Professional Documents

Culture Documents

Cranes

Cranes

Uploaded by

hazopmanCopyright:

Available Formats

You might also like

- SS 497 - Code of Practice For Design, Safe Use and Maintenance of Gantry CranesDocument20 pagesSS 497 - Code of Practice For Design, Safe Use and Maintenance of Gantry CranesTest75% (4)

- Basic Scaffolding Questions AnswersDocument11 pagesBasic Scaffolding Questions AnswersSomu Mahadevan89% (28)

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingFrom EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingRating: 5 out of 5 stars5/5 (9)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Control To Temp EquipmentDocument84 pagesControl To Temp EquipmentSteven FlynnNo ratings yet

- Safe Design and Maintenance of MEWPsDocument28 pagesSafe Design and Maintenance of MEWPsAnish BabuNo ratings yet

- CE-Standards Englisch PDFDocument1,263 pagesCE-Standards Englisch PDFHorstS123No ratings yet

- Suspended ScaffoldsDocument29 pagesSuspended ScaffoldsJason Leo100% (1)

- Sensing and Monitoring Technologies for Mines and Hazardous Areas: Monitoring and Prediction TechnologiesFrom EverandSensing and Monitoring Technologies for Mines and Hazardous Areas: Monitoring and Prediction TechnologiesNo ratings yet

- Radar and ARPA Manual: Radar, AIS and Target Tracking for Marine Radar UsersFrom EverandRadar and ARPA Manual: Radar, AIS and Target Tracking for Marine Radar UsersRating: 4.5 out of 5 stars4.5/5 (6)

- Pages From Model Code of Safe Practice Part 21 Sample PagesDocument10 pagesPages From Model Code of Safe Practice Part 21 Sample Pageshazopman0% (2)

- Lift Standards - A GlossaryDocument6 pagesLift Standards - A GlossaryUsmanKhanNo ratings yet

- Secondary Venting ArrangementDocument6 pagesSecondary Venting Arrangementir_azlan_aziz860No ratings yet

- BS 6911-3 Testing Earth-Moving MachineryDocument12 pagesBS 6911-3 Testing Earth-Moving Machinerytariq0% (1)

- K19400 - K19410 Operation ManualDocument18 pagesK19400 - K19410 Operation ManualManta SystemsNo ratings yet

- Cylinder Retest StationsDocument8 pagesCylinder Retest StationsjosearrietacoNo ratings yet

- Cranes, Hoists and Winches: Part 1: General RequirementsDocument11 pagesCranes, Hoists and Winches: Part 1: General RequirementsMilton FernandesNo ratings yet

- 04 Moduspec Justin Nally PDFDocument25 pages04 Moduspec Justin Nally PDFmojtaba_m007No ratings yet

- Offshore Mooring StandardsDocument8 pagesOffshore Mooring StandardsradrottenNo ratings yet

- K46000 - K46001 Operation ManualDocument14 pagesK46000 - K46001 Operation Manualmoh_ichwanuddinNo ratings yet

- HKV4000 Operation ManualDocument30 pagesHKV4000 Operation Manualk5sksngkdsNo ratings yet

- Easa Ad 2015-0226 1Document7 pagesEasa Ad 2015-0226 1Pavlos TsitswnisNo ratings yet

- Leea 025 PDFDocument7 pagesLeea 025 PDFmuhammad usman shahabNo ratings yet

- Is 14665Document7 pagesIs 14665Vijay ChaudharyNo ratings yet

- Overhead Crane Hoists eDocument20 pagesOverhead Crane Hoists eAltayeb YassinNo ratings yet

- Operation and Instruction ManualDocument21 pagesOperation and Instruction ManualZamir Danilo Morera ForeroNo ratings yet

- BS2655-8 1971Document20 pagesBS2655-8 1971Liquor LiamNo ratings yet

- LR Guidance For LifeboatsDocument6 pagesLR Guidance For LifeboatsPan Karas XtraNo ratings yet

- Disclosure To Promote The Right To InformationDocument68 pagesDisclosure To Promote The Right To Informationvb_2009_eeeksNo ratings yet

- Anchor Winches Offshore BS 7464Document10 pagesAnchor Winches Offshore BS 7464Moheb BotrosNo ratings yet

- XBLR3101 - OSH Legislation W3-W5Document28 pagesXBLR3101 - OSH Legislation W3-W5Islah DeanNo ratings yet

- Inspection of TanksDocument15 pagesInspection of Tankskakababa117No ratings yet

- 120405105407SS 497-2011-PreviewDocument7 pages120405105407SS 497-2011-PreviewAnonymous NUn6MESx0% (1)

- Escalators - Safety Rules 1 PDFDocument32 pagesEscalators - Safety Rules 1 PDFElmerNo ratings yet

- Simple Pressure Vessel Directive GuideDocument6 pagesSimple Pressure Vessel Directive GuidethunderNo ratings yet

- Railways and EMC DirectiveDocument5 pagesRailways and EMC DirectiveDozie KesiemeNo ratings yet

- 447 2006 - The European en 1337 On Structural BearingsDocument21 pages447 2006 - The European en 1337 On Structural BearingsGeorge ChristodoulidisNo ratings yet

- Energy Efficiency of Industrial Trucks - Test Methods - Container Straddle CarriersDocument13 pagesEnergy Efficiency of Industrial Trucks - Test Methods - Container Straddle CarriersHamouda EL Sayed Safan100% (1)

- Gearboxes Full RangeDocument65 pagesGearboxes Full RangeleoNo ratings yet

- Dvis 2Document2 pagesDvis 2Vinu KumarNo ratings yet

- Revised Guidelines For The Approval of Equivalent Fixed Gas Fire-Extinguishing Systems, As Referred To in Solas 74, For Machinery Spaces and Cargo Pump-RoomsDocument18 pagesRevised Guidelines For The Approval of Equivalent Fixed Gas Fire-Extinguishing Systems, As Referred To in Solas 74, For Machinery Spaces and Cargo Pump-RoomsDanial Haidhar YusoffNo ratings yet

- Lifting Equipment Engineers Association Part 1 Entry Examination CourseDocument22 pagesLifting Equipment Engineers Association Part 1 Entry Examination CourseMohmed AllamNo ratings yet

- Amendment in MarpolDocument10 pagesAmendment in MarpolGaurav Kumar SinghNo ratings yet

- Cranes-Design Principles For Loads and Load CombinationsDocument10 pagesCranes-Design Principles For Loads and Load CombinationsEnrique Santiago BenavidesNo ratings yet

- LEEA-059-2 Documentation and Marking - Part 2 Powered Lifting MachinesDocument6 pagesLEEA-059-2 Documentation and Marking - Part 2 Powered Lifting MachinesnoormanmubarakNo ratings yet

- Cps Crane MaintenanceDocument13 pagesCps Crane MaintenanceTarek HareedyNo ratings yet

- Pad EyesDocument60 pagesPad Eyesjuyta100% (1)

- Code of Practice For Safe Working On LiftsDocument52 pagesCode of Practice For Safe Working On Liftsavel bas100% (1)

- 12 2.1 E Student 008414 Marker 273Document3 pages12 2.1 E Student 008414 Marker 273BlissNo ratings yet

- E100 E100g MedDocument4 pagesE100 E100g MedDuong DoNo ratings yet

- Escalator Rehabilitation Specifications - Rev 1Document58 pagesEscalator Rehabilitation Specifications - Rev 1Nordiana IdrisNo ratings yet

- ESH 048 ForkliftsDocument31 pagesESH 048 ForkliftsJosh RuddyNo ratings yet

- Kik-kop-40-Pe-ge-0016-0 - Linear Actuator Override Tool Operation & Maintenance ManualDocument27 pagesKik-kop-40-Pe-ge-0016-0 - Linear Actuator Override Tool Operation & Maintenance ManualKhalid AliNo ratings yet

- Shop Maintenance Inspection, Service, Test & Release Screw Conveyor - Auger I. ScopeDocument3 pagesShop Maintenance Inspection, Service, Test & Release Screw Conveyor - Auger I. ScopeIdowu MayowaNo ratings yet

- Auditac - Press Release Nr. 2: New Documents and Tools Released by The Auditac ProjectDocument2 pagesAuditac - Press Release Nr. 2: New Documents and Tools Released by The Auditac Projectchristheo54787No ratings yet

- Automated Guided Vehicle Systems: A Primer with Practical ApplicationsFrom EverandAutomated Guided Vehicle Systems: A Primer with Practical ApplicationsNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Reliability of High-Power Mechatronic Systems 1: Aerospace and Automotive Applications: Simulation, Modeling and OptimizationFrom EverandReliability of High-Power Mechatronic Systems 1: Aerospace and Automotive Applications: Simulation, Modeling and OptimizationNo ratings yet

- Abb PDFDocument9 pagesAbb PDFhazopmanNo ratings yet

- Safety and Health Topics - Hydrogen Sulfide - Evaluating and Controlling ExposureDocument3 pagesSafety and Health Topics - Hydrogen Sulfide - Evaluating and Controlling ExposurehazopmanNo ratings yet

- ProcedureDocument1 pageProcedurehazopmanNo ratings yet

- Faset: Review of Significant Changes To EN 1263-2 2002Document1 pageFaset: Review of Significant Changes To EN 1263-2 2002hazopmanNo ratings yet

- SC 15Tw: Scanjet Tank Cleaning EquipmentDocument1 pageSC 15Tw: Scanjet Tank Cleaning EquipmenthazopmanNo ratings yet

- InControl 1 2013 enDocument12 pagesInControl 1 2013 enhazopmanNo ratings yet

- Honeywell Sensors and Switches in Mobile - Cranes - 009586-2-En - LowresDocument2 pagesHoneywell Sensors and Switches in Mobile - Cranes - 009586-2-En - LowreshazopmanNo ratings yet

- MSHA Regulation EZcomplianceDocument12 pagesMSHA Regulation EZcompliancehazopmanNo ratings yet

- Shiploader Rev2 27may2010Document24 pagesShiploader Rev2 27may2010hazopmanNo ratings yet

- Avoid Outrigger FailureDocument1 pageAvoid Outrigger FailurehazopmanNo ratings yet

- Bucket Truck Safety-PioneerDocument4 pagesBucket Truck Safety-PioneerhazopmanNo ratings yet

- Rollover Hangtag LaserresDocument2 pagesRollover Hangtag LaserreshazopmanNo ratings yet

- PDF 01 ControlsDocument6 pagesPDF 01 ControlshazopmanNo ratings yet

- Ten Points For Safe LiftDocument8 pagesTen Points For Safe LifthazopmanNo ratings yet

- 1926.1400 Convenient Pocket CardsDocument6 pages1926.1400 Convenient Pocket CardshazopmanNo ratings yet

- Forklift ChecklistDocument4 pagesForklift ChecklisthazopmanNo ratings yet

- Safety & Maintenance Inspection - Stellar Cranes Daily V0810.1Document1 pageSafety & Maintenance Inspection - Stellar Cranes Daily V0810.1hazopmanNo ratings yet

- Safety Alert177Document1 pageSafety Alert177hazopmanNo ratings yet

- Methods of Approximation and Determination of Human Vulnerability For Offshore Major Accident Hazard AssessmentDocument55 pagesMethods of Approximation and Determination of Human Vulnerability For Offshore Major Accident Hazard AssessmenthazopmanNo ratings yet

- Jihyd-11846 YemkejDocument92 pagesJihyd-11846 YemkejhaNo ratings yet

- RUBRICS For ACTIVITY MIL - Camera ShotsDocument2 pagesRUBRICS For ACTIVITY MIL - Camera ShotsJaeneth SimondoNo ratings yet

- ED-UCCP-201401A-Packaged Water Cool PDFDocument38 pagesED-UCCP-201401A-Packaged Water Cool PDFHui HuaNo ratings yet

- Afd 021019 1 1B 50Document100 pagesAfd 021019 1 1B 50Sab-Win DamadNo ratings yet

- Construction and Working Principle of Transformers, ItsDocument12 pagesConstruction and Working Principle of Transformers, ItsSandeep Joshi100% (1)

- Education Research and Development 9sometimes Called ResearchDocument4 pagesEducation Research and Development 9sometimes Called ResearchFirmanNo ratings yet

- DRRR Module 8 Concept of Disaster Risk Reduction and ManagementDocument22 pagesDRRR Module 8 Concept of Disaster Risk Reduction and ManagementJodie CabreraNo ratings yet

- Physics: FlashbackDocument2 pagesPhysics: FlashbackWonderlapseNo ratings yet

- Iot Enabled Aquatic Drone For Environmental Monitoring: João Matos, Octavian PostolacheDocument6 pagesIot Enabled Aquatic Drone For Environmental Monitoring: João Matos, Octavian PostolacheVinit Lambey (Ph.D. Student)No ratings yet

- 2011 566277Document22 pages2011 566277pascal_h_1No ratings yet

- Joining Form IndigoDocument2 pagesJoining Form IndigodkasrvyNo ratings yet

- 6308 13236 1 PBDocument6 pages6308 13236 1 PBDwiyan TeguhNo ratings yet

- Basic CryptanalysisDocument22 pagesBasic Cryptanalysisyohan suryaNo ratings yet

- Annex 1 Reg 15 Control of Discharge of OilDocument2 pagesAnnex 1 Reg 15 Control of Discharge of OilsibinmgNo ratings yet

- Mathematical Thinking Skills of BSED-Math Students: Its Relationship To Study Habits and Utilization of SchoologyDocument18 pagesMathematical Thinking Skills of BSED-Math Students: Its Relationship To Study Habits and Utilization of SchoologyPsychology and Education: A Multidisciplinary JournalNo ratings yet

- Simin BehbahaniDocument4 pagesSimin Behbahanisyedabreeha bukhariNo ratings yet

- DHCP - DORA Process Call Flow WifiDocument18 pagesDHCP - DORA Process Call Flow WifiArjunAslekarNo ratings yet

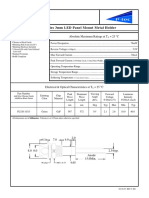

- PL320 Series 3mm LED Panel Mount Metal Holder: Features Absolute Maximum Ratings at T 25 °CDocument1 pagePL320 Series 3mm LED Panel Mount Metal Holder: Features Absolute Maximum Ratings at T 25 °CJajang JajaNo ratings yet

- Election New PPT - 231125 - 174550.pdf - 20231125 - 174959 - 0000Document12 pagesElection New PPT - 231125 - 174550.pdf - 20231125 - 174959 - 0000T SERIESNo ratings yet

- Digital BankingDocument3 pagesDigital BankingDPC Gym100% (1)

- Critical Response Paper No.2Document4 pagesCritical Response Paper No.2Glenn SentesNo ratings yet

- Donald Redford - Akhenaten - New Theories and Old FactsDocument27 pagesDonald Redford - Akhenaten - New Theories and Old FactsDjatmiko TanuwidjojoNo ratings yet

- Applying Theorems On Triangle Inequalities (Exterior Angle Inequality Theorem)Document3 pagesApplying Theorems On Triangle Inequalities (Exterior Angle Inequality Theorem)leonardoalbor05No ratings yet

- Idol Remote Instruction For Copying Face To Face - Product NumberDocument3 pagesIdol Remote Instruction For Copying Face To Face - Product NumberMarcNo ratings yet

- Fortinet Brand Guidelines Partnerv2.3Document13 pagesFortinet Brand Guidelines Partnerv2.3Betiana BoikoNo ratings yet

- Option B - BiochemistryDocument24 pagesOption B - BiochemistryRosaNo ratings yet

- 1st Quarter Exam in Eng10 (2022-2023)Document3 pages1st Quarter Exam in Eng10 (2022-2023)Ricshell VasquezNo ratings yet

- Secondary Storage Devices (1) :: Magnetic DisksDocument56 pagesSecondary Storage Devices (1) :: Magnetic DisksSamahir AlkleefaNo ratings yet

- Badugu VaraKumar PLSQLDocument5 pagesBadugu VaraKumar PLSQLNavya DasariNo ratings yet

- INFO 4650 Prototype - Course OutlineDocument7 pagesINFO 4650 Prototype - Course OutlineMax PerronNo ratings yet

Cranes

Cranes

Uploaded by

hazopmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cranes

Cranes

Uploaded by

hazopmanCopyright:

Available Formats

CPA Safety Guidance

Excavators Used as Cranes

Two new European Standards that became effective in 1996 and the new Lifting Equipment and Lifting Operations Regulations 1998 (LOLER) have changed the requirements to fit controlled lowering devices (check valves) and Automatic Safe Load Indicators (ASLI's) on excavators used as cranes. The two standards are: BSEN 474-4:1996 "Requirements for Backhoe Loaders." Implemented on 15 July 1996. BSEN 474-5:1996 "Requirements for Hydraulic Excavators." Implemented on 15 Nov 1996. These two European (harmonised) Standards give guidance on how to satisfy the "Essential Safety Requirements" as listed in the "Supply of Machinery (Safety) Regulations 1992" which implements the European "Machinery Directive" in the UK. All excavator owners throughout Europe must be guided by the Regulations and Standards and machines fitted in accordance with the Standards can be used in all EU countries. It also means that the old UK requirements to fit check valves and ASLI to excavators are now null and void, although machines fitted with these devices can still be used. It should be remembered that these previous requirements were the HSE's interpretation of the Construction (Lifting Operations) Regulations 1961 and these old regulations were replaced by LOLER on 5th December 1998. The following extracts from the text of the two new European Standards are reproduced below: BSEN 474-4 Backhoe Loaders 4.10.2.2.3 The backhoe portion used in object handling operations, with a maximum rated object handling capacity > 1000kg or an overturning moment > 40,000 Nm (Newton Meters) shall be equipped with: an acoustic or visual warning device which indicates to the operator when the rated object handling capacity / corresponding load moment is reached and continues as long as the load or load moment is exceeded.

1

a boom lowering control device on the raising boom cylinder(s) which meets the requirements of ISO 8643: 1988.

These devices may be deactivated while the backhoe equipment is performing operations other than object handling. The activation shall be clearly indicated. The control(s) of deactivation shall be within the operator's zone of comfort according to ISO 6682: 1986. BSEN 474-5 Requirements for Hydraulic Excavators 4.1.7.3.2 - Rated object handling capacity table A table of the rated object handling capacities established by the manufacturer shall be provided. The table(s) shall be available at the operator's station. 4.1.7.5 - Load safety devices Excavators intended for use in object handling operations and with a maximum rated lift capacity > 1000kg, as defined by ISO 10567: 1992, or an overturning moment > 40,000 Nm, shall be equipped with: an acoustic or visual warning device which indicates to the operator when the object handling capacity or corresponding load moment is reached and continues as long as the load or load moment is exceeded. The rated load is defined in the rated object handling capacity tables. This device may be deactivated while the excavator equipment is performing operations other than object handling. The activation shall be clearly indicated. The control of the deactivation shall be within the operators zone of comfort according to ISO 6682: 1986. a boom lowering control device on the raising boom cylinder(s) and which meets the requirements of ISO 8643:1988.

Note:

Nm = Newton Meters. > = greater than. Maximum rated object handling capacity = Safe Working Load (SWL). Lowering control device = check valve. Within operator's zone of comfort = within the operators reach and sight when sitting at the controls.

These two new European Standards make the old CPA/FMCEC booklet "Guidance for Excavators Used as Cranes" out of date. Many will be familiar with the chart that was published in 1991 in the booklet and reproduced by many manufacturers in their own manuals. Using the same format we have updated this chart which is shown below. The requirements are now much simpler than the previous HSE requirements. Implications of the Changes

The "acoustic or visual warning device" is a much cheaper alternative to an ASLI. Most manufacturers seem to be offering the two alternatives because, despite the low cost of the new warning devices, they do have a disadvantage in that they reduce the Safe Working Load (SWL) of the machine. This reduction is greatest at the shorter reaches and can be critical. The larger the machine, the more exaggerated the reductions become. The old HSE rules allowed excavators to operate as cranes with a Certificate of Exemption CON/LO 1981/82 instead of a 4 yearly Test and Thorough Examination. The European Standards change all this and all machines must now be tested and be fitted with check valves on the boom (only). Those machines with SWLs of 1 tonne or less still do not need to be fitted with check valves or acoustic or visual warning devices. The HSE and the CPA advise that all excavators used as cranes should continue with 4 yearly testing, 12 monthly (previously 14 monthly) thorough examination and weekly inspection. Similarly, excavators that are used for digging alone (ie not used as cranes) should be thorough examined every 12 months and the inspected weekly. The HSE have withdrawn their standard report forms for inspection and thorough examination and certificates of test. LOLER permits companies to record the results in any way that is convenient to them. However, the information that must be contained in a report of thorough examination is laid down by the regulations and is listed in Schedule 1 of LOLER.

The HSE have published an Approved Code of Practice and Guidance on LOLER that covers all industry sectors. They are currently writing further specific guidance for a number of different industries. The CPA are deeply involved with the construction industry guidance.

References Safe use of Lifting Equipment, L113, published by the HSE and available from HSE Books, PO Box 1999, Sudbury, Suffolk, CO10 6FS. Tel: 01787 881165, Fax: 01787 313995. European Standards BS EN 474-4 and BS EN 474-5 available from BSI Sales Department, 389 Chiswick High Road, London W4 4AL. Tel: 0181 496 7000, Fax: 0181 496 7001.

Updated: JCPV 28.06.00

Published by: Construction Plant-Hire Association 52 Rochester Row

London SW1P 1JU Telephone: 020 7630 6868 E-mail: enquiries@c-p-a.co.uk

CPA GUIDANCE CHART EXCAVATORS /BACKHOE LOADERS USED AS CRANES

JUNE 2000 REQUIRED NOT REQUIRED ACCORDING TO: LIFTING OPERATIONS AND LIFTING EQUIPMENT REGS (LOLER), EUROPEAN STANDARDS BSEN 474 - 4 AND BSEN 474 - 5.

EXCAVATORS USED AS CRANES WITH A RATED LIFT CAPACITY GREATER THAN 1 TONNE OR AN OVERTURNING MOMENT GREATER THAN 40,000 N.m.

EXCAVATORS USED AS CRANES WITHOUT ANY RESTRICTIONS AND WITH A RATED LIFT CAPACITY OF 1 TONNE OR LESS, OR AN OVER TURNING MOMENT OF 40,000 N.m OR LESS.

EXCAVATORS NOT USED AS CRANES.

A. LOWERING CONTROL DEVICE(S) TO CONFORM TO ISO 8643 FITTED ON RAISING BOOM CYLINDER(S). B. RATED OBJECT HANDLING CAPACITY TABLE IN THE CAB.

C. ACOUSTIC OR VISUAL WARNING DEVICE.

D. CRANE SAFETY HOOK OR LIFTING SHACKLE WITH SWL MARKED & TEST CERTIFICATE. E. SIX MONTHLY THOROUGH EXAMINATION OF LIFTING GEAR.

F. FOUR YEARLY TEST & THOROUGH EXAMINATION; FORM.

G. TWELVE MONTHLY THOROUGH EXAMINATION. H. WEEKLY INSPECTION OF EXCAVATOR.

You might also like

- SS 497 - Code of Practice For Design, Safe Use and Maintenance of Gantry CranesDocument20 pagesSS 497 - Code of Practice For Design, Safe Use and Maintenance of Gantry CranesTest75% (4)

- Basic Scaffolding Questions AnswersDocument11 pagesBasic Scaffolding Questions AnswersSomu Mahadevan89% (28)

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingFrom EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingRating: 5 out of 5 stars5/5 (9)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Control To Temp EquipmentDocument84 pagesControl To Temp EquipmentSteven FlynnNo ratings yet

- Safe Design and Maintenance of MEWPsDocument28 pagesSafe Design and Maintenance of MEWPsAnish BabuNo ratings yet

- CE-Standards Englisch PDFDocument1,263 pagesCE-Standards Englisch PDFHorstS123No ratings yet

- Suspended ScaffoldsDocument29 pagesSuspended ScaffoldsJason Leo100% (1)

- Sensing and Monitoring Technologies for Mines and Hazardous Areas: Monitoring and Prediction TechnologiesFrom EverandSensing and Monitoring Technologies for Mines and Hazardous Areas: Monitoring and Prediction TechnologiesNo ratings yet

- Radar and ARPA Manual: Radar, AIS and Target Tracking for Marine Radar UsersFrom EverandRadar and ARPA Manual: Radar, AIS and Target Tracking for Marine Radar UsersRating: 4.5 out of 5 stars4.5/5 (6)

- Pages From Model Code of Safe Practice Part 21 Sample PagesDocument10 pagesPages From Model Code of Safe Practice Part 21 Sample Pageshazopman0% (2)

- Lift Standards - A GlossaryDocument6 pagesLift Standards - A GlossaryUsmanKhanNo ratings yet

- Secondary Venting ArrangementDocument6 pagesSecondary Venting Arrangementir_azlan_aziz860No ratings yet

- BS 6911-3 Testing Earth-Moving MachineryDocument12 pagesBS 6911-3 Testing Earth-Moving Machinerytariq0% (1)

- K19400 - K19410 Operation ManualDocument18 pagesK19400 - K19410 Operation ManualManta SystemsNo ratings yet

- Cylinder Retest StationsDocument8 pagesCylinder Retest StationsjosearrietacoNo ratings yet

- Cranes, Hoists and Winches: Part 1: General RequirementsDocument11 pagesCranes, Hoists and Winches: Part 1: General RequirementsMilton FernandesNo ratings yet

- 04 Moduspec Justin Nally PDFDocument25 pages04 Moduspec Justin Nally PDFmojtaba_m007No ratings yet

- Offshore Mooring StandardsDocument8 pagesOffshore Mooring StandardsradrottenNo ratings yet

- K46000 - K46001 Operation ManualDocument14 pagesK46000 - K46001 Operation Manualmoh_ichwanuddinNo ratings yet

- HKV4000 Operation ManualDocument30 pagesHKV4000 Operation Manualk5sksngkdsNo ratings yet

- Easa Ad 2015-0226 1Document7 pagesEasa Ad 2015-0226 1Pavlos TsitswnisNo ratings yet

- Leea 025 PDFDocument7 pagesLeea 025 PDFmuhammad usman shahabNo ratings yet

- Is 14665Document7 pagesIs 14665Vijay ChaudharyNo ratings yet

- Overhead Crane Hoists eDocument20 pagesOverhead Crane Hoists eAltayeb YassinNo ratings yet

- Operation and Instruction ManualDocument21 pagesOperation and Instruction ManualZamir Danilo Morera ForeroNo ratings yet

- BS2655-8 1971Document20 pagesBS2655-8 1971Liquor LiamNo ratings yet

- LR Guidance For LifeboatsDocument6 pagesLR Guidance For LifeboatsPan Karas XtraNo ratings yet

- Disclosure To Promote The Right To InformationDocument68 pagesDisclosure To Promote The Right To Informationvb_2009_eeeksNo ratings yet

- Anchor Winches Offshore BS 7464Document10 pagesAnchor Winches Offshore BS 7464Moheb BotrosNo ratings yet

- XBLR3101 - OSH Legislation W3-W5Document28 pagesXBLR3101 - OSH Legislation W3-W5Islah DeanNo ratings yet

- Inspection of TanksDocument15 pagesInspection of Tankskakababa117No ratings yet

- 120405105407SS 497-2011-PreviewDocument7 pages120405105407SS 497-2011-PreviewAnonymous NUn6MESx0% (1)

- Escalators - Safety Rules 1 PDFDocument32 pagesEscalators - Safety Rules 1 PDFElmerNo ratings yet

- Simple Pressure Vessel Directive GuideDocument6 pagesSimple Pressure Vessel Directive GuidethunderNo ratings yet

- Railways and EMC DirectiveDocument5 pagesRailways and EMC DirectiveDozie KesiemeNo ratings yet

- 447 2006 - The European en 1337 On Structural BearingsDocument21 pages447 2006 - The European en 1337 On Structural BearingsGeorge ChristodoulidisNo ratings yet

- Energy Efficiency of Industrial Trucks - Test Methods - Container Straddle CarriersDocument13 pagesEnergy Efficiency of Industrial Trucks - Test Methods - Container Straddle CarriersHamouda EL Sayed Safan100% (1)

- Gearboxes Full RangeDocument65 pagesGearboxes Full RangeleoNo ratings yet

- Dvis 2Document2 pagesDvis 2Vinu KumarNo ratings yet

- Revised Guidelines For The Approval of Equivalent Fixed Gas Fire-Extinguishing Systems, As Referred To in Solas 74, For Machinery Spaces and Cargo Pump-RoomsDocument18 pagesRevised Guidelines For The Approval of Equivalent Fixed Gas Fire-Extinguishing Systems, As Referred To in Solas 74, For Machinery Spaces and Cargo Pump-RoomsDanial Haidhar YusoffNo ratings yet

- Lifting Equipment Engineers Association Part 1 Entry Examination CourseDocument22 pagesLifting Equipment Engineers Association Part 1 Entry Examination CourseMohmed AllamNo ratings yet

- Amendment in MarpolDocument10 pagesAmendment in MarpolGaurav Kumar SinghNo ratings yet

- Cranes-Design Principles For Loads and Load CombinationsDocument10 pagesCranes-Design Principles For Loads and Load CombinationsEnrique Santiago BenavidesNo ratings yet

- LEEA-059-2 Documentation and Marking - Part 2 Powered Lifting MachinesDocument6 pagesLEEA-059-2 Documentation and Marking - Part 2 Powered Lifting MachinesnoormanmubarakNo ratings yet

- Cps Crane MaintenanceDocument13 pagesCps Crane MaintenanceTarek HareedyNo ratings yet

- Pad EyesDocument60 pagesPad Eyesjuyta100% (1)

- Code of Practice For Safe Working On LiftsDocument52 pagesCode of Practice For Safe Working On Liftsavel bas100% (1)

- 12 2.1 E Student 008414 Marker 273Document3 pages12 2.1 E Student 008414 Marker 273BlissNo ratings yet

- E100 E100g MedDocument4 pagesE100 E100g MedDuong DoNo ratings yet

- Escalator Rehabilitation Specifications - Rev 1Document58 pagesEscalator Rehabilitation Specifications - Rev 1Nordiana IdrisNo ratings yet

- ESH 048 ForkliftsDocument31 pagesESH 048 ForkliftsJosh RuddyNo ratings yet

- Kik-kop-40-Pe-ge-0016-0 - Linear Actuator Override Tool Operation & Maintenance ManualDocument27 pagesKik-kop-40-Pe-ge-0016-0 - Linear Actuator Override Tool Operation & Maintenance ManualKhalid AliNo ratings yet

- Shop Maintenance Inspection, Service, Test & Release Screw Conveyor - Auger I. ScopeDocument3 pagesShop Maintenance Inspection, Service, Test & Release Screw Conveyor - Auger I. ScopeIdowu MayowaNo ratings yet

- Auditac - Press Release Nr. 2: New Documents and Tools Released by The Auditac ProjectDocument2 pagesAuditac - Press Release Nr. 2: New Documents and Tools Released by The Auditac Projectchristheo54787No ratings yet

- Automated Guided Vehicle Systems: A Primer with Practical ApplicationsFrom EverandAutomated Guided Vehicle Systems: A Primer with Practical ApplicationsNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Reliability of High-Power Mechatronic Systems 1: Aerospace and Automotive Applications: Simulation, Modeling and OptimizationFrom EverandReliability of High-Power Mechatronic Systems 1: Aerospace and Automotive Applications: Simulation, Modeling and OptimizationNo ratings yet

- Abb PDFDocument9 pagesAbb PDFhazopmanNo ratings yet

- Safety and Health Topics - Hydrogen Sulfide - Evaluating and Controlling ExposureDocument3 pagesSafety and Health Topics - Hydrogen Sulfide - Evaluating and Controlling ExposurehazopmanNo ratings yet

- ProcedureDocument1 pageProcedurehazopmanNo ratings yet

- Faset: Review of Significant Changes To EN 1263-2 2002Document1 pageFaset: Review of Significant Changes To EN 1263-2 2002hazopmanNo ratings yet

- SC 15Tw: Scanjet Tank Cleaning EquipmentDocument1 pageSC 15Tw: Scanjet Tank Cleaning EquipmenthazopmanNo ratings yet

- InControl 1 2013 enDocument12 pagesInControl 1 2013 enhazopmanNo ratings yet

- Honeywell Sensors and Switches in Mobile - Cranes - 009586-2-En - LowresDocument2 pagesHoneywell Sensors and Switches in Mobile - Cranes - 009586-2-En - LowreshazopmanNo ratings yet

- MSHA Regulation EZcomplianceDocument12 pagesMSHA Regulation EZcompliancehazopmanNo ratings yet

- Shiploader Rev2 27may2010Document24 pagesShiploader Rev2 27may2010hazopmanNo ratings yet

- Avoid Outrigger FailureDocument1 pageAvoid Outrigger FailurehazopmanNo ratings yet

- Bucket Truck Safety-PioneerDocument4 pagesBucket Truck Safety-PioneerhazopmanNo ratings yet

- Rollover Hangtag LaserresDocument2 pagesRollover Hangtag LaserreshazopmanNo ratings yet

- PDF 01 ControlsDocument6 pagesPDF 01 ControlshazopmanNo ratings yet

- Ten Points For Safe LiftDocument8 pagesTen Points For Safe LifthazopmanNo ratings yet

- 1926.1400 Convenient Pocket CardsDocument6 pages1926.1400 Convenient Pocket CardshazopmanNo ratings yet

- Forklift ChecklistDocument4 pagesForklift ChecklisthazopmanNo ratings yet

- Safety & Maintenance Inspection - Stellar Cranes Daily V0810.1Document1 pageSafety & Maintenance Inspection - Stellar Cranes Daily V0810.1hazopmanNo ratings yet

- Safety Alert177Document1 pageSafety Alert177hazopmanNo ratings yet

- Methods of Approximation and Determination of Human Vulnerability For Offshore Major Accident Hazard AssessmentDocument55 pagesMethods of Approximation and Determination of Human Vulnerability For Offshore Major Accident Hazard AssessmenthazopmanNo ratings yet

- Jihyd-11846 YemkejDocument92 pagesJihyd-11846 YemkejhaNo ratings yet

- RUBRICS For ACTIVITY MIL - Camera ShotsDocument2 pagesRUBRICS For ACTIVITY MIL - Camera ShotsJaeneth SimondoNo ratings yet

- ED-UCCP-201401A-Packaged Water Cool PDFDocument38 pagesED-UCCP-201401A-Packaged Water Cool PDFHui HuaNo ratings yet

- Afd 021019 1 1B 50Document100 pagesAfd 021019 1 1B 50Sab-Win DamadNo ratings yet

- Construction and Working Principle of Transformers, ItsDocument12 pagesConstruction and Working Principle of Transformers, ItsSandeep Joshi100% (1)

- Education Research and Development 9sometimes Called ResearchDocument4 pagesEducation Research and Development 9sometimes Called ResearchFirmanNo ratings yet

- DRRR Module 8 Concept of Disaster Risk Reduction and ManagementDocument22 pagesDRRR Module 8 Concept of Disaster Risk Reduction and ManagementJodie CabreraNo ratings yet

- Physics: FlashbackDocument2 pagesPhysics: FlashbackWonderlapseNo ratings yet

- Iot Enabled Aquatic Drone For Environmental Monitoring: João Matos, Octavian PostolacheDocument6 pagesIot Enabled Aquatic Drone For Environmental Monitoring: João Matos, Octavian PostolacheVinit Lambey (Ph.D. Student)No ratings yet

- 2011 566277Document22 pages2011 566277pascal_h_1No ratings yet

- Joining Form IndigoDocument2 pagesJoining Form IndigodkasrvyNo ratings yet

- 6308 13236 1 PBDocument6 pages6308 13236 1 PBDwiyan TeguhNo ratings yet

- Basic CryptanalysisDocument22 pagesBasic Cryptanalysisyohan suryaNo ratings yet

- Annex 1 Reg 15 Control of Discharge of OilDocument2 pagesAnnex 1 Reg 15 Control of Discharge of OilsibinmgNo ratings yet

- Mathematical Thinking Skills of BSED-Math Students: Its Relationship To Study Habits and Utilization of SchoologyDocument18 pagesMathematical Thinking Skills of BSED-Math Students: Its Relationship To Study Habits and Utilization of SchoologyPsychology and Education: A Multidisciplinary JournalNo ratings yet

- Simin BehbahaniDocument4 pagesSimin Behbahanisyedabreeha bukhariNo ratings yet

- DHCP - DORA Process Call Flow WifiDocument18 pagesDHCP - DORA Process Call Flow WifiArjunAslekarNo ratings yet

- PL320 Series 3mm LED Panel Mount Metal Holder: Features Absolute Maximum Ratings at T 25 °CDocument1 pagePL320 Series 3mm LED Panel Mount Metal Holder: Features Absolute Maximum Ratings at T 25 °CJajang JajaNo ratings yet

- Election New PPT - 231125 - 174550.pdf - 20231125 - 174959 - 0000Document12 pagesElection New PPT - 231125 - 174550.pdf - 20231125 - 174959 - 0000T SERIESNo ratings yet

- Digital BankingDocument3 pagesDigital BankingDPC Gym100% (1)

- Critical Response Paper No.2Document4 pagesCritical Response Paper No.2Glenn SentesNo ratings yet

- Donald Redford - Akhenaten - New Theories and Old FactsDocument27 pagesDonald Redford - Akhenaten - New Theories and Old FactsDjatmiko TanuwidjojoNo ratings yet

- Applying Theorems On Triangle Inequalities (Exterior Angle Inequality Theorem)Document3 pagesApplying Theorems On Triangle Inequalities (Exterior Angle Inequality Theorem)leonardoalbor05No ratings yet

- Idol Remote Instruction For Copying Face To Face - Product NumberDocument3 pagesIdol Remote Instruction For Copying Face To Face - Product NumberMarcNo ratings yet

- Fortinet Brand Guidelines Partnerv2.3Document13 pagesFortinet Brand Guidelines Partnerv2.3Betiana BoikoNo ratings yet

- Option B - BiochemistryDocument24 pagesOption B - BiochemistryRosaNo ratings yet

- 1st Quarter Exam in Eng10 (2022-2023)Document3 pages1st Quarter Exam in Eng10 (2022-2023)Ricshell VasquezNo ratings yet

- Secondary Storage Devices (1) :: Magnetic DisksDocument56 pagesSecondary Storage Devices (1) :: Magnetic DisksSamahir AlkleefaNo ratings yet

- Badugu VaraKumar PLSQLDocument5 pagesBadugu VaraKumar PLSQLNavya DasariNo ratings yet

- INFO 4650 Prototype - Course OutlineDocument7 pagesINFO 4650 Prototype - Course OutlineMax PerronNo ratings yet