Professional Documents

Culture Documents

Dpmeter Int

Dpmeter Int

Uploaded by

ALP69Copyright:

Available Formats

You might also like

- Home Made Blasting CapsDocument1 pageHome Made Blasting Capselvergonzalez183% (6)

- 3-037-R001 - Dew PointDocument1 page3-037-R001 - Dew PointJoshua AppartNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- 2954 4200 00 XRYS 557-577 CD - Product ReferenceDocument6 pages2954 4200 00 XRYS 557-577 CD - Product ReferenceALP69No ratings yet

- Berges Acm STDDocument64 pagesBerges Acm STDAdan Solano50% (4)

- Types of Printing Process PDFDocument9 pagesTypes of Printing Process PDFpavan4samudrala100% (1)

- Talmage Determining Thickener Unit Areas PDFDocument4 pagesTalmage Determining Thickener Unit Areas PDFpixulinoNo ratings yet

- Brochure Dew Point Sensors - ENDocument12 pagesBrochure Dew Point Sensors - ENosmanyildirim85No ratings yet

- Universal Process ControlDocument1 pageUniversal Process ControlJyoti PokaleNo ratings yet

- Dew Point Meter-Model Amm-15Document2 pagesDew Point Meter-Model Amm-15Juan Ricardo Ordoñez GamezNo ratings yet

- Vaisala-DM70 DatasheetDocument4 pagesVaisala-DM70 Datasheetyannick.pratte8709No ratings yet

- VP FlowScope US A4Document4 pagesVP FlowScope US A4Elena ArriagaNo ratings yet

- Data Sheet: CO2 Air Quality Sensor For Ducts With Measurement Range SwitchDocument4 pagesData Sheet: CO2 Air Quality Sensor For Ducts With Measurement Range SwitchEdward Quispe CervantesNo ratings yet

- ABB Instrumentation: 600T Series TransmittersDocument10 pagesABB Instrumentation: 600T Series Transmittersalbert_ben13No ratings yet

- NDC Tobacco Applications Brochure - English - AshxDocument11 pagesNDC Tobacco Applications Brochure - English - AshxAlexis BerrúNo ratings yet

- Brookfield Process CatalogDocument24 pagesBrookfield Process CatalogenzopandolfiNo ratings yet

- ManometerDocument4 pagesManometersaurabh_acmasNo ratings yet

- 3 038R R301 SF6 Multi AnalyserDocument3 pages3 038R R301 SF6 Multi AnalyserBen WeeNo ratings yet

- New Technology Innovations For Process Industry Pressure GaugesDocument9 pagesNew Technology Innovations For Process Industry Pressure GaugesingluferNo ratings yet

- DILO 3-038-R SF6 Multi-AnalyserDocument3 pagesDILO 3-038-R SF6 Multi-Analyserfrancis erl ligsayNo ratings yet

- Distech Controls. Peripheral Catalogue 2013Document56 pagesDistech Controls. Peripheral Catalogue 2013Filmantas63100% (1)

- Daniel Seniorsonic and Juniorsonic Gas Flow Meters With Mark Iii ElectronicsDocument12 pagesDaniel Seniorsonic and Juniorsonic Gas Flow Meters With Mark Iii ElectronicsSang RòmNo ratings yet

- 9.9 Differential Pressure TransmittersDocument99 pages9.9 Differential Pressure TransmittersorazioconiglioNo ratings yet

- Model 241CE II Hydrocarbon Dew Point Analyzer: Superior BenefitsDocument2 pagesModel 241CE II Hydrocarbon Dew Point Analyzer: Superior Benefitsbahador57No ratings yet

- On-Line Density Meter DC-400: Applications: AdvantagesDocument2 pagesOn-Line Density Meter DC-400: Applications: AdvantagescparroyoNo ratings yet

- Sensors, Transducers, Accessories: Connecting To Data Loggers ..Document4 pagesSensors, Transducers, Accessories: Connecting To Data Loggers ..HaRyono D AnwarNo ratings yet

- Model 872 Ultrasonic Level Transmitter Two-Wire, Loop PoweredDocument2 pagesModel 872 Ultrasonic Level Transmitter Two-Wire, Loop Poweredandres49mNo ratings yet

- Multi Gas Analyzer Ii PDFDocument2 pagesMulti Gas Analyzer Ii PDFSarath ChandraNo ratings yet

- CAD Product Brouchure 2010Document11 pagesCAD Product Brouchure 2010jlmunozvNo ratings yet

- AD250 Wireless Datasheet WebDocument12 pagesAD250 Wireless Datasheet WebArumugam RajendranNo ratings yet

- Meteo Dataloggers & Sensors: Automatic Measuring StationsDocument12 pagesMeteo Dataloggers & Sensors: Automatic Measuring StationsMilton Damián Cornejo ReyesNo ratings yet

- Dresser Instruments Micro Corrector Specs.Document4 pagesDresser Instruments Micro Corrector Specs.davidNo ratings yet

- Datasheet EE891 eDocument2 pagesDatasheet EE891 eFrank VassalloNo ratings yet

- Seculife DPPro Man enDocument34 pagesSeculife DPPro Man enAli Al-QurweeNo ratings yet

- DPT145 Multiparameter Transmitter For SF6 Gas: Online Reliability Risk-Free, Greener Solution The Fruit of ExperienceDocument2 pagesDPT145 Multiparameter Transmitter For SF6 Gas: Online Reliability Risk-Free, Greener Solution The Fruit of ExperienceRenzo Romero ArenasNo ratings yet

- Airflow Meter ManualDocument2 pagesAirflow Meter ManualRabindra SinghNo ratings yet

- M019-01r07 - WatercutMeters - Indd Delta-CDocument8 pagesM019-01r07 - WatercutMeters - Indd Delta-Candrej.marinichNo ratings yet

- Product Solution CatalogDocument7 pagesProduct Solution CatalogCarlos FrancoNo ratings yet

- PR Oc Ess Contr OlsDocument8 pagesPR Oc Ess Contr OlsEsteban Vanegas AlvarezNo ratings yet

- Multiple Function Weather MeterDocument6 pagesMultiple Function Weather Metersaurabh_acmasNo ratings yet

- EN 05038 en NaDocument2 pagesEN 05038 en NaFernando Tellez CordovaNo ratings yet

- Abb Zirconia Catalogue Ss - Az20 en - 2Document20 pagesAbb Zirconia Catalogue Ss - Az20 en - 2Abhinay SuratkarNo ratings yet

- TSI MassFlowMeterDocument6 pagesTSI MassFlowMetera.la_pica2161No ratings yet

- Orifice FlowMeterDocument12 pagesOrifice FlowMetersanggul elli noraNo ratings yet

- QBE2002-PDocument4 pagesQBE2002-PAnonymous 7z6OzoNo ratings yet

- ABB Level Transmiter Ss621emDocument12 pagesABB Level Transmiter Ss621emlorgio_moroNo ratings yet

- M23-9 12Document8 pagesM23-9 12OLuizaNo ratings yet

- Table Top Hydrazine MeterDocument4 pagesTable Top Hydrazine Metersaurabh_acmasNo ratings yet

- RFD MagmeterDocument7 pagesRFD MagmeterScorpio_001No ratings yet

- Temperature Chart Recorder: Stock Reference: 40007Document2 pagesTemperature Chart Recorder: Stock Reference: 40007Jaime Andres Quijano CossioNo ratings yet

- Sonartrac BI0012 VF100 Data Sheet FDocument2 pagesSonartrac BI0012 VF100 Data Sheet FJennifer JenkinsNo ratings yet

- Humidity and Temperature Transducers For Industrial ApplicationsDocument18 pagesHumidity and Temperature Transducers For Industrial ApplicationsPhotoshop-edNo ratings yet

- LAND FGA 900 Series EnglishDocument6 pagesLAND FGA 900 Series EnglishRaymundo CorderoNo ratings yet

- MCS Tailor-Made Chambers (E)Document4 pagesMCS Tailor-Made Chambers (E)bravistNo ratings yet

- Honeywell Humidicon™ Digital Humidity/Temperature Sensors: Hih6130/6131 and Hih6120/6121 SeriesDocument11 pagesHoneywell Humidicon™ Digital Humidity/Temperature Sensors: Hih6130/6131 and Hih6120/6121 SeriesSevenUp2014No ratings yet

- Pc705 Banco PresionDocument2 pagesPc705 Banco PresionJASN1980No ratings yet

- 1 Portable Dew Point MeterDocument6 pages1 Portable Dew Point Meteranupam789No ratings yet

- Curriculum Vitae - 2019-2Document2 pagesCurriculum Vitae - 2019-2Wilfredo GutierrezNo ratings yet

- Table Top Copper Concentration MeterDocument4 pagesTable Top Copper Concentration Metersaurabh_acmasNo ratings yet

- Subsea Sensor BrochureDocument16 pagesSubsea Sensor Brochurealkhwarizmi1968100% (1)

- Laboratory Equipments PDFDocument25 pagesLaboratory Equipments PDFSun ChaNo ratings yet

- Koradi Thermal Power Station: Maharashtra State Power Generation Co. LTDDocument2 pagesKoradi Thermal Power Station: Maharashtra State Power Generation Co. LTDasura22novNo ratings yet

- Druck Digital Test Gauge: Measurement & Control SolutionsDocument4 pagesDruck Digital Test Gauge: Measurement & Control SolutionsShirley CarrNo ratings yet

- Metrodyne Mps 2000Document2 pagesMetrodyne Mps 2000Bárbara Salles100% (1)

- ActuatorsDocument20 pagesActuatorsmohamedbadawyNo ratings yet

- MG30 NPT Full - Serie 800Document1 pageMG30 NPT Full - Serie 800ALP69No ratings yet

- Pipe Is Under Clamping ForceDocument7 pagesPipe Is Under Clamping ForceALP69100% (1)

- MG30 NPT Full - Serie 800Document1 pageMG30 NPT Full - Serie 800ALP69No ratings yet

- API 1102 E7 Errata5Document1 pageAPI 1102 E7 Errata5joselosabeloNo ratings yet

- Pressuredrop CalculatorDocument7 pagesPressuredrop CalculatorALP69No ratings yet

- Ultrasonic Testing of Welded Joints in Pipelines. New Techniques and InstrumentsDocument4 pagesUltrasonic Testing of Welded Joints in Pipelines. New Techniques and InstrumentsALP69No ratings yet

- Ansi-Aws A5.3-M-A5.3-1999Document26 pagesAnsi-Aws A5.3-M-A5.3-1999ALP69No ratings yet

- 30 KarpelsonDocument21 pages30 KarpelsonALP69No ratings yet

- Describe Flammable Gas Measurement: Training ModuleDocument14 pagesDescribe Flammable Gas Measurement: Training ModuleALP69No ratings yet

- Secure MVC Application - Saineshwar - Compressed PDFDocument135 pagesSecure MVC Application - Saineshwar - Compressed PDFALP69No ratings yet

- QUTE Exam Double V Report FormDocument1 pageQUTE Exam Double V Report FormALP69No ratings yet

- Oil / Gas Pressure Standard: Metrological RangeDocument2 pagesOil / Gas Pressure Standard: Metrological RangeALP69No ratings yet

- Gammamat Se Fs FinalDocument2 pagesGammamat Se Fs FinalALP69No ratings yet

- E164-97 UT Contact Examination of WeldmentsDocument23 pagesE164-97 UT Contact Examination of WeldmentsALP69No ratings yet

- QUTE Equipment Inventory ListDocument1 pageQUTE Equipment Inventory ListALP69No ratings yet

- Fomadux Roll Film enDocument1 pageFomadux Roll Film enALP69No ratings yet

- SBU-A Spec Sheet 2009 - Metric ROBBINSDocument2 pagesSBU-A Spec Sheet 2009 - Metric ROBBINSALP69No ratings yet

- CutterHistory NAT 2008Document10 pagesCutterHistory NAT 2008ALP69No ratings yet

- English - Compact P20 P40 and P60 Manual PcwiDocument16 pagesEnglish - Compact P20 P40 and P60 Manual PcwiALP69No ratings yet

- 2946 1422 00 - XRXS UnloaderDocument2 pages2946 1422 00 - XRXS UnloaderALP69No ratings yet

- 180144A Flow Unit Conversion ChartDocument1 page180144A Flow Unit Conversion ChartALP69No ratings yet

- Linear Motion Slide Toothed Belt DriveDocument20 pagesLinear Motion Slide Toothed Belt DrivePetar HosticNo ratings yet

- Clariant. MineralsDocument4 pagesClariant. MineralsLulu LcsNo ratings yet

- Tank ErectionDocument6 pagesTank ErectionHoPhuongKienNo ratings yet

- R 8200 Series Uk 180827Document2 pagesR 8200 Series Uk 180827Patrycja RadzichowskaNo ratings yet

- 03 37 13 ShotcreteDocument9 pages03 37 13 ShotcreteFirdaus AdnanNo ratings yet

- Assignment 7 FUELSDocument4 pagesAssignment 7 FUELSKester Yuree L. GimongalaNo ratings yet

- Design Sheet PileDocument75 pagesDesign Sheet Pileivan_indrawan_10111No ratings yet

- Practical Plate InspectionDocument8 pagesPractical Plate InspectionMohd Effiezool Yaser100% (1)

- Standard P14 06Document4 pagesStandard P14 06ravi00098No ratings yet

- Makalah Bing MinatDocument12 pagesMakalah Bing MinatDilyanti MayaNo ratings yet

- Pentair Goyen Blowtube Nozzles and Cartridge Cleaning Cones PDFDocument12 pagesPentair Goyen Blowtube Nozzles and Cartridge Cleaning Cones PDFAnonymous l2h7rn1No ratings yet

- Electrical Installation and MaintenanceDocument25 pagesElectrical Installation and MaintenanceMarc HillNo ratings yet

- New Thick CylindersDocument44 pagesNew Thick CylindersVinay Korukonda100% (2)

- Colligative Properties of Solutions - FDocument4 pagesColligative Properties of Solutions - FAshwin BalajiNo ratings yet

- Distillation Tower: 1. ObjectiveDocument17 pagesDistillation Tower: 1. ObjectiveEtikNo ratings yet

- Metamorphic RocksDocument7 pagesMetamorphic RocksAZUAN BIN AHMAD FAUZINo ratings yet

- Product Information: Vegabar 51 Vegabar 52 Vegabar 53 Vegabar 54Document32 pagesProduct Information: Vegabar 51 Vegabar 52 Vegabar 53 Vegabar 54Javier CarrizoNo ratings yet

- P07 The Firing and Co Firing of Biomass in Large Pulverised Coal Boilers LivingstonDocument20 pagesP07 The Firing and Co Firing of Biomass in Large Pulverised Coal Boilers LivingstonDiego Martínez FernándezNo ratings yet

- Retired Model Parts CatalogueDocument434 pagesRetired Model Parts Cataloguemaniamson93% (15)

- Water ProofingDocument20 pagesWater ProofingShashwat Jain100% (1)

- Saes A 206Document16 pagesSaes A 206Malcolm F Beall100% (1)

- 3417 Manual 20180817 PDFDocument16 pages3417 Manual 20180817 PDFHanston TVNo ratings yet

- Protectowire Linear Heat Detector: Type Epc - Type XCR Fluoropolymer JacketDocument2 pagesProtectowire Linear Heat Detector: Type Epc - Type XCR Fluoropolymer JacketCarlos YepezNo ratings yet

- Do The Meds You Take To Curb Cholesterol Lower Your Heart Disease Risk?Document2 pagesDo The Meds You Take To Curb Cholesterol Lower Your Heart Disease Risk?Mubassir QuaziNo ratings yet

- Bridge Girders BrochureDocument2 pagesBridge Girders BrochuresiamakkhajehpourNo ratings yet

- Chem September 2013Document84 pagesChem September 2013Orlando BarriosNo ratings yet

Dpmeter Int

Dpmeter Int

Uploaded by

ALP69Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dpmeter Int

Dpmeter Int

Uploaded by

ALP69Copyright:

Available Formats

DEW POINT METERS

DEW POINT METERS

Moisture in compressed air can cause severe damage. Malfuntions in production plant, costly down time, higher reject rates and increased quality control expenditure all have a negative impact on profits. For this reason, efficient and individually adapted compressed air treatment is absolutely essential. However, to guarantee process reliability, the compressed air humidity also needs to be monitored. Dew point meters from BEKO convince because of their precision and superior maintenance-free service life. Online integration with selectable parameters for evaluation and alarm functions in existing process control systems is also possible (optional).

+1: +2: +3: +4: +5:

HIGH MEASUREMENT ACCURACY THANKS TO POLYMER SENSOR

DURABLE MEASURING INSTRUMENT WITH NON-CORRODIBLE, DIRT REPELLENT SURFACE

PRECISE MEASUREMENT, QUICK DISPLAY OF MEASURED VALUES. FLOW-OPTIMISED SENSOR GEOMETRY

OPTIMUM PROCESS RELIABILITY OF COMPRESSED AIR SUPPLY. CONTINUOUS MONITORING OF DRYING LEVEL AND COMPRESSED AIR HUMIDITY

VERY EASY HANDLING. PORTABLE OR STATIONARY APPLICATION

DEW POINT METERS

DEW POINT METERS

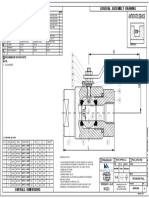

THIS IS HOW THE DEW POINT METER FUNCTIONS Function

upper electrode polymer layer

Depending on the amount of partial water vapour pressure, more or less water molecules penetrate the porous polymer layer. The capacity of the

Funktion

lower electrode

electrical connection

sensor changes as a result, and this change is converted to a humidity value and displayed.

ceramic carrier

Typical fields of application Pharmaceutical industry Petrochemical industry Plastics industry Production plants Automotive industry Semiconductor industry Power stations Metal working industry For refrigeration dryers, membrane dryers and adsorption dryers Using optional software, the factory-set values of our stationary models can be adjusted to the parameters desired by the customer.

Technical data Measuring range PDP Pressure range Power supply Accuracy at PDP -40 C at PDP -10 to +40 C Protection standard EMC Sensor protection Pre-alarm at Main alarm at Output for processing

Portable device XZ DP MO 207 - 80 to +50 C -1 to 16 bar, e internal rechargeable battery +/- 2 C +/- 0.5 C IP 65 DIN EN 61326 Slotted cap

Stationary device XZ DP ST 205 -10 to +50 C -1 to 16 bar, e 90 to 260 VAC

Stationary device XZ DP ST 206 - 80 to +20 C -1 to 16 bar, e 90 to 260 VAC +/- 2 C

+/- 0.5 C IP 65 DIN EN 61326 Sinter filter 50 m +8 C +12 C

+/- 0.5 C IP 65 DIN EN 61326 Sinter filter 50 m -40 C -35 C 4 to 20 mA in 2-conductor arrangement

PC connection

4 to 20 mA in 2-conductor arrangement

Optional service software available for displaying measurement results in other units and storing the measured values in a spreadsheet with visual evaluation.

XP DPM0 001 INT. Edition 02.06

Subject to technical changes without prior notice; the information and data do not represent product characteristics within the meaning of the German Civil Code (BGB) Registered trademarks of BEKO TECHNOLOGIES GmbH, Neuss

BEKO TECHNOLOGIES GMBH

Im Taubental 7 41468 Neuss Germany www.beko.de Phone +49 2131 988-0 Fax +49 2131 988-900 beko@beko.de

You might also like

- Home Made Blasting CapsDocument1 pageHome Made Blasting Capselvergonzalez183% (6)

- 3-037-R001 - Dew PointDocument1 page3-037-R001 - Dew PointJoshua AppartNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- 2954 4200 00 XRYS 557-577 CD - Product ReferenceDocument6 pages2954 4200 00 XRYS 557-577 CD - Product ReferenceALP69No ratings yet

- Berges Acm STDDocument64 pagesBerges Acm STDAdan Solano50% (4)

- Types of Printing Process PDFDocument9 pagesTypes of Printing Process PDFpavan4samudrala100% (1)

- Talmage Determining Thickener Unit Areas PDFDocument4 pagesTalmage Determining Thickener Unit Areas PDFpixulinoNo ratings yet

- Brochure Dew Point Sensors - ENDocument12 pagesBrochure Dew Point Sensors - ENosmanyildirim85No ratings yet

- Universal Process ControlDocument1 pageUniversal Process ControlJyoti PokaleNo ratings yet

- Dew Point Meter-Model Amm-15Document2 pagesDew Point Meter-Model Amm-15Juan Ricardo Ordoñez GamezNo ratings yet

- Vaisala-DM70 DatasheetDocument4 pagesVaisala-DM70 Datasheetyannick.pratte8709No ratings yet

- VP FlowScope US A4Document4 pagesVP FlowScope US A4Elena ArriagaNo ratings yet

- Data Sheet: CO2 Air Quality Sensor For Ducts With Measurement Range SwitchDocument4 pagesData Sheet: CO2 Air Quality Sensor For Ducts With Measurement Range SwitchEdward Quispe CervantesNo ratings yet

- ABB Instrumentation: 600T Series TransmittersDocument10 pagesABB Instrumentation: 600T Series Transmittersalbert_ben13No ratings yet

- NDC Tobacco Applications Brochure - English - AshxDocument11 pagesNDC Tobacco Applications Brochure - English - AshxAlexis BerrúNo ratings yet

- Brookfield Process CatalogDocument24 pagesBrookfield Process CatalogenzopandolfiNo ratings yet

- ManometerDocument4 pagesManometersaurabh_acmasNo ratings yet

- 3 038R R301 SF6 Multi AnalyserDocument3 pages3 038R R301 SF6 Multi AnalyserBen WeeNo ratings yet

- New Technology Innovations For Process Industry Pressure GaugesDocument9 pagesNew Technology Innovations For Process Industry Pressure GaugesingluferNo ratings yet

- DILO 3-038-R SF6 Multi-AnalyserDocument3 pagesDILO 3-038-R SF6 Multi-Analyserfrancis erl ligsayNo ratings yet

- Distech Controls. Peripheral Catalogue 2013Document56 pagesDistech Controls. Peripheral Catalogue 2013Filmantas63100% (1)

- Daniel Seniorsonic and Juniorsonic Gas Flow Meters With Mark Iii ElectronicsDocument12 pagesDaniel Seniorsonic and Juniorsonic Gas Flow Meters With Mark Iii ElectronicsSang RòmNo ratings yet

- 9.9 Differential Pressure TransmittersDocument99 pages9.9 Differential Pressure TransmittersorazioconiglioNo ratings yet

- Model 241CE II Hydrocarbon Dew Point Analyzer: Superior BenefitsDocument2 pagesModel 241CE II Hydrocarbon Dew Point Analyzer: Superior Benefitsbahador57No ratings yet

- On-Line Density Meter DC-400: Applications: AdvantagesDocument2 pagesOn-Line Density Meter DC-400: Applications: AdvantagescparroyoNo ratings yet

- Sensors, Transducers, Accessories: Connecting To Data Loggers ..Document4 pagesSensors, Transducers, Accessories: Connecting To Data Loggers ..HaRyono D AnwarNo ratings yet

- Model 872 Ultrasonic Level Transmitter Two-Wire, Loop PoweredDocument2 pagesModel 872 Ultrasonic Level Transmitter Two-Wire, Loop Poweredandres49mNo ratings yet

- Multi Gas Analyzer Ii PDFDocument2 pagesMulti Gas Analyzer Ii PDFSarath ChandraNo ratings yet

- CAD Product Brouchure 2010Document11 pagesCAD Product Brouchure 2010jlmunozvNo ratings yet

- AD250 Wireless Datasheet WebDocument12 pagesAD250 Wireless Datasheet WebArumugam RajendranNo ratings yet

- Meteo Dataloggers & Sensors: Automatic Measuring StationsDocument12 pagesMeteo Dataloggers & Sensors: Automatic Measuring StationsMilton Damián Cornejo ReyesNo ratings yet

- Dresser Instruments Micro Corrector Specs.Document4 pagesDresser Instruments Micro Corrector Specs.davidNo ratings yet

- Datasheet EE891 eDocument2 pagesDatasheet EE891 eFrank VassalloNo ratings yet

- Seculife DPPro Man enDocument34 pagesSeculife DPPro Man enAli Al-QurweeNo ratings yet

- DPT145 Multiparameter Transmitter For SF6 Gas: Online Reliability Risk-Free, Greener Solution The Fruit of ExperienceDocument2 pagesDPT145 Multiparameter Transmitter For SF6 Gas: Online Reliability Risk-Free, Greener Solution The Fruit of ExperienceRenzo Romero ArenasNo ratings yet

- Airflow Meter ManualDocument2 pagesAirflow Meter ManualRabindra SinghNo ratings yet

- M019-01r07 - WatercutMeters - Indd Delta-CDocument8 pagesM019-01r07 - WatercutMeters - Indd Delta-Candrej.marinichNo ratings yet

- Product Solution CatalogDocument7 pagesProduct Solution CatalogCarlos FrancoNo ratings yet

- PR Oc Ess Contr OlsDocument8 pagesPR Oc Ess Contr OlsEsteban Vanegas AlvarezNo ratings yet

- Multiple Function Weather MeterDocument6 pagesMultiple Function Weather Metersaurabh_acmasNo ratings yet

- EN 05038 en NaDocument2 pagesEN 05038 en NaFernando Tellez CordovaNo ratings yet

- Abb Zirconia Catalogue Ss - Az20 en - 2Document20 pagesAbb Zirconia Catalogue Ss - Az20 en - 2Abhinay SuratkarNo ratings yet

- TSI MassFlowMeterDocument6 pagesTSI MassFlowMetera.la_pica2161No ratings yet

- Orifice FlowMeterDocument12 pagesOrifice FlowMetersanggul elli noraNo ratings yet

- QBE2002-PDocument4 pagesQBE2002-PAnonymous 7z6OzoNo ratings yet

- ABB Level Transmiter Ss621emDocument12 pagesABB Level Transmiter Ss621emlorgio_moroNo ratings yet

- M23-9 12Document8 pagesM23-9 12OLuizaNo ratings yet

- Table Top Hydrazine MeterDocument4 pagesTable Top Hydrazine Metersaurabh_acmasNo ratings yet

- RFD MagmeterDocument7 pagesRFD MagmeterScorpio_001No ratings yet

- Temperature Chart Recorder: Stock Reference: 40007Document2 pagesTemperature Chart Recorder: Stock Reference: 40007Jaime Andres Quijano CossioNo ratings yet

- Sonartrac BI0012 VF100 Data Sheet FDocument2 pagesSonartrac BI0012 VF100 Data Sheet FJennifer JenkinsNo ratings yet

- Humidity and Temperature Transducers For Industrial ApplicationsDocument18 pagesHumidity and Temperature Transducers For Industrial ApplicationsPhotoshop-edNo ratings yet

- LAND FGA 900 Series EnglishDocument6 pagesLAND FGA 900 Series EnglishRaymundo CorderoNo ratings yet

- MCS Tailor-Made Chambers (E)Document4 pagesMCS Tailor-Made Chambers (E)bravistNo ratings yet

- Honeywell Humidicon™ Digital Humidity/Temperature Sensors: Hih6130/6131 and Hih6120/6121 SeriesDocument11 pagesHoneywell Humidicon™ Digital Humidity/Temperature Sensors: Hih6130/6131 and Hih6120/6121 SeriesSevenUp2014No ratings yet

- Pc705 Banco PresionDocument2 pagesPc705 Banco PresionJASN1980No ratings yet

- 1 Portable Dew Point MeterDocument6 pages1 Portable Dew Point Meteranupam789No ratings yet

- Curriculum Vitae - 2019-2Document2 pagesCurriculum Vitae - 2019-2Wilfredo GutierrezNo ratings yet

- Table Top Copper Concentration MeterDocument4 pagesTable Top Copper Concentration Metersaurabh_acmasNo ratings yet

- Subsea Sensor BrochureDocument16 pagesSubsea Sensor Brochurealkhwarizmi1968100% (1)

- Laboratory Equipments PDFDocument25 pagesLaboratory Equipments PDFSun ChaNo ratings yet

- Koradi Thermal Power Station: Maharashtra State Power Generation Co. LTDDocument2 pagesKoradi Thermal Power Station: Maharashtra State Power Generation Co. LTDasura22novNo ratings yet

- Druck Digital Test Gauge: Measurement & Control SolutionsDocument4 pagesDruck Digital Test Gauge: Measurement & Control SolutionsShirley CarrNo ratings yet

- Metrodyne Mps 2000Document2 pagesMetrodyne Mps 2000Bárbara Salles100% (1)

- ActuatorsDocument20 pagesActuatorsmohamedbadawyNo ratings yet

- MG30 NPT Full - Serie 800Document1 pageMG30 NPT Full - Serie 800ALP69No ratings yet

- Pipe Is Under Clamping ForceDocument7 pagesPipe Is Under Clamping ForceALP69100% (1)

- MG30 NPT Full - Serie 800Document1 pageMG30 NPT Full - Serie 800ALP69No ratings yet

- API 1102 E7 Errata5Document1 pageAPI 1102 E7 Errata5joselosabeloNo ratings yet

- Pressuredrop CalculatorDocument7 pagesPressuredrop CalculatorALP69No ratings yet

- Ultrasonic Testing of Welded Joints in Pipelines. New Techniques and InstrumentsDocument4 pagesUltrasonic Testing of Welded Joints in Pipelines. New Techniques and InstrumentsALP69No ratings yet

- Ansi-Aws A5.3-M-A5.3-1999Document26 pagesAnsi-Aws A5.3-M-A5.3-1999ALP69No ratings yet

- 30 KarpelsonDocument21 pages30 KarpelsonALP69No ratings yet

- Describe Flammable Gas Measurement: Training ModuleDocument14 pagesDescribe Flammable Gas Measurement: Training ModuleALP69No ratings yet

- Secure MVC Application - Saineshwar - Compressed PDFDocument135 pagesSecure MVC Application - Saineshwar - Compressed PDFALP69No ratings yet

- QUTE Exam Double V Report FormDocument1 pageQUTE Exam Double V Report FormALP69No ratings yet

- Oil / Gas Pressure Standard: Metrological RangeDocument2 pagesOil / Gas Pressure Standard: Metrological RangeALP69No ratings yet

- Gammamat Se Fs FinalDocument2 pagesGammamat Se Fs FinalALP69No ratings yet

- E164-97 UT Contact Examination of WeldmentsDocument23 pagesE164-97 UT Contact Examination of WeldmentsALP69No ratings yet

- QUTE Equipment Inventory ListDocument1 pageQUTE Equipment Inventory ListALP69No ratings yet

- Fomadux Roll Film enDocument1 pageFomadux Roll Film enALP69No ratings yet

- SBU-A Spec Sheet 2009 - Metric ROBBINSDocument2 pagesSBU-A Spec Sheet 2009 - Metric ROBBINSALP69No ratings yet

- CutterHistory NAT 2008Document10 pagesCutterHistory NAT 2008ALP69No ratings yet

- English - Compact P20 P40 and P60 Manual PcwiDocument16 pagesEnglish - Compact P20 P40 and P60 Manual PcwiALP69No ratings yet

- 2946 1422 00 - XRXS UnloaderDocument2 pages2946 1422 00 - XRXS UnloaderALP69No ratings yet

- 180144A Flow Unit Conversion ChartDocument1 page180144A Flow Unit Conversion ChartALP69No ratings yet

- Linear Motion Slide Toothed Belt DriveDocument20 pagesLinear Motion Slide Toothed Belt DrivePetar HosticNo ratings yet

- Clariant. MineralsDocument4 pagesClariant. MineralsLulu LcsNo ratings yet

- Tank ErectionDocument6 pagesTank ErectionHoPhuongKienNo ratings yet

- R 8200 Series Uk 180827Document2 pagesR 8200 Series Uk 180827Patrycja RadzichowskaNo ratings yet

- 03 37 13 ShotcreteDocument9 pages03 37 13 ShotcreteFirdaus AdnanNo ratings yet

- Assignment 7 FUELSDocument4 pagesAssignment 7 FUELSKester Yuree L. GimongalaNo ratings yet

- Design Sheet PileDocument75 pagesDesign Sheet Pileivan_indrawan_10111No ratings yet

- Practical Plate InspectionDocument8 pagesPractical Plate InspectionMohd Effiezool Yaser100% (1)

- Standard P14 06Document4 pagesStandard P14 06ravi00098No ratings yet

- Makalah Bing MinatDocument12 pagesMakalah Bing MinatDilyanti MayaNo ratings yet

- Pentair Goyen Blowtube Nozzles and Cartridge Cleaning Cones PDFDocument12 pagesPentair Goyen Blowtube Nozzles and Cartridge Cleaning Cones PDFAnonymous l2h7rn1No ratings yet

- Electrical Installation and MaintenanceDocument25 pagesElectrical Installation and MaintenanceMarc HillNo ratings yet

- New Thick CylindersDocument44 pagesNew Thick CylindersVinay Korukonda100% (2)

- Colligative Properties of Solutions - FDocument4 pagesColligative Properties of Solutions - FAshwin BalajiNo ratings yet

- Distillation Tower: 1. ObjectiveDocument17 pagesDistillation Tower: 1. ObjectiveEtikNo ratings yet

- Metamorphic RocksDocument7 pagesMetamorphic RocksAZUAN BIN AHMAD FAUZINo ratings yet

- Product Information: Vegabar 51 Vegabar 52 Vegabar 53 Vegabar 54Document32 pagesProduct Information: Vegabar 51 Vegabar 52 Vegabar 53 Vegabar 54Javier CarrizoNo ratings yet

- P07 The Firing and Co Firing of Biomass in Large Pulverised Coal Boilers LivingstonDocument20 pagesP07 The Firing and Co Firing of Biomass in Large Pulverised Coal Boilers LivingstonDiego Martínez FernándezNo ratings yet

- Retired Model Parts CatalogueDocument434 pagesRetired Model Parts Cataloguemaniamson93% (15)

- Water ProofingDocument20 pagesWater ProofingShashwat Jain100% (1)

- Saes A 206Document16 pagesSaes A 206Malcolm F Beall100% (1)

- 3417 Manual 20180817 PDFDocument16 pages3417 Manual 20180817 PDFHanston TVNo ratings yet

- Protectowire Linear Heat Detector: Type Epc - Type XCR Fluoropolymer JacketDocument2 pagesProtectowire Linear Heat Detector: Type Epc - Type XCR Fluoropolymer JacketCarlos YepezNo ratings yet

- Do The Meds You Take To Curb Cholesterol Lower Your Heart Disease Risk?Document2 pagesDo The Meds You Take To Curb Cholesterol Lower Your Heart Disease Risk?Mubassir QuaziNo ratings yet

- Bridge Girders BrochureDocument2 pagesBridge Girders BrochuresiamakkhajehpourNo ratings yet

- Chem September 2013Document84 pagesChem September 2013Orlando BarriosNo ratings yet