Professional Documents

Culture Documents

Post Tensioned Brickwork Abutments at Glinton by Pass - Engineers File Note 12

Post Tensioned Brickwork Abutments at Glinton by Pass - Engineers File Note 12

Uploaded by

Michael BeckOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Post Tensioned Brickwork Abutments at Glinton by Pass - Engineers File Note 12

Post Tensioned Brickwork Abutments at Glinton by Pass - Engineers File Note 12

Uploaded by

Michael BeckCopyright:

Available Formats

ENGINEERS FILE NOTE NO . 12 .

september 1991

POST TENSIONED

AT GLINTON BY PASS

BRICKWORK ABUTMENTS

the bridge abutments at Glinton bypass pro-

vide a useful reminder of brick's cost effective

role in heavier civilengineering projects.

The project was judged a great success by

all concerned with it.

By Richard Halsall MI Struct EMIHT

Group Engineer Structures, Cambridgeshire County Council

Although widely used for canals and railways .

structural brickwork has not been as much

used in modem dvil engineering as in light

building structures.

Post-tensioned brick diaphragm walls for

BRICK

DEVE1DPMENT

ASSOCIATION

----.......

::::;;;,t;..- \ \ -. ~ :

- - _.-.

----

Ma_eur

-- ------

D r ~ " " , "

~

Bridge

z

Chielcenng ~

... ...

Cu_

z

:c

2

z

ii

......3

INTRODUCTION

DESIGNER 'S BR IEF

Cambridge County Council were pre-

paring a 6m by-pass scheme to run

7.2 km through an area already

designated for Peterborough's future

expansion. Asignificant amount of

residential property had already been

built in what is regarded as an environ-

mentally sensitive area. The client

wanted the bridge structures to be

aesthetically pleasing not only when

first constructed but in future years too.

Minimal maintenance was also a require-

ment. The concrete option was

considered but rejected on aesthetic

grounds and additional maintainance

costs as experienced on the recently

constructed concrete bridges in the

locality. Abrick clad, reinforced concrete

solution was next considered but this

was also rejected because it did not

properly address the long-term

maintenance issue.

The design and construction of two

bridges on a by-pass for the adjacent

villages of Glinton and Northborough,

near Peterborough, Cambridgeshire,

has been widely acclaimed as marking a

rediscovery by civil engineers of brick-

work as a modern structural medium.

The abutments of the two otherwise

modest structures embody the first large

scale use in heavy civil engineering of

post-tensioned brickwork, this century,

exploiting the structural potential of the

material in addition to its many other

attributes. This project proves the

commercial potential of the technique

and was judged, by the clients, a success

both froma technical engineering stand-

point and in commercial terms too.

Sin lOCAnON PlAN

THE SOLUTION

Consideration of the brick clad solution,

although rejected, proved useful. It led

the designers within the structures

section of Cambridgeshire County

Council's Department ofTransportation

to explore a full structural masonry

solution. They were aware of recent

major advances in the use of post-

tensioned brickwork in building

structures and the combination of the

structural and aesthetic qualities

combined with low, long term mainten-

ance costs led them to explore this

alternative more fully. Permission had

first to be obtained from the Department

of Transport. When granted, it was the

first such approval given.

Avoiding the erection and dismantling

of shuttering meant that track posses-

sions from British Rail were not required

for constructing the railway bridge

abutments. Had this been required, it

may have proved problematic since, at

the planned time for construction, the

line was also to be used by trains diverted

from the main east coast route because

of a programme of electrification.

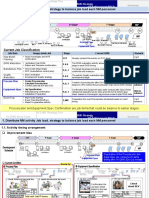

The two main structures are the 18m

span Foxcovert rail bridge and the 6 m

span Foxcovert road bridge. The abut-

ments in both cases are 6 m high and

1.5 m from front to rear. The rail bridge

abut ments are 14.6 m long while those

for the road bridge measure 13.2 m.

While piled foundations were provided

for the rail bridge, normal reinforced

concrete foundations sufficed for the

road bridge.

J.

1

PFA lntill

50 mm dia

gatvonlsed

prestressing bar

with ground

and stond

prestressin

fittingsIn sill bee

Pem10nenI

tormwork

Porouspipe wit!"

granular bed or

surround

M"""ment joint

Couplers

CROSS SICTION "'ROUGH AIlUlMENT

25 mmdia

gotvonised

prestressing bars

Drainage blanket

.': .. sill beam

"... 1' 0. o. ',-: 11::, and bollostwoll

11;>. '"'

(r

II

II

))

))

(r

II

II

))

))

(r

II

II

))

--- --- --- --- --- -,

I

I

I

Post-tensioning was achieved against

a pre-cast reinforced concrete capping

beam set on top of the abutment walls.

The steel bars, firmly anchored in the

foundations. passed through the capping

beam and were then tensioned using

hydraulic jacks. Each bar carried 1000kN

at transfer. The bricks, ranging in strength

from 56N/mm

2

to 100N/mm

2

were

supplied by Armitage BrickLimited.

Front facing brickwork is 102 mm thick

while the rear, earth retaining, face

comprises 215 mm thick brickwork.

The diaphragms are bonded to the front

and rear masonry and are positioned at

770 mm centres.

Class BEngineering bricks were used

for all underground and backing brick-

work, including the cross ribs of the

diaphragm wall. Wharfedale Mult i Rustic

and Moorland Brown Dragwire facing

bricks were used for the face work with

the Moorland Brown Dragwire bricks

acting as a DPC against rising damp by

virtue of their water absorption being

less than 4.5%.

CONSTRUCTION

The abutments were constructed using

cellular diaphragm walls which were

then post-tensioned using galvanised

steel Macalloy stressing bars contained

internally in the voids. To further protect

the bars they were wrapped in Denso

tape. The use of galvanised steel unfor-

tunately proved controversial as several

of the bars failed shortly after post-

tensioning. The cause for these failures

was established as hydrogen embrittle-

ment. It was purely a function of the steel

stressing system and in no way reflected

on t he basic soundness of using post-

tensioned structural masonry. For futu re

use, non-galvanised steel may be

preferred.

lONGITUDINAL SEC110N

Resident

Engineer: Ian Alexander BSc MICE MIHI

Contractor; May Gurney& Co Ltd

COSTS

Project

Engineer: RichardHalsall CEng MI5ructE

Client: Cambridgeshire Countycoundl ,

Peterborough Development

Corporation

ACKNOWLEDGEMENTS

Engineer: Brian Oldridge FJCE MIHT,

DirectorofTransportation

Cambridgeshire CountyCouncil

The initial costs of both projects were

broadly in line with those associated

with the reinforced concrete option with

brick cladding, This was the first major

brickwork pro ject with which the design

team had been involved: the experience

gained is expected to lead to substantial

savings on future projects. When costing

in use is considered, however, the

technique used wins considerable ground

because of the much lower expected

maintenance costs. The maintenance

schedule comprises only the need for a

repoint every 50 years,

The use of structural brickwork in this

pioneering civil engineering project was

judged a success by all concerned -

designers, client and the local community.

Indeed, Cambridgeshire County Council

has since used this technique in cons-

tructing a further road bridge in the

county. Future designs are expected to

be even more cost competitive, Involving,

perhaps as much as a 25% reduction in

the amount of brickwork used.

Perhaps because concentration had

been centred on this aspect of workman-

ship, less care was given to shuffling the

bricks on the scaffold by the normal

procedure of using two or three packs at

a time. As a result one or two ' patchy'

areas we re observed in the finished walls

when the scaffold was removed.

Weathering is expected to further

reduce this small amount of colour

banding over the next few years: it is

already markedly less pronounced than

when first constructed.

WORKMANSHIP

Ahigh level of supervision was

purposely maintained throughout the

project. For example, in addition to the

above workmanship checks, cubes were

made of each mix of mortar and all

mortar was discarded after it had been

on the spot board 1 hour. Where

coloured mortar was used for fair-faced

work, t his was made using a colouring

agent. Tilcon coloured mortar containing

styrene butadene was used for the full

bed width on all facing work.

The walls were constructed during the

winter period. Toensure good produc-

tivity temporary waterproof structures

were erected over the footings and the

brickwork was constructed with this

protection. There was, therefore, no risk

of frost damage and the brickwork was

protected against heavy rain. Further-

more, bricklaying could continue regard-

less of the vagaries of the British climate.

Special attention was given to workman-

ship, particularly supervision. For example

it was essential that all mortar bed joints

were fully fill ed and not left deeply

furrowed. This aspect of t he bricklayers'

skills which few had apparently been

called upon to exercise in recent years,

drew praise from the client.

Service ducts

Precast beams

with lnslfu end

diaphragms

':I.: .: .

. .. .. .=.:1r ,.. ..1.-;...: 16 , , . ..

" ;: ' ,,'.T I >:":',I'" '' '. ' 1:"

I.. .. ,'J ,e.t ....(I?'n,-.111 ....

I I I i I

;. - . l lt-.C) -'.1'" ...-"1' -'- ' 1

1

' . 0 -:J' r' '-111- -. . . ,-., - .

-: " ' 1>, ' .' I' , . " 1 . '1 '. ' : , I . ; I : -, ' : . ; ; 4:

. 0' ; ';111 , J",hl :.: : 111" /' .111. , ,111v , :111, 0. .. . .....

.. , . 'JII 0 ' II " . I . ' '111 III ' , .

. ... - " .' .. .. .. , i ' . 11'-; ' : ... ' . .' ..',

': '; " ," ": " " , , " 11 , ,1, :0.. ..11, <'111" ' ; '. ' ' ,.:- .

p.. .','. ... ,

....: f; '. . j:!'. ; . ...' ( . ' .

' .. _ , . - . o .. ._ . .. _. I

- ' . '-i...J" - - ,:..... ... IP-iin

:",',;,-J

.AT

- Q":"J::C'L:I,J 'I ....... ':::c .. ' __

I ---or- .-'"':"" - I .....,:;, ' .... r- ."- -:_ ' ... r _

t:i ,J - ..l- " (i=

I ..-: -:. ::-- ..,-.: -.:.. ;" 5..

.; ',:,urliI--" _.i..; c.,'--ac ...

-J :.:J' -,- '1 _ 11lI i,-, -.1I . ,. ..t..

_Qi.-" - ' J ' . ,_ _ _., __

CJ - e-, . ...=

L - - - C L _. _ ' !!! ._

f L :-:,--,-, J-r l . lIjJD ..

:-:J _,.::J=- . a-..-r:: lOIJ'::l.J_ _ ,-L CJQ.Oil , l, , 0,., .,. __

. .. . :: . =..i'.' ",.;,:.

_mJ J .l: ';I, 'ff " _.

'" ';"c;:,c"t _.=

.""'" 1 1 0 J. '" llil .1II '':iILJ:J. co;' ,_

'-''''''cJ __ --'.J ....... - fZiljlr:J OlJ_C';J-.....--:. -:'"J .""g, "" 'f.-

lJlir:JI J :..;JWl3l

f

-.J!....J..t..J -.JPlII. III ::l=:JI,1!l..... .. .."., _ _.!!I

r:-:..Jc=.J' =-W-....JU7J';) r;u ::.lJllZc- - - -_IZ::;_ au..OL:..: c "" .: ' _, .7i=I

'::1 IGilC ;aI[!IJLJO G E:1. IllJ IiIIl:1Il' .:JilIC)."lJfJ IJ__ '_OO'::O." a, __

.J_.. :::.. ::,.::;c':: "" . ' _

L r. ---.:.ll-----..:;u - .... 1 1" U:.Jl''.J-'-..h' J. , J i ll.. . .

...--:-j - r:<"' .. J- l r -, r ' C :l F<;':& 1 _.-,..... I.. , -.Jr;"d........ ' __ I .. ':;;;;!, ' -... ..... .-._,'-- ..,'_, .- _. _ ... '- '

.....0..1'-- ........ _ , ..,lt61.... - lIM - _ r-;';' , _ -:.J I ' -=. --=- ..l.A; - ......-I..-'" ,... _ '-

JI'JL... - D .. -",-j..",:, ..

,--I =.JL:_IlJJI__ .-=..i -=: . ::.I,." ,[;J OC&OD.JJLJ U1E" ,. _ ,

LJC . JOI_ I J

raiII ...JDI1l!3lLlli .

GiJ U

aiiilii. :'j ' ' s.k C:JU_ 1 ,, _

CI. gjlL ' :t J -=- ---' -, .=J rlW r- 1-" .J-=-: ". , ._

Brickwork parapet with

stainless steel reinforcement

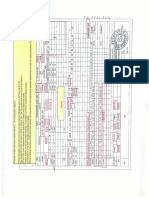

SCHEME CALCULATIONS SCHEME CALCULATIONS

1. DESIGNlOADING (BS 54OO:Part 2)' SECTIONTHROUGH ABUTMENT

wan designed as a IIee standing cantilever

- -0.396 N/mm

2

- 1.695 N/mm'

- 1.500 N/mm'

- 2.799 N/mm'

486.1 x 10" x 0.778

251.964 x 10"

486.1 X 10' x 0.778

223125 x 10'

Front Back

1.299

- 1.299 - 1.695

NegaIiIve Bending

1094.3 x 10' x 0.778

654.95 x 10' - 1.299 N/mm'

Axial

Bending

(back)

Bending

(front)

Axial

Combined - 1.299 + 1.500 - 5.446 N/mm'

- -4.048 N/mm'

- 0.411 N/mm'

4.459

1444.2 X 10' x 0.778 _ 4.459 N/mm'

251.964 x 10'

1444.2 x 10" x 0.778 _ 5.035 N/mm'

223.125 x 10'

- 0.411 - 4.459

Front Bock

j II I ! I I I ! II I I

0.411

Positive Bending

346.3 x 10' x0.778

654.95 x 10'

Axial

Bending

(back)

Bending

(f ront)

Combined - 0.411 + 5.035

Axial

AI Base

SectIon Deslgn I

Consider ultirnote stress distribution, the most

severe case will occur under min. axial and max.

bending.

R/C Sill Beam

R/C Deck

Cellular

Brickwork

R/C Piled

1' 1 Post

Tensioning

to ...

. ' .

..

" "' ., I>

H

.,

.,.' . 1

tk

::L!= II

.'T. " I

., .

" to " ...

.

v;-

-

Shear

M

UlS SlS

!'

24B 206

98 76

748 680

318 212

92 74

51 41

960 640

312 250

174 139

Engineering

(Class B)

Facing

Moment (kNm/m):

Earth pressure

Tractive terce" *

Accidental skidding"

llertlcal (kN/m):

Dead load

Superimposed

Live load (H. + H,)

Shear (kN/m):

Earth pressure

Tractive force

Accidental skidding

Type

y,trom Table 1: as S400 Part 2.

"Negative bending only occurs with

live load on bridge

MATiRIAI.S DATA

1. BrIc:kwoIt<:

Partial 5afeIy Factors: Compressive

Strength

Water obsorpnon

Soluble sulphate

(by weight)

laadbearing

classification

56.0 N/mm'

< 0.5'1>

Class 8

70 N/mm'

< 7'1>

< 0.5'1>

Class 10

loading

Materials

Shear

Steel strength

y, - Table 1. BS5400 Part 2

Ymm - 2.00 (Table 6. BS5628:Pt 2)

= 2.0 (Table 7. BS5628:Pt 2)

Ym, 1.15

Bending Bending

1.695

1.500

-4.048

-0.396

Effective prestress for bending, allow tor a minimum

ot 1N/mm' compression over whole section even at

ultimate. This ensures whole secnon usable for

shear at ultimate.

2.799

-0.396

Combined

So the combined envelope to resist worst tensile

stresses is as shown below

EARTH

FACE

Bending

\ + ve I -ve

\

\

\

\

\

\

\

\

\

\

\

5.446

5.035

--4.048

wall Proftle

Combined

Front

Back: - 251.96 x 10'mm'

- 654 95 x 1O'mm'

215

1:4 1:t

102

1565

- 185194 x 1Q9mm'

Back

3

lnerno

section madulus: Frant = 223125 x 1O"mm'

Area

(section x - x)

SECTIONGEOMETRY

655628 part 1

Table 1

(i)

Mix proportions 1:0 - . :3

Characteristic

compressive

strength f, - 16.26 N/mm' 19.2 N/mm'

cnoroctensnc

shear strength t, - 0.35 + 0.6 go' N/mm'

Yield strength

of steel f

v

- 1030 N/mm'

go - deadload stress (ta a max. of 1.75 N/mm')

Desiqncfion

Masonry Facing Class B

Characterlsttc strengths

2. Mortar:

SCHEME CALCULATIONS

1.396 + 5.048

P - 2 X 654.95

= 2109 kN/m > p shear

Therefore: Design lor Ilexure

2109 x 10' 2109 x lO'e

5.048= 654.95 x 10' + 251.964 x 1()6

Check beoring stressdirectly below anchorage

Applied

axial stress - 1094.3 kN/m Ultimate

- 962.9 kN/m Serviceability

At serviceability:

- 3.220 + 0.008e

Therefore

e - 218mm

- (2109 + (962.9 x 0.778 x 10'

654.95 X 10'

- 4.36N/mm'

Toallow for reversal of moments steel is to be

placed in two groups at the front and back 01the

wall.

Assume e - 218 mm

therelore: p x 0.218 - 0.35p, - 0.4p,

Nowp P, + p,

therefore: p, - p - P, sUbstituting:

0.218p - 0.35p, - 0.4 (p - P,)

- 0.35p, - 0.4p + 0.4p,

therefore: 0.618p - 0.75p,

0.618 x 2109

therefare: P, - 0.75 - 1738kN

therefore: p, - 2109 - 1738 - 371kN

I

P, I+- 4 o-....jP,

0.4 I H!

0.218 p

;

Pennissible - 0.33I.

""" 5.36 N/mm

2

> fe

ma

At ultimate:

- (2109 + (1094.3 x 0.778) x 10'

654.95 X 10'

4.52N/mm'

Max

pe nnissible = 1.5 IJ Ym

_ 15 x 16.25

. 2

- 12.2 N/mm' >

Therefore section satlsfactory

DESIGN POST TENSIONING mEL

It is proposed to use Macalloy smooth prestressing

bars (reler to Macalloy Special Products Publication

No.2).

The ba rsore divided into two groups at the front and

rear of the section.

!

I

Post tensioning forces - 1738 kN (Back lace)

371 (Frontface)

- M95 0.998 IJ Ym- 8.125

Design Checks

Stress at

ultimate

Front Rear

wall wall

(N/mm')

Umn

(N/mm')

Assuming 20'1. losses

Strength of steel, 0.71,

Y""

0.7 x 1030

-

115

- 627 N/mm'

Front wall , A."

Therefore use 2 no 50 mm 0 bars

371 x 10' x 1

0.8 627

- XOmm

2

Therefore use 2 no 25 mm 0 bars

. 1738 X 10' 1

Consider the back wall, Ass - 0.8 x 627

- 3465mm'

459.0 x 10' x 0.778 ,

- 32Z5 x 1565 - 0.698 N/mm

Shear at ultimate

Applied

shear

Stress at

serviceability - 5.079 2.382 0.4 f. - 6.50

Check service

at transfer

(20'1. lor losses) - 1.449 6.306 I. > 2 x 6.306

limiting

1.75 /

permissible - 2 - 0.875 N mm' > Applied

Therelore section satisfactory

Permissible

shear

_ ( 0.35 + 0.6 (346.3 + 2109) x 10' )

654.95 x 10'

2

- 1.29 N/mm'

Therefore post tensioning becomes:

2 no 50mm 0 lor back face

Force/ bar - 1086 kN

2 No 25mm 0 lor front face

Force/bor = 231 kN

The Association would be interested to hear from Engineers or Architects of projects which they

consider worthy of inclusion in The BOA Engineers' FileNote Series. All initial submissions should

contain reference to the particular area of the design which. it is considered. would be of interest to

the design profession as a whole. All enquiries should be addressed to The Technical Editor

JMorton B5cPhDCEngMICE MICeram MCIM.

The views expressed in this FileNote are those of the Authors. Readers are expressly advised that they

do not necessarily reflect the views of the Association

Todemonstrate the initial engineering decisions taken. scheme calculations have been included in the

Note. They are NOT intended to be full and detailed calculations and they should NOT be read as such.

THE ENGINEERS FILE NOTES SERIES BINDER

Aspecially designed binder has been produced to hold the FileNote Series and is available

on request from The Publication Sales Department.

The Brick Development Association. woodslde House. Winkfield. Windsor. Berkshire SL42DX.

Readers are exprnsly advised that. whilst the contents of this publicationere believedto beaccurate, correct and complete. norelianceshould beplacedupon Its

conte nts as bemg applicable to any particular c ncamstences. Anyadvice, oplni on or information ccntemed is published only on t he looting that the Brick

Developme nt ASSOdation, ll$ serveets Of "g'Pnts an d all contributors to thiS publication shall be under no liability whatsoever in respect of its conte nts

Desl8ned al1d Prod uced lor the Brick Development Association.

Woods ide House, Winkfield. Windsor. Berkshi re SL4 2DX. Telephone : Winkfield Row 10344 885651) by f rank Walter DeSign Umi ted.

C The Brick Development Association

Pnrued in Elllo:land hy Sll'\Oo kky Pn -....

You might also like

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Balanced Cantilever ConstructionDocument176 pagesBalanced Cantilever ConstructionRavi Chandra Ivp100% (2)

- Cannon Anchorage To ConcreteDocument47 pagesCannon Anchorage To ConcretePaul EvansNo ratings yet

- A Case Study of Deep Excavation in Urban Area in Hong KongDocument17 pagesA Case Study of Deep Excavation in Urban Area in Hong KongMark Chan100% (2)

- ALS-R User's Manual: Amplified Spontaneous Emission Light SourceDocument16 pagesALS-R User's Manual: Amplified Spontaneous Emission Light SourceAnonymous 60esBJZIjNo ratings yet

- Design and Construction Problems of A "Big Inch" Outfall: Carlo Avanzini and Pierantonio QuiriciDocument8 pagesDesign and Construction Problems of A "Big Inch" Outfall: Carlo Avanzini and Pierantonio Quiricijean miguel oscorima celisNo ratings yet

- CS - P08-1186 International Tower Capital CentreDocument4 pagesCS - P08-1186 International Tower Capital Centrefrog15No ratings yet

- 1976 ACI JournalDocument5 pages1976 ACI JournalpappadowNo ratings yet

- Structural Design of Immersed TunnelsDocument17 pagesStructural Design of Immersed TunnelsTrong TranNo ratings yet

- American: S Societ CodeDocument1 pageAmerican: S Societ CodePaulo BurceNo ratings yet

- Design of Brick Diaphragm WallsDocument43 pagesDesign of Brick Diaphragm WallsdavidongpongNo ratings yet

- Bin WallBridgeAbutmentsDocument8 pagesBin WallBridgeAbutmentsandyhrNo ratings yet

- Shotcrete Use in The Southern Link Tunnel, Stockholm: Swedish National Road AdministrationDocument6 pagesShotcrete Use in The Southern Link Tunnel, Stockholm: Swedish National Road AdministrationHarold TaylorNo ratings yet

- A Reinforced Brickwork Freestanding Boundary Wall 0188 PDFDocument8 pagesA Reinforced Brickwork Freestanding Boundary Wall 0188 PDFArnabNo ratings yet

- Design, Retrofit and Inspection of Railway Bridges in New ZealandDocument23 pagesDesign, Retrofit and Inspection of Railway Bridges in New Zealandatac101No ratings yet

- Design Hand Dug WellsDocument6 pagesDesign Hand Dug WellssubxaanalahNo ratings yet

- Selection of The Most Effective Designs AND Methods of Construction of Deepwater Pile Foundations FOR Hydraulic Structures in Mud SoilsDocument5 pagesSelection of The Most Effective Designs AND Methods of Construction of Deepwater Pile Foundations FOR Hydraulic Structures in Mud Soilsjuan carlos molano toroNo ratings yet

- Individual Case Study - Queen Elizabeth's Olympic ParkDocument6 pagesIndividual Case Study - Queen Elizabeth's Olympic ParkMichael CostaNo ratings yet

- For Several Miles in The Elwood Area, The Coast Line Is Marked by A VeryDocument9 pagesFor Several Miles in The Elwood Area, The Coast Line Is Marked by A VeryIndus ConsultantsNo ratings yet

- WPM For Internal Wet AreaDocument53 pagesWPM For Internal Wet AreaGeraldNo ratings yet

- Restoration of Masonry Arch Bridges: Bridge Engineering September 2012Document23 pagesRestoration of Masonry Arch Bridges: Bridge Engineering September 2012Comet AstroNo ratings yet

- Deep Shaft Design and ConstructionDocument14 pagesDeep Shaft Design and ConstructionFabio Nascimento100% (3)

- Cut and Cover Tunnels - Waterproof Magazine Winter 2012 PDFDocument5 pagesCut and Cover Tunnels - Waterproof Magazine Winter 2012 PDFfethi42No ratings yet

- 1201-Cheng Kim Hua Pipe Roof As Alternative in Building - UnderpassDocument11 pages1201-Cheng Kim Hua Pipe Roof As Alternative in Building - UnderpassCheng KimHuaNo ratings yet

- Concrete PilingDocument12 pagesConcrete Pilingeko.kusgmail.comNo ratings yet

- My Bhokar Site Report Final Check...Document24 pagesMy Bhokar Site Report Final Check...Md IsmailNo ratings yet

- The Cracking of StormwaterDocument8 pagesThe Cracking of StormwaterBen SinambelaNo ratings yet

- 2001-04 BO-01-01 MTO Development of Flexible Link SlabDocument46 pages2001-04 BO-01-01 MTO Development of Flexible Link Slabcraig.mcleodNo ratings yet

- Report119 - Part5 of 5 InspectionsDocument11 pagesReport119 - Part5 of 5 InspectionshjdNo ratings yet

- Millau Viaduct: Detailed Design of Concrete Piers: C. CalamoneriDocument9 pagesMillau Viaduct: Detailed Design of Concrete Piers: C. CalamoneriAmirhossein AbbasiNo ratings yet

- Composite Steel-Concrete Bridges With Double Composite ActionDocument7 pagesComposite Steel-Concrete Bridges With Double Composite ActionOanh PhanNo ratings yet

- Nicoll Highway IncidentDocument8 pagesNicoll Highway IncidentAnonymous PeeXLtNsMpNo ratings yet

- Precast Prestressed Concrete Short Span BridgesDocument41 pagesPrecast Prestressed Concrete Short Span Bridgescdestudos100% (1)

- Design of Concrete Lined Flood Control ChannelsDocument26 pagesDesign of Concrete Lined Flood Control Channelswikoboy100% (1)

- Cost Forecasting FormatDocument102 pagesCost Forecasting Formatchandanprakash30No ratings yet

- Hollow Core Planks Application and Design GuideDocument46 pagesHollow Core Planks Application and Design Guidemixi1978100% (1)

- I-10 Twin Span Bridges Over Lake Pontchartrain: ProfileDocument4 pagesI-10 Twin Span Bridges Over Lake Pontchartrain: ProfileAnonymous 4ghB3BQNo ratings yet

- Sheet Pile Retaining Walls Design and Construction in A Brown Fields Environment Amir Holakoo KBRDocument6 pagesSheet Pile Retaining Walls Design and Construction in A Brown Fields Environment Amir Holakoo KBREng mohammadNo ratings yet

- Box Pushing Technology: Seminar Report Submitted by Uvais.A REG NO:20010536 Civil EngineeringDocument18 pagesBox Pushing Technology: Seminar Report Submitted by Uvais.A REG NO:20010536 Civil EngineeringUvais Majeed100% (2)

- Application of Expansion Joints in DiaphDocument8 pagesApplication of Expansion Joints in DiaphLuthfi NNo ratings yet

- 1.inplant Training Presentation ReportDocument37 pages1.inplant Training Presentation ReportRajkumarNo ratings yet

- Chairman Mike Downing Welcomes New Members: Green Car ParkDocument4 pagesChairman Mike Downing Welcomes New Members: Green Car ParkmagdyamdbNo ratings yet

- Raymond Pile BrochureDocument16 pagesRaymond Pile Brochuremoyarek100% (4)

- Cut and Cover TunnelsDocument5 pagesCut and Cover Tunnelsfethi42No ratings yet

- Design of Steel Fibre Reinforced Segmental Lining For The Gold Coast Desal TunnelsDocument8 pagesDesign of Steel Fibre Reinforced Segmental Lining For The Gold Coast Desal Tunnelsrajesh005No ratings yet

- TKBT Anchor EquipmentDocument32 pagesTKBT Anchor EquipmentLuca Brandi100% (1)

- SES2DB464C8RGPO0U Use of Steel Fiber Reinforced Sprayed Concrete in The Final Lining of Conventionally ExcavateDocument8 pagesSES2DB464C8RGPO0U Use of Steel Fiber Reinforced Sprayed Concrete in The Final Lining of Conventionally Excavatemoin4cuetNo ratings yet

- Precast-Prestressed Concrete I-Beam BridgesDocument10 pagesPrecast-Prestressed Concrete I-Beam BridgesSigmaE107No ratings yet

- Hydrological StudyDocument4 pagesHydrological StudybertinNo ratings yet

- CE 416 Prestressed Concrete Sessional (Lab Manual)Document64 pagesCE 416 Prestressed Concrete Sessional (Lab Manual)RahulKikaniNo ratings yet

- CE 416 Prestressed Concrete Sessional (Lab Manual)Document64 pagesCE 416 Prestressed Concrete Sessional (Lab Manual)julesNo ratings yet

- Code Tiltup PrecastDocument47 pagesCode Tiltup Precastkorosh75No ratings yet

- 10.3 Micropile Foundations - The Easy Way - Brandner PDFDocument11 pages10.3 Micropile Foundations - The Easy Way - Brandner PDFVandolph Quilab LozanoNo ratings yet

- Diaphargm Wall Construction DetailsDocument48 pagesDiaphargm Wall Construction DetailsAkshay Joshi100% (1)

- Immersed Cross SectionsDocument17 pagesImmersed Cross SectionsAlexandra MoldovanNo ratings yet

- Design of Precast Segmental Tunnel Lining For Pawtucket CSO Tunnel ProjectDocument12 pagesDesign of Precast Segmental Tunnel Lining For Pawtucket CSO Tunnel ProjectJosé Luis Rodríguez SánchezNo ratings yet

- Maintenance of PSC GirdersDocument10 pagesMaintenance of PSC GirdersradhakrishnangNo ratings yet

- Underground StructuresDocument51 pagesUnderground StructuresFauzankalibataNo ratings yet

- Jack Pesch Bicycle and Pedestrian Bridge (QLD)Document4 pagesJack Pesch Bicycle and Pedestrian Bridge (QLD)yyanan1118No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionFrom EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionNo ratings yet

- After Review Sig Sixma UR65 Standoff Vision Improvement IrinaDocument41 pagesAfter Review Sig Sixma UR65 Standoff Vision Improvement IrinaBetty RosalinaNo ratings yet

- Solution To Exam #1 For Chemical Engineering Thermodynamics (2018)Document2 pagesSolution To Exam #1 For Chemical Engineering Thermodynamics (2018)ramesh pokhrelNo ratings yet

- Department of Education: Republic of The PhilippinesDocument3 pagesDepartment of Education: Republic of The PhilippinesAirishAinneNo ratings yet

- Mothership-Unit Description - Game - StarCraft IIDocument8 pagesMothership-Unit Description - Game - StarCraft IIcalmansoorNo ratings yet

- 2 Logic Design For 4-Bit ComparatorDocument6 pages2 Logic Design For 4-Bit Comparatoramta1No ratings yet

- Automotive EngineeringDocument5 pagesAutomotive EngineeringJANNo ratings yet

- Parenting Style As A Moderator of Locus of Control, Self Esteem and Academic Stress Among AdolescentsDocument11 pagesParenting Style As A Moderator of Locus of Control, Self Esteem and Academic Stress Among Adolescentsharano mamunNo ratings yet

- Advancement in Energy Storage DevicesDocument9 pagesAdvancement in Energy Storage Devicesash200459No ratings yet

- Seeq 2023 Analytics Resolutions GuideDocument7 pagesSeeq 2023 Analytics Resolutions GuidebinaycNo ratings yet

- Ehv Ac & DC Transmission MCQ Unit - 5 - Math TradersDocument3 pagesEhv Ac & DC Transmission MCQ Unit - 5 - Math TradersRitNo ratings yet

- The New Aramaic Dialect of Qaraqosh HousDocument15 pagesThe New Aramaic Dialect of Qaraqosh HousPierre BrunNo ratings yet

- 25.03 MRL For Abrasive ServiceDocument1 page25.03 MRL For Abrasive ServiceAnonymous LeC3YexoBoNo ratings yet

- 30ra 040 240 ManualDocument31 pages30ra 040 240 Manualmichel correa de limaNo ratings yet

- Experimental Optimization of Radiological Markers For Artificial Disk Implants With Imaging/Geometrical ApplicationsDocument11 pagesExperimental Optimization of Radiological Markers For Artificial Disk Implants With Imaging/Geometrical ApplicationsSEP-PublisherNo ratings yet

- RPS Goals December 7 2021Document16 pagesRPS Goals December 7 2021inforumdocsNo ratings yet

- Kingspan Jindal Ext. Wall Panel SystemDocument32 pagesKingspan Jindal Ext. Wall Panel Systemabhay kumarNo ratings yet

- Belzona 1311Document2 pagesBelzona 1311Bobby SatheesanNo ratings yet

- MTC 17022021063931Document1 pageMTC 17022021063931Ahmed LepdaNo ratings yet

- Value of G at Different Locations On EarthDocument4 pagesValue of G at Different Locations On EarthDannyRaoNo ratings yet

- Cobb Douglas ProductionDocument4 pagesCobb Douglas ProductionMim ShakilNo ratings yet

- Ch.4 Elastic Collisions in 1DDocument1 pageCh.4 Elastic Collisions in 1D17latifaNo ratings yet

- Presentation FixDocument3 pagesPresentation FixDanny Fajar SetiawanNo ratings yet

- TE1 Terminal CircuitDocument2 pagesTE1 Terminal Circuitcelestino tuliaoNo ratings yet

- FIBER OPTIC DEPLOYMENT CHALLENGES & SOLUTIONS Final PDFDocument63 pagesFIBER OPTIC DEPLOYMENT CHALLENGES & SOLUTIONS Final PDFamrefat77100% (1)

- Piping General Arrangement Cooling Tower Water System AreaDocument1 pagePiping General Arrangement Cooling Tower Water System AreaajmainNo ratings yet

- Bhoomika Kedia ResumeDocument1 pageBhoomika Kedia Resumerajeev456No ratings yet

- The Discovery of America An Out-Growth of The Conquest of The Moors by The Spaniards (1883)Document32 pagesThe Discovery of America An Out-Growth of The Conquest of The Moors by The Spaniards (1883)Tram Dickerson El100% (5)

- Characterization Paper Bag BookDocument15 pagesCharacterization Paper Bag BookAnonymous CzfeUsqNo ratings yet

- Temas de Ensayo de MacroeconomíaDocument6 pagesTemas de Ensayo de Macroeconomíag69zer9d100% (1)