Professional Documents

Culture Documents

Vessel Parametric Seat Modeling For Change Enhanced Usability

Vessel Parametric Seat Modeling For Change Enhanced Usability

Uploaded by

IJERDOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vessel Parametric Seat Modeling For Change Enhanced Usability

Vessel Parametric Seat Modeling For Change Enhanced Usability

Uploaded by

IJERDCopyright:

Available Formats

International Journal of Engineering Research and Development e-ISSN: 2278-067X, p-ISSN : 2278-800X, www.ijerd.

com Volume 5, Issue 10 (January 2013), PP. 37-40

Vessel Parametric Seat Modeling for Change Enhanced Usability

Soon-kak Kwon1, Kyung-seok Kim2

1,2

Dep. of Computer Software Engineering, Dongeui University, Korea

Abstract:- Vessel designers have to go through many processes of input/change of numerical values of each part on vessel seat since the implementation of the automation of vessel design drawings. This paper is intended to relieve the consequent discomfort and provide convenience by identifying something in common in the series of steps and making a routine out of the found common facts. Keywords:- Vessel, Seat Modeling, Standard Type, Special Type

I.

INTRODUCTION

There are many courses and skills in nesting processing. Some processes, which are not necessary during the work, come up and interrupt the courses of nesting such as losing face of processes and missing some delicate parts of the work. For fixing such problems, the nesting is proposed to provide convenience and better work performances[1,2]. Three functions are trim, polyline, and overline. Those can improve the nesting processing speed and save the product resources. Recently a lot of vessel design drawings are generated thanks to the design automation. Among these drawings, those with different forms of numerical measurement are considered to be different vessel seat even if their shape is very similar or exactly the same. Like this, if there are similar drawings when they are being generated, the efficiency of drawing generation can be improved by only modifying the dimensions of the drawings rather than generating new drawings. In addition the convenience may be maximized by programming a series of overlapping processes. To implement this, knowledge is necessary on the overall functionality of the AM and modifying of the seat. On UI, which provides the convenience, are shown the information that the user requires, 3D configuration, and the shape to be changed to. This better optimization is expected to be applied to other designs such as heavy industries as well as the vessel's seat.

II.

CHANGING THE PARAMETRIC SEAT

Trim connects an object to the other one by finding an intersection point between two objects. Also it gets rid of unnecessary work that is not meant. This course will improve the nesting processing speed. Several series of process are needed in order to modify and identify the attributes and 3D geometry of the seat from the existing AM. After the detailed information on the seat is confirmed from the drafting, more detailed can be viewed or modified by entering commands in the Command Window. The changes in 3D shape can be checked in the out-fitting. Changes in the dimensions, which make 3D shape, can be made of course in the drafting. However, it is inconvenient to change all the materials one by one if the kinds of them of the parts are too many. This kind of problem of repetitive tasks through the Command Window mentioned earlier can be solved by receiving and processing the input values with the implemented program. Using the implemented UI, faster identification of information that needs changing is possible, and checking the information saved in the CVS file is also possible to find information that does not exist in the AM. In this respect, it is possible to improve working speed, accuracy and readability, and to minimize the execution of the out-fitting for checking of 3D modelling.

III.

ALGORITHM OF PROPOSED FUNCTIONS

In Fig 1, information can be imported from the DB in the AM through the name that is set in the seat. Fig 2 shows the modification and saving of the imported information.

37

Vessel Parametric Seat Modeling for Change Enhanced Usability

Fig. 1: Flow chart of Information

Fig. 2: Flow chart of SCTN Length The currently implemented function is for the length. Since the position becomes other type when changed, the program has been made to allow change only length information and to the extent that the shape can be maintained after the change.

IV.

IMPLEMENTATION

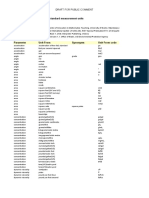

The seat name and block shall be output in UI, and the project number is displayed in vessel No. The type of the corresponding seat is displayed in Type. If there is length information on the attributes window, type borrows the same symbol from the CSV file to display; and in case of order code, the order code that has the same length level as the type is brought to be displayed. If there is no information of length, on the other hand, the symbol is left blank and the order code shown in the attributes window is read and displayed. If there is length in the standard type, Kg value is read from the CSV; if not, Usrweight value is imported from attributes window. Special type outputs special-weight value, and if necessary, applies the devised method of calculation for the output.

38

Vessel Parametric Seat Modeling for Change Enhanced Usability

Fig. 3: Display of seats information

Fig. 4: Display of Seats information The ChangeLength button, this program's main function receives and modifies the sub-located Length1, Length2 and Length3 values. The displayed information is checked and the Length value is modified using CE button, followed by execution by pushing the ChangeLength button. This time, the modified modeling and information are output once more to check for the changes.

Fig. 5: Before the process

39

Vessel Parametric Seat Modeling for Change Enhanced Usability

Fig. 6: After the process A function to change the position was implemented to make this feature. Though one function is enough for the implementation, it was made for flexible applicability by the type by making functions that change the starting and ending points respectively because flexibility could not be attained if applied by the types.

V.

CONCLUTSIONS

The current program may be fully applied, if it can be applied to most types, for parts that have SCTN. Problems are found when positions are changed with PANE included, and when applied by types. At this point, additional work is needed when the DB is updated. If improved a little further, it is expected to provide the convenience through applying and modifying for the specifications including PANE, CONE, CYLI as well as SCTN.

ACKNOWLEDGMENT

The authors would like to thank Cadwin System, Ltd for providing nesting software, CADWIN*NEST. Corresponding author : Soon-kak Kwon (skkwon@deu.ac.kr).

REFERENCES

[1]. [2]. Y. Kim, K. Gotoh, and M. Toyosada, Automatic two-dimensional layout using a rule-based heuristic algorithm, Journal of Marine Science and Technology, vol.8, pp. 3746, May 2003. W.-C. Lee, H. Ma, and B.-W. Cheng, A heuristic for nesting problems of irregular shapes, Computer-Aided Design, vol.40, pp. 625633, May 2008.

40

You might also like

- Orion PDFDocument365 pagesOrion PDFLeggotunglei86% (7)

- Cad Cam Third Edition Solution ManualDocument155 pagesCad Cam Third Edition Solution ManualGabriel Dias100% (2)

- Catia v5 Piping DesignDocument194 pagesCatia v5 Piping DesignMathieu CoffynNo ratings yet

- Parametric Finite Element Model of AIRBUS Engine Pylon With MSC - PatranDocument9 pagesParametric Finite Element Model of AIRBUS Engine Pylon With MSC - Patranventus45No ratings yet

- Biomimicry in ArchitectureDocument10 pagesBiomimicry in Architecturerodolfo barbosaNo ratings yet

- Jib Crane Design and ParametersDocument5 pagesJib Crane Design and ParametersNicole DavisNo ratings yet

- Recent Advances in Avl'S CFD Mesh Generation Software - Ese-ToolsDocument6 pagesRecent Advances in Avl'S CFD Mesh Generation Software - Ese-ToolsNhựt KhôiNo ratings yet

- 2022T3 Release HighlightsDocument16 pages2022T3 Release HighlightsДмитрий ГанжаNo ratings yet

- 2021T3 Release HighlightsDocument24 pages2021T3 Release HighlightsДмитрий ГанжаNo ratings yet

- Conveyor Profile DesignDocument6 pagesConveyor Profile DesignIrwan SattuNo ratings yet

- CamDocument9 pagesCamhemaf85No ratings yet

- Legolitie Sample MechanicalDocument25 pagesLegolitie Sample MechanicalAnwar ChowdhuryNo ratings yet

- Develop3d Nov09 ProeDocument3 pagesDevelop3d Nov09 ProeGopi NathNo ratings yet

- BIW Design ProcessDocument9 pagesBIW Design Processprasungovindan100% (1)

- 4 MethodologyDocument5 pages4 Methodologypramo_dassNo ratings yet

- Yusuf WESIC2003 Paper PDFDocument6 pagesYusuf WESIC2003 Paper PDFSalehNo ratings yet

- Boom Bucket2Document6 pagesBoom Bucket2Praveen KumarNo ratings yet

- A Step-Based Feature Modeler For Capp: S.M. Amaitik, S.E. KiliçDocument6 pagesA Step-Based Feature Modeler For Capp: S.M. Amaitik, S.E. KiliçSalehNo ratings yet

- CAD-Based Parametric Cross-Section Designer For Gas Turbine Engine MDO ApplicationsDocument10 pagesCAD-Based Parametric Cross-Section Designer For Gas Turbine Engine MDO ApplicationsValiyakattel NilsNo ratings yet

- Concept of Step Ap224 Features Based Modeling For Rotational PartsDocument6 pagesConcept of Step Ap224 Features Based Modeling For Rotational PartsSalehNo ratings yet

- CNC Programming Systems PDFDocument22 pagesCNC Programming Systems PDFSurendra SainiNo ratings yet

- Knowledge-Based Engineering System For Determining The Shape of Fuel Distribution in An Aircraft WingDocument10 pagesKnowledge-Based Engineering System For Determining The Shape of Fuel Distribution in An Aircraft WingSilva JoãoNo ratings yet

- RM Bridge CONNECT Edition V11 Update 8 Release Notes (May 2020)Document21 pagesRM Bridge CONNECT Edition V11 Update 8 Release Notes (May 2020)Ave Robin M. RamosNo ratings yet

- Cad-Cam Manual PDFDocument34 pagesCad-Cam Manual PDFM.Saravana Kumar..M.E100% (2)

- Mapping 2D Midship Drawings Into A 3D Ship Hull Model Based On STEP AP218Document11 pagesMapping 2D Midship Drawings Into A 3D Ship Hull Model Based On STEP AP218John RongNo ratings yet

- Erp A Manufacturing Perspective Chapter-4Document5 pagesErp A Manufacturing Perspective Chapter-4Rahul Abhishek MehraNo ratings yet

- AnsaDocument12 pagesAnsaarunkumarnoolaNo ratings yet

- Moi University School of Information Science Dit 010: Management Information System Section A Question OneDocument7 pagesMoi University School of Information Science Dit 010: Management Information System Section A Question OneKiprotich KibetNo ratings yet

- Rbtic ArmDocument18 pagesRbtic ArmmnervadesuNo ratings yet

- Two Dimensional Airfoil Optimisation Using CFD in A Grid Computing EnvironmentDocument8 pagesTwo Dimensional Airfoil Optimisation Using CFD in A Grid Computing Environmentananth9660No ratings yet

- Fixture Design PDFDocument9 pagesFixture Design PDFali ahmadiNo ratings yet

- Operations Management: Facility LayoutDocument46 pagesOperations Management: Facility LayoutsanjaykhatwaniNo ratings yet

- Additive Manufacturing - Question Bank With Answers - May 2023Document13 pagesAdditive Manufacturing - Question Bank With Answers - May 2023Surya100% (2)

- Wheel BRG Stiffness CalDocument8 pagesWheel BRG Stiffness Calmans2014No ratings yet

- Csicol ManualDocument118 pagesCsicol ManualEsmeraldo L. ErandioNo ratings yet

- d3d Visi19 LowDocument5 pagesd3d Visi19 Lowgrg_greNo ratings yet

- Expressed in Terms of ParameterDocument4 pagesExpressed in Terms of ParameterRidaNo ratings yet

- Seat-Antisubmarine Performance SeatDocument5 pagesSeat-Antisubmarine Performance SeatKarthik IyerNo ratings yet

- Design and Analysis of Robot Manipulators by Integrated Cae Procedures 1 Brat Rotatie 12 PaginiDocument30 pagesDesign and Analysis of Robot Manipulators by Integrated Cae Procedures 1 Brat Rotatie 12 PaginiCristi AlexNo ratings yet

- Simulayt Composite Modeler ExampleDocument10 pagesSimulayt Composite Modeler ExamplealwynhartmanNo ratings yet

- A Framework For Aerodynamic and StructurDocument10 pagesA Framework For Aerodynamic and StructurAnas SalehNo ratings yet

- Template-Based Integrated Design: A Case Study: Ali K. Kamrani and Abhay VijayanDocument10 pagesTemplate-Based Integrated Design: A Case Study: Ali K. Kamrani and Abhay VijayanmurgadeepNo ratings yet

- Mcsullog,+10 21791IJEMS 2020 2 35Document15 pagesMcsullog,+10 21791IJEMS 2020 2 35Yasar KhanNo ratings yet

- Experience in The Exchange of Procedural Shape Models Using ISO 10303 (STEP)Document10 pagesExperience in The Exchange of Procedural Shape Models Using ISO 10303 (STEP)Michael CifuentesNo ratings yet

- Amaitik Turkey PDFDocument9 pagesAmaitik Turkey PDFSalehNo ratings yet

- BobCAD V26 Build 1182Document5 pagesBobCAD V26 Build 1182Paul VeramendiNo ratings yet

- An Overview of Pro/ENGINEERDocument20 pagesAn Overview of Pro/ENGINEERrajasekarkalaNo ratings yet

- Dynaform 5.9: Release NotesDocument5 pagesDynaform 5.9: Release NotesFidel LazaroNo ratings yet

- Powerful 3 Axis CNC Programming OperationsDocument28 pagesPowerful 3 Axis CNC Programming OperationsNanda KishoreNo ratings yet

- 18me4105 - Additive Manufacturing Key & Scheme of Evaluation Dec-2022Document13 pages18me4105 - Additive Manufacturing Key & Scheme of Evaluation Dec-2022srinivas kanakalaNo ratings yet

- ASME Conf TemplateDocument3 pagesASME Conf TemplatePradeep ReddyNo ratings yet

- ADA Multidisciplinary Design OptDocument10 pagesADA Multidisciplinary Design OptDhiren DarjiNo ratings yet

- Catia v5 Sheet Metal DesignDocument6 pagesCatia v5 Sheet Metal DesignirfaniumNo ratings yet

- PLCM, Module-5Document41 pagesPLCM, Module-5Sunil Kumar M50% (2)

- Structural Analysis ProfessionalDocument10 pagesStructural Analysis ProfessionalFractosNo ratings yet

- Mold Tooling Design (V5R16) - CatiaDocument306 pagesMold Tooling Design (V5R16) - Catiageorge_ichim100% (1)

- AutoCAD Electrical 2020 for Electrical Control Designers, 11th EditionFrom EverandAutoCAD Electrical 2020 for Electrical Control Designers, 11th EditionNo ratings yet

- Autodesk Inventor 2019 For Beginners - Part 1 (Part Modeling)From EverandAutodesk Inventor 2019 For Beginners - Part 1 (Part Modeling)No ratings yet

- Router 1X3 - RTL Design and VerificationDocument10 pagesRouter 1X3 - RTL Design and VerificationIJERDNo ratings yet

- Moon-Bounce: A Boon For VHF DxingDocument5 pagesMoon-Bounce: A Boon For VHF DxingIJERDNo ratings yet

- Investigations On Properties of Light Weight Cinder Aggregate ConcreteDocument10 pagesInvestigations On Properties of Light Weight Cinder Aggregate ConcreteIJERDNo ratings yet

- Emotion Detection From TextDocument12 pagesEmotion Detection From TextIJERDNo ratings yet

- Raoult's LawDocument8 pagesRaoult's LawHARSH DHOLAKIYANo ratings yet

- Data Analytics Assignment 1Document11 pagesData Analytics Assignment 1RADHIKA CHANDAKNo ratings yet

- Know Your Venus SignDocument19 pagesKnow Your Venus SignBimz MeisnamNo ratings yet

- Asme Sec V A-2 RT PDFDocument44 pagesAsme Sec V A-2 RT PDFmsalinasaguilar71% (7)

- 0026-1394 41 1 001 PDFDocument8 pages0026-1394 41 1 001 PDFOmar PonsNo ratings yet

- LEcture 14Document15 pagesLEcture 14asdsdNo ratings yet

- Strengths: Mixers - AeratorsDocument2 pagesStrengths: Mixers - AeratorsKashif MasudNo ratings yet

- Recognition of Isolated Signs in Ethiopian Sign Language Tefera GimbiDocument98 pagesRecognition of Isolated Signs in Ethiopian Sign Language Tefera GimbinaNo ratings yet

- For All Sanfoundry MCQ (1000+ MCQ) JOIN Telegram GroupDocument472 pagesFor All Sanfoundry MCQ (1000+ MCQ) JOIN Telegram GroupRitesh DeshmukhNo ratings yet

- Multipliers Used To Convert To Standard Measurement Units ReferencesDocument18 pagesMultipliers Used To Convert To Standard Measurement Units Referencesira huttNo ratings yet

- MAD Worksheet 1Document8 pagesMAD Worksheet 1harshasingha450No ratings yet

- WiproDocument46 pagesWiprorajabharathreddyNo ratings yet

- (Auditing and Accounting Studies) Kristina Yankova (Auth.)-The Influence of Information Order Effects and Trait Professional Skepticism on Auditors’ Belief Revisions_ a Theoretical and Empirical AnalyDocument321 pages(Auditing and Accounting Studies) Kristina Yankova (Auth.)-The Influence of Information Order Effects and Trait Professional Skepticism on Auditors’ Belief Revisions_ a Theoretical and Empirical AnalyYahya Chiguer100% (1)

- 1) Monitor Oracle BackupsDocument5 pages1) Monitor Oracle Backupsjerome MossNo ratings yet

- Full of Example Guys!!!!! Heheheheh: Chapter 4: Flow in Pipes Example #1Document6 pagesFull of Example Guys!!!!! Heheheheh: Chapter 4: Flow in Pipes Example #1ilya danisyahNo ratings yet

- Wang Heng - Active Neutral Point Clamped (ANPC)Document16 pagesWang Heng - Active Neutral Point Clamped (ANPC)matias parra cuellarNo ratings yet

- BPC 10.1 Exercises - Workshop PDFDocument77 pagesBPC 10.1 Exercises - Workshop PDFPradeep Kumar Reddy GNo ratings yet

- Mémoire de Fin D'Études: en Hydrobiologie Marine Et ContinentaleDocument40 pagesMémoire de Fin D'Études: en Hydrobiologie Marine Et ContinentaleOumaima AmrouneNo ratings yet

- Thumb Rules in Building Construction For Civil Engineers - Important Point of Civil Engineering - Construction Thumb Rules - Civil SiteDocument36 pagesThumb Rules in Building Construction For Civil Engineers - Important Point of Civil Engineering - Construction Thumb Rules - Civil SiteSandeep Kumar100% (2)

- Free Training On Liquified Natural Gas 2Document4 pagesFree Training On Liquified Natural Gas 2CilliaNo ratings yet

- Creating Hello World Web Widget With HTML CSS and JavascriptDocument10 pagesCreating Hello World Web Widget With HTML CSS and Javascriptrajeshlal100% (1)

- Lecture 2 - Load Balancing MethodDocument13 pagesLecture 2 - Load Balancing MethodLexi BarcelonNo ratings yet

- Basic Engine: Systems OperationDocument2 pagesBasic Engine: Systems OperationMedo SowarNo ratings yet

- The UniverseDocument5 pagesThe UniverseAn MaNo ratings yet

- 2nd Year PPT ModelDocument14 pages2nd Year PPT ModelanbuelectricalNo ratings yet

- Chapter 2Document40 pagesChapter 2Negash adane100% (1)

- Optimization Techniques: Amrita Vishwa VidyapeethamDocument38 pagesOptimization Techniques: Amrita Vishwa Vidyapeethamsivasrinivas venigallaNo ratings yet

- MSDS 6. 33kv, 33 KV, PTDocument2 pagesMSDS 6. 33kv, 33 KV, PTRamu RamuNo ratings yet

- Mechanical Datasheet - Wellhead Compressor Package Rev BDocument12 pagesMechanical Datasheet - Wellhead Compressor Package Rev BRokan Pipeline100% (1)

- Cemb Data Sheet TR-26 Atex 06 GB PDFDocument2 pagesCemb Data Sheet TR-26 Atex 06 GB PDFhamzaNo ratings yet