Professional Documents

Culture Documents

STK24!4!30ft AirFloat AirSkate

STK24!4!30ft AirFloat AirSkate

Uploaded by

Manoel PadilhaCopyright:

Available Formats

You might also like

- BS-1377 Part 9Document5 pagesBS-1377 Part 9syed jafar saeed100% (2)

- Cummins QSB 6.7 Parts Book AbbyDocument97 pagesCummins QSB 6.7 Parts Book Abbyhafiz100% (2)

- Tyre RetreadingDocument24 pagesTyre RetreadingRuksana BhanuNo ratings yet

- Proof RollingDocument33 pagesProof Rollingazcomp100% (8)

- VDS CEA 4001en - 2010Document252 pagesVDS CEA 4001en - 2010Mihai CatalinNo ratings yet

- Plumbing SkillsDocument131 pagesPlumbing SkillsSathish Kumar Karne100% (5)

- Reverse L Shaped Cantilever RETAINING WALLDocument6 pagesReverse L Shaped Cantilever RETAINING WALLHusen Ghori100% (2)

- 01-9601 Technical Manual Chance Helical Anchor p12Document12 pages01-9601 Technical Manual Chance Helical Anchor p12Kwan YiuNo ratings yet

- Week 5 TractionDocument8 pagesWeek 5 TractionJaya BerjayaNo ratings yet

- How Airbearings Work Products: o o o o o o o o o o oDocument15 pagesHow Airbearings Work Products: o o o o o o o o o o oVenu GopalNo ratings yet

- 16 - Bruce Ireland - Joint DetailsDocument32 pages16 - Bruce Ireland - Joint DetailsTian NgNo ratings yet

- Design On Slab On GradeDocument4 pagesDesign On Slab On GradeAhmad Mensa100% (1)

- Residential GarageDocument2 pagesResidential Garagevikas.gautamNo ratings yet

- 236s 2007-08-20 Proof RollingDocument5 pages236s 2007-08-20 Proof RollingIbato RutaNo ratings yet

- Performance of Unreinforced Concrete Bored Piles Under Different Loading ConditionsDocument19 pagesPerformance of Unreinforced Concrete Bored Piles Under Different Loading ConditionsarslanpasaNo ratings yet

- 05 May Contractor FocusDocument3 pages05 May Contractor FocusTrương KhảiNo ratings yet

- Air CasterDocument5 pagesAir CasterNitin Tembhurnikar0% (1)

- Design and Construction of Joints For Concrete Streets: Jointing ConsiderationsDocument12 pagesDesign and Construction of Joints For Concrete Streets: Jointing Considerationsandrei_magnus100% (1)

- BS 1377 Part 9: 1990 StandardDocument9 pagesBS 1377 Part 9: 1990 StandardDetoned StonedNo ratings yet

- Machine Power RequirementsDocument69 pagesMachine Power RequirementschileNo ratings yet

- Aerostatic Bearings: - Aerostatic Bearings Utilize A Thin Film of High-Pressure AirDocument21 pagesAerostatic Bearings: - Aerostatic Bearings Utilize A Thin Film of High-Pressure AirEdmilson DantasNo ratings yet

- Unit 4 MaterialsDocument17 pagesUnit 4 MaterialsYuvaraj DhanasekarNo ratings yet

- Design of Rigid Pavements and AnalysisDocument68 pagesDesign of Rigid Pavements and AnalysisJuanithaNo ratings yet

- Determination of Bearing Capacity of Soil Using Plate Load TestDocument6 pagesDetermination of Bearing Capacity of Soil Using Plate Load TestABe MustofaNo ratings yet

- Calcul Fundatii Micropiloti Metalici ElicoidaliDocument10 pagesCalcul Fundatii Micropiloti Metalici ElicoidaliNistor FlorinNo ratings yet

- Pavement Design: Seminar OnDocument31 pagesPavement Design: Seminar OnManish kumarNo ratings yet

- Helical Foundations What An Engineer Needs To KnowDocument6 pagesHelical Foundations What An Engineer Needs To Knowameensderaj100% (1)

- What Are Screw PilesDocument13 pagesWhat Are Screw Pilesanju krishnaNo ratings yet

- Chapter 4 - Jeu Dave F. Tadiamon BSCE - 5 Pavement DesignDocument5 pagesChapter 4 - Jeu Dave F. Tadiamon BSCE - 5 Pavement DesignCrystal Ann TadiamonNo ratings yet

- ATMECE, MysuruDocument11 pagesATMECE, MysuruPrajwal Kumar.BNo ratings yet

- CompactionDocument64 pagesCompactionRamesh Konakalla100% (1)

- CE 632 Shallow Foundations Part-1Document39 pagesCE 632 Shallow Foundations Part-1Abdul KabasyNo ratings yet

- 03-OHE FoundationDocument78 pages03-OHE Foundationsugind sNo ratings yet

- Crane Pad AceDocument1 pageCrane Pad AceReda ElawadyNo ratings yet

- Flexible and Rigid PavementsDocument25 pagesFlexible and Rigid Pavementssyeda75% (4)

- W01 358 9603Document29 pagesW01 358 9603MROstop.comNo ratings yet

- q07 g3 Ahmad AmalludinDocument4 pagesq07 g3 Ahmad AmalludinAmal AmranNo ratings yet

- Pile DesignDocument15 pagesPile Designmohanty_anantakumar6332100% (1)

- Guide To Mobile CranesDocument7 pagesGuide To Mobile CranesvigneshNo ratings yet

- Smooth Drum Rollers Are Probably The Most Traditional Type of Equipment Used For Compaction ofDocument2 pagesSmooth Drum Rollers Are Probably The Most Traditional Type of Equipment Used For Compaction ofcrizelNo ratings yet

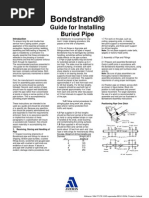

- Guide For Installing RTR Pipe Courtesy Bondstrand For InfoDocument4 pagesGuide For Installing RTR Pipe Courtesy Bondstrand For InfoHafiz Ali Alvi100% (1)

- Technical Advisory Slab PAVEMENTDocument6 pagesTechnical Advisory Slab PAVEMENTNoli PaladNo ratings yet

- BS 1377 Part 9: 1990 StandardDocument4 pagesBS 1377 Part 9: 1990 StandardAlbert Jopson100% (2)

- Choice of Foundation For BrigdesDocument15 pagesChoice of Foundation For BrigdesSamuel AntobamNo ratings yet

- Handout 3 Earthwork OperationsDocument25 pagesHandout 3 Earthwork OperationsthuraiyaNo ratings yet

- Shallow FoundationDocument130 pagesShallow FoundationSanki ChoraNo ratings yet

- For Mobile Cranes: by Theodore Christensen and Daniel DeitzDocument3 pagesFor Mobile Cranes: by Theodore Christensen and Daniel Deitzdsn_sarmaNo ratings yet

- DD 9Document11 pagesDD 9linamohdzhor4815No ratings yet

- Paving Systems Using Clay Pavers in A Mortar Setting Bed: Technical Notes 14CDocument15 pagesPaving Systems Using Clay Pavers in A Mortar Setting Bed: Technical Notes 14CprmraoNo ratings yet

- CE-632 Foundation Analysis and Design: Shallow FoundationsDocument33 pagesCE-632 Foundation Analysis and Design: Shallow FoundationsMadhu SulaniyaNo ratings yet

- Elastomeros PDFDocument69 pagesElastomeros PDFBeatriz Bautista GutierrezNo ratings yet

- Pavement PPT Unit1Document13 pagesPavement PPT Unit1Rahul jichkarNo ratings yet

- A Field Guide To Mining Machine ApplicationDocument9 pagesA Field Guide To Mining Machine ApplicationLeo Manaure Rada100% (1)

- Bucket TerminologyDocument4 pagesBucket TerminologySamuel Hendra SinagaNo ratings yet

- Example 11: Driveability Analysis (Blow Count vs. Depth) : GRLWEAP Standard ExamplesDocument4 pagesExample 11: Driveability Analysis (Blow Count vs. Depth) : GRLWEAP Standard ExamplesbozarromegustaNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- DSR Electrical 2012Document60 pagesDSR Electrical 2012vijay_raina31140% (1)

- EHS Guidelines Page 1 of 64Document64 pagesEHS Guidelines Page 1 of 64Shyam MurugesanNo ratings yet

- Current Trends in Digester Mixing Technologies: Becky Daugherty Brian HemphillDocument60 pagesCurrent Trends in Digester Mixing Technologies: Becky Daugherty Brian Hemphillerfan davariNo ratings yet

- Rate Analysis (2016) - Cpwd-Part1Document4,174 pagesRate Analysis (2016) - Cpwd-Part1dreamspacearchitects100% (1)

- Cpa 50e - 1Document3 pagesCpa 50e - 1JerNo ratings yet

- Katalog Harga Lantai Kayu VinylDocument2 pagesKatalog Harga Lantai Kayu VinylYana SubagjaNo ratings yet

- Roofing TechniqueDocument30 pagesRoofing TechniqueLuke Obusan100% (1)

- Product Catalog0 7Document1 pageProduct Catalog0 7sunbopumpNo ratings yet

- Model Free Flow Nose To Side Check Valve: CAPACITY: 10 GPM / CAVITY: T-162ADocument2 pagesModel Free Flow Nose To Side Check Valve: CAPACITY: 10 GPM / CAVITY: T-162AsnsnagarajanNo ratings yet

- Rational Design of Pipe Racks Used For Oil Sands and Petrochemical FacilitiesDocument11 pagesRational Design of Pipe Racks Used For Oil Sands and Petrochemical Facilitieseddie eddNo ratings yet

- B VEGADocument22 pagesB VEGAPetru CordosNo ratings yet

- PADEYE Calculation - 9th ASDDocument13 pagesPADEYE Calculation - 9th ASDshivaNo ratings yet

- TQ53810 PDFDocument1 pageTQ53810 PDFCarjan BogdanNo ratings yet

- Building Real Buildings With Cardboard: WWW - Cardboardschool.co - UkDocument3 pagesBuilding Real Buildings With Cardboard: WWW - Cardboardschool.co - UksamNo ratings yet

- Weekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekDocument8 pagesWeekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekfcfernandoNo ratings yet

- Masonry Labor Construction Productivity Variation: An Indian Case StudyDocument9 pagesMasonry Labor Construction Productivity Variation: An Indian Case StudyMar John RicamaraNo ratings yet

- Strip Foundation DesignDocument2 pagesStrip Foundation DesignersivarajNo ratings yet

- #PRESENTATION Green RoofDocument21 pages#PRESENTATION Green RoofMistyNo ratings yet

- Title DefenseDocument34 pagesTitle DefenseHerwinn Ruiz ReyesNo ratings yet

- Dindigul Bypass To Samyanallore On NH 7 in The State of Tamil Nadu Vol - Iii PDFDocument29 pagesDindigul Bypass To Samyanallore On NH 7 in The State of Tamil Nadu Vol - Iii PDFVinay YadavNo ratings yet

- NIST 2617 Transit Space ClearancesDocument10 pagesNIST 2617 Transit Space Clearances4493464No ratings yet

- Retaining Wall 2Document16 pagesRetaining Wall 2Shahin AlomNo ratings yet

- Gencore Cebu QuoteDocument22 pagesGencore Cebu QuoteAlleo MarquezNo ratings yet

- Punching Shear in Flat Slab Sefi DiscussionDocument13 pagesPunching Shear in Flat Slab Sefi DiscussionHiren DesaiNo ratings yet

- John Crane Dry Gas Seal Example Inspection ReportDocument14 pagesJohn Crane Dry Gas Seal Example Inspection Reportchimmy chinNo ratings yet

- L&T Construction Heavy Civil Infrastructure - Edrc: Chennai Metro Rail Corporation Limited Embye ConsortiumDocument115 pagesL&T Construction Heavy Civil Infrastructure - Edrc: Chennai Metro Rail Corporation Limited Embye ConsortiumGladson JsNo ratings yet

STK24!4!30ft AirFloat AirSkate

STK24!4!30ft AirFloat AirSkate

Uploaded by

Manoel PadilhaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STK24!4!30ft AirFloat AirSkate

STK24!4!30ft AirFloat AirSkate

Uploaded by

Manoel PadilhaCopyright:

Available Formats

Lifting Gear Hire Corporation

P: 800.878.7305 | F: 708-430-3536 | www.lgh-usa.com | sales@lgh-usa.com

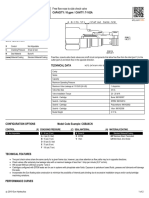

50,000 lbs. Capacity Air Skate System

Air Float STK-24-4-30ft

Air Bearing Skids

Load Module System

These air bearing skids let you move loads from 2,400 to 40,000 pounds per skid easily and safely. Look over the specifications and packages and please contact LGH with any questions.

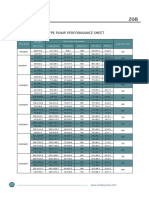

Steel Air Skate Specifications

Model Number STK-24-4-30ft Capacity Per Skate Set (lbs) 50,000 Dimension Per Skate (in) (A x B x H) 25 1/2 x 25 1/4 x 3 1/2 Mounting Holes (in) 2 @ 3/8 - 16 on 3 1/2 Ctr Inlet Size NPT (in) 2-prong Chicago Fitting Lift (in) 3/4 Flow CFM; M3/Min 60 - 100; 1.68 - 2.80 Minimum Load Area* (in) 6x6 Weight Per Set (lbs) 360

*Minimum contact area of load against each skid.

Steel Air Skid Packages

Each load skid system includes four or six steel single bearing air skids plus an appropriate CP control package console including on/off valve, pressure regulator, flow control valves. Includes hose with quick disconnect for each skid. Does not include main supply hose.

LGH2012-2

Lifting Gear Hire Corporation

P: 800.878.7305 | F: 708-430-3536 | www.lgh-usa.com | sales@lgh-usa.com

General Specifications Concrete Floors

Design

In most applications, when loads are moving on air bearings, the unit floor loading is very low compared to conventional wheeled traffic, or loading which results when the air is turn off and the air bearing platform comes to rest on its skid pads. This, floor slab design must usually be based on soil load bearing capacity and requirements for other wheeled traffic or loads expected to be placed on the floor. Local conditions and requirements vary so greatly, that new floors should be designed individually for each application. Recommendation: Design floor thickness and reinforcement to withstand the most severe expected loading, and for actual soil loading capacity. If possible, avoid expansion joints in path of air bearing movement.

Flatness and Levelness

Air bearing equipment needs flat and level floors for best operation for three reasons. First, any slopes add to the force needed to move or guide the equipment. Second, floor undulations can exceed bearing lift and equipment can run aground or hang up on raised portions of uneven floors. This is normally a problem only with very large equipment. Third, when air bearings are deflated, the frame or landing pads contact the floor. If the load is very large, heavy and rigid, floor loading can be extremely high on raised portions of the floor. On a flat, level and smooth floor, the force required to move air bearing equipment is very low, often in the range of 1 to 5 pounds per 1,000 pounds of weight (.5 to .1% friction). With this low friction, even a small amount of floor slope greatly affects moving force and guiding effort. For example, a slope of in 10 feet requires an added force of 4 pounds per 1,000 pounds of load. A floor can be generally level over its entire area, but have local undulations that greatly affect movement. For example, a load depression of on in 3 feet can add 7 pounds of moving force per 1,000 pounds, for the bearing or bearings moving in the depression. Recommendation: Two different tolerances are suggested. Select one according to the manner of use: A. For light loads, large bearings, or powered movement: floors should be flat with no more than deviation from a 10 foot straight edge laid on the surface, and the straight edge should lie level within . B. For heavy loads, smaller bearings, and manual movement: the above deviation should be reduced to only 1/8 for both flatness and levelness.

Smoothness

Air bearings operate with a very thin air film between the diaphragm and floor. Even minute floor projections that are on greater than a few thousandths of an inch high, can cause increased drag and air consumption. Recommendation: Finish floors with powered steel trowel for a dense, smooth, flat floor. Continue successive troweling passes until surface becomes polished. Number of trowelings will vary with mix and weather conditions. Following troweling operation, a sprayable concrete sealer should be applied to the floor to prevent dusting.

Expansion Joints

Recommendations: Expansion joints should be minimized in the path of air bearing movement. When their use is unavoidable to prevent floor cracking, make certain that reinforcing bars are carried through across the joint to minimize slab movement. Fill with flexible epoxy crack filler.

Disclaimer: This document covers only general specifications for concrete floors. Specific types of equipment; processes; sizes of, quantity and spacing of air bearings; may dictate more specific requirements. Please contact a Lifting Gear Hire representative for review of specific requirements. Lifting Gear Hire is not a flooring expert. New floor installation processes, coatings & refinishing processes are constantly being developed. It is the customers responsibility to choose a floor contractor who can meet the above specifications and provide a floor that will be economical, durable and maintainable.

LGH2012-2

You might also like

- BS-1377 Part 9Document5 pagesBS-1377 Part 9syed jafar saeed100% (2)

- Cummins QSB 6.7 Parts Book AbbyDocument97 pagesCummins QSB 6.7 Parts Book Abbyhafiz100% (2)

- Tyre RetreadingDocument24 pagesTyre RetreadingRuksana BhanuNo ratings yet

- Proof RollingDocument33 pagesProof Rollingazcomp100% (8)

- VDS CEA 4001en - 2010Document252 pagesVDS CEA 4001en - 2010Mihai CatalinNo ratings yet

- Plumbing SkillsDocument131 pagesPlumbing SkillsSathish Kumar Karne100% (5)

- Reverse L Shaped Cantilever RETAINING WALLDocument6 pagesReverse L Shaped Cantilever RETAINING WALLHusen Ghori100% (2)

- 01-9601 Technical Manual Chance Helical Anchor p12Document12 pages01-9601 Technical Manual Chance Helical Anchor p12Kwan YiuNo ratings yet

- Week 5 TractionDocument8 pagesWeek 5 TractionJaya BerjayaNo ratings yet

- How Airbearings Work Products: o o o o o o o o o o oDocument15 pagesHow Airbearings Work Products: o o o o o o o o o o oVenu GopalNo ratings yet

- 16 - Bruce Ireland - Joint DetailsDocument32 pages16 - Bruce Ireland - Joint DetailsTian NgNo ratings yet

- Design On Slab On GradeDocument4 pagesDesign On Slab On GradeAhmad Mensa100% (1)

- Residential GarageDocument2 pagesResidential Garagevikas.gautamNo ratings yet

- 236s 2007-08-20 Proof RollingDocument5 pages236s 2007-08-20 Proof RollingIbato RutaNo ratings yet

- Performance of Unreinforced Concrete Bored Piles Under Different Loading ConditionsDocument19 pagesPerformance of Unreinforced Concrete Bored Piles Under Different Loading ConditionsarslanpasaNo ratings yet

- 05 May Contractor FocusDocument3 pages05 May Contractor FocusTrương KhảiNo ratings yet

- Air CasterDocument5 pagesAir CasterNitin Tembhurnikar0% (1)

- Design and Construction of Joints For Concrete Streets: Jointing ConsiderationsDocument12 pagesDesign and Construction of Joints For Concrete Streets: Jointing Considerationsandrei_magnus100% (1)

- BS 1377 Part 9: 1990 StandardDocument9 pagesBS 1377 Part 9: 1990 StandardDetoned StonedNo ratings yet

- Machine Power RequirementsDocument69 pagesMachine Power RequirementschileNo ratings yet

- Aerostatic Bearings: - Aerostatic Bearings Utilize A Thin Film of High-Pressure AirDocument21 pagesAerostatic Bearings: - Aerostatic Bearings Utilize A Thin Film of High-Pressure AirEdmilson DantasNo ratings yet

- Unit 4 MaterialsDocument17 pagesUnit 4 MaterialsYuvaraj DhanasekarNo ratings yet

- Design of Rigid Pavements and AnalysisDocument68 pagesDesign of Rigid Pavements and AnalysisJuanithaNo ratings yet

- Determination of Bearing Capacity of Soil Using Plate Load TestDocument6 pagesDetermination of Bearing Capacity of Soil Using Plate Load TestABe MustofaNo ratings yet

- Calcul Fundatii Micropiloti Metalici ElicoidaliDocument10 pagesCalcul Fundatii Micropiloti Metalici ElicoidaliNistor FlorinNo ratings yet

- Pavement Design: Seminar OnDocument31 pagesPavement Design: Seminar OnManish kumarNo ratings yet

- Helical Foundations What An Engineer Needs To KnowDocument6 pagesHelical Foundations What An Engineer Needs To Knowameensderaj100% (1)

- What Are Screw PilesDocument13 pagesWhat Are Screw Pilesanju krishnaNo ratings yet

- Chapter 4 - Jeu Dave F. Tadiamon BSCE - 5 Pavement DesignDocument5 pagesChapter 4 - Jeu Dave F. Tadiamon BSCE - 5 Pavement DesignCrystal Ann TadiamonNo ratings yet

- ATMECE, MysuruDocument11 pagesATMECE, MysuruPrajwal Kumar.BNo ratings yet

- CompactionDocument64 pagesCompactionRamesh Konakalla100% (1)

- CE 632 Shallow Foundations Part-1Document39 pagesCE 632 Shallow Foundations Part-1Abdul KabasyNo ratings yet

- 03-OHE FoundationDocument78 pages03-OHE Foundationsugind sNo ratings yet

- Crane Pad AceDocument1 pageCrane Pad AceReda ElawadyNo ratings yet

- Flexible and Rigid PavementsDocument25 pagesFlexible and Rigid Pavementssyeda75% (4)

- W01 358 9603Document29 pagesW01 358 9603MROstop.comNo ratings yet

- q07 g3 Ahmad AmalludinDocument4 pagesq07 g3 Ahmad AmalludinAmal AmranNo ratings yet

- Pile DesignDocument15 pagesPile Designmohanty_anantakumar6332100% (1)

- Guide To Mobile CranesDocument7 pagesGuide To Mobile CranesvigneshNo ratings yet

- Smooth Drum Rollers Are Probably The Most Traditional Type of Equipment Used For Compaction ofDocument2 pagesSmooth Drum Rollers Are Probably The Most Traditional Type of Equipment Used For Compaction ofcrizelNo ratings yet

- Guide For Installing RTR Pipe Courtesy Bondstrand For InfoDocument4 pagesGuide For Installing RTR Pipe Courtesy Bondstrand For InfoHafiz Ali Alvi100% (1)

- Technical Advisory Slab PAVEMENTDocument6 pagesTechnical Advisory Slab PAVEMENTNoli PaladNo ratings yet

- BS 1377 Part 9: 1990 StandardDocument4 pagesBS 1377 Part 9: 1990 StandardAlbert Jopson100% (2)

- Choice of Foundation For BrigdesDocument15 pagesChoice of Foundation For BrigdesSamuel AntobamNo ratings yet

- Handout 3 Earthwork OperationsDocument25 pagesHandout 3 Earthwork OperationsthuraiyaNo ratings yet

- Shallow FoundationDocument130 pagesShallow FoundationSanki ChoraNo ratings yet

- For Mobile Cranes: by Theodore Christensen and Daniel DeitzDocument3 pagesFor Mobile Cranes: by Theodore Christensen and Daniel Deitzdsn_sarmaNo ratings yet

- DD 9Document11 pagesDD 9linamohdzhor4815No ratings yet

- Paving Systems Using Clay Pavers in A Mortar Setting Bed: Technical Notes 14CDocument15 pagesPaving Systems Using Clay Pavers in A Mortar Setting Bed: Technical Notes 14CprmraoNo ratings yet

- CE-632 Foundation Analysis and Design: Shallow FoundationsDocument33 pagesCE-632 Foundation Analysis and Design: Shallow FoundationsMadhu SulaniyaNo ratings yet

- Elastomeros PDFDocument69 pagesElastomeros PDFBeatriz Bautista GutierrezNo ratings yet

- Pavement PPT Unit1Document13 pagesPavement PPT Unit1Rahul jichkarNo ratings yet

- A Field Guide To Mining Machine ApplicationDocument9 pagesA Field Guide To Mining Machine ApplicationLeo Manaure Rada100% (1)

- Bucket TerminologyDocument4 pagesBucket TerminologySamuel Hendra SinagaNo ratings yet

- Example 11: Driveability Analysis (Blow Count vs. Depth) : GRLWEAP Standard ExamplesDocument4 pagesExample 11: Driveability Analysis (Blow Count vs. Depth) : GRLWEAP Standard ExamplesbozarromegustaNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- DSR Electrical 2012Document60 pagesDSR Electrical 2012vijay_raina31140% (1)

- EHS Guidelines Page 1 of 64Document64 pagesEHS Guidelines Page 1 of 64Shyam MurugesanNo ratings yet

- Current Trends in Digester Mixing Technologies: Becky Daugherty Brian HemphillDocument60 pagesCurrent Trends in Digester Mixing Technologies: Becky Daugherty Brian Hemphillerfan davariNo ratings yet

- Rate Analysis (2016) - Cpwd-Part1Document4,174 pagesRate Analysis (2016) - Cpwd-Part1dreamspacearchitects100% (1)

- Cpa 50e - 1Document3 pagesCpa 50e - 1JerNo ratings yet

- Katalog Harga Lantai Kayu VinylDocument2 pagesKatalog Harga Lantai Kayu VinylYana SubagjaNo ratings yet

- Roofing TechniqueDocument30 pagesRoofing TechniqueLuke Obusan100% (1)

- Product Catalog0 7Document1 pageProduct Catalog0 7sunbopumpNo ratings yet

- Model Free Flow Nose To Side Check Valve: CAPACITY: 10 GPM / CAVITY: T-162ADocument2 pagesModel Free Flow Nose To Side Check Valve: CAPACITY: 10 GPM / CAVITY: T-162AsnsnagarajanNo ratings yet

- Rational Design of Pipe Racks Used For Oil Sands and Petrochemical FacilitiesDocument11 pagesRational Design of Pipe Racks Used For Oil Sands and Petrochemical Facilitieseddie eddNo ratings yet

- B VEGADocument22 pagesB VEGAPetru CordosNo ratings yet

- PADEYE Calculation - 9th ASDDocument13 pagesPADEYE Calculation - 9th ASDshivaNo ratings yet

- TQ53810 PDFDocument1 pageTQ53810 PDFCarjan BogdanNo ratings yet

- Building Real Buildings With Cardboard: WWW - Cardboardschool.co - UkDocument3 pagesBuilding Real Buildings With Cardboard: WWW - Cardboardschool.co - UksamNo ratings yet

- Weekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekDocument8 pagesWeekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekfcfernandoNo ratings yet

- Masonry Labor Construction Productivity Variation: An Indian Case StudyDocument9 pagesMasonry Labor Construction Productivity Variation: An Indian Case StudyMar John RicamaraNo ratings yet

- Strip Foundation DesignDocument2 pagesStrip Foundation DesignersivarajNo ratings yet

- #PRESENTATION Green RoofDocument21 pages#PRESENTATION Green RoofMistyNo ratings yet

- Title DefenseDocument34 pagesTitle DefenseHerwinn Ruiz ReyesNo ratings yet

- Dindigul Bypass To Samyanallore On NH 7 in The State of Tamil Nadu Vol - Iii PDFDocument29 pagesDindigul Bypass To Samyanallore On NH 7 in The State of Tamil Nadu Vol - Iii PDFVinay YadavNo ratings yet

- NIST 2617 Transit Space ClearancesDocument10 pagesNIST 2617 Transit Space Clearances4493464No ratings yet

- Retaining Wall 2Document16 pagesRetaining Wall 2Shahin AlomNo ratings yet

- Gencore Cebu QuoteDocument22 pagesGencore Cebu QuoteAlleo MarquezNo ratings yet

- Punching Shear in Flat Slab Sefi DiscussionDocument13 pagesPunching Shear in Flat Slab Sefi DiscussionHiren DesaiNo ratings yet

- John Crane Dry Gas Seal Example Inspection ReportDocument14 pagesJohn Crane Dry Gas Seal Example Inspection Reportchimmy chinNo ratings yet

- L&T Construction Heavy Civil Infrastructure - Edrc: Chennai Metro Rail Corporation Limited Embye ConsortiumDocument115 pagesL&T Construction Heavy Civil Infrastructure - Edrc: Chennai Metro Rail Corporation Limited Embye ConsortiumGladson JsNo ratings yet