897 2002 . 3 I. M. Hutchings, Tribology: Friction and Wear of Engineering Materials Edward Arnold, London, 1992 . 4 P. J. Blau, Friction Science and Technology Marcel Dekker, New York, 1996 . 5 E. Rabinowicz, Stick and slip, Sci. Am. 1945, 109118 1956 . 6 F. Heslot, T. Baumberger, B. Perrin, B. Caroli, and C. Caroli, Creep, stick-slip and dry-friction dynamics, Phys. Rev. E 49, 4973 4988 2004 . 7 R. Morrow, A. Grant, and D. P. Jackson, A strange behavior of friction, Phys. Teach. 37, 412 415 1999 . 8 R. Cross, Grip-slip behavior of a bouncing ball, Am. J. Phys. 70, 1093 1102 2002 . 9 J. Witters and D. Duymelinck, Rolling and sliding resistive forces on balls moving on a at surface, Am. J. Phys. 54, 80 83 1986 . 10 J. Hong and J. M. Layton, Friction in textiles, Textile Prog. 34, 192 2003 . 11 B. N. J. Persson, Sliding Friction Springer, Berlin, 1998 , pp. 395397. 12 J. Krim, Friction at the atomic scale, Sci. Am. 27510, 48 56 1996 .

1 a

NOW AVAILABLE: 23 ADDITIONAL YEARS OF BACK ISSUES The contents of the American Journal of Physics are available online. AJP subscribers can search and view full text of AJP issues from 1975 to the present. Browsing abstracts and tables of contents of online issues and the searching of titles, abstracts, etc. back to 1975 is unrestricted. For access to the online version of AJP, please visit http://aapt.org/ajp. Institutional and library nonmember subscribers have access via IP addresses to the full text of articles that are online; to activate access, these subscribers should contact AIP, Circulation & Fulllment Division, 800-344-6902; outside North America 516-576-2270 or subs@aip.org. Individual member subscribers to the print version who wish for an additional fee to add access to the online version should contact AAPT or go to the AAPT website: https://www.aapt.org/Membership/secure/agreement.cfm. Full text back to the rst issue of AJP is scheduled to be available online sometime in 2005.

816

Am. J. Phys., Vol. 73, No. 9, September 2005

Rod Cross

816

You might also like

- Lab 112 ReportDocument3 pagesLab 112 ReportKing100% (3)

- Belt Friction Full ReportDocument8 pagesBelt Friction Full ReportJoshua Reynolds73% (11)

- Senarai Amali Fizik SPM Ting 4Document52 pagesSenarai Amali Fizik SPM Ting 4Hazrina Awang100% (3)

- MarblesDocument3 pagesMarblesLeandro LeandroNo ratings yet

- Solenoid Actuators: Theory and Computational MethodsFrom EverandSolenoid Actuators: Theory and Computational MethodsRating: 3 out of 5 stars3/5 (1)

- Fluids Lab - Experiment 2 - Fluid Properties: ViscosityDocument9 pagesFluids Lab - Experiment 2 - Fluid Properties: ViscosityJordan Hines100% (6)

- Golf-Racht, T. D. Van. - Fundamentals of Fractured Reservoir EngineeringDocument729 pagesGolf-Racht, T. D. Van. - Fundamentals of Fractured Reservoir Engineeringionizedx50% (2)

- BE Tonsil Optimum FFDocument2 pagesBE Tonsil Optimum FFbourtyNo ratings yet

- Rosin-Rammler Paper 1980Document3 pagesRosin-Rammler Paper 1980Metalurgia En Verde100% (1)

- Circ MPYDocument7 pagesCirc MPYsinghmantejveer8No ratings yet

- Phy Report Exp2Document5 pagesPhy Report Exp2audiliciousNo ratings yet

- TheoryDocument12 pagesTheoryAhmad FikriNo ratings yet

- Lab 7: Uniform Circular Motion: Professor Dr. K. H. ChuDocument5 pagesLab 7: Uniform Circular Motion: Professor Dr. K. H. ChuJamkevin SariegoNo ratings yet

- The Bounce of A Ball: Rod CrossDocument6 pagesThe Bounce of A Ball: Rod CrossAhmed MagedNo ratings yet

- Revision Midterm Exam Physics1 NEWDocument17 pagesRevision Midterm Exam Physics1 NEWBaoduy NguyenNo ratings yet

- F4experiments 120222235933 Phpapp02Document52 pagesF4experiments 120222235933 Phpapp02Syafiq HazwanNo ratings yet

- Revision Midterm Exam Physics1 NEWDocument14 pagesRevision Midterm Exam Physics1 NEWBá Phong LêNo ratings yet

- Free Fall LabDocument9 pagesFree Fall Labapi-263210614No ratings yet

- F4 ExperimentsDocument52 pagesF4 ExperimentsKiTTy94% (16)

- Dynamic FREE FALL Lab ReportDocument6 pagesDynamic FREE FALL Lab ReportKevin TanNo ratings yet

- Pulley MechanicsDocument8 pagesPulley MechanicslaestatNo ratings yet

- Centripetal Force Experiment - For PG 63, Q12Document5 pagesCentripetal Force Experiment - For PG 63, Q12lz lzNo ratings yet

- Centripetal ForceDocument8 pagesCentripetal ForceShukor AzNo ratings yet

- Physics DP1 Lab Report William Ivan RealDocument8 pagesPhysics DP1 Lab Report William Ivan RealyfyvddjhpjNo ratings yet

- EGR365 Lab8 - Drag Coefficient of A SphereDocument4 pagesEGR365 Lab8 - Drag Coefficient of A Spherejoeblow4224No ratings yet

- Physics 11 Sample PaperDocument3 pagesPhysics 11 Sample PaperFAISAL GHEYASNo ratings yet

- Topic 1 General PhysicsDocument17 pagesTopic 1 General PhysicsSashideran ThilagesuaryNo ratings yet

- Coefficient of Kinetic Friction and Drag ForceDocument7 pagesCoefficient of Kinetic Friction and Drag ForcejhhjjhNo ratings yet

- High and Low Strain Dynamic Pile Testing - Independent Geoscience Pty LTDDocument5 pagesHigh and Low Strain Dynamic Pile Testing - Independent Geoscience Pty LTDindependentgeoscienceNo ratings yet

- Creep Lab ManualDocument11 pagesCreep Lab ManualapproachtheprobNo ratings yet

- (Physics) AnswersDocument15 pages(Physics) AnswersLoraine Rose EstivaNo ratings yet

- Laws of Motion 1Document7 pagesLaws of Motion 1AdityaNo ratings yet

- Newton's Laws of Motion: AdvnlDocument4 pagesNewton's Laws of Motion: AdvnlRashad AlamNo ratings yet

- PHY 303K - Florin - Exam IV - Fall 2013Document42 pagesPHY 303K - Florin - Exam IV - Fall 2013Roger100% (1)

- Modeling of Rocking of Shallow FoundationDocument14 pagesModeling of Rocking of Shallow FoundationsinisavucibatinaNo ratings yet

- BeltfrictionlabreportfullDocument12 pagesBeltfrictionlabreportfullShasmita LakshmiNo ratings yet

- Physics Week 2Document9 pagesPhysics Week 2gelvirnaNo ratings yet

- Direct Shear TestDocument11 pagesDirect Shear Testshahrolhazrien91% (34)

- Report AlphaalphaalphaDocument3 pagesReport AlphaalphaalphaNik HumphriesNo ratings yet

- Air Over A Two-Dimensional Studies Velocity Speed-Up, Roughness Effects and TurbulenceDocument20 pagesAir Over A Two-Dimensional Studies Velocity Speed-Up, Roughness Effects and TurbulenceGonKilNo ratings yet

- Stokes Law PDFDocument3 pagesStokes Law PDFmartim_martinsNo ratings yet

- Dynamic Deformation of Earth and Motion Effects Caused by Universe's Gravitational FieldFrom EverandDynamic Deformation of Earth and Motion Effects Caused by Universe's Gravitational FieldNo ratings yet

- Selected Problems in Physics with AnswersFrom EverandSelected Problems in Physics with AnswersRating: 3 out of 5 stars3/5 (2)

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Pressure, Resistance, and Stability of Earth American Society of Civil Engineers: Transactions, Paper No. 1174, Volume LXX, December 1910From EverandPressure, Resistance, and Stability of Earth American Society of Civil Engineers: Transactions, Paper No. 1174, Volume LXX, December 1910No ratings yet

- Experiments on the Absence of Mechanical Connexion between Ether and MatterFrom EverandExperiments on the Absence of Mechanical Connexion between Ether and MatterNo ratings yet

- Method of Moments for 2D Scattering Problems: Basic Concepts and ApplicationsFrom EverandMethod of Moments for 2D Scattering Problems: Basic Concepts and ApplicationsNo ratings yet

- Barron's Physics Practice Plus: 400+ Online Questions and Quick Study ReviewFrom EverandBarron's Physics Practice Plus: 400+ Online Questions and Quick Study ReviewNo ratings yet

- Physico-Chemistry of Solid-Gas Interfaces: Concepts and Methodology for Gas Sensor DevelopmentFrom EverandPhysico-Chemistry of Solid-Gas Interfaces: Concepts and Methodology for Gas Sensor DevelopmentNo ratings yet

- Applications of Derivatives Rate of Change (Calculus) Mathematics Question BankFrom EverandApplications of Derivatives Rate of Change (Calculus) Mathematics Question BankNo ratings yet

- The World Factbook: South Asia:: AfghanistanDocument1 pageThe World Factbook: South Asia:: Afghanistanpaperbirds1199No ratings yet

- The World Factbook: Europe:: AlbaniaDocument1 pageThe World Factbook: Europe:: Albaniapaperbirds1199No ratings yet

- The World Factbook: Africa:: AlgeriaDocument1 pageThe World Factbook: Africa:: Algeriapaperbirds1199No ratings yet

- The World Factbook: Europe:: AkrotiriDocument1 pageThe World Factbook: Europe:: Akrotiripaperbirds1199No ratings yet

- BackDocument1 pageBackpaperbirds1199No ratings yet

- Bangladesh AdminDocument1 pageBangladesh Adminpaperbirds1199No ratings yet

- BosniaHerzegovina TransportationDocument1 pageBosniaHerzegovina Transportationpaperbirds1199No ratings yet

- United StatesDocument1 pageUnited Statespaperbirds1199No ratings yet

- Middle EastDocument1 pageMiddle Eastpaperbirds1199No ratings yet

- Centra AmericaDocument1 pageCentra Americapaperbirds1199No ratings yet

- Design of Geocell Reinforced Flexible PavementDocument4 pagesDesign of Geocell Reinforced Flexible Pavementsundra0No ratings yet

- BS 4360 50eeDocument1 pageBS 4360 50eeTimNo ratings yet

- Basics of MechanismsDocument26 pagesBasics of MechanismsAtal KumarNo ratings yet

- Theory of The Streaming Current MonitorDocument10 pagesTheory of The Streaming Current MonitorMirza Quanta Ahady HusainiyNo ratings yet

- Chap10no1 PDFDocument2 pagesChap10no1 PDFTajiriMollel0% (9)

- CS/B.TECH (CE) /SEM-8/CE-801/4/08: Advanced Foundation Engineering (Semester - 8)Document6 pagesCS/B.TECH (CE) /SEM-8/CE-801/4/08: Advanced Foundation Engineering (Semester - 8)Debanjan BanerjeeNo ratings yet

- Motox WormDocument34 pagesMotox WormCristianDuarteNo ratings yet

- Department of Mechanical Engineering Visvesvaraya National Institute of Technology-NagpurDocument6 pagesDepartment of Mechanical Engineering Visvesvaraya National Institute of Technology-NagpurNikhil MulikNo ratings yet

- Assignment b3 MetfisDocument3 pagesAssignment b3 MetfisDewi Lestari Natalia MarpaungNo ratings yet

- Material Science Quiz: AnswersDocument3 pagesMaterial Science Quiz: Answersairbuk doeingNo ratings yet

- Advances in WiresDocument47 pagesAdvances in WiresHarshita DabasNo ratings yet

- Ferrocement AND Fiber Reinforced Concrete: Submitted by - Parth Pranav SaloniDocument18 pagesFerrocement AND Fiber Reinforced Concrete: Submitted by - Parth Pranav Salonisaloni karakNo ratings yet

- 3 BDocument3 pages3 BadnandjNo ratings yet

- Tabla Qw-252.1 - Asme IxDocument1 pageTabla Qw-252.1 - Asme IxAngelTinocoNo ratings yet

- 12 Physics Notes ch05 Magnetism and Matter PDFDocument2 pages12 Physics Notes ch05 Magnetism and Matter PDFAashna JenaNo ratings yet

- Pigments TiO2Document43 pagesPigments TiO2dougNo ratings yet

- Razon Tile Fix A1 Tile & Stone AdhesiveDocument3 pagesRazon Tile Fix A1 Tile & Stone Adhesiveshrikrishna rathodNo ratings yet

- Optimol Longtime PD 1 + 2 eDocument2 pagesOptimol Longtime PD 1 + 2 ericardoruedaNo ratings yet

- Interpreting Carburized Case DepthsDocument4 pagesInterpreting Carburized Case Depthsmp87_ing100% (1)

- Marpol - Coatings - Series - Tech - Specs PDFDocument12 pagesMarpol - Coatings - Series - Tech - Specs PDFYashwant RajeshirkeNo ratings yet

- Soft Soils Improved by Prefabricated Vertical Drains: Performance and PredictionDocument22 pagesSoft Soils Improved by Prefabricated Vertical Drains: Performance and PredictionJunieli Niel MendrofaNo ratings yet

- FEFCO Angle of Slip 104Document4 pagesFEFCO Angle of Slip 104Ml AgarwalNo ratings yet

- Shear Strength in The New Eurocode 2. A Step ForwardDocument10 pagesShear Strength in The New Eurocode 2. A Step ForwardChineseAssassinNo ratings yet

- SKD61-Hot Work Tool SteelDocument2 pagesSKD61-Hot Work Tool SteelAgustine SetiawanNo ratings yet

- Gear HoningDocument2 pagesGear HoningMargam Kiran KumarNo ratings yet

- El Ctrophilic: SolutionDocument41 pagesEl Ctrophilic: SolutionManaswini PNo ratings yet