Professional Documents

Culture Documents

Break Even Analysis of A Mobile Crane and Maintenance: A Case Study

Break Even Analysis of A Mobile Crane and Maintenance: A Case Study

Uploaded by

IJERDCopyright:

Available Formats

You might also like

- Building Work Method StatementDocument32 pagesBuilding Work Method StatementMuhammad Waqas97% (33)

- Quiet Title Complaint Template Sample Example FormDocument5 pagesQuiet Title Complaint Template Sample Example FormZionNo ratings yet

- Module 1 (Database Management in Construction)Document42 pagesModule 1 (Database Management in Construction)MARTHIE JASELLYN LOPENANo ratings yet

- Design and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050Document8 pagesDesign and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050The ash Designe GalaryNo ratings yet

- Design of Single Storey RCC Framed BuildingDocument86 pagesDesign of Single Storey RCC Framed BuildingBaba Maisam Shabir89% (97)

- Chapter 2 Shipyard-Layout Lecture Notes From South Hampton UniversityDocument10 pagesChapter 2 Shipyard-Layout Lecture Notes From South Hampton UniversityJonnada KumarNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Biomimicry in ArchitectureDocument10 pagesBiomimicry in Architecturerodolfo barbosaNo ratings yet

- Maintenance, Repair and Operations Parts Inventory Management in The Era of Industry 4.0Document6 pagesMaintenance, Repair and Operations Parts Inventory Management in The Era of Industry 4.0Tiago Camargo AlvesNo ratings yet

- PA 28 181 ChecklistDocument1 pagePA 28 181 Checklistrobk182No ratings yet

- Cost Estimation Ship ConstructionDocument10 pagesCost Estimation Ship ConstructionJoseramirezjlrt100% (1)

- Developments in Modular Construction ForDocument13 pagesDevelopments in Modular Construction Forshiva1978in@gmail.comNo ratings yet

- Modular ConstructionDocument9 pagesModular ConstructionSunil Kumar P GNo ratings yet

- Survey On Flexible Shipbuilding Technologies For Curved Ship BlocksDocument8 pagesSurvey On Flexible Shipbuilding Technologies For Curved Ship BlocksGEORGE.K.CNo ratings yet

- Case Study Report, PM SuperalloysDocument24 pagesCase Study Report, PM SuperalloysPunit JainNo ratings yet

- Optimization of Material Handling: A Case StudyDocument57 pagesOptimization of Material Handling: A Case StudyVenkatraj NagarajanNo ratings yet

- Performance Based Analysis of Bridges: (Peer-Reviewed, Open Access, Fully Refereed International Journal)Document9 pagesPerformance Based Analysis of Bridges: (Peer-Reviewed, Open Access, Fully Refereed International Journal)IRJMETS JOURNALNo ratings yet

- Ijce Ncraccess P107 PDFDocument5 pagesIjce Ncraccess P107 PDFJilShethNo ratings yet

- Cost AnalysisDocument13 pagesCost AnalysisReaditReaditNo ratings yet

- Chapter 1 - Intro To CTDocument38 pagesChapter 1 - Intro To CTKhairi AzharNo ratings yet

- Irjet V2i6202 PDFDocument4 pagesIrjet V2i6202 PDFkovaryNo ratings yet

- Key Performance Indicator Development For Ship-ToDocument11 pagesKey Performance Indicator Development For Ship-ToM. Ikhsan NurpratamaNo ratings yet

- Design and Development of A Five-Axis Machine Tool With High Accuracy, Stiffness and e Ciency For Aero-Engine Casing ManufacturingDocument12 pagesDesign and Development of A Five-Axis Machine Tool With High Accuracy, Stiffness and e Ciency For Aero-Engine Casing ManufacturingMido MoussaNo ratings yet

- Karachi Shipyard and Engineering Works LimitedDocument26 pagesKarachi Shipyard and Engineering Works LimitedEngr Muhammad Ehsan80% (5)

- Soma Enterprises: Four Lane NH Connectivity To Ictt CochinDocument53 pagesSoma Enterprises: Four Lane NH Connectivity To Ictt CochinshijinkuttanNo ratings yet

- Lists of Notations: Dept. of Civil Engg. Sait 2018-2019Document50 pagesLists of Notations: Dept. of Civil Engg. Sait 2018-2019Arunesh KumarNo ratings yet

- Irjet V5i11228Document3 pagesIrjet V5i11228Rahul SunilNo ratings yet

- 2022.11.30 TechnicalWebinar V1 WithRecording2 PDFDocument90 pages2022.11.30 TechnicalWebinar V1 WithRecording2 PDFAnggi AryantoNo ratings yet

- Feature of Shipbuilding IndustryDocument38 pagesFeature of Shipbuilding IndustryarvindkaushikNo ratings yet

- Iaetsd-jaras-Design & Manufacturing of Hydraulic Crane An OverviewDocument4 pagesIaetsd-jaras-Design & Manufacturing of Hydraulic Crane An OverviewiaetsdiaetsdNo ratings yet

- 2021 A Systematic Approach of Lean Supply Chain ManagementDocument11 pages2021 A Systematic Approach of Lean Supply Chain Managementİsmet AkyelNo ratings yet

- Hull'S Manufacturing Cost Structure: Miguel Leal José Manuel GordoDocument24 pagesHull'S Manufacturing Cost Structure: Miguel Leal José Manuel GordoThe MatrixNo ratings yet

- Computer Aided Analysis and Design of A Multistoreyed Hospital Building1Document100 pagesComputer Aided Analysis and Design of A Multistoreyed Hospital Building1Sabid KanakkayilNo ratings yet

- Prod Uv TivityDocument8 pagesProd Uv Tivityعلي حميد زغيرNo ratings yet

- Design of Hydraulic Portable Crane Ijariie17796Document9 pagesDesign of Hydraulic Portable Crane Ijariie17796Diogo VidinhaNo ratings yet

- Shreedhar T BeamDocument10 pagesShreedhar T BeamYazer ArafathNo ratings yet

- Machines Used in Modern Construction: Bachelor of TechnologyDocument23 pagesMachines Used in Modern Construction: Bachelor of TechnologyKalyan Reddy AnuguNo ratings yet

- Karachi Shipyard and Engineering Works LimitedDocument26 pagesKarachi Shipyard and Engineering Works Limitedshahid_ali21100% (1)

- Burj Khalifa - Construction and Quality Control: D.S. Rajendra PrasadDocument11 pagesBurj Khalifa - Construction and Quality Control: D.S. Rajendra PrasadAsif MahmoodNo ratings yet

- Master of Engineering in Civil (Structures)Document39 pagesMaster of Engineering in Civil (Structures)suhasNo ratings yet

- Hps Project Report 2 AniketDocument12 pagesHps Project Report 2 Aniketjohnboi2409No ratings yet

- 15A 8 Fabrication PDFDocument25 pages15A 8 Fabrication PDFBruno MiguelNo ratings yet

- A Novel Approach of Performance Measurement of Shipbuilding Supply Chain by AHP-FCE ModelDocument8 pagesA Novel Approach of Performance Measurement of Shipbuilding Supply Chain by AHP-FCE ModelКонстантин НечетNo ratings yet

- Design Optimization of EOT Crane GirderDocument5 pagesDesign Optimization of EOT Crane Girdermech_abhiNo ratings yet

- Hospital Building ProjectDocument58 pagesHospital Building ProjectAnonymous yM5XLR694% (18)

- CIG-704-Final-Exam WS14 15 MADocument14 pagesCIG-704-Final-Exam WS14 15 MAZeyad ElhoutNo ratings yet

- GopiDocument8 pagesGopirfvz6sNo ratings yet

- Crane Lifting Optimization and Construction Monitoring in Steel Bridge Construction Project Based On BIM and UAVDocument15 pagesCrane Lifting Optimization and Construction Monitoring in Steel Bridge Construction Project Based On BIM and UAVGogyNo ratings yet

- Establishment of Profile Production Line For Shipbuilding in Shipyard (Paper)Document5 pagesEstablishment of Profile Production Line For Shipbuilding in Shipyard (Paper)pal_malayNo ratings yet

- ReportDocument29 pagesReportPrateekAggarwal100% (2)

- ProjectDocument17 pagesProjectRavi ChotaliyaNo ratings yet

- P14-22Document9 pagesP14-22JamalNo ratings yet

- New Generation Ingot Crane Design, Finite Element Analysis (FEA) and Prototype ManufacturingDocument18 pagesNew Generation Ingot Crane Design, Finite Element Analysis (FEA) and Prototype ManufacturingSAMET DÖNERKAYANo ratings yet

- Overview of History Ofconstruction Technology and EquipmentDocument18 pagesOverview of History Ofconstruction Technology and EquipmentDipesh ChaudharyNo ratings yet

- Thesis TitleDocument11 pagesThesis TitleReanna Mae A. BaganiNo ratings yet

- Development and Performance of Electro Hydraulic ExcavatorDocument7 pagesDevelopment and Performance of Electro Hydraulic ExcavatorEditor IJTSRDNo ratings yet

- BSS552 Lect 1 PDFDocument23 pagesBSS552 Lect 1 PDFAiRem_90No ratings yet

- ShipyardsDocument12 pagesShipyardsNAVEEN KUMARNo ratings yet

- SP43Document352 pagesSP43SourabhAdikeNo ratings yet

- 7 FormworkDocument3 pages7 FormworkCIVIL DEPARTMENT MMANTCNo ratings yet

- Koch Et Al. (2015)Document15 pagesKoch Et Al. (2015)Atila MarconcineNo ratings yet

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresFrom EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNo ratings yet

- Sustainable Steel Buildings: A Practical Guide for Structures and EnvelopesFrom EverandSustainable Steel Buildings: A Practical Guide for Structures and EnvelopesBernhard HaukeNo ratings yet

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerFrom Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerNo ratings yet

- Router 1X3 - RTL Design and VerificationDocument10 pagesRouter 1X3 - RTL Design and VerificationIJERDNo ratings yet

- Moon-Bounce: A Boon For VHF DxingDocument5 pagesMoon-Bounce: A Boon For VHF DxingIJERDNo ratings yet

- Investigations On Properties of Light Weight Cinder Aggregate ConcreteDocument10 pagesInvestigations On Properties of Light Weight Cinder Aggregate ConcreteIJERDNo ratings yet

- Emotion Detection From TextDocument12 pagesEmotion Detection From TextIJERDNo ratings yet

- Hammad Hussian: Mass and Weight Gravitational Fields DensityDocument95 pagesHammad Hussian: Mass and Weight Gravitational Fields DensityRaiyaan BawanyNo ratings yet

- RFS UD Series DipoleDocument2 pagesRFS UD Series DipoleBryan PittmanNo ratings yet

- DPR TemplateDocument2 pagesDPR TemplateAM PRABAKARANNo ratings yet

- Department of Health: Overnment OticeDocument49 pagesDepartment of Health: Overnment OticeconfithanNo ratings yet

- AI Curriculum HandbookClassXI Level2Document119 pagesAI Curriculum HandbookClassXI Level2asraadeebNo ratings yet

- Nyepi Packages I RevisedDocument10 pagesNyepi Packages I Revisedreservation.rumahkitatravelNo ratings yet

- 1280 2556 1 SMDocument7 pages1280 2556 1 SMAbdurahman AbdNo ratings yet

- The Proprietary Theory and The Entity Theory of Corporate Enterpr PDFDocument242 pagesThe Proprietary Theory and The Entity Theory of Corporate Enterpr PDFAnusha GowdaNo ratings yet

- Master of Information Technology and Systems (973AA)Document4 pagesMaster of Information Technology and Systems (973AA)kira_suziniNo ratings yet

- NIBDocument NIB31Document92 pagesNIBDocument NIB31Ashish Kumar VermaNo ratings yet

- FX2N-16DNET Devicenet User ManualDocument126 pagesFX2N-16DNET Devicenet User ManualNguyen QuanNo ratings yet

- Circuits Virtual LabDocument2 pagesCircuits Virtual LabPaula GómezNo ratings yet

- Filtration Systems With Pile Cloth Filter MediaDocument8 pagesFiltration Systems With Pile Cloth Filter MediaSagnik DasNo ratings yet

- 0450e - Application For Certification As A Welding InspectorDocument6 pages0450e - Application For Certification As A Welding InspectorJayNo ratings yet

- IQ Air CompressorDocument16 pagesIQ Air CompressorDhaval ChaplaNo ratings yet

- Summon and ModesDocument7 pagesSummon and Modesdiksha chouhanNo ratings yet

- Iwc DumpDocument28 pagesIwc DumpSendy Rubio bonilla96No ratings yet

- Tutorial: IBM Cognos InsightDocument25 pagesTutorial: IBM Cognos InsightViji BanuNo ratings yet

- Act Roi WebsitepayDocument2 pagesAct Roi Websitepaynagendra reddy panyamNo ratings yet

- Kap2 EnerdisDocument16 pagesKap2 EnerdiskailasamvvNo ratings yet

- World Health OrganizationDocument13 pagesWorld Health OrganizationVincent Ranara Sabornido100% (1)

- Heirs of Jose Lim vs. Lim, 614 SCRA 141, March 03, 2010Document13 pagesHeirs of Jose Lim vs. Lim, 614 SCRA 141, March 03, 2010raikha barraNo ratings yet

- Pest & Steep AnalysisDocument16 pagesPest & Steep Analysismamasita25No ratings yet

- Ethics in Engineering Profession - IES General StudiesDocument16 pagesEthics in Engineering Profession - IES General StudiesSandeep PrajapatiNo ratings yet

- Module 1 MacroeconomicsDocument19 pagesModule 1 MacroeconomicsAlex De Leon Montero II100% (1)

- Fowler - The New MethodologyDocument18 pagesFowler - The New MethodologypglezNo ratings yet

Break Even Analysis of A Mobile Crane and Maintenance: A Case Study

Break Even Analysis of A Mobile Crane and Maintenance: A Case Study

Uploaded by

IJERDOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Break Even Analysis of A Mobile Crane and Maintenance: A Case Study

Break Even Analysis of A Mobile Crane and Maintenance: A Case Study

Uploaded by

IJERDCopyright:

Available Formats

International Journal of Engineering Research and Development e-ISSN: 2278-067X, p-ISSN : 2278-800X, www.ijerd.

com Volume 5, Issue 6 (December 2012), PP. 01-07

Break Even Analysis of a Mobile Crane and Maintenance: a Case Study

1

1

Sankaraiah. M, 2Rambabu. E, 3Eswara Reddy. C

Research Scholar, Dept. of Mech. Engg, S.V.U. College of Engg.,Tirupati-517502 A.P. India. 2 General Manager, A. P. Rajiv Swagruha Corpn. Ltd., Jawahar Nagar, Hyderabad, A.P 3 Professor of Mech. Engineering, Sri Venkateswara University, Tirupati - 517502, A.P.

Abstract:- Productivity improvements are always of important aspect of any Industry. As a ressult, introducing the new materials and automated construction processes are always desirable as long as they are less expensive and consistent with desired performance. Mechanical handling and material handling go together as that of hand-in glove in the modern construction of the Dams, Roads, Bridges, Buildings, Over Head Water Tanks, Towers, Residential and Industrial buildings, High-rise buildings having many stories, etc. The manual handling of concrete remains commonplace in the construction of high-rise buildings despite obvious risks to operatives. As such, the construction of a multti-storeyed building is studied. The present paper concentrates on the usage of a Mobile Crane (Hydrau) for loading, mounting, carrying large loads and for work performed in the construction of multi-storeyed buildings. In the paper, the fundamental operations, utilization and maintenance of Mobile crane are analyzed for Break-Even analysis. The time, cost, reputations savings and safety of the manual handling is compared with Mechanical handling and established that the mechanical handling of materials is much better than manual handling in the construction of high-rise buildings. Key words:- Material handling, Mechanical handling, Mobile crane, Construction, Concrete.

I.

INTRODUCTION

Construction is generally hard task and becomes hazardous in the construction of high-rise buildings. The literature states that working days are last due to injuries or illness or fatal deaths. The indirect costs like reduced worker productivity, delays in projects, administrative time, damage to equipment and the facility. In contrast, to most industrial accidents, innocent bystanders may also be injured by construction accidents. Several crane collapses from high rise buildings under construction have resulted in fatalities to passer-byes. Therefore, the Construction Cranes like Mobile Cranes are being used in a long useful working life that far exceeds the common values of their economic life. The manual material handling in the building constructions is very difficult and un-safe. The professional labours and skilled labours more in number is required for manual handling of RCC components in the building construction. It is also a major problem to involve the men for take up the heavy load duties repeatedly. Therefore, the mechanical equipment like Mobile Crane is more useful for lifting, loading, un-loading and carrying of heavy bodies like pre-casted RCC components and steel frames from one place to another. The study consists of the daily out put / usage of the mobile crane for a period of one week, considering regular manual labour charges. The average out-put interms of labour charges is estimated and compared with total expenditure on the vehicle and the Break-even point of Mobile crane is after 4 years from the date of commencement of utility.

II.

LITERATURE SURVEY AND OBJECTIVE

Technology Management is a process, which includes planning, directing, control and co-ordination. The implementation of Technological capabilities to shape and accomplish the strategic and operational objectives of the organization [1]. The Mechanical equipment is playing key role for material handling such as Tower Cranes in the construction of high-rise buildings. The Tower cranes are used for lifting, loading and un-loading of RCC components, in the fixed area height at high-rise buildings construction [2]. The construction of Ground Floor and Stilt Floor is carried out in conventional methods in High-rise buildings [3]. The fundamental motions of a rotary crane are rotation, boom luffing, and load hoisting. Loads are transferred by a combination of these motions. Using a crane, a load can be transferred to any place within a limited area [4], and Break Even Analysis, [5]. The issues of shortening construction time, reducing cost and improving production performance have engaged both practitioners and researchers for a long time. Being one of the greatest technological improvements in construction, pre-fabrication and industrialization have been used successfully in limited

Break Even Analysis of a Mobile Crane and Maintenance: a Case Study

regions such as Finland and Israel as well as in wider regions such as rebuilding of Europe after the destruction of the Second World War [6]. Due to the ennibaliation of valuable components for possible reuse in secondary markets is becoming a popular option. However, recovery processes are characterized by high levels of uncertainty regarding the quality of components returned at their end-of-life [7]. The volume of output at which neither profit nor loss is incurred is called as the Break-Even Point of the particular vehicle. It is also called minimum output to Break even the total cost incurred [8]. Therefore, construction of high-rise building with 14 Floors is taken -up in the present work. Objective: The objective of the paper is to find out the utilization of the Mobile Crane (Hydrau) with material handling and utilization charges so as to suggest a suitable Break-Even Analysis on the material handling system.

III.

LAY-OUT OF THE SITE

The lay-out of the site under study is shown in Figure 1. The destinations of each area are shown in Table 1.

Figure-1: Lay-out of the site

Break Even Analysis of a Mobile Crane and Maintenance: a Case Study

Table 1. Lay-out and destinations Location Area Location Name Location Name site (sqm) code

Location Site Code

Area (sqm)

A1 A2 A3 A4 A5 B1 B2 B3 B4 B5

A-type Building(1) A-type Building(2) A-type Building(3) A-type Building(4) A-type Building(5) B-type Building(1) B-type Building(2) B-type Building(3) B-type Building(4) B-type Building(5)

86x28 86x28 86x28 86x28 86x28 98x23 98x23 98x23 98x23 98x23

C1 C2 C3 C4 C5 C6 D1 D2 D3 D4 D5

Pre-casting Yard PCY Stores Steel Yard C-type Building(6) C-type Building(5) Materials stores D-type Building(1) D-type Building(2) D-type Building(3) D -type Building(4) D-type Building(5)

100x120 80x120 180x120 63x16 63x16 120x180 54x13 54x13 54x13 54x13 54x13

IV.

METHODOLOGY

The Methodology in the construction of the floors is explained in the Flow Chart, Figure 2, considering different operations. The experiments conducted on Mechanical Handling of materials by the Mobile crane and the destinations at the construction of multi-storeyed building of 17 blocks of each G + 14 floors in an extent of 52.00 Acres are as shown in detail in Table-1.

Pre-casting yard Stores Erection

Crane Stationary

Crane Movable

Crane fixed

Moulding Reinforcement with steel Filling with Concrete and Job Description Vibrating De-moulding & finishing Lifting of component Loading in the Truck-I

Un-loadingRCC Components Storing Water curing Q.C. Testing Loading in Truck -II

Un-loading

Lifting pre-casting components Erection, Collection of SCC Lifting of SCC to top of columns Filling with SSC Fixing of siporex slabs Grouting the components

Figure2: Flow chart of construction Methodology Table 2: Job Description of manual construction and mechanical construction. Manual Construction Mechanical Construction Sl. No . 1 2 3 4 5 6 Job Description Trade Sl. No . 1 2 3 4 5 6 Job Description Trade Sl. No . 11 12 13 14 15 16 Job Description Trad e

Bar bending Steel fabrication Centering Preparation of CC CC Transportation Filling of CC

t1 t2 t3 t4 t5 t6

Bar bending Steel fabrication Shifting of steel frames Preparation of Moulds Reinforcement Preparation of CC

T1 T2 T3 T4 T5 T6

De-moulding Storing Water Curing Shift of RCC components Supply of Siporex Slabs Columns, beams, S. slabs erection

T11 T12 T13 T14 T15 T16

Break Even Analysis of a Mobile Crane and Maintenance: a Case Study

7 8 9 10 CC Compaction Finishing Water curing De-centering t7 t8 t9 t10 7 8 9 10 CC Transportation Concreting Compaction Finish of Groves, cores T7 T8 T9 T10 17 18 19 20 SCC Preparation SCC Transportn Grout with SCC Screed with CC T17 T18 T19 T20

Mobile Crane: Mobile Crane used in the handling materials is shown in Figure -3 and the specifications are in the following followed by the handling of RCC Columns s shown in Figure 4. Escorts Construction Equipment Limited Model: F 15; Diesel Engine: No: 28 BK 5422. Cost of the Vehicle : Rs.21.90 Lakhs; Date of Purchase : 21.09.2009 Simple Interest on Capital : Rs.12%; Depreciation time: 15 years.

Figure-3: Conveyance of steel frames RCC columns

Figure-4: Lifting of RCC columns

Output of the Mobile Crane: The daily ouput of the Mobile Crane (Hydrau) is shown in Table 3 followed by the daily expenditure on the Mobile Crane in Table -4. The total worth and cumulative output of the Mobile crane for 6 years ( Amount in Rs. Lakhs) is shown in Table 5. Table-3: Daily output of Mobile Crane on dt: 01-02-2010 Utilisation of the crane : Starting Time - Closing Time = 1662 1671 = 9 hrs Transporta Distance Manual requirement tion travelled Nature of Quan Wt. Wit With Tim Labour handling - tity (gs) T h out Me e From Charges o load load n (Hrs (Rs) ) 11 2 3 4 5 6 7 8 9 10 RCC columns 2 367 C1 C 180 26 208 3796 (1.20x0.30x2.535 4 2 m) Return journey C2 C 180 1 RCC columns 2 367 C1 C 180 (1.20x0.30x2.535 4 2 m) Return journey C2 C 180 1 RCC columns 2 367 C1 C 180 (1.20x0.30x2.535 4 2 m) Return journey C2 C 180

S. N o 1 1

2 3

4 5

Break Even Analysis of a Mobile Crane and Maintenance: a Case Study

1 C 2 C 3 A 1 C 3 C 4 C 6 A 3 C 6 A 3 A 1 A 5 C 6

8 9 10 11 12 13 14 15 16 17 18

RCC columns (1.20x0.30x2.535 m) Return journey Steel Rods shifting Return journey Steel Rods shifting Return journey Crane Materials shifting Return journey Crane Materials shifting Return journey Concrete Bucket shifting Return journey

367 4 160 0 200 0 500 500 350 -

C1

180

1 1 2 2 1 -

C2 C3 A1 C3 C4 C6 A3 C6 A3 A1 A5

101 5 290 503 503 217 324 8

400 1015 290 503 41 719 3508 37 296 5402 2 16 292 4 32 584 3 24 438 2 16 292

Table-4: Daily Expenditure and out put of the Mobile crane from 01-02-2010 to 06-02-2010 Expenditure Time S. Date of Time taken Out put taken Oil Labor No. working (Hrs) (Rs) (Hrs) Consumption involved 1 01.02.2010 450 780 9 5402 296 2 02.02.2010 400 780 8 5110 280 3 03.02.2010 300 780 6 5308 296 4 04.02.2010 450 780 9 4526 248 5 05.02.2010 400 780 8 6570 360 6 06.02.2010 400 780 8 5986 328 Total 2400 4680 48 32902 1808 Average 400 780 8 5484 301 Table-5: The total worth and cumulative out put of the Mobile crane for 6 years ( Amount in Rs. Lakhs) Cumulati Total Sl. Total Cumulative Vehicle ve Total worth output of No Year Expenditu Output of Worth expendit of vehicle vehicle . re vehicle ure (Avg) 1 1 2 21.9.200 9 (Purchas e) 1 year 2 years 3 years 4 years 3 21.90 4 -5 -6 21.90 7 -8 --

2 3 4 5

24.53 27.47 30.77 34.46

4.30 4.30 4.30 4.30

-8.61 12.92 17.22

28.83 36.08 43.69 51.68

12.83 12.83 12.83 12.83

12.83 25.66 38.49 51.32

Break Even Analysis of a Mobile Crane and Maintenance: a Case Study

6 7 5 years 6 years 38.60 44.22 4.30 4.30 21.53 25.83 60.12 70.06 12.83 12.83 64.15 76.98

V.

RESULTS AND DISCUSSIONS

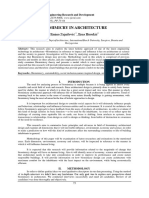

The results obtained from the Methodology are discussed in the following. The Mobile Crane ( Hydrau) is utilized for handling of different types of materials like, steel rods, steel frames, crane materials, RCC components, etc., between steel yards, pre-casting yard, construction site, and stores as per the requirement. The mobile crane in action is shown in Figures -3 and 4. The daily out-put from the Mobile crane with different types of operations are measured and the results noted down in the Table 2 & 3 for a period of 6 days. The Mechanical handling of materials of the above are also converted into manual handling and noted the same in the Tables -2 & 3. The actual men engaged for Mechanical Handling and maintenance charges of the Mobile crane for the same period are noted down in Table-4. Labour charges and expenditure on the Mobile Crane are calculated as shown below . The maximum capacity of a man carrying at single time = 35 Kgs The maximum working time per day by a man = 8 hrs The cost of oil consumption for the Mobile crane per hr = Rs.50 The maximum weight of the RCC column per 1.00 Cum = 2400 Kgs Maintenance charges of the Mobile crane =Rs. 1200 per week ( 6 days) Aaverage expenditure on the Mobile crane = Maintenance cost in Rs. + Daily expenditure (Table 3) The expenditure . = Rs. 200 + 400 + 780 = Rs. 1380 per day Annual expenditure on Mobile Crane= Rs. 1380 x 312 days = Rs.430560 The daily output from the Mobile Crane = Rs.5484 The fluctuations in the work out put i.e., 25% = Rs 1371 Therefore, the actual output of the Mobile crane per day = Rs.4113 The annual out put from by the Mobile crane = Rs.4113 x 312 days = Rs.1283256 Worth of the vehicle: The worth of the crane is calculated using the formulae as follows. Let, P = Present worth, i = Rate of interest and F = Future worth of P after sometime At the end of 1 year ; F1 = P + iP = P(1 + i) (1) At the end of second year; F2 = P(1 + i) + iP(1 + i) = P(1 + i) 2 (2) Similarly, for n years Fn = P(1 + i)n (3) Break Even Point: The total worth and total time taken-up by the Mobile crane as per the Table-4 are compared and found that the Break Even point of the crane is after 4 years as shown in Figurer 5

90 80 70

Cost (In Lakhs)

60 50 40 30 20 10 0 0 1 2 3 4 5 6 7 Duration (Years) Worth Output

Figure 5: Break-Even Point of Hydrau

VI.

CONCLUSIONS

The Break Even Point of the Mobile crane is shown in Figure-5. It can be see that the Break-Even Point is achieved after 4 years with a worth of Rs.51.32 lakhs. The Mobile crane is used at the construction site for critical handling locations where the Manual handling is not possible and to difficult. The time taken for

Break Even Analysis of a Mobile Crane and Maintenance: a Case Study

Mechanical Handling is 8 hrs per day, where as in manual handling it is 301 hrs for the same output of the work. Therefore, the time saving from the Mechanical handling is 38 times over manual handling. Transportation technique can be applied. ACKNOWLEDGEMENT The authors expresses their sense of gratitude for the help and cooperation extended by P. Rajiv Swagruha Corporation Limited, Jawahar Nagar, Hyderabad, India.

REFERENCES

[1]. [2]. [3]. Shu-hsien Liao Technology management methodologies and applications A Literature review from 1995 to 2003, Technovation, pp: 381-393, .2005. Sankariah. M, Rambabu.E and Eswara Reddy.C., Role of Material Handling equipment in construction of High-rise buildings. Proc. of 2nd A.P. Academy of Sciences: S.V. University, Tirupati, India, 2009. Sankaraiah.M, Rambabu.E and Reddy.C.E, Mechanical Handling of Materials in the construction of Multi-storeyed buildings A Case Study; 3rd International Conf. Advances in Mech. Engineering, Surat India, .Jan 4 6, 2010. Kazuhiko Terashima, Ying Shen and Kenichi YanoModeling an optimal control of a rotary crane using the straight transfer transformations method: Journal of Science Direct: 1179-1192, 2007. Sankaraiah.M, Rambabu. E and Eswara Reddy. C., Maintainability and Break Even Analysis of Mobile Crane A Case Study, Proc. of the National Conference on Recent Advances in Mechanical Engineering, RVR & JC Engineering College, Guntur, India, pp. 227 233, July, 7-8, 2011. Tam,C.M., Deng.Z .M and Zeng. S.X), Evaluation of construction methods and performance for high rise public housing construction in Hong Kong: Jl. of Building and environment, pp. 983-991, 2002. Ajith Kumar Parlikad and Duncan McFarlane, Quantifying the impact of AIDC technologies for vehicle component recovery: Journal of Computers and Industrial Engineering, 2010. Kumar. B., National Institute of Technology, Jamshedpur, India, Industrial Engineering-Text Book for Engineering Sstudents: Pages 581583, 1989.

[4]. [5].

[6]. [7]. [8].

You might also like

- Building Work Method StatementDocument32 pagesBuilding Work Method StatementMuhammad Waqas97% (33)

- Quiet Title Complaint Template Sample Example FormDocument5 pagesQuiet Title Complaint Template Sample Example FormZionNo ratings yet

- Module 1 (Database Management in Construction)Document42 pagesModule 1 (Database Management in Construction)MARTHIE JASELLYN LOPENANo ratings yet

- Design and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050Document8 pagesDesign and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050The ash Designe GalaryNo ratings yet

- Design of Single Storey RCC Framed BuildingDocument86 pagesDesign of Single Storey RCC Framed BuildingBaba Maisam Shabir89% (97)

- Chapter 2 Shipyard-Layout Lecture Notes From South Hampton UniversityDocument10 pagesChapter 2 Shipyard-Layout Lecture Notes From South Hampton UniversityJonnada KumarNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Biomimicry in ArchitectureDocument10 pagesBiomimicry in Architecturerodolfo barbosaNo ratings yet

- Maintenance, Repair and Operations Parts Inventory Management in The Era of Industry 4.0Document6 pagesMaintenance, Repair and Operations Parts Inventory Management in The Era of Industry 4.0Tiago Camargo AlvesNo ratings yet

- PA 28 181 ChecklistDocument1 pagePA 28 181 Checklistrobk182No ratings yet

- Cost Estimation Ship ConstructionDocument10 pagesCost Estimation Ship ConstructionJoseramirezjlrt100% (1)

- Developments in Modular Construction ForDocument13 pagesDevelopments in Modular Construction Forshiva1978in@gmail.comNo ratings yet

- Modular ConstructionDocument9 pagesModular ConstructionSunil Kumar P GNo ratings yet

- Survey On Flexible Shipbuilding Technologies For Curved Ship BlocksDocument8 pagesSurvey On Flexible Shipbuilding Technologies For Curved Ship BlocksGEORGE.K.CNo ratings yet

- Case Study Report, PM SuperalloysDocument24 pagesCase Study Report, PM SuperalloysPunit JainNo ratings yet

- Optimization of Material Handling: A Case StudyDocument57 pagesOptimization of Material Handling: A Case StudyVenkatraj NagarajanNo ratings yet

- Performance Based Analysis of Bridges: (Peer-Reviewed, Open Access, Fully Refereed International Journal)Document9 pagesPerformance Based Analysis of Bridges: (Peer-Reviewed, Open Access, Fully Refereed International Journal)IRJMETS JOURNALNo ratings yet

- Ijce Ncraccess P107 PDFDocument5 pagesIjce Ncraccess P107 PDFJilShethNo ratings yet

- Cost AnalysisDocument13 pagesCost AnalysisReaditReaditNo ratings yet

- Chapter 1 - Intro To CTDocument38 pagesChapter 1 - Intro To CTKhairi AzharNo ratings yet

- Irjet V2i6202 PDFDocument4 pagesIrjet V2i6202 PDFkovaryNo ratings yet

- Key Performance Indicator Development For Ship-ToDocument11 pagesKey Performance Indicator Development For Ship-ToM. Ikhsan NurpratamaNo ratings yet

- Design and Development of A Five-Axis Machine Tool With High Accuracy, Stiffness and e Ciency For Aero-Engine Casing ManufacturingDocument12 pagesDesign and Development of A Five-Axis Machine Tool With High Accuracy, Stiffness and e Ciency For Aero-Engine Casing ManufacturingMido MoussaNo ratings yet

- Karachi Shipyard and Engineering Works LimitedDocument26 pagesKarachi Shipyard and Engineering Works LimitedEngr Muhammad Ehsan80% (5)

- Soma Enterprises: Four Lane NH Connectivity To Ictt CochinDocument53 pagesSoma Enterprises: Four Lane NH Connectivity To Ictt CochinshijinkuttanNo ratings yet

- Lists of Notations: Dept. of Civil Engg. Sait 2018-2019Document50 pagesLists of Notations: Dept. of Civil Engg. Sait 2018-2019Arunesh KumarNo ratings yet

- Irjet V5i11228Document3 pagesIrjet V5i11228Rahul SunilNo ratings yet

- 2022.11.30 TechnicalWebinar V1 WithRecording2 PDFDocument90 pages2022.11.30 TechnicalWebinar V1 WithRecording2 PDFAnggi AryantoNo ratings yet

- Feature of Shipbuilding IndustryDocument38 pagesFeature of Shipbuilding IndustryarvindkaushikNo ratings yet

- Iaetsd-jaras-Design & Manufacturing of Hydraulic Crane An OverviewDocument4 pagesIaetsd-jaras-Design & Manufacturing of Hydraulic Crane An OverviewiaetsdiaetsdNo ratings yet

- 2021 A Systematic Approach of Lean Supply Chain ManagementDocument11 pages2021 A Systematic Approach of Lean Supply Chain Managementİsmet AkyelNo ratings yet

- Hull'S Manufacturing Cost Structure: Miguel Leal José Manuel GordoDocument24 pagesHull'S Manufacturing Cost Structure: Miguel Leal José Manuel GordoThe MatrixNo ratings yet

- Computer Aided Analysis and Design of A Multistoreyed Hospital Building1Document100 pagesComputer Aided Analysis and Design of A Multistoreyed Hospital Building1Sabid KanakkayilNo ratings yet

- Prod Uv TivityDocument8 pagesProd Uv Tivityعلي حميد زغيرNo ratings yet

- Design of Hydraulic Portable Crane Ijariie17796Document9 pagesDesign of Hydraulic Portable Crane Ijariie17796Diogo VidinhaNo ratings yet

- Shreedhar T BeamDocument10 pagesShreedhar T BeamYazer ArafathNo ratings yet

- Machines Used in Modern Construction: Bachelor of TechnologyDocument23 pagesMachines Used in Modern Construction: Bachelor of TechnologyKalyan Reddy AnuguNo ratings yet

- Karachi Shipyard and Engineering Works LimitedDocument26 pagesKarachi Shipyard and Engineering Works Limitedshahid_ali21100% (1)

- Burj Khalifa - Construction and Quality Control: D.S. Rajendra PrasadDocument11 pagesBurj Khalifa - Construction and Quality Control: D.S. Rajendra PrasadAsif MahmoodNo ratings yet

- Master of Engineering in Civil (Structures)Document39 pagesMaster of Engineering in Civil (Structures)suhasNo ratings yet

- Hps Project Report 2 AniketDocument12 pagesHps Project Report 2 Aniketjohnboi2409No ratings yet

- 15A 8 Fabrication PDFDocument25 pages15A 8 Fabrication PDFBruno MiguelNo ratings yet

- A Novel Approach of Performance Measurement of Shipbuilding Supply Chain by AHP-FCE ModelDocument8 pagesA Novel Approach of Performance Measurement of Shipbuilding Supply Chain by AHP-FCE ModelКонстантин НечетNo ratings yet

- Design Optimization of EOT Crane GirderDocument5 pagesDesign Optimization of EOT Crane Girdermech_abhiNo ratings yet

- Hospital Building ProjectDocument58 pagesHospital Building ProjectAnonymous yM5XLR694% (18)

- CIG-704-Final-Exam WS14 15 MADocument14 pagesCIG-704-Final-Exam WS14 15 MAZeyad ElhoutNo ratings yet

- GopiDocument8 pagesGopirfvz6sNo ratings yet

- Crane Lifting Optimization and Construction Monitoring in Steel Bridge Construction Project Based On BIM and UAVDocument15 pagesCrane Lifting Optimization and Construction Monitoring in Steel Bridge Construction Project Based On BIM and UAVGogyNo ratings yet

- Establishment of Profile Production Line For Shipbuilding in Shipyard (Paper)Document5 pagesEstablishment of Profile Production Line For Shipbuilding in Shipyard (Paper)pal_malayNo ratings yet

- ReportDocument29 pagesReportPrateekAggarwal100% (2)

- ProjectDocument17 pagesProjectRavi ChotaliyaNo ratings yet

- P14-22Document9 pagesP14-22JamalNo ratings yet

- New Generation Ingot Crane Design, Finite Element Analysis (FEA) and Prototype ManufacturingDocument18 pagesNew Generation Ingot Crane Design, Finite Element Analysis (FEA) and Prototype ManufacturingSAMET DÖNERKAYANo ratings yet

- Overview of History Ofconstruction Technology and EquipmentDocument18 pagesOverview of History Ofconstruction Technology and EquipmentDipesh ChaudharyNo ratings yet

- Thesis TitleDocument11 pagesThesis TitleReanna Mae A. BaganiNo ratings yet

- Development and Performance of Electro Hydraulic ExcavatorDocument7 pagesDevelopment and Performance of Electro Hydraulic ExcavatorEditor IJTSRDNo ratings yet

- BSS552 Lect 1 PDFDocument23 pagesBSS552 Lect 1 PDFAiRem_90No ratings yet

- ShipyardsDocument12 pagesShipyardsNAVEEN KUMARNo ratings yet

- SP43Document352 pagesSP43SourabhAdikeNo ratings yet

- 7 FormworkDocument3 pages7 FormworkCIVIL DEPARTMENT MMANTCNo ratings yet

- Koch Et Al. (2015)Document15 pagesKoch Et Al. (2015)Atila MarconcineNo ratings yet

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresFrom EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNo ratings yet

- Sustainable Steel Buildings: A Practical Guide for Structures and EnvelopesFrom EverandSustainable Steel Buildings: A Practical Guide for Structures and EnvelopesBernhard HaukeNo ratings yet

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerFrom Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerNo ratings yet

- Router 1X3 - RTL Design and VerificationDocument10 pagesRouter 1X3 - RTL Design and VerificationIJERDNo ratings yet

- Moon-Bounce: A Boon For VHF DxingDocument5 pagesMoon-Bounce: A Boon For VHF DxingIJERDNo ratings yet

- Investigations On Properties of Light Weight Cinder Aggregate ConcreteDocument10 pagesInvestigations On Properties of Light Weight Cinder Aggregate ConcreteIJERDNo ratings yet

- Emotion Detection From TextDocument12 pagesEmotion Detection From TextIJERDNo ratings yet

- Hammad Hussian: Mass and Weight Gravitational Fields DensityDocument95 pagesHammad Hussian: Mass and Weight Gravitational Fields DensityRaiyaan BawanyNo ratings yet

- RFS UD Series DipoleDocument2 pagesRFS UD Series DipoleBryan PittmanNo ratings yet

- DPR TemplateDocument2 pagesDPR TemplateAM PRABAKARANNo ratings yet

- Department of Health: Overnment OticeDocument49 pagesDepartment of Health: Overnment OticeconfithanNo ratings yet

- AI Curriculum HandbookClassXI Level2Document119 pagesAI Curriculum HandbookClassXI Level2asraadeebNo ratings yet

- Nyepi Packages I RevisedDocument10 pagesNyepi Packages I Revisedreservation.rumahkitatravelNo ratings yet

- 1280 2556 1 SMDocument7 pages1280 2556 1 SMAbdurahman AbdNo ratings yet

- The Proprietary Theory and The Entity Theory of Corporate Enterpr PDFDocument242 pagesThe Proprietary Theory and The Entity Theory of Corporate Enterpr PDFAnusha GowdaNo ratings yet

- Master of Information Technology and Systems (973AA)Document4 pagesMaster of Information Technology and Systems (973AA)kira_suziniNo ratings yet

- NIBDocument NIB31Document92 pagesNIBDocument NIB31Ashish Kumar VermaNo ratings yet

- FX2N-16DNET Devicenet User ManualDocument126 pagesFX2N-16DNET Devicenet User ManualNguyen QuanNo ratings yet

- Circuits Virtual LabDocument2 pagesCircuits Virtual LabPaula GómezNo ratings yet

- Filtration Systems With Pile Cloth Filter MediaDocument8 pagesFiltration Systems With Pile Cloth Filter MediaSagnik DasNo ratings yet

- 0450e - Application For Certification As A Welding InspectorDocument6 pages0450e - Application For Certification As A Welding InspectorJayNo ratings yet

- IQ Air CompressorDocument16 pagesIQ Air CompressorDhaval ChaplaNo ratings yet

- Summon and ModesDocument7 pagesSummon and Modesdiksha chouhanNo ratings yet

- Iwc DumpDocument28 pagesIwc DumpSendy Rubio bonilla96No ratings yet

- Tutorial: IBM Cognos InsightDocument25 pagesTutorial: IBM Cognos InsightViji BanuNo ratings yet

- Act Roi WebsitepayDocument2 pagesAct Roi Websitepaynagendra reddy panyamNo ratings yet

- Kap2 EnerdisDocument16 pagesKap2 EnerdiskailasamvvNo ratings yet

- World Health OrganizationDocument13 pagesWorld Health OrganizationVincent Ranara Sabornido100% (1)

- Heirs of Jose Lim vs. Lim, 614 SCRA 141, March 03, 2010Document13 pagesHeirs of Jose Lim vs. Lim, 614 SCRA 141, March 03, 2010raikha barraNo ratings yet

- Pest & Steep AnalysisDocument16 pagesPest & Steep Analysismamasita25No ratings yet

- Ethics in Engineering Profession - IES General StudiesDocument16 pagesEthics in Engineering Profession - IES General StudiesSandeep PrajapatiNo ratings yet

- Module 1 MacroeconomicsDocument19 pagesModule 1 MacroeconomicsAlex De Leon Montero II100% (1)

- Fowler - The New MethodologyDocument18 pagesFowler - The New MethodologypglezNo ratings yet