Professional Documents

Culture Documents

Development of A MATLAB Based Bioprocess Simulation Tool

Development of A MATLAB Based Bioprocess Simulation Tool

Uploaded by

মোঃ মেজবাউর রহমান সোহেলOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Development of A MATLAB Based Bioprocess Simulation Tool

Development of A MATLAB Based Bioprocess Simulation Tool

Uploaded by

মোঃ মেজবাউর রহমান সোহেলCopyright:

Available Formats

Development of a MATLAB based bioprocess simulation tool

B. Sevella, G. Bertalan

Abstract A simple user friendly mathematical modelling

tool was developed on the basis of MATLAB software. The

program system provides the possibility of solving dif-

ferential equation system with the aid of an easy-to-use

graphical surface. It is suitable for bioprocess engineering

simulations to describe the dynamic behaviour of a great

series of various enzyme, fermentation and environmental

bioreaction systems. It is especially benecial that non-

time interventions can also be modelled and graphical

representations can be realized on a wide palette.

List of symbols

ODE Ordinary differential equation

X, X

prey

, X

pred

Biomass, prey and predator biomass

concentration

X

max

, X

min

Preset values of biomass in turbido-

stat fermentation

S, S

feed

Concentration of C/energy source and

its inlet concentration

C, C

+

Dissolved oxygen concentration and

its saturation value

Y

i

Overall yield coefcients

K

i

Substrate saturation (MONOD) con-

stants

K

L

a Volumetric oxygen absorption coef-

cient

a LuedekingPiret proportionality con-

stant

D Dilution rate

l

maxi

Maximum specic growth rates

1

Introduction

Nowadays mathematics based computer simulations be-

come essential part of research and higher education

systems because of their cost effectiveness and time saving

features. This is of even higher importance in the case of

teaching bioengineers (one of the main educational ac-

tivity of TU Budapest, Chemical Engineering Faculty)

where the necessarily many conventional laboratory

courses are getting more and more expensive and at least a

part of them has to be replaced by such simulation prac-

tices. A rather simple batch fermentation run in a pilot-

scale bioreactor needs tens of hours of experimental time

and several hundreds of USD for materials and energy. At

the same time using a proper simulation program tens of

various ``experimental'' runs can be carried out during

several minutes with an almost negligible price, keeping

naturally in mind that real manual experimentation and

model based simulations together are able to effectively

deepen our and our students' knowledge.

There have been a lot of efforts to develop math-based

simulation tools for bioreaction engineering. One of the

best known is the MATLAB based program system de-

veloped by S-O. Enfors [1] which can be used for the

simulation of a series of fermentation processes. It is

characteristic of this program system that

In theory the whole MATLAB-served functionality can

be exploited,

There are no clear denition-le formats,

In order to modify a given model, MATLAB les have

to be modied,

Parameter denition to the models is based upon

global variables and constants,

The user surface is rather unfriendly and visualization

of results is not taylor made, functions can not be

scaled,

The user surface and visualization need individual

developing work from model to model.

Another widely used approach is based upon the model-

ling work of Dunn et al. [2]. The earlier applied and a bit

cumbrous ISIM simulation language has recently been

replaced by the much more user friendly MADONNA

software. Numerous chemical and biochemical as well as

environmental engineering model examples are now ac-

cessible as sharewere programs on the Web [3, 4].

MADONNA is an easily programmable software pro-

viding special modelling environment: an ``equation win-

dow'' for formulating the system denition le, a

``parameter window'' to set numerical values of the equa-

tion constants, and a ``graph window'' for visualization of

the simulation results, with some other benecial features

like possibility of multiple running with one start and

statistical evaluation of the results and opportunity of

showing the results in table-format and others make this

approach a distinguished modelling tool. On the other

hand an unpleasant disadvantage of the MADONNA is that

programmed changing of model parameters is possible

exclusively in the function of time (as independent vari-

Bioprocess Engineering 23 (2000) 621626 Springer-Verlag 2000

621

Received: 6 December 1999

B. Sevella, G. Bertalan (&)

Department of Agricultural Chemical Technology,

TU Budapest H-1521 Szt. Gellert ter 4. Budapest Hungary

This work was supported by OTKA grant T-022182 and T-029882.

able). This does not make possible e.g. modelling those

systems where non-time variables should regulate the bi-

oreactions like in the case of turbidostat, varying feed rate

fed batch fermentations and so on.

To overcome some unpleasant drawback of the known

simulation tools we developed a program system with

which either simple unstructured and structured or more

sophisticated biological i.e. enzyme, microbial fermenta-

tion and environmental bioreactions can be simulated with

differential equation systems and the results can be

visualised on user-friendly graphical surfaces.

2

Designing the simulation program

Applying the built-in possibilities of the MATLAB 5.3

software our simulation program development met a set of

requirements:

1. The mathematical models can be described in the

ODEle (ordinary differential equation) denition

format of the MATLAB.

2. Solution of the model equations can be performed by

the MATLAB ODEsolvers.

3. Simple use of the program: the built-in options of the

ODEle and the proper ODEsolver can be chosen on

the graphic surface and the state of the running is

shown during the solution process therefore it can be

stopped at any time if the solution lasted too long.

4. Modications of the initial conditions as well as the

parameters of the model differential equations are

possible on the same graphic surface.

5. Regarding the visual appearance of the simulation

results the following benecial features of the program

can be applied during various simulations:

More than one result set can be shown at the same

time.

The results can be stored in les and these les are

reloadable and are printable at any time.

Individual or arbitrary combinations of the resulting

functions can be shown on preselected graphs and

results can be graphed not only as time functions but

any of the model variables can be chosen as ``inde-

pendent'' variable.

The graph axes of the functions are individually scal-

able.

Three dimensional graphical representations of the

results are also possible.

Designing of this simulation program based upon the use

of UML (Unied Modelling Language) methodologies [5]

and the structure of the resulting system is shown in the

Fig. 1.

3

Structure and use of the simulation program

Starting a simulation run can be initiated on the command

window of MATLAB with the ``ODEmain'' command. The

resulting window is empty with the only active ``Load

ODEle'' element which enables the loading of the de-

nition le of the actual mathematical model. For the sake

of simplicity here the single limiting substrate MONOD-

type model with bacterial growth, substrate consumption

and product formation serves as introductory example and

the whole denition le is shown in the Appendix.

Figure 2 shows the after-loading active picture of the

Fig. 1. Structure of the bioprocess simu-

lation program. After starting MATLAB

software only the xed ODEmain block

has to be started, all the others if they

are located in the same directory are

called automatically. The given model is

described in the Denition ODEle

Fig. 2. Active picture of ODE Driver Main Window showing all

the intervention, changing and varying possibilities before

running a simulation

622

Bioprocess Engineering 23 (2000)

``Main window'' on which the rst column denes the

variables of the model and the second refers to the model

parameters. Under these two columns one can give the

required numerical value of the variables initial values and

the model parameters. The ranges in which they are shif-

table have to be given in the ODEle. The third column

gives choices between the MATLAB ODEle denition

options but the value of these may also be empty (as is

shown in Fig. 2). At the right lower corner of this central

panel the time interval of the simulation can be given with

setting the start and end time of the simulation, while at

the upper corner the actual differential equation solving

algorithm can be chosen out of seven different built-in

MATLAB methods. During the simulation the picture of

the panel changes to the one shown in Fig. 3 where all the

elds and buttons are inactive but running coloured bars

indicate the status of solution process. If these bars are

moving too slow (possibly the solution method is not ef-

fective enough) the process can be interrupted by the only

active stop button. When the solution has completed the

button ``Display'' becomes active and the simulation re-

sults are to be graphed. This can be carried out with the

use of the ODE Driver Display Window (Fig. 4), with

which the following manipulations can be done with the

results:

In the case of step by step simulations all the consec-

utive set of results are shown on the same graph.

Saving the actual visible set of results in the form of

reloadable and ASCII convertible les is possible.

Scaling arbitrarily the variable axes thus making the

very much different order of magnitude results (e.g.:

biomass and dissolved oxygen tension) visible in one

coordinate system is a useful option.

Hiding or showing discretionary variable(s) simply

clicking on the chosen curve(s) helps the thorough

examination of the results.

Hiding and showing the parameters of the chosen set of

simulation could also be fruitful.

Any of the variables can be chosen as independent

variable not only the time that makes easier to interpret

the results exploring the correlations between impor-

tant process variables.

More than one simulation may also be graphed in a

three dimensional form, giving a clearer overview

among the various curves.

In the following section we demonstrate the use of our

simulation package through some practical instances with

special regards to some programming and graphic repre-

sentation advantages of the system.

Case 1: Simulation of a special fed batch fermentation

One of the disadvantages of many simulation tools is that

use of variables other than time as control variables is

difcult if not impossible. It is also clumsy if breaking the

time run is necessary and after that stop a new start is

needed. Such a typical event-control problem system is the

fed batch fermentation with a feed control on the basis of

dissolved oxygen tension. This system is widely used if a

relatively low C-source concentration is to be maintained

for some reasons, e.g. in the case of bakers yeast fermen-

tation. Saccharomyces cerevisiae is able to convert glucose

to cell mass with high overall yield only if alcoholic fer-

mentation is excluded i.e. if the oxygen level is high en-

ough (Pasteur effect) and glucose concentration is low

enough (Crabtree effect). These conditions can be satised

with an on-off controller. Depletion of the glucose results

in an increase of the dissolved oxygen level, if this exceeds

a certain preset level a substrate feeding pump has to start

the addition of glucose (ON state). As a consequence the

dissolved oxygen level (DO) change turns back because the

respiration rate of the microbes increases. When DO

crosses the setpoint downward the feeding stops (OFF

state) and it remains suspended until DO level goes

through the setpoint upward. With the proper choice of

the DO setpoint, substrate addition rate and allowed

overshoot above and underswing below the DO setpoint

makes it possible to maintain a stable fed batch yeast

fermentation.

The most important part of an ODEle which is able to

simulate the behaviour of such a system is given below. In

this case the double substrate (carbon source and oxygen)

MONOD model was applied to model the growth with

constant overall yields and the formation of one growth

associated product was also supposed, and the oxygen

transfer with constant K

L

a was described:

Fig. 3. Picture of the ODE Driver Main Window during solution

process. This actually shows a state very near to the end of a

solution. It can be seen that during the solution process only the

stop button is active giving the opportunity to cease of running

the program

Fig. 4. ODE Driver Display Window which shows the three

solutions of monod_b.m denition le describing a simple

MONOD-type system. Left hand side of the window shows some

possibilities of processing the results. Kinetic parameters:

K

S

= 1.3, Y

X/S

= 0.6, a = 0:667; l

max

= 0:5 and 0.25 on the

steeper and atter curve respectively

623

B. Sevella, G. Bertalan: Development of a MATLAB based bioprocess simulation tool

dX

dt

= l

max

S

K

S

S

c

K

O

c

X ;

dS

dt

=

1

Y

X=S

l

max

S

K

S

S

C

K

O

C

X ;

dP

dt

= a

dX

dt

;

dC

dt

=

1

Y

O

l

max

S

K

S

S

C

K

O

C

X K

L

a C

+

C ( ) :

Figure 5 shows the simulation results at a given param-

eter combination. The initial batch phase of the cultiva-

tion is consciously overemphasized, to demonstrate how

the system behaves when the substrate is getting

exhausted.

Case 2: Simulation of turbidostat fermentation

Turbidostat fermentation system is a useful experimental

tool when diluted culture media and unicellular micro-

organisms are to be cultured. The growing cell mass in-

creases the turbidity of the culture broth (measured in the

form of optical density i.e. absorbancy of a monochro-

matic light beam through a ow cell) and this value as a

measure of the cell mass can be used as control variable

for feeding of the fresh medium. When the turbidity of

the broth reaches a preset value (X

max

) a timer system

starts a medium feeding pump and at the same time

culture broth is taken off the bioreactor with an other

pump and with the same volumetric speed. This results in

a dilution of the culture broth thus the optical density

decreases. If it reaches another, arbitrarily chosen lower

turbidity setpoint (X

min

) both pumps stop and a new

growth period begins. X

min

is dened as a given percent

of X

max

.

The following minute detail program is a part of the

turbidostat simulating ODEle and it is responsible for the

denition of the parameters, equations and the turbidity

control unit. The routine is apparently a chemostat-algo-

rithm but during the growth periods dilution rate = 0

(thus it gives back a batch performance), while during the

medium addition and broth removal periods an enor-

mously high dilution rate is applied simulating a very high

speed pump operation. The variable subs determines the

amount of broth taken off during one pump operation

period.

function dydt=f(t; y; mumax; Kmonod; Yieldxs;

; Sfeed; Xmax; subs)

global D;

% Constants:

Dfinal=1e6;

Dinit=0;

%Variables:

X=y(1);

S=y(2);

P=y(3);

% Differential equations:

dydt=[D+XX+mumax+S=(SKmonod);...

% function dydt =

f (t, y, mumax, Ks, Ko, Yxsl, Yps1, Yos1, Yxs2, Yps2,

Yos2; Kla; c

star, X

feed, Sfeed, Pfeed, Smin, Ffinal, c

lim, c band)

global F t lim flag;

% Variables:

x = y(1);

S = y(2); P = y(3);

C = y(4); V = y(5);

if isempty (flag) & S < Smin

flag = 1;

t lim = t;

end;

if t < t lim

Yxs = Yxsl;

Yps = Yps1;

Yos = Yos1;

else

Yxs = Yxs2;

Yps = Yps2;

Yos = Yos2;

if c > c lim c band=2

F = F final;

elseifc < c lim c band=2

F = 0;

end;

end;

% Differential equations :

dydt = [F=V + (Xfeed X) X + mumax + S=(S Ks)+

c=(c Ko); . . .

F=V + (Sfeed S) X + (1=Yxs) + mumax + S=(S Ks)

+c=(c Ko); . . .

F=V + (Pfeed P) X + (Yps=Yxs) + mumax + S=(S Ks)

+c=(c Ko); . . .

Kla + (c star c) X + (Yos=Yxs) + mumax + S=(S Ks)

+c=(c Ko); %Kla

>> F=VF[;

Fig. 5. Simulation results of a dissolved oxygen level controlled

fed batch bakers yeast fermentation. Parameters of the kinetic

model: K

S

= 1.3, Y

X/S

= 0.6, a = 0:667; l

max

= 0:25, K

O

= 0.0006,

K

L

a = 200, C

+

= 0.006

624

Bioprocess Engineering 23 (2000)

D+(SfeedS)X+(1=Yieldxs) +mumax+S=(SKmonod);...

D+PX+(Yieldps=Yieldxs) +mumax+S=(SKmonod)[;

if X>Xmax

D=Dfinal;

elseif X<(1subs) +Xmax

D=Dinit;

end;

Example simulation results are shown in Fig. 6 where

one can see one of the benecial features of the developed

graphical surface: the possibility of three dimensional

representations. Here we wanted to examine the effect of

the broth removal. Fixing its value at three different levels

(0.7, 0.2 and 0.05) it can be seen that the rst run corre-

sponds to a highly discontinuous fermentation, as a matter

of fact it is a semi-continuous cultivation while the second

approaches and the third reaches a real continuous tur-

bidostat system behaviour.

Case 3: Simulation of a predator-prey system

A two species predator-prey interaction in a chemostat

culture can be described by the following set of differential

equations:

dX

prey

dt

= DX

prey

X

prey

l

max 1

S

K

S1

S

X

pred

1

Y

pp

l

max 2

X

prey

K

prey 2

X

prey

;

dX

pred

dt

= D

pred

X

pred

X

pred

l

max 2

X

prey

K

prey 2

X

prey

;

dS

dt

= D S

feed

S ( ) X

prey

1

Y

sp

l

max 1

S

K

S1

S

:

A suitably written ODEle composed similarly to that we

have shown above made possible to simulate this preda-

tion system. A set of results are shown in the Fig. 7 where

the kinetic parameters of the simulations refer to a system

of predator Dictyostelium discoideum and E. coli as prey

(6). The preparation of the gure is based upon a le of the

simulation result saved in ASCII format which has been

processed by the Excel software.

One of the favorable attributes of our program, that

any of the variables may be independent variable not

exclusively the time, is demonstrated with Fig. 8. System

behaviour is represented on a phase plane diagram which

shows a hard-oscillation of the concentrations of the

predator and prey species along a stable limit cycle.

4

Conclusion

Among recently used scientic approaches mathematical

modelling of bioprocesses plays an increasingly important

role. In numero experimentation i.e. mathematical simu-

lation serves as a cost effective and time saving method-

ology besides in vivo and in vitro techniques.

The kinetic representations of these systems usually

consist of ordinary differential equation systems, the so-

lution of which is possible with many well known com-

Fig. 7. Simulation results of a predato/prey interaction. The

system is a chemostat (D = 0.05) with the kinetic constants of the

two species: K

S1

= 0.1, K

prey2

= 0.25, Y

pp

= 0.5, Y

sp

= 0.5,

l

max 1

= 0:5, l

max 2

= 0:1

Fig. 8. Phase plane graph of the predator/prey system which

shows one stable oscillation around a non-existing steady state.

Parameters are the same as in the Fig. 7

Fig. 6. Original printout of a turbidostat simulation. Parameters

of the MONOD-type model: same as in Fig. 5. X

max

= 3.5,

S

feed

= 10. Curve 1: semicontinuous performance with 70%

withdrawal of the broth. Curve 2: course of the turbidostat with

high X

max

X

min

. Curve 3: real turbidostat with small X

max

X

min

625

B. Sevella, G. Bertalan: Development of a MATLAB based bioprocess simulation tool

mercial softwares and sharewares. We intended to im-

prove some undesired features of these programs with the

development of a MATLAB based simulation tool. This

work resulted in a exible, easy to use program with the

characteristics as follows:

It makes possible to use any of the MATLAB served

differential equation solving functions and denitions,

Extending the denition les the program serves as a

general modelling environment but does not require

the thorough knowledge of MATLAB.

It communicates with the model-maker through a user

friendly graphic surface on that results can be pre-

sented in suitable graphs.

It is able to convert the results into a savable and

further processable format.

It can be further developed on demand.

Testing the program with the presented cases prove the

exibility and usefulness of the system.

References

1. Enfors, S-O.: Continuous and fed batch operation of fermen-

tation processes. In: Bioreactor Engineering Course Notes EFB

Working Party on Bioreactor Performance, Saltsjobaden 1996

2. Dunn, I.J.; Heinzle, E.; Ingham, J.; Prenosil, J.E.: Biological

Reaction Engineering, Principles, Applications and Modelling

with PC simulations. Weinheim: Wiley-VCH 1992

3. Macey, R.; Oster, G.; Zahnley, T.: Madonna User's Guide.

(1998): Univ. of California Dept. of Molecular and Cellular

Biology. Berkeley, CA, http://www.kagi.com/authors

4. Heinzle, E.: http://www.uni-sb.de/matfak/fb12/heinzle/ma-

donna

5. Rumbaugh, J.; Jacobson, I.; Booch, G.: The Unied Modeling

LanguageReference Manual. Addison Wesley Longman, Inc.

Reading, MA, ISBN 0-201-30998-X (1999)

6. Blanch, H.W.; Clark, D.S.: Biochemical Engineering, Marcel

Dekker, Inc. New York, Basel, Hong Kong, 1996

Appendix

Definition file of the MONOD-model

function varargout = monod(t,y,flag,mumax,Kmonod,Yxs,Yps)

% Batch fermentation with Monod kinetics

% This routine gives the differential equations that are used for

% a batch fermentation process with Monod kinetics.

% == It demonstrate the usage of extra parameters and the naming

%== conventions for the output values.

switch flag

case `` % Return dy/dt = f(t,y).

varargout1 = f(t,y,mumax,Kmonod,Yxs,Yps);

case `mumax' % Return by default,min,max.

varargout1 = [0:25; 0; 2[;

case `Kmonod'

varargout1 = [1:3; 0; 10[;

case `Yxs'

varargout1 = [0:6; 0; 1[;

case `Yps'

varargout1 = [0:4; 0; 1[;

case `init' % Return default [tspan,y0,options].

[varargout1:3[ = init(mumax);

otherwise

error([`Unknown flag ```flag'''.']);

end

function [tspan,y0,options] = init(mumax)

tspan = [0; 100

+

mumax];

y0 = [1; 10; 0[;

options = odeset;

function dydt = f(t,y,mumax,Kmonod,Yxs,Yps)

% Constants:

% Variables:

X = y(1);

% P = y(3) faster if defined in comment

S = y(2);

% Differential equations:

dydt = [X

+

mumax

+

S/(S Kmonod); . . .

X

+

(1/Yxs)

+

mumax

+

S/(S Kmonod); . . .

X

+

(Yps/Yxs)

+

mumax

+

S/(S Kmonod)[;

%this is faster than transpose the matrix

626

Bioprocess Engineering 23 (2000)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ABCLX Driver Help: Citect Pty. LimitedDocument56 pagesABCLX Driver Help: Citect Pty. Limitedjoy insideoutNo ratings yet

- Handbook of Hypergeometric Integrals PDFDocument160 pagesHandbook of Hypergeometric Integrals PDFYohansli Noya100% (3)

- Safety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument9 pagesSafety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/Undertakingমোঃ মেজবাউর রহমান সোহেলNo ratings yet

- Adetex 22: Technical Data SheetDocument1 pageAdetex 22: Technical Data Sheetমোঃ মেজবাউর রহমান সোহেলNo ratings yet

- Astm D2274-14Document6 pagesAstm D2274-14মোঃ মেজবাউর রহমান সোহেলNo ratings yet

- Bashundhara Bitumen Plant: Section Name Where To Use Purpose No of Bicycle RequiredDocument4 pagesBashundhara Bitumen Plant: Section Name Where To Use Purpose No of Bicycle Requiredমোঃ মেজবাউর রহমান সোহেলNo ratings yet

- Failure of Titanium Lined VesselDocument10 pagesFailure of Titanium Lined Vesselমোঃ মেজবাউর রহমান সোহেলNo ratings yet

- Role of OTS in Operator Training ProgramDocument10 pagesRole of OTS in Operator Training Programমোঃ মেজবাউর রহমান সোহেলNo ratings yet

- Cemba 162 New 3rd Asi 170118Document15 pagesCemba 162 New 3rd Asi 170118মোঃ মেজবাউর রহমান সোহেলNo ratings yet

- Predicting Stock Market Price Using Support Vector RegressionDocument7 pagesPredicting Stock Market Price Using Support Vector Regressionমোঃ মেজবাউর রহমান সোহেলNo ratings yet

- Cemba-Mpa Student FaqsDocument20 pagesCemba-Mpa Student Faqsমোঃ মেজবাউর রহমান সোহেলNo ratings yet

- Subject: HSE Requirements in MAXIMO Up-Gradation Project: Department: Required Safety Plan MAXIMO Up-Graded VersionDocument2 pagesSubject: HSE Requirements in MAXIMO Up-Gradation Project: Department: Required Safety Plan MAXIMO Up-Graded Versionমোঃ মেজবাউর রহমান সোহেলNo ratings yet

- Sic XEDocument17 pagesSic XEinvincible_shalin6954No ratings yet

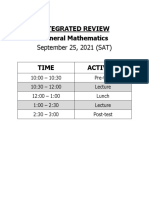

- Integrated Review Week 2 MathematicsDocument28 pagesIntegrated Review Week 2 MathematicsMarvin PameNo ratings yet

- Problem Solving Involving Combination and PermutationDocument12 pagesProblem Solving Involving Combination and PermutationBaby Ann MotarNo ratings yet

- Moment and Angular MomentumDocument4 pagesMoment and Angular MomentumCarlos RubianoNo ratings yet

- Jovan Marjanovic Basic Principles of Overunity Electro MachinesDocument22 pagesJovan Marjanovic Basic Principles of Overunity Electro Machineswangha6No ratings yet

- AerodynamicsDocument42 pagesAerodynamicsFreda FungNo ratings yet

- Unit 9. Going To: Positive Form Subject Verb To Be Going To InfinitiveDocument8 pagesUnit 9. Going To: Positive Form Subject Verb To Be Going To InfinitiveAne RuilobaNo ratings yet

- Facts and FactorsDocument72 pagesFacts and FactorsleipdfNo ratings yet

- Advanced Model CheckingDocument3 pagesAdvanced Model CheckingJunaid AkramNo ratings yet

- Assembly Design AdvancedDocument220 pagesAssembly Design AdvancedAdi Fiera100% (1)

- SSC CGL Tier-I Practice Set 4Document10 pagesSSC CGL Tier-I Practice Set 4Vothi ThuyhanhNo ratings yet

- Reinventing The WheelDocument149 pagesReinventing The WheelKmengNo ratings yet

- Autodesk Simulation Mechanical IIDocument1 pageAutodesk Simulation Mechanical IIkanteron6443No ratings yet

- MCQS (Control Engg.)Document166 pagesMCQS (Control Engg.)azeem sheikhNo ratings yet

- Refraction at Plane Surfaces Report To FinalDocument13 pagesRefraction at Plane Surfaces Report To FinalProy DC100% (1)

- Estimation: Nearest Ten: Estimate The Sum by Rounding Each Addend To The Nearest TenDocument2 pagesEstimation: Nearest Ten: Estimate The Sum by Rounding Each Addend To The Nearest TenCookie RamoNo ratings yet

- Maths Sa1 Sp2Document15 pagesMaths Sa1 Sp2Shivam PandeyNo ratings yet

- Final SP'23Document8 pagesFinal SP'23Hazem AhmedNo ratings yet

- Implementation of Informed RRT - On A Pre-Mapped Octomap Generated by RTAB MapDocument9 pagesImplementation of Informed RRT - On A Pre-Mapped Octomap Generated by RTAB MapMuhammad AdhipatiunusNo ratings yet

- Chapter 7: Other Variable Control Charts: OutlineDocument18 pagesChapter 7: Other Variable Control Charts: OutlineNohaM.No ratings yet

- Force Analysis of Metal Sheet in BendingDocument6 pagesForce Analysis of Metal Sheet in Bendingmohamed.hassan031No ratings yet

- Computer Fund Part IV Lesson 02Document22 pagesComputer Fund Part IV Lesson 02Annabelle Rigat de LeonNo ratings yet

- FM 306: Size Reduction and Sieving: ObjectiveDocument6 pagesFM 306: Size Reduction and Sieving: ObjectiveErcille Mae Oraiz PacamoNo ratings yet

- Half Yearly Test Paper - EconomicsDocument3 pagesHalf Yearly Test Paper - Economicslohiyadhrumil2007No ratings yet

- 2nd Quarter Math Week 5 (Day 1-5)Document19 pages2nd Quarter Math Week 5 (Day 1-5)MICHAEL VERINANo ratings yet

- MTBF - Report - Rambutan (-I) - V1Document15 pagesMTBF - Report - Rambutan (-I) - V1Madhuseptember2022No ratings yet

- Real Time SimulationDocument7 pagesReal Time SimulationkumarNo ratings yet

- DSP Lab-01Document28 pagesDSP Lab-01Mekonen AberaNo ratings yet