Professional Documents

Culture Documents

Research Proposal

Research Proposal

Uploaded by

Yasith WeerasingheOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Research Proposal

Research Proposal

Uploaded by

Yasith WeerasingheCopyright:

Available Formats

RESEARCH PROPOSAL

TITLE The Impact of Pre-Printing Waste to the Overall Cost of Printing Industry, Based on Mithuru Printers (PVT) Ltd

1.0

INTRODUCTION

1.1 BACKGROUNG OF THE COMPANY

1.2 PRODUCT & SERVICES

1.3 PERFORMANCE

-1-

1.4 STATEMENT OF THE PROBLEM The problem of spoilage and waste control in the printing industry in Sri Lanka cannot be overemphasized. It had been discussed in printers association. Observation showed that waste created in printing business in the cities of Colombo and Outstation was enormous-a lot of papers, inks, darkroom chemicals, films, and plates. The practice has become a normal trend for the employees and management of these printing businesses, without realizing the effect waste poses on the customers, the company, the environment, and the Sri Lankan society as a whole. The quantity of waste created affects the production cost, and its disposal poses a threat to the environment. In Sri Lanka, the disposal of printing waste doesnt cost printing businesses financially. Even though there are laws governing the proper disposal of waste, these laws are not enforced. Since there are no strict penalties for improper disposal of waste and spoilage, printing businesses dispose of their waste anywayin gutters, in dumpsters, in rivers, and on the land. Emission of VOCs leads to the formation of photochemical smog (ozone) by reacting with oxides of nitrogen, other pollutants and sunlight. Photochemical smog affects human health. A number of VOCs are considered to be hazardous air pollutants, e.g. Toluene, MEK etc. Many plant oils can be used as vehicles for pigments in ink. In fact, prior to the early 1960s, linseed, soy, corn and canola were common ingredients in ink. Petroleum products were substituted on a large scale from the early 60s on, primarily because presses were running faster and needed shorter drying times. However, modern technologies, such as UV/EB curing, do enable fast drying times using plant derived or aqueous inks and coatings. Pollution is caused by the evaporation of organic solvents. Organic solvents evaporate at different rates. The vapor pressure of a solvent will indicate how quickly it will evaporate. A high vapor pressure solvent will evaporate quickly (eg. toluene). Many solvents used for press washing and in fountain solutions lose up to half of their volume before they even get to perform the work they are intended for. For example 40-50% of IPA (Isopropyl Alcohol) employed in alcohol dampening systems evaporates in the fountain. Similar volumes of press cleaning solvents will evaporate before any cleaning function is accomplished. As indicated above pre-printing waste contributes a lot to the overall waste in printing industry and it directly affects the total cost of printing industry as well. Hence, this research aims to investigate the relationship between pre-printing waste and overall cost of printing industry.

-2-

1.5 RESEARCH QUESTIONS

1.3.1 1.3.2

Why pre-printing waste is important to printing industry? What is the relationship between pre-printing waste and overall waste of

printing? 1.3.3 1.3.4 cost? What is the relationship between pre-printing waste and overall printing cost? What is the relationship between overall waste of printing and overall printing

1.6 HYPOTHESIS There is a positive co-relation exists between pre-printing waste and overall cost of printing industry.

1.7 RESEARCH OBJECTIVES

1.5.1

To find out the significance of pre-printing waste to overall cost of printing

industry. 1.5.2 To identify the relationship between pre-printing waste and overall waste of

printing. 1.5.3 cost. 1.5.4 To determine the relationship between overall waste of printing and overall To discover the relationship between pre-printing waste and overall printing

printing cost.

-3-

2.0

REVIEW OF THE LITERATURE

Waste is defined as something lying unproductive, inhabited, or desolate. Generally all waste appears in three forms, namely: solid waste, wastewater (liquid waste), and air emission (Appiah, 2002). Waste reduction which is vital to the growth and development of printing businesses in Sri Lanka cannot be overemphasized. In order to run a printing business as economically and efficiently as possible, one should reduce all types of wastes including hazardous wastes, solid wastes, and air and water emissions. Waste generation is inevitable in printing industry. All the printing processes, namely, offset lithographic printing, gravure printing, flexography/letterpress, and screen printing use materials and chemicals that generate waste. When the waste generated causes financial loss to a company and poses a threat to the environment-air, water, and land, then it becomes a problem to society at large. The Printing Industry The printing industry uses various printing technologies for printing books, magazine, newspapers, business documents, catalogs, form, etc. These technologies include lithography, rotogravure, flexography, screen, letter-press, and digital technologies including inkjet and electro-photography. The use of these technologies depends on the required quality of the print, number of impressions to be printed, availability of required resources, cost of the equipment, consumables cost per unit, need to use variable content, and other factor (Romano, 2004).

Classification of Waste It is important to note that waste does differ from process to process and the methods of reducing waste in one printing process do not necessarily apply to other printing processes. There are three major waste streams found in the printing industry. They include: (a) Solid waste in general printing environment solid waste could consist of the following: empty containers, used film packages, outdated materials, damaged plates, developed films, dated materials, test production, bad printing or spoilage, damaged product, and scrap papers. (b) Water waste water waste from printing operations may contain lubricating oils, waste ink, clean-up solvents, photographic chemicals, acids, alkaline, and plate coatings, as well as metals such as silver, iron, chromium, copper, and barium. (c) Air emissions printing operations produce volatile organic compound emissions from the use of cleaning solvents and inks, as well as alcohol and other wetting agents used in lithographic printing. Larger plants can be the source of sulfur dioxide emissions (Lewis, 1982). Finishing operations may include final trimming, die cutting, folding, collating, binding, laminating, embossing, and assembling

-4-

operations. Binding methods include stitching (stapling), gluing, and mechanical binding. The primary waste are binding and laminating chemicals and scrap papers (Banerjee, 2001). This study reviews literature on waste generation and reduction in offset lithographic printing. However, to give a reader a fair understanding of what the researcher does intend, the literature was written.

-5-

3.0

METHODOLOGY

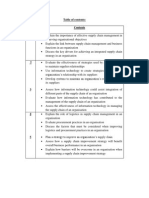

3.1 CONCEPTUAL FRAMEWORK

Dependant Variable

Intermediary Variable

Indipendant Variables

Pre-printing Waste Raw Material Waste

Volatile Organic Compounds Heavy Metals & NonRenewables

Overall Cost

Overall Waste

Energy Waste

Ink Waste

Emission Waste

3.2 SAMPLING

In view of collecting primary data, stratified simple random sampling method is used in this study.

3.3 INSTRUMENTATION Data collection will be carried out through a form of survey method in the research by the researcher. This survey uses a questionnaire to collect data and sometimes researcher will use interview techniques to collect primary data. This questionnaire -6-

will be consisting of qualitative and quantitative question forms to collect trustworthy data in order to eliminate the prejudice of research data collection.

3.4 DATA COLLECTION AND ANALYSIS

For data presentation and analysis, both descriptive and inferential statistics will be used. Descriptive statistics will be increasingly described the data that will be collected by means of frequency counts, ranges (high and low scores or values), means, modes, median scores, and standard deviations. For better understanding, variables and distributions will be described that are considered as the essential concepts of descriptive statistics.

Inferential statistics were used to draw conclusions and make predictions based on the descriptions of data. In this case, Pearson correlation was employed along with probability, populations, and sampling.

LIMITATIONS AND DELIMITATIONS

As stated, this research will be focusing on procurement functions and overall cost of printing industry. Therefore procurement function involved in other supply chain managements will not be considered in this research. The selected sample might not represent a true picture of the entire population; the researcher will be using a non probability, judgment sampling method. All possible measures will be taken to limit biasness and other errors during sampling.

The reluctance of the respondents to disclose their names and addresses and hesitation to answer some of the questions were also limitations. Reluctance of certain inhabitants due to frighten to the existing government rules and regulations will also limitations.

-7-

RESEARCH PLAN

10.1 10.2 10.3 10.4 10.5 10.6

Introduction. Literature Review. Methodology. Data Presentation and Analysis. Conclusion. Recommendations.

ACTION PLAN

WEEKS NEEDED FROM 17 DEC 12 - 30 MAY 13 DESCRIPTION 1st Week 2nd Week 3rd Week 4th Week 5th Week 6th Week 7th Week 8th Week 9th Week 10th Week 11th Week 12th Week 13th Week 14th Week 15th Week 16th Week 17th Week 18th Week 19th Week 20th Week 21st Week 22nd Week 23rd Week

Literature review 17 Dec 12 - 21 Jan 13 Preparation of questionnaires 22 - 28 Jan 13 Field work 29 Jan - 19 Feb 13 Submission of Proposal 22 Feb 13 Clean/Edit/Coding data 23 Feb - 5 Mar 13 Analysis of data 6 - 30 Mar 13 Report writing (Initial work) 31 Mar - 28 May 13 Final Report Submission 30 May 13

-8-

REFERENCES & BIBLIOGRAPHY

Appiah, I. K. (2002). Printing techniques. Kumasi, Ghana: Kwame Nkrumah. University of Science & Technology Publishing. Banerjee, S. B. (2001). Managerial perceptions of corporate environmentalism: Interpretations from industry and strategic implications for organizations. Journal of Management Studies, 38, 489-513. Dalessandro, W. (2001). Critical issues in strategic corporate environmental management. Arlington, MA: Business and the Environment, Cutter Information Corp. Hird, K. F. (1991). Offset Lithographic Technology. Tinley Park, Ill: Goodheart-Willcox Company, Inc. Lewis, P. V. (1982). Managing Human Relations. Boston, MA: Kent Publishing Company. Romano, F. (2003). The state of printing in the United States. Electronic Publishing, 27:12. Romano, F. (2004). An investigation into printing industry trends (PICRM-2004-01). Rochester, NY: Rochester Institute of Technology, Printing Industry Center. Rothenberg, S., Toribia, R. & Becker, M. (2002). Environmental management in lithographic printing (PICRM-2002-07). Rochester, NY: Rochester Institute of Technology, Printing Industry Center. Tilley, F. (1999). The gap between the environmental attitude and the environmental behavior of small firms. Business Strategy and the Environment, 8, 238-248. http://www.colduv.com/ http://www.epri.com/EPRI_Journal/dec_1994/Electech_cure.html http://kaos.erin.gov.au/portfolio/epg/environet/ncpd/auscase_studies/fildes.htm http://www.erin.gov.au/portfolio/epg/environet/ncpd/auscase_studies/ http://www.pneac.org/pneac.html http://www.edf.org/pubs/EDF-Letter/1993/Nov/k_pollprvc.html http://es.cpa/gov/techinfo/facts/mass/tura-fs6.html http://www.epa.gov/opptintr/dfe/flexography/case_studies/case1 http://www.epa.gov/opptintr/dfe/flexography/case_studies/case2 http://www.maricopa.gov/sbeap/printp3.htm

-9-

You might also like

- Easy Media Profiling GuideDocument88 pagesEasy Media Profiling Guidegfxtoolscz100% (2)

- Ipscmi Sample Exam Paper Certified International Supply Chain Manager BLUE OCEAN Training & ConsultancyDocument5 pagesIpscmi Sample Exam Paper Certified International Supply Chain Manager BLUE OCEAN Training & ConsultancyYasith Weerasinghe100% (1)

- Filament Feasibility Study 250416Document19 pagesFilament Feasibility Study 250416epsilon. idNo ratings yet

- Blue Operation ManualDocument92 pagesBlue Operation ManualRakesh Basdeo67% (3)

- Project Report On Fully Automatic Paper Straw (Eco Friendly) Manufacturing PlantDocument4 pagesProject Report On Fully Automatic Paper Straw (Eco Friendly) Manufacturing PlantEIRI Board of Consultants and PublishersNo ratings yet

- Disfonía Del Niño y Del Adolescente - Adriana HabbabyDocument176 pagesDisfonía Del Niño y Del Adolescente - Adriana HabbabyStephanie García EscobarNo ratings yet

- US Navy Course NAVEDTRA 14065 Illustrator Draftsman 3 & 2 Vol 4-Presentations GraphicsDocument276 pagesUS Navy Course NAVEDTRA 14065 Illustrator Draftsman 3 & 2 Vol 4-Presentations GraphicsGeorgesNo ratings yet

- Bagworkshop Pantone Colour Guide PDFDocument1 pageBagworkshop Pantone Colour Guide PDFAchmad Nyangnyang100% (1)

- Atexco VEGA 3180DT Digital Textile PrinterDocument6 pagesAtexco VEGA 3180DT Digital Textile PrinterAsim67% (3)

- TypographyDocument8 pagesTypographyapi-348232256100% (1)

- Ink Related Pollution in Printing IndustriesDocument11 pagesInk Related Pollution in Printing Industriesanon_351034890No ratings yet

- Environmental Impacts of Offset PrintingDocument4 pagesEnvironmental Impacts of Offset PrintingAseem Chauhan100% (2)

- Life Cycle Assessment of An in Kjet Print Cartridge: PollockDocument7 pagesLife Cycle Assessment of An in Kjet Print Cartridge: PollockMaxNo ratings yet

- Case Study - Wastewater ETPDocument21 pagesCase Study - Wastewater ETPsarwar jahanNo ratings yet

- Life Cycle Analysis of Tissue Paper ManufacturingDocument8 pagesLife Cycle Analysis of Tissue Paper ManufacturingSashi AgustinaNo ratings yet

- (Management and Production Engineering Review) Life Cycle Analysis of Tissue Paper Manufacturing From Virgin Pulp or Recycled Waste PaperDocument8 pages(Management and Production Engineering Review) Life Cycle Analysis of Tissue Paper Manufacturing From Virgin Pulp or Recycled Waste Paper2742481No ratings yet

- Research Paper RmitDocument8 pagesResearch Paper Rmitgvzf446w100% (1)

- Green Printing: Inevitability For Printing Industry SustainabilityDocument4 pagesGreen Printing: Inevitability For Printing Industry SustainabilitySarath SachuNo ratings yet

- LCA FinalDocument38 pagesLCA FinalJunard LandinginNo ratings yet

- Ijaiem 2012 11 09 010Document8 pagesIjaiem 2012 11 09 010International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- PDFFFFFFFFFFFFF RemovedDocument34 pagesPDFFFFFFFFFFFFF RemovedSURENDAAR DNo ratings yet

- Al Hameedi2020Document15 pagesAl Hameedi2020Anissa Dafa KamilaNo ratings yet

- Superseded PPM Bref-1201Document509 pagesSuperseded PPM Bref-1201Zahid LatifNo ratings yet

- Environmental Engg 82 Assignmnet 2Document22 pagesEnvironmental Engg 82 Assignmnet 2sikkikhan1234No ratings yet

- The Chemistry of Printing Inks and Their Electronics and Medical ApplicationsFrom EverandThe Chemistry of Printing Inks and Their Electronics and Medical ApplicationsNo ratings yet

- E-Waste Management Literature ReviewDocument5 pagesE-Waste Management Literature Reviewgw060qpy100% (1)

- Synopsis DocumentDocument7 pagesSynopsis DocumentRani JaiswalNo ratings yet

- World Class OperationsDocument6 pagesWorld Class OperationsvNo ratings yet

- Dr. Tran Van NHAN: Hanoi University of Technology (Vietnam)Document2 pagesDr. Tran Van NHAN: Hanoi University of Technology (Vietnam)yus11No ratings yet

- Recycling of Printed Papers and Usability in Flexo Printing PackagingDocument11 pagesRecycling of Printed Papers and Usability in Flexo Printing PackagingoximasraiaNo ratings yet

- Management of Industrial WastesDocument11 pagesManagement of Industrial WastesVivek YadavNo ratings yet

- BananaDocument15 pagesBananaIrvany PetitNo ratings yet

- PulpPaper PDFDocument57 pagesPulpPaper PDFNavaganesh KannappenNo ratings yet

- Local Sustainability and Competitiveness: The Case of The Ceramic Tile IndustryDocument54 pagesLocal Sustainability and Competitiveness: The Case of The Ceramic Tile IndustryPhuc DcNo ratings yet

- Papermaking Vol5 Nr1 2019 - Complete Issue - LRDocument205 pagesPapermaking Vol5 Nr1 2019 - Complete Issue - LRAndrew Richard ThompsonNo ratings yet

- Literature Review On Solid Waste ManagementDocument4 pagesLiterature Review On Solid Waste Managementafmzjbxmbfpoox100% (1)

- An Inventory Framework For Inclusion of Textile CHDocument11 pagesAn Inventory Framework For Inclusion of Textile CHSaisab AhmedNo ratings yet

- Final Report MainDocument24 pagesFinal Report MainHL DARSHANNo ratings yet

- Characteristicsand Treatmentof Pulpand Paper Mill Effluents AReviewDocument9 pagesCharacteristicsand Treatmentof Pulpand Paper Mill Effluents AReviewJaderson CarvalhoNo ratings yet

- Sustainable Supply Chain in Pulp and Paper Industry: A ReviewDocument13 pagesSustainable Supply Chain in Pulp and Paper Industry: A ReviewDiscord YtNo ratings yet

- Reducing Paper Usage Research PaperDocument10 pagesReducing Paper Usage Research PaperNandaa PutriiNo ratings yet

- Dissertation On Waste ManagementDocument4 pagesDissertation On Waste ManagementWriteMyPaperCanada100% (2)

- Team 17: Estimation of Environmrntal Impact of Additive Manufacturing MaterialsDocument9 pagesTeam 17: Estimation of Environmrntal Impact of Additive Manufacturing MaterialsjSunayanaNo ratings yet

- SLT ResearchDocument49 pagesSLT ResearchChamod KanishkaNo ratings yet

- AramcoDocument9 pagesAramcoTamsila AmjadNo ratings yet

- Optimization of Managing Waste in Textile Industry: K. Prabhakumari S.R.Tamil SelvanDocument6 pagesOptimization of Managing Waste in Textile Industry: K. Prabhakumari S.R.Tamil SelvanIJSREDNo ratings yet

- SCH3U: Chemistry and The Environment ProjectDocument2 pagesSCH3U: Chemistry and The Environment Projectswagmaster415No ratings yet

- Abstrac 1Document18 pagesAbstrac 1Sozdar ArgoshiNo ratings yet

- EPM Mod5@AzDOCUMENTS - inDocument14 pagesEPM Mod5@AzDOCUMENTS - inRaunitNo ratings yet

- Research Project: Community Waste Management SystemDocument59 pagesResearch Project: Community Waste Management SystemGaurav KumarNo ratings yet

- Developing and Implementing A Web-Based Recycling System For Protecting The Green EnvironmentDocument14 pagesDeveloping and Implementing A Web-Based Recycling System For Protecting The Green EnvironmentAnonymous rVWvjCRLGNo ratings yet

- Assessment of Carbon Footprint in Different Industrial Sectors, Volume 1 (Esther Sanyé-Mengual Etc.)Document297 pagesAssessment of Carbon Footprint in Different Industrial Sectors, Volume 1 (Esther Sanyé-Mengual Etc.)Dr Abhijeet GangulyNo ratings yet

- 10 1016@j Psep 2020 05 034Document82 pages10 1016@j Psep 2020 05 034Kevin SalvatierraNo ratings yet

- Guidelines and Legislation For Dye House Ef Uents: C. Hessel, C. Allegre, M. Maisseu, F. Charbit, P. MoulinDocument10 pagesGuidelines and Legislation For Dye House Ef Uents: C. Hessel, C. Allegre, M. Maisseu, F. Charbit, P. MoulinDinesh VermaNo ratings yet

- Solution 1 First Step (Pre-Environmental Impact Assessment)Document12 pagesSolution 1 First Step (Pre-Environmental Impact Assessment)Ajewole Eben TopeNo ratings yet

- 2015 127 CruzDocument10 pages2015 127 CruzAnonymous 2KdsynJXGxNo ratings yet

- Persyaratan Laboratorium Lingkungan Dan Kondisinya Di IndonesiaDocument12 pagesPersyaratan Laboratorium Lingkungan Dan Kondisinya Di IndonesiaRusmin NuryadinNo ratings yet

- Analisis Material, Energi Dan Toksisitas (Met) Pada Industri PenyamakanDocument13 pagesAnalisis Material, Energi Dan Toksisitas (Met) Pada Industri PenyamakanFerry ApriliantoNo ratings yet

- Chemical WasteDocument13 pagesChemical WasteHunter BaderNo ratings yet

- Guides To Pollution Prevention - The Paint Manufacturing IndustryDocument72 pagesGuides To Pollution Prevention - The Paint Manufacturing Industryalfonsus_ligouriNo ratings yet

- Integrated Pollution Prevention and Control (IPPC) Reference Document On Best Available Techniques For The Textiles Industry July 2003Document22 pagesIntegrated Pollution Prevention and Control (IPPC) Reference Document On Best Available Techniques For The Textiles Industry July 2003Ahmed Munirul HaqueNo ratings yet

- Life Cycle Analysis and Environmental Impact Assessment97Document63 pagesLife Cycle Analysis and Environmental Impact Assessment97Alexis PulhinNo ratings yet

- 12 - Chapter 1Document5 pages12 - Chapter 1Arnav SenNo ratings yet

- Art 00008Document21 pagesArt 00008Ahmet AltunNo ratings yet

- Solid Waste ManagementDocument38 pagesSolid Waste Managementshri kanetkarNo ratings yet

- Format For ChaptersDocument10 pagesFormat For ChaptersVijay VanveNo ratings yet

- Final Technical ReportDocument27 pagesFinal Technical ReportvenkNo ratings yet

- INTRODUCTIONDocument1 pageINTRODUCTIONYasith WeerasingheNo ratings yet

- Internet of Things in Power Distribution Networks - State of The ArtDocument5 pagesInternet of Things in Power Distribution Networks - State of The ArtYasith Weerasinghe100% (1)

- Literature ReviewDocument1 pageLiterature ReviewYasith WeerasingheNo ratings yet

- PWC Reverse Logistics PDFDocument97 pagesPWC Reverse Logistics PDFYasith Weerasinghe100% (2)

- Strategic Supply Chain Management and Logistics-120626131827-Phpapp01Document15 pagesStrategic Supply Chain Management and Logistics-120626131827-Phpapp01awais04100% (1)

- DRDRDocument1 pageDRDRYasith WeerasingheNo ratings yet

- Management System Based On The ISO 9001:2008 International Quality StandardsDocument48 pagesManagement System Based On The ISO 9001:2008 International Quality StandardsYasith WeerasingheNo ratings yet

- California Management Review, Vol 44, No 3 For Guidance On Demand and Supply Uncertainties 10 May 2014Document1 pageCalifornia Management Review, Vol 44, No 3 For Guidance On Demand and Supply Uncertainties 10 May 2014Yasith WeerasingheNo ratings yet

- (60Sq) (30Sq) : Floor 1 35 FeetDocument2 pages(60Sq) (30Sq) : Floor 1 35 FeetYasith WeerasingheNo ratings yet

- A Dossier On The Brand Samsung Product: Samsung Mobile: Submitted To Prof Srinivas Govindrajan On 10-Aug-2013Document27 pagesA Dossier On The Brand Samsung Product: Samsung Mobile: Submitted To Prof Srinivas Govindrajan On 10-Aug-2013Yasith WeerasingheNo ratings yet

- S.No Name of The University State: Category "A"Document6 pagesS.No Name of The University State: Category "A"Yasith WeerasingheNo ratings yet

- Part 03 - Eport-Factory Layout PlanDocument1 pagePart 03 - Eport-Factory Layout PlanYasith WeerasingheNo ratings yet

- The Significance of Improving Customer Reliability Through Customer Service A Study Based On Upcountry Manpower AgencyDocument10 pagesThe Significance of Improving Customer Reliability Through Customer Service A Study Based On Upcountry Manpower AgencyYasith WeerasingheNo ratings yet

- Blockbuster Blu-Ray Zone Movie TitlesDocument55 pagesBlockbuster Blu-Ray Zone Movie TitlesYasith WeerasingheNo ratings yet

- The Impact of Resource Commitment On Reverse Logistics and Customer Loyalty A Study Based On Consumer Electronics Retail Industry in Sri LankaDocument2 pagesThe Impact of Resource Commitment On Reverse Logistics and Customer Loyalty A Study Based On Consumer Electronics Retail Industry in Sri LankaYasith WeerasingheNo ratings yet

- FixdadaDocument1 pageFixdadaYasith WeerasingheNo ratings yet

- Alcholism ResearchDocument68 pagesAlcholism ResearchYasith WeerasingheNo ratings yet

- BSC Ugc 120106Document6 pagesBSC Ugc 120106Yasith WeerasingheNo ratings yet

- PDocument1 pagePYasith WeerasingheNo ratings yet

- Shortnotes GhgsourcingDocument11 pagesShortnotes GhgsourcingYasith WeerasingheNo ratings yet

- Security PrintingDocument3 pagesSecurity PrintingalamunNo ratings yet

- Top 10 Futura Alternatives For 2017 TypewolfDocument5 pagesTop 10 Futura Alternatives For 2017 TypewolfluisricardosantosNo ratings yet

- Popfold 001vaultboy (Updated)Document4 pagesPopfold 001vaultboy (Updated)Grisha KovalchukNo ratings yet

- Riso Print Guide PDFDocument7 pagesRiso Print Guide PDFrosa carrara100% (1)

- SK Ensure Machinery PVT LTD Final Cataloge NewDocument23 pagesSK Ensure Machinery PVT LTD Final Cataloge NewRATSITOHARA EricNo ratings yet

- AOP Lecture Sheet 04Document8 pagesAOP Lecture Sheet 04Nakib Ibna BasharNo ratings yet

- Cinematic Fonts: My Favorite Christian Maté GrabDocument12 pagesCinematic Fonts: My Favorite Christian Maté GrabSMK ST PETRUSNo ratings yet

- Scope of PrintmakingDocument68 pagesScope of PrintmakingAditi PurwarNo ratings yet

- Quickmove Logo & Brand Identity GuidelinesDocument9 pagesQuickmove Logo & Brand Identity Guidelinesbrian steelNo ratings yet

- Digital: Modern Presentation TemplateDocument120 pagesDigital: Modern Presentation Templatehq bNo ratings yet

- SIBERIAN Font Billy Argel Fonts FontSpaceDocument1 pageSIBERIAN Font Billy Argel Fonts FontSpaceVedanshi DesaiNo ratings yet

- Rembrandts Etchings and Japanese EchizenDocument28 pagesRembrandts Etchings and Japanese EchizenRichard GabrielNo ratings yet

- ACCORIESS PrinterDocument1 pageACCORIESS PrinterSuparjoNo ratings yet

- css3 Cheatsheet Emezeta Eng PDFDocument2 pagescss3 Cheatsheet Emezeta Eng PDFismail096100% (1)

- Lipman Bottle Company Case Analysis - Group 1Document13 pagesLipman Bottle Company Case Analysis - Group 1Varun Gupta100% (1)

- DIXON 2002 Typeface ClassificationDocument11 pagesDIXON 2002 Typeface ClassificationTipo GráficoNo ratings yet

- 002 GPP M501 Image Carrier PreparationDocument5 pages002 GPP M501 Image Carrier PreparationRohit ShindeNo ratings yet

- Paper IndustryDocument24 pagesPaper IndustryJonas ParagasNo ratings yet

- Graphic Design HistoryDocument12 pagesGraphic Design HistorynissasusanNo ratings yet

- Satyam MishraDocument19 pagesSatyam Mishraphoto singhNo ratings yet

- BI Publisher Implementation IssuesDocument5 pagesBI Publisher Implementation IssuesShailesh DoiphodeNo ratings yet

- Bulletin16 Real Colegio de Anestesia PDFDocument56 pagesBulletin16 Real Colegio de Anestesia PDFRaul ForjanNo ratings yet

- Requisition Cross CountryDocument1 pageRequisition Cross CountryJP7090No ratings yet