Professional Documents

Culture Documents

Chapter 45 Sop Format - Fecal Coliform Version

Chapter 45 Sop Format - Fecal Coliform Version

Uploaded by

Aziz SyahputraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 45 Sop Format - Fecal Coliform Version

Chapter 45 Sop Format - Fecal Coliform Version

Uploaded by

Aziz SyahputraCopyright:

Available Formats

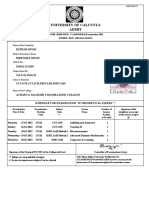

QUALITY SYSTEM DOCUMENT STANDARD OPERATING PROCEDURE EXAMPLE

Prepared by

VA AWWA/VWEA Laboratory Practice Committee

July 30, 2009

Page 1 of 21

ACKNOWLEDGEMENTS

The VA AWWA/VWEA Laboratory Practice Committee would like to thank the many hard-working volunteers and organizations who collectively contributed to the development of this example of an environmental laboratory quality system document. This guidance document would not have been actualized without their knowledge, time and effort. We hope you find this document to be a useful tool in working towards the goal of quality data and document control.

DISCLAIMER

While the VA AWWA/VWEA Laboratory Practice Committee attempts to include accurate information in the guidance document, occasional errors or omissions in content may occur. The VA AWWA/VWEA Laboratory Practice Committee will make reasonable efforts to correct errors or omissions but can make no representation of the accuracy of the information provided. Mention of trade names or commercial products does not constitute endorsement or recommendation for use.

Page 2 of 21

STANDARD OPERATING PROCEDURE: METHOD: Fecal Coliform Membrane Filter Technique; SM 9222D

Revision Number: __________ _____________________

Effective Date:

Name and title of author:

_____________________________________________________________________________ _

Approved by Quality Assurance Coordinator:

_____________________________________________________________________________ _

Approved by Technical Director:

_____________________________________________________________________________ _

Page 3 of 21

STANDARD OPERATING PROCEDURE: METHOD: Fecal Coliform Membrane Filter Technique; SM 9222D

RECORD OF REVIEW

Review Date: ____________ QAC Initials: ________ No

Revision (circle):Yes

Review Date: ____________ QAC Initials: ________ No

Revision (circle):Yes

Review Date: ____________ QAC Initials: ________ No

Revision (circle):Yes

Review Date: ____________ QAC Initials: ________ No

Revision (circle):Yes

Review Date: ____________ QAC Initials: ________ No

Revision (circle):Yes

Review Date: ____________ QAC Initials: ________ No

Revision (circle):Yes

Review Date: ____________ QAC Initials: ________ No

Revision (circle):Yes

Page 4 of 21

Review Date: ____________ QAC Initials: ________ No

Revision (circle):Yes

Review Date: ____________ QAC Initials: ________ No

Revision (circle):Yes

Review Date: ____________ QAC Initials: ________ No STANDARD OPERATING PROCEDURE:

Revision (circle):Yes

1.

Test Method

1.1 Fecal coliform membrane filter; SM 9222D

2.

Matrix or matrices

2.1 Surface water and recreational waters

3.

Method detection limit

3.1 1 cfu/100 mL

4.

Scope and application

4.1 Membrane filter is used in monitoring and enumerating fecal coliform bacteria in various untreated and recreational waters. The fecal coliform group (subset of the total coliform group) is defined as being comprised of many facultative anaerobic, gramnegative, non-spore forming, rod-shaped bacteria that have the ability to ferment lactose at elevated temperatures (44.5 0.2 C). 4.2 The laboratory application is to determine the fecal coliform bacteria levels in untreated surface water supplies including reservoir and tributaries; untreated sewage overflow and unknown runoff, and disinfected swimming pools.

5.

Summary of test method

Page 5 of 21

5.1 After sampling and filtration of the water sample through a 0.45 micron pore size filter, the membrane filter is placed on top of MFC medium containing lactose, protein digest, vitamins, bile salts, selective chemicals, and aniline blue dye. As the membrane incubates for 24 hr submerged in a 44.5 0.2 C water bath, the medium diffuses through the pores in the filter, supplying nutrients to the multiplying bacteria. The non-fecal coliforms, due to heat shock, generally do not grow. As the fecal coliforms grow, they ferment lactose and produce acid that reacts with the aniline dye to produce a blue color. When viewed with a 10-15X magnification, all colonies exhibiting a blue color are considered fecal coliforms.

6.

Definitions

6.1 Acceptance criteria: Specified limits placed on characteristics of an item, process, or service defined in requirement documents. 6.2 Blank: A sample that has not been exposed to the analyzed sample stream in order to monitor contamination during sampling, transport, storage or analysis. 6.3 Confluent growth: Is defined as a continuous bacterial growth covering the entire membrane filter without evidence of total coliform-type colonies. 6.4 Demonstration of capability (DOC): The procedure to establish the ability of the analyst to generate data of acceptable accuracy and precision. 6.5 Holding time: Is defined as the maximum time that a sample may be held prior to analysis and still be considered valid or not compromised. 6.6 Method detection limit: Is defined as the lowest concentration or amount of target analyte that can be determined from zero by a single measurement at a stated degree of confidence. 6.7 Matrix: The component or substrate that may contain the analyte of interest.

Page 6 of 21

6.8 TNTC: Too numerous to count is defined as greater than 200 colonies on the membrane filter in the absence of detectable coliforms. 6.9 Positive control: Measures taken to ensure that a test or its components are working properly and producing correct or expected results from positive test subjects.

7.

Interferences

7.1 Interferences include any non-fecal thermophilic colonies appearing on the filter. These colonies exhibit a green, gray or beige color.

8.

Safety

8.1 Use of lab coat, protective eye equipment and gloves during sample filtration is recommended. 8.2 Use of isopropanol is recommended for disinfection of the equipment and counter area. See material safety data sheets for more detailed information regarding the chemicals used in this test method. 8.3 Wrap the 1 Liter overflow flask in duct tape to prevent implosion. 8.4 Use plastic ampule breaker covers for opening M-FC broth ampules if glass ampules are purchased.

9.

Equipment and supplies

9.1 9.2 9.3 Water bath set for 44.5 0.2 C Autoclave Incubator set for 35.5 0.5 C

9.4 1 mL disposable pipettes with 1 mL pipette pump 9.5 10 mL disposable pipettes with 10 mL pipette pump 9.6 Sterile petri dishes with pads (50 x 9 mm) Page 7 of 21

9.7 Sterile membrane filters (47 mm, 0.45 micron pore size, white gridded) 9.8 Membrane filtration unit 9.8.1. Sterile glass funnels (wrapped in foil) with metal clamps 9.8.2 Manifold with attached 2 Liter (excess sample collector and 1 Liter flasks (overflow flask) 9.8.3 Suction pump 9.8.4 Smooth tipped forceps 9.8.5 Propane torch or alcohol lamp with mechanical lighter 9.9 Dissecting microscope set for 10-15X magnification

9.10 Sample containers (100 mL sterile IDEXX vessels) 9.11 Surface water sampling apparatus 9.12 Whirl-Pak bags for sample storage (remove sodium thiosulfate pill) 9.13 E.coli stock culture tube and sterile disposable inoculating loop 9.14 E. faecalis stock culture tube and sterile disposable inoculating loop

9.15 Calibrating new glass funnels 9.15.1 9.15.2 100 mL Graduated cylinder Glass etcher

9.16 Latex gloves or hand sanitizer (alternatively, wash hands thoroughly) 9.17 Plastic cover ampule breakers if glass ampules used 9.18 UV lamp (366 wavelength) 9.19 Stopwatch

10. Reagents and standards

10.1 Commercially prepared M-FC broth ampules (2.0 mL in each) 10.2 Sterile buffered rinse water (1 Liter) with sterile nozzle (wrapped in foil) Page 8 of 21

10.2.1

Preparation of potassium phosphate stock solution: Mix 34 grams of potassium phosphate with 500 mL deionized water, adjust pH to 7.20 0.5 with 1 N NaOH, then dilute to 1 Liter with lab pure water. Working solution of potassium phosphate solution: 1.25 mL / 1 Liter deionized water

10.2.2

Preparation of magnesium chloride stock solution: Mix 81.1 grams of magnesium chloride with 1 Liter deionized water Working solution of magnesium chloride solution: 5 mL / 1 Liter deionized water

10.3 Commercially purchased sterile buffered dilution water (99 mL) 10.4 Non-denatured ethanol in vial (only 0.5 cm full for disinfecting tip of forceps) 10.5 Denatured isopropanol alcohol for disinfection 10.6 Nonselective growth medium 1X Tryptic Soy broth (TSB) 10.6.1 10.6.2 30 grams media / 1 Liter lab pure water in a 2 Liter beaker and mix on stirrer until clear. Add 40 mL of the mixture to a pH cup. Check pH of mixture prior to and after autoclaving on calibrated pH meter. Cover pH cup with foil. Add the appropriate amount of mixture to etched or marked glass bottles, either 25 or 50 mL volume, whichever is needed. Autoclave bottles, pH cup and maximum registering thermometer (shaken down to room temperature). Set autoclave for 15 minutes. Do not exceed 45 minutes.

10.6.3

10.6.4

Page 9 of 21

10.6.5

Remove bottles from autoclave, cool and label. Check pH after autoclaving; acceptance range is 7.3 0.2. Perform a sterility check and a positive quality control check (inoculate with E. coli stock culture bacterium) prior to using. Discard TSB if quality controls do not meet desired results.

10.6.6

10.7 Nonselective growth medium 2X Tryptic Soy broth

10.7.1 10.7.2

60 grams media / 1 Liter lab pure water in a 2 Liter beaker and mix on stirrer until clear. Follow the above procedure 10.6.2 through 10.6.6.

11. Sample collection, preservation, shipment and storage

11.1 Sample from a river, stream, lake or reservoir by holding the bottle near its base in the hand and plunging it, neck down ward, below the surface. Turn bottle until neck points slightly upward and mouth is directed toward the current. If there is no current, as in the case of a reservoir, create a current artificially by pushing bottle forward horizontally in a direction away from the hand. When sampling from a boat, obtain samples from upstream side of boat. If it is not possible to collect samples from these sites in this way, attach a weight to base of bottle and lower it into the water. In any case, take care to avoid contact with bank or streambed; otherwise water fouling may occur. When a sampling apparatus is used, sample vessels should be placed in apparatus firmly. 11.2 Sample collection vessels contain sodium thiosulfate as a neutralizing agent for samples containing chlorine. Source water samples must be held a <10 C in a cooler. 11.3 The time from sample collection to initiation of analysis for fecal coliforms in source water must not exceed 8 hours. All samples received in the laboratory should be analyzed on the day of Page 10 of 21

receipt. All samples are to be placed in the bacteriological refrigerator immediately upon arrival to the laboratory.

12. Quality control

12.1 Water bath temperature reading (44.5 0.2 C) must be taken twice daily four hours apart. 12.2 Bacteriological refrigerator temperature reading (1-5 C) must be taken once per day. 12.3 If the capability of the water bath is compromised, a known positive will be included with the samples to determine if the growth condition for the fecal coliform bacteria is suitable. This consists of inoculating a 99 mL sterile buffered dilution water bottle with the stock culture E.coli. Filter only 1.0 mL. 12.4 Prior to using a new lot of M-FC broth, inoculate a prepared fecal coliform plate with the stock culture organism E.coli as a positive quality control. Prior to using the new lot of M-FC broth, inoculate a prepared fecal coliform plate with the stock culture organism E. faecalis as a negative quality control. Incubate an additional M-FC broth plate (without sample or bacterium) for a sterility check. Incubate all three at 44.5 0.2 C in water bath for 24 hrs. Observe for expected result. 12.5 Check the pH of the M-FC broth when it is received. It must meet the manufacturers specified range. 12.6 For each membrane filter funnel set, a BEFORE and AFTER blank of 100 mL rinse water is filtered. After every 10 water samples for each membrane filter funnel, a DURING blank of 100 mL rinse water is filtered. If any of these blanks become contaminated, all samples filtered from that funnel set are rejected. 12.7 Upon receiving new lot Colilert vessels (sample collection bottles), the following quality controls are performed: 12.7.1 A new lot Colilert vessel sterility check with the nonselective growth medium 1X Tryptic Soy broth is performed. Incubate in the incubator at 35.5 0.5 C for 24 and 48 hrs. The quality control is considered positive when growth is observed. Do not use lot. Page 11 of 21

12.7.2 The effectiveness of the manufacturer added sodium thiosulfate must be tested prior to using the sample containers. In a one gallon water jug add 3 Liters of lab pure water and 0.3 mL of store bought bleach. Shake thoroughly and measure total chlorine residual (this procedure should yield roughly 6 ppm). Adjust the bleach solution if necessary to yield 5-10 ppm total chlorine residual. Add 100 mL of the bleach solution to the Colilert vessel and shake. Measure the total chlorine residual once more. Results should show the sodium thiosulfate neutralizes the chlorine. Adjustments to the bleach solution preparation will need to be made as bleach oxidizes over time. 12.7.3 Check 100 mL mark on Colilert vessel with 100 mL class A graduated cylinder. Add water to the 100 mL mark on vessel, and then pour into the graduated cylinder and measure. If not within 2.5% tolerance, do not use lot. 12.7.4 Check Colilert vessel for autofluorescence with UV lamp. If the vessel gives off fluorescence, do not use lot. 12.8 A newly prepared buffered rinse water is checked for sterility with the nonselective growth medium 2X Tryptic Soy broth. Incubate in the incubator at 35.5 0.5 C for 24 and 48 hrs. The quality control is considered positive when growth is observed. Do not use batch. 12.9 One membrane filter from each new lot shall be check for sterility with the nonselective growth medium 1X Tryptic Soy broth. The quality control is considered positive when growth is observed. Do not use lot. 12.10 The laboratory pure water for medium and reagent preparation (type I or II water) shall receive the following analyses: 12.10.1 Monthly: Measure the total chlorine residual. Results should yield < 0.1 mg / Liter. 12.10.2 Monthly: Measure the specific conductance. Result should yield > 0.5 Megaohm at 25 C. 12.10.3 Monthly: Analyze for heterotrophic bacteria (HPC). Results should yield < 500 cfu / mL.

Page 12 of 21

12.10.4 Yearly: Analyze for Pb, Cd, Cr, Cu, Ni and Zn metals. Results should yield no greater than 0.05 mg / L per contaminant and/or collectively, no greater than 0.1 mg / L. 12.11 Autoclave quality controls: 12.11.1 Biological indicators shall be used once per month to determine effective sterilization. 12.11.2 Temperature sensitive tape shall be used with the contents of each autoclave run to indicate that the autoclave contents have been processed. 12.11.3 Annual maintenance check shall be performed either internally or by service contract and shall include pressure check and calibration of temperature device. 12.11.4 The autoclave mechanical timing device shall be checked quarterly against a stopwatch and the actual time elapsed documented. 12.12 Disposable pipettes are checked for accuracy upon receipt. A tolerance of 2.5% is allowed.

13. Calibration and standardization

13.1 The water bath and bacteriological refrigerator thermometers are calibrated against an ASTM thermometer yearly. Apply necessary correction factors. 13.2 Glass funnels are calibrated against a 100 mL class A graduated cylinder. If the manufacturers 100 mL mark differs from the calibration reading, etch a new line.

14. Procedure

14.1 Thoroughly disinfect the counter with isopropanol. 14.2 Disinfect hands with hand sanitizer or wash hands, alternatively wear latex gloves.

Page 13 of 21

14.3 Attach the manifold to the 2 Liter flask. Attach the 2 Liter flask to the overflow 1 Liter flask and attach the overflow flask to the pump. 14.4 Disinfect the inside of the manifold openings, valves and clamps with isopropanol. Place valves in off position (horizontal). 14.5 Confirm that the membrane filter dispenser will not be depleted of membrane filters during the run. Refill if dispenser is low (less than ten membranes). Always have individually wrapped membrane filters available. 14.6 Remove the amount of M-FC ampules needed from the refrigerator and place them on the counter. Use isopropanol to disinfect them before opening. Remove the amount of petri dishes with pads and ampule breakers (if glass ampules) needed. Once the isopropanol has dried, cover the ampules with the plastic ampule breakers and break at scored line (alternatively, if plastic ampules used, no plastic ampule breakers needed). Dispense the broth into the petri dish aseptically. Carefully remove any excess broth (membrane should not be swimming in broth). 14.7 If all three funnels are used, three BEFORE blank petri dishes are labeled LEFT, MIDDLE and RIGHT. Each of these blanks correspond to the left, middle and right funnel. All three BEFORE blanks are run prior to filtering the samples. All three AFTER blanks are run after filtering the samples. For every ten samples a DURING blank for each funnel must be additionally run. Label the rest of the plates with the five digit laboratory ID number. 14.8 Remove the samples from the refrigerator and place in ascending laboratory ID number order. 14.9 Light the propane torch (or alcohol lamp). Direct the flame away from any flammable objects. The blue flame of the torch should be approximately on inch in length. Open the ethanol vial and place forceps in the ethanol. 14.10 Loosen the cap to the rinse water bottle. Aseptically peel back the foil from the nozzle while holding it from the other side and insert it into the rinse water bottle. Screw on tightly.

Page 14 of 21

14.11 Aseptically remove the foil from the three funnel sets and place them on the manifold. 14.12 Sample volume will be determined by expected bacterial density. An ideal sample volume will yield 20 to 60 coliform colonies. Dilutions and/or lesser volumes will be needed to achieve the colony count range. 14.13 Place the forceps in the ethanol vial once to cover the tip and then run through the flame. Do not blow out the flame; allow the flame to burn off the alcohol. This step is repeated prior to dispensing or moving a membrane filter. 14.14 Aseptically remove a membrane filter and place on the bottom portion of the funnel. When removing the top portion, do not set it down. While holding the top portion of funnel, center the membrane filter (grid-side up) on the surface of the funnel support, replace the top portion, and secure both segments with the clamp. 14.15 Fill each funnel first with 100 mL sterile rinse water. These are the BEFORE LEFT, MIDDLE and AFTER blanks. Turn on the vacuum and open manifold valves (vertical position). After the water has filtered through, rinse with three portions of 20-30 mL of buffered rinse water with a swirling action making sure to rinse at or above the 100 mL line. 14.16 Remove top portion of funnel and using forceps remove the membrane filter at the edge. Lift off the top of the petri dish and line the edge of the membrane filter with the inside of the plate. Roll the membrane filter onto the broth never letting go until it seats well in the petri dish. Avoid trapping any air bubbles under the membrane filter (nutrients from broth cannot come in contact with membrane filter; therefore no colonies will grow on an air bubble). Repeat this step for all blanks and samples. 14.17 Any samples requiring less than 50 mL to be filtered (diluted or not) will need 20 mL of rinse water to be added to the funnel prior to filtering. The 20 mL rinse water will allow the bacteria to disperse on the membrane filter for isolated colony growth (it will avoid confluent growth). For dilution instructions see section 23.

Page 15 of 21

Samples requiring the full 100 mL to be filtered do not need additional 20 mL rinse water added to funnel. 14.18 Shake the sample vigorously 25 times for proper mixing and pipette the appropriate amount of sample directly into the 20 mL rinse water. After the water has filtered through, rinse with three portions of 20-30 mL of buffered rinse water with a swirling action making sure to rinse at or above the water level (to wash down any bacteria off sides of funnel onto membrane filter). Repeat for all samples. 14.19 After all samples have been filtered, fill each funnel with 100 mL sterile rinse water. These are the AFTER LEFT, MIDDLE and AFTER blanks. After the water has filtered through, rinse with three portions of 20-30 mL of buffered rinse water with a swirling action making sure to rinse at or above the 100 mL line. The filtration series is considered ended when more than 30 minutes elapses between successive filtrations. 14.20 When complete, place two petri dishes in a Whirl-Pak bag and close tightly (water proof the bag). Add an additional bag over this one if necessary. Repeat for all petri dishes. Place wrapped petri dishes inverted, submerged under water, in a plastic test tube rack in the water bath. Use bottles filled with water or rustproof weights to anchor petri dishes below the water level. Place weights on plastic test tube rack. Place all prepared cultures in the water bath within 30 minutes after filtration. Incubate 24 2 hrs at 44.5 0.2 C.

15. Calculations

15.1 Colonies produced by fecal coliform bacteria on M-FC medium are various shades of blue. Non-fecal coliform colonies are gray to cream colored. Count the colonies under 10-15X magnification on the dissecting microscope. Use the equation below to calculate the result in cfu/100 mL (colony forming units / 100 mL). cfu / 100 mL = Bacterial colonies counted x 100 mL of sample Page 16 of 21

16. Method performance

16.1 All growth and recovery media shall be checked to assure that the target organism responds in an acceptable and predictable manner. 16.2 To ensure that analysis results are accurate, target organism identity shall be verified as specified in the method, e.g., by use of the completed test, or by use of secondary verification tests such as a catalase test. 16.3 Duplicate count shall be performed monthly on one positive sample, for each month that the test is performed. 16.4 If the lab has two or more analysts, each analyst shall count typical colonies on the same plate. Counts shall be within 10% difference to be acceptable. In a laboratory with only one analyst, the analyst shall count the same plate twice, with no more than 5% difference between the counts. 16.5 Demonstrate proficiency with the test method prior to first use. Analyze a minimum of 10 spiked samples whose quality system matrix is representative of those normally submitted to the laboratory, or by analyzing and passing one proficiency test series provided by an approved proficiency sample provider.

17. Pollution prevention

17.1 All fecal coliform samples shall be placed in an autoclave bag and autoclaved for 30 minutes.

18. Data assessment and acceptance for quality control measures

18.1 18.2 18.3 Results reported in units of cfu/100mL and corrected for any dilution factors. Reported results must meet all test method, certification and internal quality control measures. All sample results and all quality control results are reviewed by the bacteriologist prior to data entry into LIMS.

Page 17 of 21

18.4 18.5

All sample results are reviewed for plant, permit, internal and external customer specifications. The bacteriological sample result logbook is reviewed with LIMS by the quality assurance officer.

19. Corrective actions for out-of-control data

19.1 Sample data associated with a failed quality control are evaluated for the need to be reanalyzed or qualified. 19.2 Unacceptable quality control results are documented, and if the evaluation requires cause analysis, the cause and solution are recorded. 19.3 The analyst is responsible for initiating corrective actions and ensuring that exceedances of quality control acceptance criteria are documented and reported to the bacteriologist, quality assurance officer and/or technical director as appropriate. 19.4 Correction may include collecting another sample and/or reanalysis without further assessment. The test method SOP addresses the specific quality control procedures to take, otherwise, corrective actions start with assessment of the cause of the problem. 19.5 Corrective actions are recorded in the bacteriological logbook and documented on the corrective actions form. Comments and/or data qualifiers are entered in the comment section of the sample analysis result in LIMS by the bacteriologist and reviewed by the quality assurance officer.

20. Contingencies for handling out-of-control or unacceptable data

20.1 Compliance sample plates that do not produce countable colonies, such as those exhibiting confluent growth, are qualified in LIMS and a sample is re-collected as soon as possible. 20.2 Non-compliance sample plates that do not produce countable colonies are re-collected if necessary and/or possible, otherwise are qualified in LIMS and used for in-house information only and not reported. Page 18 of 21

20.3 Sample results associated with failed quality control, such as a positive blank, are rejected. The samples associated with the failed quality control are re-collected. 20.4 Effected internal and external customers are immediately notified verbally by the bacteriologist to arrange for sample recollection. 20.5 The out-of-control situation including cause and solution is documented in the corrective actions logbook.

21. Waste management

21.1 After sterilization, the bag can be disposed of using routine laboratory waste procedures.

22. References

22.1 Standard Methods for the Examination of Water and Wastewater; 20th Edition, 9222 D. Fecal Coliform Membrane Filter Procedure. 22.2 Chapter 45 Certification for Noncommercial Environmental Laboratories; 1VAC30-45-40, 1VAC30-45-730, 1VAC30-45-790 through 798. 22.3 National Environmental Laboratory Accreditation Conference; Chapter 5, Quality Systems, 2003 NELAC Standard.

23. Tables, diagrams, flowcharts and validation data

23.1 Serial Dilutions for Non-Potable Water

A

Undiluted Sample

B

Dilution of 10x

C

Dilution of 100x or 10-2 dilution

Page 19 of 21

pipette 11 mL 99 mL dilution water

pipette 11 mL 99 mL dilution water

C

Dilution of 100x or 10-2 dilution as prepared above

D

Dilution of 1000x or 10-3 dilution

E

Dilution of 10,000x or 10-4 dilution

pipette 11 mL 99 mL dilution water

pipette 11 mL 99 mL dilution water

23.2 Bacteriological Laboratory Correction Action Form Cause of out-of-control incident (check one): _____________ Analyst error _____________ Laboratory accident (result of lab equipment or circumstance) _____________ Other: Explain ____________________________________________

Page 20 of 21

____________________________________________ Date of incident: _________________

Date incident detected: _________________ Analyst(s) involved: _________________ Type of samples: ________________________ ________________________ ________________________ ________________________

Affected samples (lab ID number) __________________________________________ __________________________________________ __________________________________________ __________________________________________ Incident:

___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ Solution and corrective action taken: Date: __________ Initials: _______

___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________

Page 21 of 21

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- POWER BI TutorialDocument77 pagesPOWER BI TutorialAashirtha S100% (3)

- Handbook Conical MountingsDocument28 pagesHandbook Conical MountingsVito DigeoNo ratings yet

- Garden Seed Handbook Part 31Document5 pagesGarden Seed Handbook Part 31gezarolNo ratings yet

- 3 - APUSH Period 8 Notes 3 - Eisenhowers Cold WarDocument60 pages3 - APUSH Period 8 Notes 3 - Eisenhowers Cold WarChrisNo ratings yet

- Goodman ss-gsz16Document36 pagesGoodman ss-gsz16nam nguyenNo ratings yet

- p103-Stts-gec-Asi-ms-ele-009 - Method Statement For Installation of Light Fitting FixtureDocument5 pagesp103-Stts-gec-Asi-ms-ele-009 - Method Statement For Installation of Light Fitting FixtureAnandu AshokanNo ratings yet

- National Open University of Nigeria: Wallet Payment StatusDocument4 pagesNational Open University of Nigeria: Wallet Payment Statusokoro collinsNo ratings yet

- Gemini Column CareDocument3 pagesGemini Column CareLee MingTingNo ratings yet

- Datasheet Honeywell Dolphin 70e BlackDocument2 pagesDatasheet Honeywell Dolphin 70e Blackblue 1234No ratings yet

- 93admit Card Semester-V 011 12-01-2022 16-51-1Document37 pages93admit Card Semester-V 011 12-01-2022 16-51-1Spotify premiumNo ratings yet

- Playbook Overcoming Cloud Security ConcernsDocument8 pagesPlaybook Overcoming Cloud Security Concernsshekhar785424No ratings yet

- AFATL-TR-72-401 - Developement of 20MM and 30MM Plastic-Aluminium Cartridge Cases (1972)Document91 pagesAFATL-TR-72-401 - Developement of 20MM and 30MM Plastic-Aluminium Cartridge Cases (1972)defendercc130No ratings yet

- Notes:: Dialog Plant Services Sdn. BHDDocument1 pageNotes:: Dialog Plant Services Sdn. BHDTengku ZhafriNo ratings yet

- ARTH 103 Introduction To Architecture: Course Description and ObjectivesDocument7 pagesARTH 103 Introduction To Architecture: Course Description and ObjectivesWall Street News AgencyNo ratings yet

- Seam 6 Prelim ModuleDocument36 pagesSeam 6 Prelim ModuleI Hack YouNo ratings yet

- Reparacion de Una Maquina Caja Reductora LufkinDocument4 pagesReparacion de Una Maquina Caja Reductora LufkinDiego TorresNo ratings yet

- Master Degree InformationDocument3 pagesMaster Degree InformationBivash NiroulaNo ratings yet

- Chapter 5 - Elasticity and Its ApplicationDocument37 pagesChapter 5 - Elasticity and Its ApplicationOktaviana MuktiNo ratings yet

- Nature of Urban Interventions in Changing The OldDocument10 pagesNature of Urban Interventions in Changing The OldAneesha MuthurajNo ratings yet

- Sales Force Data LoaderDocument41 pagesSales Force Data LoaderhertzelNo ratings yet

- Identification, Storage, and Handling of Geosynthetic Rolls: Standard Guide ForDocument2 pagesIdentification, Storage, and Handling of Geosynthetic Rolls: Standard Guide ForSebastián RodríguezNo ratings yet

- Sustainability 12 04099Document14 pagesSustainability 12 04099Dorothy Joy Sayson FonacierNo ratings yet

- Pelargonium Sidoides SA 4Document1 pagePelargonium Sidoides SA 4rin_ndNo ratings yet

- Overview of Extended RealityDocument7 pagesOverview of Extended RealityAkul DevtaNo ratings yet

- Experiment # 15: LABORATORY MANUAL For ENGR2860U-Fluid MechanicsDocument10 pagesExperiment # 15: LABORATORY MANUAL For ENGR2860U-Fluid MechanicsAbdullah Alshihri100% (1)

- Add A SubheadingDocument2 pagesAdd A SubheadingAditya ChakravartyNo ratings yet

- DIY Ring-Flash For Your DSLR - SlashGearDocument7 pagesDIY Ring-Flash For Your DSLR - SlashGearBill Chan ChandlerNo ratings yet

- Texas AM PDFDocument43 pagesTexas AM PDFJorgito AriasNo ratings yet

- Super Notes Flamingo PoemsDocument23 pagesSuper Notes Flamingo PoemsVishnuNo ratings yet

- Pratik ResumeDocument2 pagesPratik ResumeHarshada lawaleNo ratings yet