Professional Documents

Culture Documents

Voltage Drop After NEC Requirements

Voltage Drop After NEC Requirements

Uploaded by

nadeem UddinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Voltage Drop After NEC Requirements

Voltage Drop After NEC Requirements

Uploaded by

nadeem UddinCopyright:

Available Formats

Code Corner

Voltage Drop after NEC Requirements

John Wiles

Sponsored by the Photovoltaic Systems Assistance Center, Sandia National Laboratories

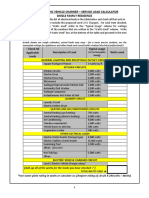

excessive voltage drops cause wasted power and energy, and require longer battery charging times. In utility-interactive systems, voltage drops and the resultant power losses represent expensive energy that doesnt make it to the load or to the grid. Current through conductors that have resistance to that current results in a voltage drop developing in a length of the conductor. The relationship is: V=IxR V (in volts) is the voltage drop in a conductor that has a resistance R (in ohms) and has a current of I amperes (amps). In any circuit, there are two conductors, and there is a voltage drop in each conductor. Since the two conductors are usually equal in length, the distance from source to load (as the conductors are routed) is usually doubled to get a total length that is used for determining the resistance to be used in the calculation. Conductor resistance decreases as conductor size increases, and resistance increases as conductor temperature increases. Since we are dealing with electrical power circuits, I have selected conductor resistance values from Table 8, Chapter 9 of the 1999 NEC. These DC resistance values, presented below, are for stranded, uncoated copper conductors (no tin or other coatings on the actual copper) at a temperature of 75C (167F). This temperature is typical of operating power circuits designed to NEC requirements and will not, of Table 1: Resistance of Copper Wire

Size Metric Size (mm2) Ohms / 1,000 ft.

fter the National Electrical Code (NEC) requirements for conductor size (based on ampacity) have been met, the performance question (not a code requirement) of voltage drop should be addressed. In this Code Corner, I will show how voltage drops are calculated (no fancy tables), and then Ill cover some typical module wiring installations in the next issue of Home Power.

Voltage Drop First of all, it should be made clear that voltage drop is not a code issue per se. It is a performance issue, not a safety issue in most cases. The code addresses voltage drop only in Fine Print Notes that are not part of the code, and are to be used only for added information. I frequently get calls asking why articles published in Home Power and elsewhere on conductor voltage drop do not agree. Each of these articles is based on a set of assumptions that may or may not be consistent from article to article. And a few of the articles have had corrections printed in subsequent issues that may have been missed by the reader. Ill be presenting a method for calculating voltage drop that does not use short-cut tables, just plain old math. Voltage drop is somewhat critical in PV systems operating at low voltages (12 and 24 volt systems). This is because at night under discharge, batteries have a low terminal voltage, and excessive voltage drop in the circuits causes the loads (including inverters) to operate poorly or not at all. In the PV charging circuits,

14* 12* 10* 8* 6* 4* 3* 2* 1* 1/0* 2/0* 3/0* 4/0* 250** 300**

* AWG ** kcmils

2.08 3.31 5.26 8.37 13.29 21.15 26.67 33.62 42.41 53.48 67.43 85.01 107.22 167.70 201.30

3.1400 1.9800 1.2400 0.7780 0.4910 0.3080 0.2450 0.1940 0.1540 0.1220 0.0967 0.0766 0.0608 0.0515 0.0429

116

Home Power #80 December 2000 / January 2001

Code Corner

course, match similar conductor resistance values at other temperatures. AC resistance and impedance values may be significantly different, and are beyond the scope of this article. DC values may be used only as a very rough estimate for AC circuits. To get the resistance R for the voltage drop calculation, double the one-way length of the circuit from source to load. If the circuit (source to load) length of the conductors is 40 feet (for example), the total resistance would be based on a length of 80 feet (2 x 40). If #10 (5 mm2) conductors were being used with a resistance of 1.24 ohms per 1,000 feet, then the resistance R for the voltage drop calculation would be: R = 1.24 x 80 1,000 = 0.0992 ohms Now we have to consider what current to use in the equation. As current increases, the voltage drop also increases. In utility-interactive PV source circuits, I tend to use the rated peak-power current of the module (marked on the back of the module) or group of modules connected in parallel. In a battery-charging system, the peak-power current might also be used, but some consideration should be given to using the short-circuit current from the modules or the PV array. This higher current might be used, since at low battery states of charge, the module currents tend toward this value due to the low battery voltages. For example, a PV module might have a short-circuit current of 3.5 amps and a peak-power operating current of 3.0 amps. For a system with ten modules or strings of modules connected in parallel, I might use 35 amps as the current in a battery charging system, and 30 amps as the current in a utility-interactive PV system. In DC load circuits, I use the maximum steady-state currents for the DC loads or the inverter. If there are high motor starting surges on the inverter, they might cause the inverter to shut down as the surge causes the voltage at the inverter input terminals to drop to the low voltage disconnect point. I would at least calculate the voltage drop at these high surge currents. In a battery-to-inverter circuit, the maximum steadystate DC current into the inverter might be 100 amps (for example) and I would use that current in the calculation. However, if there were well pumps or sewerage lift pumps operating at night that had peak currents of 300 amps, I would see what effect this higher current, and the resulting voltage drop, would have on the inverter operation. With the resistance established and the current estimated, the voltage drop can be calculated.

For example, an inverter is located 20 feet (circuit length) from the batteries and is connected to a resistive load (no surges) that causes the inverter to draw 100 amps on a 24 volt system. Yes, this is a heavy AC load at about 2,200 watts. The low voltage disconnect is set at 22 volts. #4/0 (107 mm 2 ) conductors are being considered. The resistance R is calculated as: R = 0.0608 x 40 1,000 = 0.00243 ohms The voltage drop is 0.00243 x 100 = 0.243 volts. The operating voltage of the inverter is 24 - 0.243 = 23.76 volts when the batteries are at the nominal system voltage of 24 volts. Now lets see what happens when there is a well pump on the inverter output that causes the inverter to require a surge current of 300 amps from the batteries. The conductor resistance will cause the voltage drop to increase to 0.729 volts. This drop alone would cause the inverter terminal voltage to drop to 23.27 volts in a good battery bank. However, the internal resistance of the batteries and other resistances in the circuit will also cause a voltage drop. The total voltage drop may cause the low voltage disconnect point of 22 volts to be reached, shutting down the inverter. Finer Points Ah yes, batteries have an internal resistance that varies all over the place depending on the type of battery and the state of charge. These are very hard numbers to pin down and verify. For golf cart batteries and L-16 style batteries, I use 0.00075 ohms per 6 volt battery. I just add the number of 6 volt batteries in series and use that number times 0.00075 and add this to the conductor resistance. That comes out to 0.0015 for a 12 volt system, 0.003 for a 24 volt system, and 0.006 ohms for a 48 volt system. Remember that these are just ballpark numbersyour mileage will vary. Contacts in connectors and switchgear also have resistances. I use 0.0002 ohms for each good battery terminal, power block terminal, split-bolt, or twist-on wire connection. I use a resistance of 0.002 ohms for each circuit breaker pole and a resistance of 0.006 for each fused disconnect switch pole (this accounts for the resistance of two terminals, the switch blade, the moving contact, the fuse element, and the two fuse blades). Again, these are very rough estimates for well-made connections and devices, and the actual numbers will vary widely. High-current devices will usually have lower resistances than low-current devices. The resistances

Home Power #80 December 2000 / January 2001

117

Code Corner

Table 2: Example Circuit Resistances

Type of Resistance Ohms*

Battery internal resistance Battery contacts (8) Inverter contacts (2) Circuit breaker Conductors Total

* Very rough estimates.

0.0030 0.0016 0.0004 0.0020 0.0024 0.0094

Summary After the code-required ampacity calculations are made to determine the size of the conductors, additional calculations should be made for the voltage drops in the system. If these voltage drops are excessive, increasing the conductor size may help to reduce them. If you have questions about the NEC or the implementation of PV systems following the requirements of the NEC, feel free to call, fax, email, or write me. Sandia National Laboratories sponsors my activities in this area as a support function to the PV Industry. This work was supported by the United States Department of Energy under Contract DE-FC0400AL66794. Sandia is a multi-program laboratory operated by Sandia Corporation, a Lockheed Martin Company, for the United States Department of Energy. Access John C. Wiles Southwest Technology Development Institute, New Mexico State University, Box 30,001/ MSC 3 SOLAR, Las Cruces, NM 88003 505-646-6105 Fax: 505-646-3841 jwiles@nmsu.edu www.nmsu.edu/~tdi Sponsor: Sandia National Laboratories, Ward Bower, Department 6218, PO Box 5800 MS 0753, Albuquerque, NM 87185 505-844-5206 Fax: 505-844-6541 wibower@sandia.gov www.sandia.gov/pv National Electrical Code and NEC are registered trademarks of the National Fire Protection Association. The 1999 NEC and the NEC Handbook are available from the NFPA, 11 Tracy Dr., Avon, MA 02322 800-344-3555 or 508-895-8300 Fax: 800-593-6372 or 508-895-8301 custserv@nfpa.org www.nfpa.org National Renewable Energy Laboratory solar radiation and weather database: http://rredc.nrel.gov/solar/ old_data/nsrdb/redbook/sum^2

for each circuit are composed of the conductor resistance plus the battery internal resistances, plus all contact and switchgear resistances. In the preceding inverter example, let us assume that the #4/0 (107 mm2) cables are routed through a single 250 amp circuit breaker. The circuit resistances are now as shown in Table 2. At 100 amps, the voltage drop is 0.94 volts. During a 300 amp surge, the voltage drop is 2.82 volts, which might just cause problems. Some of this voltage drop, but not all of it, can be reduced by using larger conductors. This is one of the reasons that getting good, tight, quality connections is necessary in a PV system. Every milliohm counts. Percentage voltage drop may be expressed as the voltage drop divided by the nominal system voltage and then multiplied by 100. In this example, the voltage drop is 0.94 24 x 100 = 3.9 percent for the 100 amp load, and three times that for the 300 amp surge. I try to keep the voltage drop below 2 percent for 12 and 24 volt systems and below 3 percent for 48 volt systems. Higher voltage systems can sometimes carry higher voltage drops. But the operating points and losses of power should be compared with the costs of increasing the conductor sizes to reduce those losses. In many cases, the resistance of switchgear, poor connections, and aging batteries may cause far more voltage drop than the conductors alone do. Increasing conductors above the code ampacity requirements wont help much, but may be necessary. In many cases, long distances between the PV array and the batteries might indicate that the conductors may require oversizing to lower the voltage drop. If the circuit conductors are increased above minimum ampacity requirements, the equipment-grounding conductor for these circuits may also have to be increased. See previous Code Corners and NEC Section 250-122 for details.

118

Home Power #80 December 2000 / January 2001

You might also like

- Fire Alarm Sys Nec 760Document10 pagesFire Alarm Sys Nec 760nadeem Uddin100% (1)

- 538 Parts PDFDocument47 pages538 Parts PDFc.a.g.p.100% (1)

- ECE3710 - Lab 1 - Resistors and Basic Resistive Circuits: NameDocument6 pagesECE3710 - Lab 1 - Resistors and Basic Resistive Circuits: NameParker Santo DomingoNo ratings yet

- AURETR003 Learner WorkbookDocument49 pagesAURETR003 Learner WorkbookJuan Carlos RodriguezNo ratings yet

- Electrical Load WorksheetDocument1 pageElectrical Load WorksheetroldskiNo ratings yet

- Module 5 Community Solar Playbook 9.9.16Document72 pagesModule 5 Community Solar Playbook 9.9.16Reselyn PalabinoNo ratings yet

- ECE 315 TextDocument395 pagesECE 315 TextjoelmcramerNo ratings yet

- EV Car Load ClaculationDocument3 pagesEV Car Load ClaculationBurhaan TaskeenNo ratings yet

- Dsd213 Electrical Load Calculation WorksheetDocument1 pageDsd213 Electrical Load Calculation WorksheetAlaa RamadanNo ratings yet

- Guidelines For Water Management and Irrigation DevelopmentDocument183 pagesGuidelines For Water Management and Irrigation DevelopmentLitesh AttardeNo ratings yet

- PRF - Learning - PVSYST - Guidelines For Assumptions in Simulation - Ver 1 0Document5 pagesPRF - Learning - PVSYST - Guidelines For Assumptions in Simulation - Ver 1 0Lakshmi NarayananNo ratings yet

- Gci-1.5k PV ManualDocument16 pagesGci-1.5k PV Manualfarchipmm580% (1)

- Understanding Solar PV Permitting InspectingDocument82 pagesUnderstanding Solar PV Permitting InspectingMarty Mah100% (1)

- MCC & ContactorsDocument9 pagesMCC & ContactorsbimboawotikuNo ratings yet

- SP3.6 Array Voltage ConsiderationsDocument8 pagesSP3.6 Array Voltage ConsiderationsSIDI ahmedou yahyaNo ratings yet

- Amvic ICF CA Design GuideDocument108 pagesAmvic ICF CA Design GuidedanNo ratings yet

- Se Application Fixed String VoltageDocument3 pagesSe Application Fixed String VoltageOlivier ORMANNo ratings yet

- Planning and Decision Guide For Solar PV Systems PDFDocument53 pagesPlanning and Decision Guide For Solar PV Systems PDFkhal manNo ratings yet

- DC Testing Solar InverterDocument5 pagesDC Testing Solar Inverterzeljkoc21No ratings yet

- 01 Solar PV Rooftop Training Program - Handbook For Utility EngineersDocument88 pages01 Solar PV Rooftop Training Program - Handbook For Utility EngineersM. AlimNo ratings yet

- Must-Have Consumer Guide To Solar Power Generation SystemsDocument36 pagesMust-Have Consumer Guide To Solar Power Generation SystemspavanuNo ratings yet

- Solar Panels: DeployableDocument8 pagesSolar Panels: DeployableRajib ChowdhuryNo ratings yet

- Rural Building, Basic KnowledgeDocument170 pagesRural Building, Basic Knowledgerizaazari4530No ratings yet

- Fine Homebuilding - Issue 299 June 2021Document92 pagesFine Homebuilding - Issue 299 June 2021saale.cefranNo ratings yet

- Photovoltaic Effect: Solar CellDocument9 pagesPhotovoltaic Effect: Solar CellAbdullah MomtazNo ratings yet

- Comments: Inspection Points and Their ReasonsDocument2 pagesComments: Inspection Points and Their ReasonsBruno Samos100% (1)

- Workshop On Battery Testing Procedures (2014)Document52 pagesWorkshop On Battery Testing Procedures (2014)Enrique MachucaNo ratings yet

- Solar System Sizing - Open ElectricalDocument1 pageSolar System Sizing - Open ElectricalkakagoNo ratings yet

- Manual (Repaired)Document11 pagesManual (Repaired)Chandranidas06No ratings yet

- 210-12 Pad Mount Data Sheet PDFDocument12 pages210-12 Pad Mount Data Sheet PDFRonald H Santos100% (1)

- Specification For Inverter 15-03Document2 pagesSpecification For Inverter 15-03Văn ST QuangNo ratings yet

- Training Report ORIGiNALDocument151 pagesTraining Report ORIGiNALAnkit BansalNo ratings yet

- CH4 PhotovoltaicsDocument19 pagesCH4 Photovoltaicsibrahim irhomaNo ratings yet

- Guideline For Solar PV System Installation For Solar ProvidersDocument105 pagesGuideline For Solar PV System Installation For Solar ProvidersNazir Samath100% (1)

- PV STD Permit InstructionsDocument22 pagesPV STD Permit InstructionsjuancrangelNo ratings yet

- Experimental Investigation of Soiling Impact On PV Module PerformanceDocument10 pagesExperimental Investigation of Soiling Impact On PV Module PerformanceEbenezer ButarbutarNo ratings yet

- PV Doctor: For The Inspection and Fault Location of The Photovoltaic ModulesDocument16 pagesPV Doctor: For The Inspection and Fault Location of The Photovoltaic ModulesSiddhartha SenguptaNo ratings yet

- Wind Turbine Guide: Backup Generators Tracking The SunDocument132 pagesWind Turbine Guide: Backup Generators Tracking The SunAbang Rezal100% (1)

- Local Media5941271462837301265Document65 pagesLocal Media5941271462837301265jason mr.perfect11No ratings yet

- Electrical Installation - CircuitsDocument8 pagesElectrical Installation - CircuitsAmos KormeNo ratings yet

- Voltage DividerDocument11 pagesVoltage DividerLorshiel Anne TusingNo ratings yet

- Power ConverterDocument26 pagesPower Converterhardih123No ratings yet

- Voltage Drop Describes How The SuppliedDocument4 pagesVoltage Drop Describes How The SuppliedrngwenaNo ratings yet

- Application For Industrial Power SupplyDocument5 pagesApplication For Industrial Power SupplySunghoonie KangNo ratings yet

- How To Find The Proper Size of Wire & Cable - Metric & Imperial SystemsDocument17 pagesHow To Find The Proper Size of Wire & Cable - Metric & Imperial SystemsP.Rajan GuruNo ratings yet

- Electrical Circuits III PDFDocument42 pagesElectrical Circuits III PDFRolando Cruz33% (3)

- EnphaseTechBrief Vdrop M250Document12 pagesEnphaseTechBrief Vdrop M250Lia SantosNo ratings yet

- Components FullDocument15 pagesComponents FullFlux PrimeNo ratings yet

- Project Components 1.diode: Pin ConfigurationDocument20 pagesProject Components 1.diode: Pin ConfigurationMahesh UgalmugaleNo ratings yet

- Installation ExamplesDocument53 pagesInstallation ExamplesJohnNo ratings yet

- Buck Converter Design DemystifiedDocument6 pagesBuck Converter Design DemystifiedEric MorissetNo ratings yet

- Single-Phase Power Systems: Practical Circuit AnalysisDocument13 pagesSingle-Phase Power Systems: Practical Circuit AnalysisAl Patrick Dela CalzadaNo ratings yet

- Automated Unified System For LPG UsingDocument84 pagesAutomated Unified System For LPG UsingVirat KaliNo ratings yet

- A n1 n2 V1 V2 I2 I1Document13 pagesA n1 n2 V1 V2 I2 I1Abdullah AlzahraniNo ratings yet

- PLC Based Load Sharing On Slide ShareDocument28 pagesPLC Based Load Sharing On Slide ShareHemu Bhai PatelNo ratings yet

- Automatic Power Factor Controlling PanelDocument15 pagesAutomatic Power Factor Controlling PanelheruvalaNo ratings yet

- Clipper & Clamper CircuitsDocument19 pagesClipper & Clamper CircuitsDianaAuroraNo ratings yet

- Electrical Design Training Class: Line LossDocument54 pagesElectrical Design Training Class: Line Losssri_electricalNo ratings yet

- EE ckts3Document33 pagesEE ckts3Darren BernardoNo ratings yet

- Protectia Inst FotovoltaiceDocument3 pagesProtectia Inst FotovoltaiceBalan DanielNo ratings yet

- A2400 Basic Electrical MeasurementsDocument6 pagesA2400 Basic Electrical MeasurementsYunia LieNo ratings yet

- Chapter 3Document10 pagesChapter 3Vikas UpadhyayNo ratings yet

- Input Line ReactorsDocument4 pagesInput Line Reactorsviy11No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Name REF RemarkDocument2 pagesName REF Remarknadeem UddinNo ratings yet

- Pages From ECBC-CodeDocument16 pagesPages From ECBC-Codenadeem UddinNo ratings yet

- Deep Breathing TechniquesDocument1 pageDeep Breathing Techniquesnadeem UddinNo ratings yet

- Fire Alarm Sys - Installation ChecklistDocument1 pageFire Alarm Sys - Installation Checklistnadeem UddinNo ratings yet

- Opt Vs IonDocument2 pagesOpt Vs Ionnadeem UddinNo ratings yet

- Active Doc ListDocument405 pagesActive Doc Listnadeem UddinNo ratings yet

- SLD of DBDocument1 pageSLD of DBnadeem UddinNo ratings yet

- Data Center Tier RequirementsDocument1 pageData Center Tier Requirementsnadeem UddinNo ratings yet

- Comparison Sheet of Fusion ModelDocument3 pagesComparison Sheet of Fusion Modelnadeem UddinNo ratings yet

- Data Center RequirementsDocument3 pagesData Center Requirementsnadeem Uddin100% (1)

- Cable Sizing Rev.3Document13 pagesCable Sizing Rev.3nadeem UddinNo ratings yet

- Ms Glanding & Termination of LV CablesDocument18 pagesMs Glanding & Termination of LV Cablesnadeem UddinNo ratings yet

- Boxes Raceways SpecificationDocument21 pagesBoxes Raceways Specificationnadeem UddinNo ratings yet

- F2 Chapter 7 7.1 (Part 2) 7.2Document61 pagesF2 Chapter 7 7.1 (Part 2) 7.2ChuahSiewHoonNo ratings yet

- ITR.2 Data Sheet CF20 5-04Document1 pageITR.2 Data Sheet CF20 5-04Tiu TonNo ratings yet

- VSO Low Flow: Thermally Compensated Proportional ValveDocument6 pagesVSO Low Flow: Thermally Compensated Proportional Valvebiomed2083No ratings yet

- Experiment 3 Final PDFDocument7 pagesExperiment 3 Final PDFMuhammad TouheedNo ratings yet

- Sistemas de Potencia Dodge DurangoDocument244 pagesSistemas de Potencia Dodge Durangomatias quezadaNo ratings yet

- Power Line ParametersDocument11 pagesPower Line ParametersurdemalezNo ratings yet

- Welcom To Circuit Analysis - EE211 Program: CE (Fall 2014)Document38 pagesWelcom To Circuit Analysis - EE211 Program: CE (Fall 2014)Babar Ali RoomiNo ratings yet

- Assignment #1Document46 pagesAssignment #1Héctor Manuel Rodríguez FelicianoNo ratings yet

- Basic RL and RC CircuitsDocument9 pagesBasic RL and RC CircuitsJazperNo ratings yet

- VERIM 4-Manual PDFDocument61 pagesVERIM 4-Manual PDFTatianaPadillaNo ratings yet

- A2XS (FL) 2Y 1x 500RM - 50 110kV IEC 60840Document3 pagesA2XS (FL) 2Y 1x 500RM - 50 110kV IEC 60840Anonymous LNdiNQNo ratings yet

- N2XSERYDocument5 pagesN2XSERYRinda_RaynaNo ratings yet

- GenEd ProfDocument78 pagesGenEd ProfHernan BarrettoNo ratings yet

- Class 10: Class 10 Electricity Important QuestionsDocument45 pagesClass 10: Class 10 Electricity Important QuestionsSoma Paine SardarNo ratings yet

- ADZ - SMH DatasheetDocument4 pagesADZ - SMH DatasheettamanogNo ratings yet

- Basic Electrical and Electronics EngineeringDocument8 pagesBasic Electrical and Electronics EngineeringNagendra PrasadNo ratings yet

- Radio Data Reference Book Jessop 1967Document148 pagesRadio Data Reference Book Jessop 1967Cubelinho ResuaNo ratings yet

- Edexel IAS Physics Unit 2 Physics at Work Topic 4 Technology in Space Test With Mark Scheme 16 - 17Document24 pagesEdexel IAS Physics Unit 2 Physics at Work Topic 4 Technology in Space Test With Mark Scheme 16 - 17Paul BurgessNo ratings yet

- 4 Factors On Which The Resistance of A Conductor DependsDocument22 pages4 Factors On Which The Resistance of A Conductor DependsSunitha ShankarNo ratings yet

- Ais-156 Mechanical Shock & Drop Test Requirment of ReessDocument6 pagesAis-156 Mechanical Shock & Drop Test Requirment of Reesspratikshah910No ratings yet

- IEEE 13 Node Test FeederDocument11 pagesIEEE 13 Node Test FeederJuan Carlos HuaquisacaNo ratings yet

- CircuitsSE PDFDocument5 pagesCircuitsSE PDFJack JackNo ratings yet

- 18771-UG TN Resist Vol1 E1-4ZM PDFDocument20 pages18771-UG TN Resist Vol1 E1-4ZM PDFguddu guptaNo ratings yet

- Astm d5682Document4 pagesAstm d5682Ernesto Morales100% (1)

- Chapter 18: Electric Current and CircuitsDocument55 pagesChapter 18: Electric Current and CircuitsAshok PradhanNo ratings yet

- PHYSICS. Electricity FORM 5. Cikgu Khairul Anuar. Cikgu Desikan SMK Changkat Beruas, Perak. Chapter 7. SMK Seri Mahkota, Kuantan.Document49 pagesPHYSICS. Electricity FORM 5. Cikgu Khairul Anuar. Cikgu Desikan SMK Changkat Beruas, Perak. Chapter 7. SMK Seri Mahkota, Kuantan.Abdul Rahman100% (4)

- Chapter 4 - Charge, Current, Voltage, Energy and PowerDocument8 pagesChapter 4 - Charge, Current, Voltage, Energy and PowerMathMore1No ratings yet