Professional Documents

Culture Documents

Refining Al-Si Alloy - USBM Report of Investigation 5781

Refining Al-Si Alloy - USBM Report of Investigation 5781

Uploaded by

Neale NeelamegghamCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Crude Distiller RBI Intro (Updated)Document31 pagesCrude Distiller RBI Intro (Updated)harrinsonf100% (2)

- University of Cambridge International Examinations International General Certifi Cate of Secondary EducationDocument16 pagesUniversity of Cambridge International Examinations International General Certifi Cate of Secondary EducationHiphop602No ratings yet

- How To Hardface: The Ten-Step ApproachDocument2 pagesHow To Hardface: The Ten-Step ApproachCarlos Anibal OrtizNo ratings yet

- 1 Pirastro Violin Abril 2019Document7 pages1 Pirastro Violin Abril 2019Kely KurtzNo ratings yet

- Solaf SPM Chemistry Electrochemistry: Electrolytes and Non-ElectrolytesDocument21 pagesSolaf SPM Chemistry Electrochemistry: Electrolytes and Non-ElectrolytesSiti Aishah ZolkanainNo ratings yet

- Group 2 Non Ferrous Metal ME3Document52 pagesGroup 2 Non Ferrous Metal ME3ELLIENo ratings yet

- Ribeirodossantos 2019Document7 pagesRibeirodossantos 2019Mauricio FariaNo ratings yet

- Stainless Steel Grade 202 (UNS S20200)Document3 pagesStainless Steel Grade 202 (UNS S20200)MuhammadJawadNo ratings yet

- Chemistry - Chemical Equations WorksheetDocument2 pagesChemistry - Chemical Equations WorksheetKareesh ShamilsanNo ratings yet

- 4.3: Reaction Stoichiometry: Learning ObjectivesDocument6 pages4.3: Reaction Stoichiometry: Learning ObjectivesRicki HanNo ratings yet

- Final Exam Practice ProblemsDocument7 pagesFinal Exam Practice ProblemsAuto CadNo ratings yet

- Chapter 3Document24 pagesChapter 3Rayn OutlawNo ratings yet

- TermochemistryDocument20 pagesTermochemistryMasitah Abu BakarNo ratings yet

- Emission Factors in KG CO2-equivalent Per UnitDocument4 pagesEmission Factors in KG CO2-equivalent Per Unitkrishna somaNo ratings yet

- AFT Lab ProcedureDocument34 pagesAFT Lab ProceduresubrassNo ratings yet

- Song 2017Document5 pagesSong 2017201400738No ratings yet

- Balancing Redox Reactions Acidic ConditionsDocument3 pagesBalancing Redox Reactions Acidic ConditionsCtNo ratings yet

- The Effect of Slag Modeling To Improve Steelmaking Processes PDFDocument12 pagesThe Effect of Slag Modeling To Improve Steelmaking Processes PDFPaulo J. C. EstevesNo ratings yet

- The Actinides - David A. JohnsonDocument14 pagesThe Actinides - David A. JohnsonAni MoNo ratings yet

- 11 Introduction To Engineering MaterialsDocument20 pages11 Introduction To Engineering MaterialsomkardashetwarNo ratings yet

- Atoms: Frederick A. Bettelheim William H. Brown Mary K. Campbell Shawn O. FarrellDocument45 pagesAtoms: Frederick A. Bettelheim William H. Brown Mary K. Campbell Shawn O. FarrellShereen Al-ObinayNo ratings yet

- Method 8.7 - Refined Sugar: Reducing Sugars by The Knight and Allen MethodDocument3 pagesMethod 8.7 - Refined Sugar: Reducing Sugars by The Knight and Allen Methodmari100% (1)

- Specification Guide: Chrome High Temp Fittings & FlangesDocument4 pagesSpecification Guide: Chrome High Temp Fittings & FlangesAdrian EspinosaNo ratings yet

- Ammonia Combustion Catalysts - Review by HinokumaDocument8 pagesAmmonia Combustion Catalysts - Review by HinokumaAnanthakishnanNo ratings yet

- Aluminium NitrateDocument3 pagesAluminium NitrategumtammNo ratings yet

- Balanced EquationDocument13 pagesBalanced EquationMiha FlorentinaNo ratings yet

- SP1Document25 pagesSP1mugu12No ratings yet

- 1.2 The Periodic Table QPDocument36 pages1.2 The Periodic Table QPMaheenNo ratings yet

- 2.COA of Potassium NitrateDocument3 pages2.COA of Potassium NitrateJeisson DazaNo ratings yet

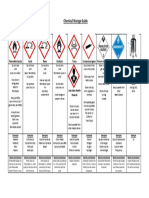

- Chemical Storage Guide: and Other HealthDocument1 pageChemical Storage Guide: and Other HealthVictorNo ratings yet

Refining Al-Si Alloy - USBM Report of Investigation 5781

Refining Al-Si Alloy - USBM Report of Investigation 5781

Uploaded by

Neale NeelamegghamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Refining Al-Si Alloy - USBM Report of Investigation 5781

Refining Al-Si Alloy - USBM Report of Investigation 5781

Uploaded by

Neale NeelamegghamCopyright:

Available Formats

D I bureau of mines 5781

n report of investigations

USING MOLTEN ZINC TO EXTRACT

ALUMINUM FROM ALUMINUM-SILICON

ALLOYS: A PROGRESS REPORT

By H. S. Caldwell, Ir., and M. I. Spendlove

UNITED STATES DEPARTMENT OF THE INTERIOR

BUREAU OF MINES

(1961)

Burea.u of Mines

of

USING MOLTEN

H. S.

3

TO EXTRACT ALUMINUM FROM ALUMINUM-SILICON

ALLOYS: A PROGRESS REPORT

by

, Jr. and M. J. Spendlove

ERRATA

Should rea.d in part

from the lower vessel (4) and

condensed to the liquid state in

the upper vessel (2). The liquid

zinc is refluxed into the lower

vessel (

5

5, first by

block (1).

the water-cooled

USING MOLTEN ZINC TO EXTRACT

ALUMINUM FROM ALUMINUM-SILICON

ALLOYS: A PROGRESS REPORT

By H. S. Caldwell, Jr., and M. J. Spendlove

reporl of investigations 5781

UNITED STATES DEPARTMENT OF THE INTERIOR

Stewart L. Udall, Secretary

BUREAU OF MINES

Marling J. Ankeny, Director

This publication has been cataloged as follows:

Caldwell, Herbert S

Using molten zinc to extract aluminum from aluminum-silicon

alloys: a progress report, by H. S. Caldwell, Jr., and M. J.

Spendlove. [Washington] U. S. Dept. of the Interior, Bureau

of Mines [1961J

15 p. illus., rabies. 27 em. (U. S. Bureau of Mines. Report of

investigations, 5781)

Bihliographieal footnotes.

1. Aluminum. 2. Aluminum-silicon alloys. 3. Zinc-Metallurgy. I.

Spendlove, Max J joint author. I. Title: Molten zinc to extracr

aluminum. (Series)

[TN23.U7 no. 578J.] 622.06173

U. S. Dept. of the Int. Library

CONTENTS

Surnrnary " " , Iff " " It " Iff " " " " " Iff II , " "

Introduction ..................

Aluminum extraction process ........................

Application of extraction process, procedure and results

Crude alloy feed ....

Induction-heated unit .. " .. """""""".",,.,,"" """""."""

Electrical-resistance-heated unit .

Gas .... fired unit .. ".""",,. ".,.""""""".. """""""""

Study of process conditions.

Pressure .

Leaching .

Conclusions ..

Future research.

1.

2.

3.

4.

5.

6.

1.

2

3

4.

5

6

7.

ILLUSTRATIONS

Fundamentals of aluminum extraction.

Diffusion of zinc into AI-Si alloy,.

Induction-heated unit ...

Extraction of aluminum from AI-Si alloy ...

Electrical-resistance-heated unit ....

Gas-fired unit."""""".,,""""""""",,.

TABLES

Extraction experiments, induction-heated unit ..

Extraction experiments, gas-fired unit

Effect of pressure on dissolution of aluminum .

Liquid-zinc leaching" .. "",,"""""" III " " " " " " " II " " " " " " " "

Zinc-vapor leaching" .. ",,"""""" II " " .. " " " Iff " " ill II " .. "" " " " 0 ". " ..

Effect of alloy particle size on leaching

Effect of AI-Si alloy iron content on aluminum

ext rae tion" " " " " " ., " " " II " " " " " " " " " " " " , " " " " .. " III " ......

1

1

3

5

5

5

7

9

11

11

12

15

15

3

4

6

7

8

10

6

11

12

13

13

14

14

USING MOLTEN ZINC TO EXTRACT ALUMINUM

FROM ALUMINUM-SILICON ALLOYS:

A PROGRESS REPORT.Y

by

H. S. Caldwell, Jr.V and M. J. SpendloveV

SUMMARY

Molten zinc, condensed from zinc vapor, was used by the Federal Bureau of

Mines to leach aluminum from an aluminum-silicon alloy made by carbo thermic re-

duction of silicious aluminum ores. Zinc requirements were minimized by re-

fluxing condensed zinc in a low-pressure, Soxhlet-type distillation unit. The

minimum ratio of zinc used to aluminum in the crude alloy was approximately

2:1. When the system pressure was reduced from atmospheric pressure to 100

microns or less, the rate of aluminum extraction increased by a factor of 20.

Leaching rates were much higher when the zinc vapor was condensed directly on

the crude alloy than when molten zinc was passed over the alloy in the absence

of appreciable zinc vapors.

Observations indicated higher extraction efficiencies from crude alloys

containing greater amounts of iron. Complete extraction was obtained with

negligible loss of zinc.

Assuming complete removal of zinc, the aluminum products will contain 1

to 6 percent silicon and about 0.5 percent iron plus titanium. The leached

crude-alloy residue is a highly friable spongelike material containing about

80 percent silicon, several percent iron and titanium, with the remainder

aluminum.

This extraction method has been patented (Patent 2,810,637) and assigned

to the Government. Research and development investigations are continuing at

the College Park Metallurgy Research Center.

INTRODUCTION

Although aluminum is the most abundant metal in the earth's crust, baux-

ite is the only ore used commercially for producing aluminum. Ordinarily,

only ores containing more than 45 percent alumina and less than 15 percent

silica are considered commercially valuable.

II Work on manuscript completed November 1960.

II Metallurgist, Metallurgy Research Center, Bureau of Mines, College Park,

Md.

2

Because the domestic reserve of high-grade bauxite are is relatively

meager, considerable research has been directed towards developing methods

for producing aluminum freml low-grade bauxite, clay, anorthosite, and other

abundant raw materials that cannot be processed by present commercial methods.

One pertinent project, conducted at the Tennessee Valley Authority labo-

ratories in 1947, was devoted to the production of an aluminum-silicon alloy

by electrothermal reduction of clay with coke.11 More recently, the Bureau

of Mines, in cooperation with the Apex Smelting Co. of Chicago, developed

significant improvements in this process during electric-smelting experiments

on calcined clay, silica, and

The crude AI-Si alloy produced in this reduction is a bright, large-

grained, brittle material containing 30 to 60 percent aluminum, 30 to 50 per-

cent silicon, and a few percent iron and titanium. A similar alloy produced

in Europe by this method is reported to be used as a deoxidizing agent in

steelmaking and in the production of "silumin" casting alloys. Two commer-

cially important binary alloys of aluminum and silicon, No. 43 and No. 13,

each contain 12 percent silicon. Alloy 43 is used in producing sand and

permanent mold castings, and alloy 13 is widely used in diecasting. There

are no known commercial processes in which the alloy is used as a starting

material for producing a marketable grade of aluminum metal.

Methods for separating aluminum from Al-Si alloys have been suggested

by other The most prominent of these proposals is the

Loevenstein in which molten AI-Si alloy is cooled to the eutectic

temperature of 577

0

C. and the aluminum-rich liquid phase, containing 11.7

percent Silicon, is filtered off. Further refining is achieved by adding

zinc to the filtrate to form a eutectic having a melting point of 382

0

C.

Additional silicon is filtered from the zinc-aluminum at this temperature

to form an alloy containing only minor amounts of silicon. Differences in

the volatility of aluminum and zinc permit the refining of the aluminum prod-

uct by evaporating the zinc. The Zn-Al eutectic at 382

0

C. contains about

95 percent zinc, all of which must be evaporated to obtain refined aluminum.

11 Striplin, M. M., Jr" and Kelley, W. M., Aluminum-Silicon Alloys by

Electrothermal Reduction of Clay With Coke: Chem. Eng. Prog., vol. 43,

1947, pp. 569-578.

Rasmussen, R. T. C., Electric Smelting at the Bureau of Mines Seeks Utili-

zation of Northwest Ores: Jour. Metals, vol. 4, No. 12, December 1952,

pp. 1276-1277.

Banning, L. H., and Hergert, W. V., Experimental Production of Al-Si

Alloys in a 3-PhaseFurnace: Jour. Metals, vol. 7, No, 5, May 1955,

pp. 630-633.

Fursman, Oliver C., and Banning, Lloyd R., Experimental Smelting of

Aluminum Silicates to Produce Aluminum-Silicon Alloys: Bureau of Mines

Rept. of Investigations 5575, 1960, 23 pp.

il Hayakawa, Y., The Steam Process and Its Mechanisms: Jour. Electrochemical

Assoc. (Japan), No. 16, 1948, pp. 37-42.

Loevenstein, H., Process for Manufacturing of Aluminum: U.S. Patent

2,198,673, Apr. 30, 1940.

2

\

1---

\

/ / ~

\

/ I-=-

\

/ I

\

/ f

\

/

\

I

\

I

I I

I

I

I

I

I

I

I

I

I

I

\

I

I

x

\

I

I

x

/

x

4 x

\

I

x- x - x - x

- x - x -- x --

-- )( -

I Cooling block

2 Condenser

3 AI-Si column

4 Zinc evaporator

x Aluminum

o Silicon

- - Zinc

3

The aluminum-extraction ap-

paratus and process described in

this report were designed to

eliminate the need for very large

quantities of zinc and to reduce

the separate dissolution, filter-

ing, and distillation steps to

manipulative phases of one opera-

tion. It was proposed to perform

the operation at reduced pressure

for higher rates of zinc vapori-

zation at low operating tempera-

tures.

The specific objectives of

the investigation were:

1. To obtain relatively

pure aluminum from alwninum-

silicon alloys.

2. To design, construct,

and test gas and electrically-

heated extraction units.

3. To develop leaching

techniques that require a mini-

mum of zinc and retain the ad-

vantages of zinc as a leaching

agent.

4. To determine optimum

temperature, time, pressure,

particle size, and alloy compo-

sition for maximum extraction

efficiency.

ALUMINUM EXTRACTION PROCESS

The fundamentals of the ex-

traction process are illustrated

j

in fig. 1. Zinc is volatilized

(

from tha lower vessel (3) and

c ~ n d e n s e d to the liquid state in

the upper vessel (1). The liquid

~ zinc is refluxed into the lower

~ vessel (2), which contains a

charge of crushed Al-Si alloy.

Aluminum is selectively leached

from the crude alloy by the

molten zinc and returns with FIGURE 1_ - Fundamentals of Aluminum Extraction.

4

AI-Si alloy; X100, Etch, 0.5 percent HF,

20 seconds.

Zinc completely diffused into AI-Si alloy;

X 100, Etch, 0.5 percent HF, 20 seconds.

Zinc partly diffused into AI-Si alloy; X100,

Etch, 0.5 percent HF, 20 seconds.

Si Sponge, AI and Zn removed; X20.

FIGURE 2. - Diffusion of Zinc Into AI-Si Alloy.

5

the zinc to the lower vessel as an aluminum-saturated zinc alloy. Relatively

little zinc is required by this technique because zinc can be vaporized readily )\

from the aluminum and recycled through the Al-Si alloy many times during the j

extraction operation. After a specified leaching period the upper vessel is ~ ~

cooled below the\melting point of zinc by lowering the water-cooled block (4) . ~ \

The zinc vapors are then condensed to the solid state and retained in the ----- j

upper vessel. Refined aluminum is left in the lower vessel, and a bed of ~

porous silicon and other impurities remains in the leaching vessel.

Photomicrographs of the various stages of the leaching process are shown

in figure 2. View ~ shows the microstructure of the Al-Si alloy before leach-

ing. The large plates and bars are silicon crystals formed when the molten

Al-Si alloy was slowly solidified. The area surrounding these large crystals

is a mixture of Al-Si corresponding closely to the eutectic composition, 88.3

percent aluminum and 11.7 percent silicon.

View B shows a section partly leached with zinc. The dark area at the

bottom right is where zinc has diffused into the crude alloy. The extent of

diffusion is clearly marked by the sharp boundary between the dark and light

area. The microstructure of the alloy after a period of complete leaching is

shown in view f. The silicon crystals appear to dissolve more slowly than the

Al-Si eutectic mixture. The areas about the plates are small channels of Zn-

Al alloy. The porosity of the silicon sponge after removal of zinc and alumi-

num is shown in the photomacrograph, view D.

APPLICATION OF EXTRACTION PROCESS, PROCEDURE AND RESULTS

Crude Alloy Feed

The same crude alloy was used in all tests except those in which the

effect of variations in iron content was studied. Analysis of the alloy re-

vealed the following percentages: Al, 47; Si, 42; Fe, 6.5; and Ti, 4.5.

Induction-Heated Unit

The unit used in the initial phase of the experiment is described in

figure 3. Heat is supplied to the unit by a high-frequency induction coil

(17) which is inductively coupled to a carbon crucible (7). A hollow, quartz

cylinder (22) provides a vacuum-tight enclosure for the various other carbon

vessels shown. Crushed Al-Si alloy is placed in a circular trough like vessel

(2), which has an axial opening for conducting the zinc vapor from the evapo-

ration crucible (la). High rates of zinc evaporation were obtained at rela-

tively low distillation temperatures by reducing the system pressure below

100 microns. Samples for analysis were obtained at the end of each time

interval by shutting off the furnace and allowing it to cool to room tempera-

ture before opening it.

Results of typical extraction experiments with the induction-heated unit

are presented in table 1. The composition of the recovered aluminum was cal-

culated on the basis of 100 percent removal of zinc.

6

5

(J-- {;j -=<J-

I II

18 / 1

I

I I I , , ~ ~

/0 Carbon -evaporation crucible

Ib Carbon-condensing crucible

2 Crude-alloy container

3 Carbon-cooling cylinder

4 Water jacket

5 Cooling-cylinder adjustment

6 Vacuum slipjoint

7 Induction-furnace crucible

8 Insulation

9 I nsulating brick

/0 Carbon spacer

/ I Thermocouple well

/2 Thermocouple channel

/3 Rubber stopper

/4 Water-cooling tubes

/5 Pressure-distribution ring

/6 Adjustment nuts

/7 Induction coil

/8 Induction-furnace housing

/9 Vacuum line

20 Vacuum head

2/ Rubber gasKet

22 Quartz cylinder

o 4 8 12 16 20

Scale, inches

FIGURE 3. - Induction-Heated Unit.

TABLE 1. - Extraction experiments

l

induction-heated unit

Leach Aluminum Total Composition of

Test Zn-A1 temper- Leach avai1- Aluminum aluminum product,

No. ratio ature, period, able, extracted, extracted, percent

cC.

minutes grams grams percent Al Si Fe Ti

1 10.84 500 0-105 172.0 50.9 29.6 97.2 1.6 0.6 0.6

105-165 138.4 30.1 47.0 96.8 2.5 .4 .4

165-225 105.3 19.9 58.5 96.9 2.0 .7 .4

2 9.39 560 0-120 1,341. 0 537.2 40.1 97.8 1.1 .2 .9

120-240 803.8 419.3 71.3 96.9 2.4 .2 .5

240-360 384.5 238.7 89.1 96.4 3.0 .2 .4

3 2.26 580 0-240 990 862.2 87.1 93.8 5.4 Fe+Ti -Y.8

240-480 127.9 127.9 100.0 93.5 5.8 Fe+Ti 1.1.7

1./ Estimated.

7

Test 1 in the table shows approximately 60 percent of the aluminum ex-

tracted after a leaching period of 225 minutes. The aluminum content of the

product after removal of zinc was 96.9

Test 2 shows about 90 percent of the

uct 96.4 aluminum and 3.0

recovered as a final prod-

silicon.

In test 3, a 100-percent aluminum extraction was achieved, but the

nurn 5.8 percent silicon. A very low zinc-to-aluminum ratio .26:1)

was used in this test. Although 100-percent aluminum extraction was achieved,

the final product contained a perc of impurities due primarily to a

higher leaching temperature and a longer leaching period.

Calculated rates of aluminum extraction for these tests are illustrated

in 4. The rate increased with increasing leaching temperature,

silicon contamination also increased from 2 to 3 percent between tests 1 and 2

and from 3 to 6 percent between tests 2 3.

c:

Q)

u

(;;

D-

o

w

f-

U

0::

f-

X

w

::2:

z

::2:

-l

-'

f-

0

f-

40

20

60 120 180 240

TIME, minutes

300 360

FrGURE 4. - Extraction of AI num From AI-Si AI loy.

420 480

An electrical-resistance furnace was constructed to include the features

shown in figure 5. The 24- by 20- by 7-inch, box-shaped evaporator (8) was

made large and shallow to provide a maximum evaporation area with a minimum

8

6

LEGEND

_ Steel

n::::::l Graphite

~ Insulating brick

IlII1Ill Rubber

Cooling coils

o Heating elements

2

.

o 2 4 6 8

-- -- Scale, inches

2

3

4

5

6

T

8

9

10

/I

12

II

Condenser adjustment

Water-cooled jacket

Condenser sleeve

Condenser

Leaching column

Thermocouple wells

Alloyreturn conduit

Evaporator

Vacuum port

Vapor conduit

Vacuum-tight enclosure

Collector plate

FIGURE 5_ - Electrical-Resistance-Heated Unit.

6

of zinc. The condenser (4) was an inverted cup-shaped vessel that could be

raised or lowered inside of a water-cooled metal jacket (2). The zinc vapor

passed from the evaporator through a heated conduit (10) to the top of the

10-inch-diameter leaching column (5). Zinc vapor was condensed to the liquid

state in the condenser and refluxed into the bed of Al-Si alloy below. Alu-

minum was leached from the alloy as the zinc passed through the alloy bed.

The Al-Zn alloy was collected in the annular recesses of a removable collector

plate (12) and transferred through the return line (7) into the evaporator. A

9

liquid-metal trap was provided in the return line to prevent eroded silicon

particles from becoming mechanically entrapped in the Zn-Al alloy and carried

into the evaporator. The floor of the evaporator was elevated at the entrance

so that the molten Zn-Al flowed some distance over the heated floor be-

fore it reached the main of molten metal. The turbulence caused in the

metal this action provided more metal surface for evaporation and reduced

the tendency for aluminum to concentrate at the evaporating surface as the

alloy became depleted of zinc. Separate heating elements were provided for

the various compartments. elements were not installed about the

leaching column (5), since it was believed that a little heat would be needed

in this area to compensate for conduction and radiation losses. The principal

advantages of this unit over the induction-heated unit are: (1) Greater evap-

oration area in proportion to the amount of zinc, (2) greater available volume

in the extraction vessel, and (3) easier removal of products.

Several unforeseen characteristics were observed when the

unit was put in operation. The erature of the leaching column continued

to rise for some time after the heat had been turned off and external cooling

had been applied. Also, the condenser cooling capacity was far less than ex-

pected because the actual heat conduction from the graphite condenser to the

cooling jacket was lower than estimated. However, tests were continued since

the work schedule did not extensive modification of the unit.

The results for a typical operation follow:

The evaporator was stabilized at 580

0

C. Under these conditions, the

condenser temperature stabilized at 458

0

C. and the leaching column era-

ture at 455

0

C. The test was run for 8 hours; this period 48.1 percent

of the aluwinum was extracted. The final product showed 98.4 percent aluminum,

1.5 silicon, and less than 0.2 percent iron plus titanium. Although

this recovery was lower than that for the induction-heated unit, the quality

of the aluminum extracted was ly improved.

The observed rate of zinc was considerably less than the

theoretical maximum rate corresponding to the temperature and surface area

of the evaporator. Factors contributing to the low recovery were: (1) Zinc

was not being evaporated from a pure zinc bath, and (2) the failure of the

small zinc-vapor conduit leading into the leaching column to permit free

escape of zinc vapors from the evaporation crucible.

The NichromeZl electrical heating elements showed appreciable deteriora-

tion after 50 hours of operation under vacuum.

Gas-Fired Unit

Neither of the electrical units to offer promis

possibilities for practical application because of the high cost per unit of

7/ Reference to specific makes or models of equipment is made to facilitate

understanding and does not imply indorsement of such devices by the

Bureau of Mines.

10

/0

o 2 4 6 8 10 12

Scale, inches

/ Furnace insulation 6 Condenser

2 Evaporator T Vacuum line

3 Vapor conduit 8 Leaching column

4 Cooling coil 9 Alloy-return conduit

5 Thermocouple well /0 Water-cooled end plate

/ / Combustion chamber

FIGURE 6_ - Gas-Fired Unit.

/0

heat and the rela-

tive difficulty in

conducting it into

a vacuum. A gas-

fired unit was con-

structed to examine

the problems in

this type of heat-

ing. Thea e per-

tained primarily to

furnace design and

construction mate-

rials. Materials

with high thermal

conductivity and

corrosion resist-

ance were required,

and the design

would have to pro-

vide optimum condi-

tions for the proc-

ess. Features of

the gas-fired ex-

traction apparatus

are shown in fig-

ure 6. The zinc

evaporation cham-

ber (2) is posi-

tioned horlz-ontally

below the vertical

leaching column (8).

The purpose is to

expose a maximum

surface area of

mol ten zinc for

maximum rates of

evaporation. The

zinc-evaporator

section consists

of an outside shell

of stainless steel,

29 inches long,

with a l/4-inch

wall thickness and

a 4-1/2-inch inside

diameter. A graph-

ite inner liner is

used as the cruci-

ble to retain 30 pounds of zinc charge and protect the shell from attack by

the zinc.

Zinc vapors are conveyed from the evaporation crucible to the condenser

through a 4-inch-inside-diameter, graphite-lined stainless steel pipe (3),

The condenser (6) is a water-cooled iron cylinder closed at the bottom and

protected on the furnace side by a graphite sleeve. The condenser extends

into the leaching section so that the flanged, open end engages a mating

flange on the leaching column. A rubber gasket is used to make a vacuum-

tight seal. The condensing temperature is controlled by varying the rate of

circulation of water or air through the open end of the condenser.

11

The leaching column comprises a cylindrical, stainless steel outer shell

protected by a 1/4-inch-thick graphite liner. The column has a charge capac-

ity of 20 pounds of crushed Al-Si alloy. A graphite-lined stainless steel

pipe joins the leaching column to the evaporation chamber and serves as a

return line (9) for the molten Zn-Al alloy.

This design was intended to permit separate controls for heating each

basic section of the unit (condenser, leach column, and evaporator) to within

a few degrees of the desired temperature.

Results of tests with the gas-fired extraction unit are shown in table 2.

The percentage of aluminum recovered increased approximately linearly within

the 448

0

to 475

0

C. temperature range. This is in agreement with results of

extraction for tests run in the induction-heated unit in which extraction rate

is uniform up to about 40 percent aluminum extraction.

STUDY OF PROCESS CONDITIONS

The preceding tests were devoted primarily to an investigation of the

effects of various combina-tions of leaching temperature and time of aluminum

extraction efficiency. Additional experiments were run to determine the

parameters for other process conditions including system pressure, particle

size, alloy composition, and the relative merits of liquid and vaporous zinc

as leaching agents.

TABLE 2. - Extraction experiments, gas-fired unitl

l

Leach Aluminum Average Composition of product,

Test No. temperature, recovered, extraction rate, percent

C. percent grams per minute Al Fe Si Ti

1 ...... 448 19.9 1.61 94.09 0.28 5.62 10.01

2 451 22 .5 1.81 94.92 .64 4.42 .02

3 ...... 458 25.3 2.03 95.46 .04 4.50 .005

4 ...... 462 27.4 2.20 93.78 .11 6.09 .02

5 .. 475 35.6 2.85 93.59 .15 6.2 .06

II Leaching period, 240 minutes; Zn-Al ratio, 2.12; charge for each test,

10 pounds.

Pressure

The beneficial effects of performing the extraction in a vacuum enclosure

are shown in table 3. In the a tests, part of an Al-Si alloy was held under a

12

cover of molten zinc for 2 hours at 500

0

and 600

0

C., at a pressure of 25

microns. The zinc was prevented from evaporating by a tightly-fitting cover.

The tests were then duplicated (tests b) in a system filled with an inert gas

at atmospheric pressure.

Results of these experiments show that dissolution of aluminum at low

pressure is approximately 20 times greater than at atmospheric pressure. How-

ever, the disso1utio n of silicon also increas es at reduced pressure. As

expected, the solubilities of silicon and aluminum are greater at higher

temperatures. It is believed that the increase in leaching rate at reduced

pressure can be attributed in part to the absence of gas films and absorbed

gases within the alloy, which would tend to prevent the zinc from wetting the

Al-Si surfaces.

TABLE 3. - Effect of pressure on dissolution of aluminum

Relative

Test Time, Tempera- Pressure, Aluminum Silicon extraction ratio AI-Si

No. minutes ture, millimeters extracted, extracted, Al Si ratio

OCt

Hg percent percent (a):(b) (a):(b)

a 120 500 0.025 7.86 0.25 20.2 1.25 31.4

b 120 500 760 .36 .20 1.95

a 120 600 .025 18.11 .89 23.2 4.5 20.3

b 120 600 760 .78 .20

3.9

Leaching

A series of tests was G0n-duGted to determin-e the relative effectiveness

of liquid zinc and zinc vapors as leaching agents. Table 4 shows the results

of tests using liquid zinc only. Leaching was accomplished by passing zinc,

at several selected rates, through a vertical evacuated column of crushed

Al-Si alloy. Leaching efficiencies were determined by analysis of the amount

of aluminum dissolved by the zinc during transit through the column. Tempera-

ture within the column was maintained at 475

0

C. for each test.

Results show that the ratio of aluminum extracted per gram of zinc

decreased as the flow rate of zinc increased. However, the total weight of

aluminum recovered was greatest at the highest zinc flow rate. Aluminum

extraction ranged from 1 percent at a rate of 25,.4 grams of zinc per minute

to 4 percent at a rate of 66.7 grams per minute.

The effect of zinc vapor on leaching was studied with a modified smal1-

scale reflux-leaching unit in which the vapors were condensed directly on the

A1-Si alloy during the leaching cycle instead of refluxing liquid zinc through

the alloy. This procedure exposed the alloy to high concentrations of zinc

vapor for a short period of time until liquid-vapor equilibrium conditions

were established in the leaching column. Distillation of zinc into the Al-Si

alloy bed was continued until approximately the same amount of zinc was dis-

tilled as had been passed through the alloy in the liquid-leaching tests.

However, due to the restricted evaporation surface area, it was impossible

to achieve distillation rates comparable to the liquid-zinc flow rates.

13

The results of these tests are shown in table 5. The aluminum extracted

ranged from 8 to 28 percent. Although the two groups of tests are not compa-

rable in every respect because of differences in leaching time and the amount

of zinc used, they reveal two significant observations. First, zinc in the

vapor state penetrates more thoroughly than liquid zinc into the smallest

interstices of the aluminum particles where it gradually condenses to the

liquid state. Second, the Al-Si particles are more thoroughly wetted by the

vapor than by the liquid zinc. These observations indicate that the zinc

vapor contributes markedly to the extraction efficiency by saturating the

AI-Si particles to a greater degree than liquid zinc. However, after the

initial penetration and saturation of the Al-Si alloy, liquid zinc probably

leaches as effectively as zinc vapor.

TABLE Lt. - Liquid-Zinc leaching ..

hI

Zinc Aluminum Aluminum extracted

Test No. Zinc flow rate, used, extracted, per gram zinc used,

grams per minute grams grams grams

l .... a ....... 25.4 721 4.69 0.0065

2-a. ,. ..... 38.0 1,114 6.57 .0059

3 ..... a .. 11 51.1 1,499 7.19 .0048

4-a ..... 66.7 2,164 9.31 .0043

11 Leach temperature, 475

0

C.; pressure, 0.05 millimeters.

TABLE 5. - Zinc-vapor leaching

11

Zinc Aluminum Aluminum extracted per

Test No. distilled, extracted, gram zinc distilled,

grams

21

grams grams

I-b" . 41. " II II " II III .. II " II II

768 33.7 0.044

2 .... b .. II II II II"."" II." II. II II 768 29.7 .039

3-b .................. 1,536 102.6 .067

4-b" . " II " " " ...... II II " II II

2,496 118.6 .044

11 Leach temperature, 475

0

C.; pressure, 0.05 millimeters.

~ I Based on experimentally determined distillation rate of 8.05

grams per minute.

During the regular aluminum extraction tests the extraction rates varied

among tests conducted at identical temperature, time, and pressure conditions.

An examination of the AI-Si charge material for these tests showed that vari-

ations of the average particle size of the charge resulted in differences in

the aluminum extracted from the alloy. Therefore, a series of tests was made

to compare the aluminum extracted from different-sized pieces of AI-Si alloy.

Each size group was tested for 3 hours at leaching temperatures of 450

0

, 475,

and 500

0

C. Results of these experiments are shown in table 6,

Within the optimum leaching-temperature range (450

0

-500 C.) the minus

3/4- plus 1/2-inch charge material yielded the highest aluminum recovery.

When small pieces of Al-Si alloy were used, much zinc was retained in the

leaching column, usually enough to form a shallow pool of liquid metal on top

of the crushed alloy. The solids were too compact to allow the free flow of

14

zinc through the leaching column back to the evaporator section. Tests with

minus 1- plus 3/4-inch material showed a better aluminum recovery than tests

with the smaller material, but recovery was less than in tests with minus 3/4-

plus 1/2-inch material treated in the same way. In the case of the large mate-

rial, penetration of zinc vapor and liquid into the alloy was not as rapid or

as complete owing to the smaller total surface area exposed and the larger size

of the Al-Si alloy particles.

The amount of aluminum extracted from the minus 3/4- plus 1/2-inch mate-

rial was 5 to 10 percent greater than that from the other sizes.

TABLE 6. - Effect of alloy particle size on leaching

1

/

Leach Average rate of

Test

Al-Si alloy particle ternpera- Aluminum Aluminum aluminum

No. average diameter,

ture, extraction, extraction, extraction,

inches C. grams percent grams per minute

1 -1/2, +1/4 450 63.1 15.0 0.35

2 -3/4, +1/2 450 105.9 25.2 .59

3 -

1, +3/4 450 65.2 15.5 .36

4 -1/2, +1/4 475 174.5 41.5 .97

5 -3/4, +1/2 475 217.6 51.7 1.21

6

-

1, +3/4 475 199.4 47.5 1.11

7 -1/2, +1/4 500 208.5 49.6 1.16

8 -3/4, +1/2 500 252.5 60.1 1.40

9 - 1, +3/4 500 209.0 49.8 1.17

1/ Leaching time, 3 hours; distillation temperature, 550

0

C.

Investigation of the effect of iron content on the efficiency of aluminum

extraction from Al-Si alloys showed an increase in leaching efficiency with an

increase in the iron content of the alloys. Table 7 gives results of tests in

which Al-Si alloys containing 5.25, 10.2, and 13.7 percent iron were leached

at 500

0

C. for 1 to 3 hours.

TABLE 7. - Effect of Al-Si alloy iron content on aluminum extraction

Iron in Al-Si alloy, Time, Aluminum extracted,

Test No. nominal percentl/ hours percent

1 ............... 5 1 6.45

2 ... 10 1 9.53

3 ........ 13 1 12.16

4 .... 5 2 10.24

5 ... 10 2 15.43

6 . 13 2 23.9

7 .. 5 3 40.3

8 .......... 10 3 46.1

9 .. 13 3 70.8

Charge analysis, percent:

Tests 1, 4, 7--Fe, 5.25; Si, 42.2; AI, 51.0; Ti, 1.5.

Tests 2, 5, 8--Fe, 10.2; Si, 33.9; AI, 50.6; Ti, 5.3.

Tests 3, 6, 9--Fe, 13.7; Si, 35.9; AI, 45.3; Ti, 5.1.

15

The only physical differences observed among the alloys were in porosity

and brittleness; these were greater in the alloy with the highest iron con-

tent. The greater porosity is believed to allow the zinc vapors to penetrate

more rapidly and thoroughly into the AI-Si particles to dissolve aluminum at a

faster rate. Specimens of the alloys prepared for X-ray diffraction analysis

showed no apparent phase differences between the alloys.

CONCLUSIONS

The following conclusions are drawn from the results of these

investigations:

1. The reflux leaching method is an effective means for extracting alumi-

num from crude AI-Si alloy. Aluminum obtained by this method will contain

from I to 6 percent silicon, 0.04 to 0.8 percent iron, and 0.01 to 0.9 percent

titanium. With only minor changes in composition by dilution of impurities

with pure aluminum, the leached aluminum would serve as a base alloy for pro-

ducing approximately 50 percent of the commercially used sand-casting alloys.

2. Dissolution of aluminum and silicon increases with increasing leaching

temperature, and the rate of dissolution is affected by alloy particle size,

iron content, and the system pressure.

3. The rate of aluminum extraction is approximately linear with respect

to time between 0- and 40-percent extraction. Complete removal of aluminum

can be obtained,although the advantage of complete extraction at low leaching

temperatures may be lost to the unwarrantable expense of time.

4. It is desirable to maintain the sys tem pressure at 100 microns or

lower. The rate of aluminum extraction is increased about 20 times by decreas-

ing the pressure from atmospheric pressure to a pressure of 100 microns or less.

5. Aluminum extraction can be accomplished with relatively little zinc as

the leaching agent by a continuous cycle of operation including evaporation,

condensation, leaching, and reevaporation.

6. The optimum AI-Si alloy particle size for leaching is one large enough

to permit a relatively free flow of zinc through the leaching column and small

enough to allow rapid penetration of the zinc into the leach material. Experi-

mental results indicate an optimum particle size of minus 3/4- plus 1/2-inch.

7. Aluminum extraction is increased by using Al-Si alloys containing

increased amounts of iron. The porosity of the alloy appears to become greater

as the iron content increases and allows more rapid penetration of zinc into

the alloy particles.

FUTURE RESEARCH

Continuation of the research and development program reported here

includes a number of larger scale extraction tests to supplement data obtained

in the small-scale work and to reveal difficulties which may be encountered in

large-scale operations. Equipment for these tests has been designed for 100-

pound charges of the alloy. Studies will be continued on the effect of various

AI-Si alloy constituents on leaching rates and efficiency of aluminum recovery.

An investigation of the properties of the silicon residues will be made to

determine the possibilities of developing processing methods to produce a

usable product from this material.

fNT.-BU.OF MINES,PGH. ,PA. 2456

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Crude Distiller RBI Intro (Updated)Document31 pagesCrude Distiller RBI Intro (Updated)harrinsonf100% (2)

- University of Cambridge International Examinations International General Certifi Cate of Secondary EducationDocument16 pagesUniversity of Cambridge International Examinations International General Certifi Cate of Secondary EducationHiphop602No ratings yet

- How To Hardface: The Ten-Step ApproachDocument2 pagesHow To Hardface: The Ten-Step ApproachCarlos Anibal OrtizNo ratings yet

- 1 Pirastro Violin Abril 2019Document7 pages1 Pirastro Violin Abril 2019Kely KurtzNo ratings yet

- Solaf SPM Chemistry Electrochemistry: Electrolytes and Non-ElectrolytesDocument21 pagesSolaf SPM Chemistry Electrochemistry: Electrolytes and Non-ElectrolytesSiti Aishah ZolkanainNo ratings yet

- Group 2 Non Ferrous Metal ME3Document52 pagesGroup 2 Non Ferrous Metal ME3ELLIENo ratings yet

- Ribeirodossantos 2019Document7 pagesRibeirodossantos 2019Mauricio FariaNo ratings yet

- Stainless Steel Grade 202 (UNS S20200)Document3 pagesStainless Steel Grade 202 (UNS S20200)MuhammadJawadNo ratings yet

- Chemistry - Chemical Equations WorksheetDocument2 pagesChemistry - Chemical Equations WorksheetKareesh ShamilsanNo ratings yet

- 4.3: Reaction Stoichiometry: Learning ObjectivesDocument6 pages4.3: Reaction Stoichiometry: Learning ObjectivesRicki HanNo ratings yet

- Final Exam Practice ProblemsDocument7 pagesFinal Exam Practice ProblemsAuto CadNo ratings yet

- Chapter 3Document24 pagesChapter 3Rayn OutlawNo ratings yet

- TermochemistryDocument20 pagesTermochemistryMasitah Abu BakarNo ratings yet

- Emission Factors in KG CO2-equivalent Per UnitDocument4 pagesEmission Factors in KG CO2-equivalent Per Unitkrishna somaNo ratings yet

- AFT Lab ProcedureDocument34 pagesAFT Lab ProceduresubrassNo ratings yet

- Song 2017Document5 pagesSong 2017201400738No ratings yet

- Balancing Redox Reactions Acidic ConditionsDocument3 pagesBalancing Redox Reactions Acidic ConditionsCtNo ratings yet

- The Effect of Slag Modeling To Improve Steelmaking Processes PDFDocument12 pagesThe Effect of Slag Modeling To Improve Steelmaking Processes PDFPaulo J. C. EstevesNo ratings yet

- The Actinides - David A. JohnsonDocument14 pagesThe Actinides - David A. JohnsonAni MoNo ratings yet

- 11 Introduction To Engineering MaterialsDocument20 pages11 Introduction To Engineering MaterialsomkardashetwarNo ratings yet

- Atoms: Frederick A. Bettelheim William H. Brown Mary K. Campbell Shawn O. FarrellDocument45 pagesAtoms: Frederick A. Bettelheim William H. Brown Mary K. Campbell Shawn O. FarrellShereen Al-ObinayNo ratings yet

- Method 8.7 - Refined Sugar: Reducing Sugars by The Knight and Allen MethodDocument3 pagesMethod 8.7 - Refined Sugar: Reducing Sugars by The Knight and Allen Methodmari100% (1)

- Specification Guide: Chrome High Temp Fittings & FlangesDocument4 pagesSpecification Guide: Chrome High Temp Fittings & FlangesAdrian EspinosaNo ratings yet

- Ammonia Combustion Catalysts - Review by HinokumaDocument8 pagesAmmonia Combustion Catalysts - Review by HinokumaAnanthakishnanNo ratings yet

- Aluminium NitrateDocument3 pagesAluminium NitrategumtammNo ratings yet

- Balanced EquationDocument13 pagesBalanced EquationMiha FlorentinaNo ratings yet

- SP1Document25 pagesSP1mugu12No ratings yet

- 1.2 The Periodic Table QPDocument36 pages1.2 The Periodic Table QPMaheenNo ratings yet

- 2.COA of Potassium NitrateDocument3 pages2.COA of Potassium NitrateJeisson DazaNo ratings yet

- Chemical Storage Guide: and Other HealthDocument1 pageChemical Storage Guide: and Other HealthVictorNo ratings yet