Professional Documents

Culture Documents

Engine Developing 165 FHP (123 KW) Standard Equipment

Engine Developing 165 FHP (123 KW) Standard Equipment

Uploaded by

DhirendraRaviCopyright:

Available Formats

You might also like

- Original PDF Design of Water Resource Recovery Facilities Manual of Practice No 8 6th Edition PDFDocument41 pagesOriginal PDF Design of Water Resource Recovery Facilities Manual of Practice No 8 6th Edition PDFcynthia.stewart295100% (37)

- Atlas Copco RH 656 PartsDocument16 pagesAtlas Copco RH 656 PartsTiago HenriquesNo ratings yet

- Kirloskar Engine EA10 & EA20Document34 pagesKirloskar Engine EA10 & EA20Niten Gupta100% (1)

- Mingde Machinery Company Introducing and Produ PDFDocument12 pagesMingde Machinery Company Introducing and Produ PDFSabir AliNo ratings yet

- Escort Compactor Ec 5250Document2 pagesEscort Compactor Ec 5250Felix Sanders100% (3)

- Conveyor Idlers PDFDocument10 pagesConveyor Idlers PDFDhirendraRaviNo ratings yet

- Holmes-Poirot DocumentDocument2 pagesHolmes-Poirot Documentapi-242851904No ratings yet

- PhET Plate Tectonics - 2013Document2 pagesPhET Plate Tectonics - 2013CloudKielGuiangNo ratings yet

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler Dozerthirsheel balaji100% (1)

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerJackson Phinni100% (1)

- BD85Document4 pagesBD85Bipin KumarNo ratings yet

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerAnsh MishraNo ratings yet

- 20170905061501BH60MDocument4 pages20170905061501BH60MRajkumarNo ratings yet

- 497 Na Ex 70Document50 pages497 Na Ex 70Kamaldeep SinghNo ratings yet

- Motor Grader: BEML BSIII CEV Compliance Engine High Productivity Easy Operation Operator ComfortDocument4 pagesMotor Grader: BEML BSIII CEV Compliance Engine High Productivity Easy Operation Operator ComfortPrabjot SinghNo ratings yet

- BD 50Document4 pagesBD 50amit_sharma333No ratings yet

- Dynapac CC125 ManualDocument75 pagesDynapac CC125 ManualCalvin ThamNo ratings yet

- BG405ADocument4 pagesBG405ABipin KumarNo ratings yet

- 140 Series O&M ManualDocument48 pages140 Series O&M ManualSalem DabaouiNo ratings yet

- D475a 5Document14 pagesD475a 5RasoolKhadibi100% (1)

- 4R1040T-Engine 62.5kVA 50Hz Rev00-1Document3 pages4R1040T-Engine 62.5kVA 50Hz Rev00-1Mohan BabuNo ratings yet

- DX700LC PDFDocument20 pagesDX700LC PDFA Ramos GabyNo ratings yet

- Presentation On SLM 4000Document12 pagesPresentation On SLM 4000saimunNo ratings yet

- Dozco D135 Op - PMDocument65 pagesDozco D135 Op - PMabu talibNo ratings yet

- HUSKY 620: Product GuideDocument8 pagesHUSKY 620: Product Guidegaurav champawatNo ratings yet

- M Op. - SR14MADocument128 pagesM Op. - SR14MAFranco SartoriNo ratings yet

- Demo pc210lc-10Document30 pagesDemo pc210lc-10dani100% (1)

- Bliss Price ListDocument19 pagesBliss Price ListprintNo ratings yet

- Blazo 37 PDFDocument22 pagesBlazo 37 PDFabcNo ratings yet

- Cummins Industrial Engine 6BTAA5.9-C180 For Construction MachineDocument2 pagesCummins Industrial Engine 6BTAA5.9-C180 For Construction Machineh1977h22100% (1)

- HB335/335LC HB365/365LC: PreliminaryDocument8 pagesHB335/335LC HB365/365LC: PreliminaryLTATECNICONo ratings yet

- Ambitec Price ListDocument40 pagesAmbitec Price ListMohit TyagiNo ratings yet

- Operating Weight 5,560kg Bucket Capacity 0.18m Rated Power 36.2kw / 2,200rpmDocument7 pagesOperating Weight 5,560kg Bucket Capacity 0.18m Rated Power 36.2kw / 2,200rpmChulunk04No ratings yet

- Wa470 7Document16 pagesWa470 7Iann ApazaNo ratings yet

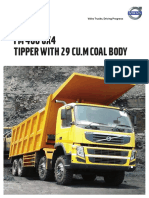

- FM 400 8X4 Tipper With 29 Cu.M Coal BodyDocument4 pagesFM 400 8X4 Tipper With 29 Cu.M Coal BodymaiquelernNo ratings yet

- Hyundai r230lm India Smart TroubleshootingDocument55 pagesHyundai r230lm India Smart TroubleshootingraghavNo ratings yet

- 697 Na Engine For Excavator Ex-110: (Parts List)Document58 pages697 Na Engine For Excavator Ex-110: (Parts List)SUMAN SURJIT BISWAL0% (2)

- Komatsu d65p 8 S N 45001 UpDocument1 pageKomatsu d65p 8 S N 45001 UpSuharto ZuhriNo ratings yet

- Mikasa MRH800GSDocument112 pagesMikasa MRH800GSorlandolanchipaNo ratings yet

- Beml Bd80 DozerDocument5 pagesBeml Bd80 DozerSanjay KulkarniNo ratings yet

- Parts List of Engine Assy of FMX 440 (PC-24) - TP-836Document7 pagesParts List of Engine Assy of FMX 440 (PC-24) - TP-836CwsNo ratings yet

- 300 EXC/XC-W/SD 2010: Spare Parts Manual: EngineDocument24 pages300 EXC/XC-W/SD 2010: Spare Parts Manual: EngineMikel Etxeberria ErrazkinNo ratings yet

- DG Sets (Stationary Engines)Document7 pagesDG Sets (Stationary Engines)கோவி கோபால் ஆர்ட்ஸ்100% (1)

- 655CFM Compressor PDSDocument1 page655CFM Compressor PDShendra Pryal100% (1)

- Section 1: IndexDocument124 pagesSection 1: IndexAhmed Kaoud SakrNo ratings yet

- PC 200 Fuel Filter KitDocument16 pagesPC 200 Fuel Filter KitSandip Maiti100% (1)

- JCB432ZXDocument10 pagesJCB432ZXpangapuvvuNo ratings yet

- HM400 3M0 PDFDocument20 pagesHM400 3M0 PDFFakhrur RizkyNo ratings yet

- Sunway Sunflex Catalog 1 Piece TypeDocument66 pagesSunway Sunflex Catalog 1 Piece TypeAna Plaza GriffithsNo ratings yet

- Canvass Form: 4/2/2018 Equipment BDZ-006 Project Shantui SD13 Engine Req # 112408 SC8D143G2B1Document3 pagesCanvass Form: 4/2/2018 Equipment BDZ-006 Project Shantui SD13 Engine Req # 112408 SC8D143G2B1Joemar ReveloNo ratings yet

- 05 HD785-7 Engine 12V140-2 Presentation Part1Document9 pages05 HD785-7 Engine 12V140-2 Presentation Part1Satria Fajri100% (1)

- Ajce Catalogue (Eng)Document4 pagesAjce Catalogue (Eng)Tabacaru Liviu Catalin- RKU UNIONNo ratings yet

- 6.0-P.pf1 Hydrostatic Sensor Paver - APPOLO 550Document4 pages6.0-P.pf1 Hydrostatic Sensor Paver - APPOLO 550anoopsurendran100% (1)

- 01 D155 IntroductionDocument22 pages01 D155 IntroductionMichael DavenportNo ratings yet

- VMT 860 Brochure Issue 2Document16 pagesVMT 860 Brochure Issue 2Florin Paraschivescu100% (1)

- DozerDocument4 pagesDozerbipin kumarNo ratings yet

- Cummins Service SY120 & SY210 & SY215Document1 pageCummins Service SY120 & SY210 & SY215satyam gangeleNo ratings yet

- Spesifikasi Vibro Compactor HAMM 3410Document2 pagesSpesifikasi Vibro Compactor HAMM 3410MuqorobinNo ratings yet

- JCB Trial Protocol PDFDocument3 pagesJCB Trial Protocol PDFRizvan QureshiNo ratings yet

- 2dx Backhoe LoaderDocument8 pages2dx Backhoe LoaderKarpun PeguNo ratings yet

- Ex110 5Document7 pagesEx110 5adi078No ratings yet

- Digmax Parts CatalogeDocument630 pagesDigmax Parts CatalogeChirag BansalNo ratings yet

- D6H LGP Crawler Dozer SpecDocument2 pagesD6H LGP Crawler Dozer SpecLasitha Wi100% (1)

- HITACHI - Clamshell Telescopic Arm KA-En072Document4 pagesHITACHI - Clamshell Telescopic Arm KA-En072fvmattosNo ratings yet

- Conveyor Pulleys PDFDocument8 pagesConveyor Pulleys PDFDhirendraRaviNo ratings yet

- Mines Act 1952Document33 pagesMines Act 1952DhirendraRaviNo ratings yet

- Vihangam Yoga - Divya Jeevan KathaDocument88 pagesVihangam Yoga - Divya Jeevan KathaAMIT MORE83% (6)

- Skeptimedia Cure Cancer The Natural Way?: 6 September 2010. One of The Most Common Medical Scams Is The "Document4 pagesSkeptimedia Cure Cancer The Natural Way?: 6 September 2010. One of The Most Common Medical Scams Is The "DhirendraRaviNo ratings yet

- Miscible Blend & ImMisible BlendDocument18 pagesMiscible Blend & ImMisible BlendHamzahSardarNo ratings yet

- Midterm Exam in P.E 1Document3 pagesMidterm Exam in P.E 1Condrad Casido0% (1)

- Comparing Effectiveness of Family Planning Methods: How To Make Your Method More EffectiveDocument1 pageComparing Effectiveness of Family Planning Methods: How To Make Your Method More EffectiveGabrielle CatalanNo ratings yet

- JD ExamDocument2 pagesJD ExamCarmen T. TamacNo ratings yet

- Pemurnian EnzimDocument54 pagesPemurnian EnzimwulanNo ratings yet

- Ijiset V2 I12 50Document11 pagesIjiset V2 I12 50AndiNo ratings yet

- Exercises 1Document4 pagesExercises 1Xena Nurraini Anun CakranegaraNo ratings yet

- Fred Review 16Document8 pagesFred Review 16Justin HsuNo ratings yet

- MonitersDocument25 pagesMonitersJaveed AhamedNo ratings yet

- Multiple SclerosisDocument45 pagesMultiple Sclerosispriyanka bhowmikNo ratings yet

- Critikon Dinamap Compact - Service Manual 2Document78 pagesCritikon Dinamap Compact - Service Manual 2Ayaovi JorlauNo ratings yet

- VPS Impression MaterialsDocument55 pagesVPS Impression MaterialsalhaleemNo ratings yet

- Accelerated Storage, Shelf Life and Color of Mango PowderDocument19 pagesAccelerated Storage, Shelf Life and Color of Mango PowderAmandaInggitaNo ratings yet

- Apollo 7 Air-To-Ground Voice TranscriptionDocument1,188 pagesApollo 7 Air-To-Ground Voice TranscriptionBob AndrepontNo ratings yet

- Sample History Dissertation AbstractDocument4 pagesSample History Dissertation AbstractIDon'TWantToWriteMyPaperSingapore100% (1)

- Gpi ProjectDocument60 pagesGpi Projectrushikesh kakadeNo ratings yet

- Ntroduction: Dr. Hammad Iqbal SheraziDocument14 pagesNtroduction: Dr. Hammad Iqbal SherazisamoleNo ratings yet

- Cronica Report Malcolm McLeanDocument2 pagesCronica Report Malcolm McLeanomar andres rodriguez veraNo ratings yet

- Homeostasis Lab PDFDocument2 pagesHomeostasis Lab PDFSip BioNo ratings yet

- Course Syllabus: L&S 126 Strategy Formulation First Semester SY 2012 - 2013 Instructors & ScheduleDocument5 pagesCourse Syllabus: L&S 126 Strategy Formulation First Semester SY 2012 - 2013 Instructors & ScheduleJullie Kaye Frias DiamanteNo ratings yet

- STM Unit-1,2,3 PDFDocument88 pagesSTM Unit-1,2,3 PDFsaranyaNo ratings yet

- Q2 - Lesson 6 Student Listening Complete The Notes Below. Write Numbers and / or No More Than Three Words For Each AnswerDocument7 pagesQ2 - Lesson 6 Student Listening Complete The Notes Below. Write Numbers and / or No More Than Three Words For Each AnswerLương Huệ PhươngNo ratings yet

- Freedom - Pharrell WilliamsDocument2 pagesFreedom - Pharrell WilliamsFaiz Hafizy IINo ratings yet

- Back To School LiturgyDocument2 pagesBack To School LiturgyChristopher C HootonNo ratings yet

- Lecture 12Document11 pagesLecture 12hafsaah46No ratings yet

- Notes of Cost (Microeconomics)Document10 pagesNotes of Cost (Microeconomics)Nishant DoshiNo ratings yet

- Basic Surgical InstrumentsDocument31 pagesBasic Surgical Instrumentskameru_25No ratings yet

Engine Developing 165 FHP (123 KW) Standard Equipment

Engine Developing 165 FHP (123 KW) Standard Equipment

Uploaded by

DhirendraRaviOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Developing 165 FHP (123 KW) Standard Equipment

Engine Developing 165 FHP (123 KW) Standard Equipment

Uploaded by

DhirendraRaviCopyright:

Available Formats

BD65 BULL DOZER A. B.

MODEL : BD65 BULL DOZER SCOPE OF SUPPLY : BD65 BULL DOZER POWERED BY BS6D125-1 ENGINE DEVELOPING 165 FHP (123 KW) STANDARD EQUIPMENT. SPEC SHEET DESCRIPTION: EQUIPMENT: Heavy duty Crawler Mounted 165 HP Bull dozer mechanical / hydraulic operated suitable to work in iron ore mines having iron ore of bulk density 2.4 to 3.0 ton per cum.( BD65 Bull Dozer) 2. ENGINE 4 Stroke, 4 cycle, water cooled, turbo-charged, diesel engine to generate 165 HP (min). The details are furnished below: 1. 2. 3. 4. 5. 6. 7. 8. 9. 3. Make : M/s. BEML Model : BS6D125-1 HP : 165 hp (123 KW) Bore X stroke : 125mm X 150mm Displacement : 11.04 l (0.01104 m3) Nos. of cylinders and their Arrangements : 6, in line Max. Torque : 765 N-m @ 1000 r / min. R.P.M. : 1850 r /min. Fuel Consumption ( Ltrs / hrs.) : Specific fuel consumption 163g / kw-hr.. : ATTACHED (Form No. BD65/D/002/07/2007)

C. 1.

DRIVE SYSTEM Power transmission from the engine to the crawler drive sprocket is through conventional means i.e., power shift planetary gear multiple disc clutch transmission, final drive, steering and brakes. 3.1 TRASMISSION Power shift planetary gear multiple transmission consisting of 3 elements, single stage single phase and gear shift with lock lever having 4 forward and 4 reverse speeds.

.2 3.2 FINAL DRIVE Heavy Duty spurs gear, double reduction type final drive with splash lubrication having reduction ratio of 16.66 : 1 3.3 STEERING Hand operated steering clutches are hydraulically boosted for light touch and actuation. 3.4 HOSES All hoses and piping are clamped and protected from damage. 4. DRAW BAR PULL Maximum draw bar pull is 28000 kg. 5. UNDER CARRIAGE The under carriage is heavy duty rugged designed suitably, suspended with oscillating type equalizer bar and pivot shaft to reduce shock loads transmitted to the dozer. Track frames and track rollers are of sufficient strength to withstand the high loads. The sprocket is segmented bolt on type. Track tensioning arrangement is provided. Extreme service single grouser shoes of 510mm width are provided. 6. HYRAULIC SYSTEM It is equipped with a powerful gear pump and 2 nos. of lift cylinders. 7. BRAKES: Brakes are of wet, contracting band, foot operated, steering brakes with hydraulic booster for light touch actuation. Brakes and clutches are interconnected for easy steering. 8. ELECTRIC SYSTEM 24 V electrical systems along with sufficient, front and rear head light for night operation. Reverse warning system to be provided. .3 2 -

- 39. BLADE Straight type and made from, wear resistant, high tensile steel material for Iron ore application. 10. METER GAUGES & SAFETY SYSTEM All controls, gauges & meters are clearly and permanently marked with easily recognizable symbols Machine should be fitted with all the standard accessories, meters, gauges & safety system. 11. FIRE EXTINGUISHER 2 nos. dry type (cartridge type) fire extinguishers confirming to IS -2171 should provided at suitable location having minimum capacity of 5 kg. 12. ADDITIONAL One set of standard tools and tackles and minimum 3 sets of operation & maintenance manuals and parts catalogue to be supplied with each equipment. --------- o --------

You might also like

- Original PDF Design of Water Resource Recovery Facilities Manual of Practice No 8 6th Edition PDFDocument41 pagesOriginal PDF Design of Water Resource Recovery Facilities Manual of Practice No 8 6th Edition PDFcynthia.stewart295100% (37)

- Atlas Copco RH 656 PartsDocument16 pagesAtlas Copco RH 656 PartsTiago HenriquesNo ratings yet

- Kirloskar Engine EA10 & EA20Document34 pagesKirloskar Engine EA10 & EA20Niten Gupta100% (1)

- Mingde Machinery Company Introducing and Produ PDFDocument12 pagesMingde Machinery Company Introducing and Produ PDFSabir AliNo ratings yet

- Escort Compactor Ec 5250Document2 pagesEscort Compactor Ec 5250Felix Sanders100% (3)

- Conveyor Idlers PDFDocument10 pagesConveyor Idlers PDFDhirendraRaviNo ratings yet

- Holmes-Poirot DocumentDocument2 pagesHolmes-Poirot Documentapi-242851904No ratings yet

- PhET Plate Tectonics - 2013Document2 pagesPhET Plate Tectonics - 2013CloudKielGuiangNo ratings yet

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler Dozerthirsheel balaji100% (1)

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerJackson Phinni100% (1)

- BD85Document4 pagesBD85Bipin KumarNo ratings yet

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerAnsh MishraNo ratings yet

- 20170905061501BH60MDocument4 pages20170905061501BH60MRajkumarNo ratings yet

- 497 Na Ex 70Document50 pages497 Na Ex 70Kamaldeep SinghNo ratings yet

- Motor Grader: BEML BSIII CEV Compliance Engine High Productivity Easy Operation Operator ComfortDocument4 pagesMotor Grader: BEML BSIII CEV Compliance Engine High Productivity Easy Operation Operator ComfortPrabjot SinghNo ratings yet

- BD 50Document4 pagesBD 50amit_sharma333No ratings yet

- Dynapac CC125 ManualDocument75 pagesDynapac CC125 ManualCalvin ThamNo ratings yet

- BG405ADocument4 pagesBG405ABipin KumarNo ratings yet

- 140 Series O&M ManualDocument48 pages140 Series O&M ManualSalem DabaouiNo ratings yet

- D475a 5Document14 pagesD475a 5RasoolKhadibi100% (1)

- 4R1040T-Engine 62.5kVA 50Hz Rev00-1Document3 pages4R1040T-Engine 62.5kVA 50Hz Rev00-1Mohan BabuNo ratings yet

- DX700LC PDFDocument20 pagesDX700LC PDFA Ramos GabyNo ratings yet

- Presentation On SLM 4000Document12 pagesPresentation On SLM 4000saimunNo ratings yet

- Dozco D135 Op - PMDocument65 pagesDozco D135 Op - PMabu talibNo ratings yet

- HUSKY 620: Product GuideDocument8 pagesHUSKY 620: Product Guidegaurav champawatNo ratings yet

- M Op. - SR14MADocument128 pagesM Op. - SR14MAFranco SartoriNo ratings yet

- Demo pc210lc-10Document30 pagesDemo pc210lc-10dani100% (1)

- Bliss Price ListDocument19 pagesBliss Price ListprintNo ratings yet

- Blazo 37 PDFDocument22 pagesBlazo 37 PDFabcNo ratings yet

- Cummins Industrial Engine 6BTAA5.9-C180 For Construction MachineDocument2 pagesCummins Industrial Engine 6BTAA5.9-C180 For Construction Machineh1977h22100% (1)

- HB335/335LC HB365/365LC: PreliminaryDocument8 pagesHB335/335LC HB365/365LC: PreliminaryLTATECNICONo ratings yet

- Ambitec Price ListDocument40 pagesAmbitec Price ListMohit TyagiNo ratings yet

- Operating Weight 5,560kg Bucket Capacity 0.18m Rated Power 36.2kw / 2,200rpmDocument7 pagesOperating Weight 5,560kg Bucket Capacity 0.18m Rated Power 36.2kw / 2,200rpmChulunk04No ratings yet

- Wa470 7Document16 pagesWa470 7Iann ApazaNo ratings yet

- FM 400 8X4 Tipper With 29 Cu.M Coal BodyDocument4 pagesFM 400 8X4 Tipper With 29 Cu.M Coal BodymaiquelernNo ratings yet

- Hyundai r230lm India Smart TroubleshootingDocument55 pagesHyundai r230lm India Smart TroubleshootingraghavNo ratings yet

- 697 Na Engine For Excavator Ex-110: (Parts List)Document58 pages697 Na Engine For Excavator Ex-110: (Parts List)SUMAN SURJIT BISWAL0% (2)

- Komatsu d65p 8 S N 45001 UpDocument1 pageKomatsu d65p 8 S N 45001 UpSuharto ZuhriNo ratings yet

- Mikasa MRH800GSDocument112 pagesMikasa MRH800GSorlandolanchipaNo ratings yet

- Beml Bd80 DozerDocument5 pagesBeml Bd80 DozerSanjay KulkarniNo ratings yet

- Parts List of Engine Assy of FMX 440 (PC-24) - TP-836Document7 pagesParts List of Engine Assy of FMX 440 (PC-24) - TP-836CwsNo ratings yet

- 300 EXC/XC-W/SD 2010: Spare Parts Manual: EngineDocument24 pages300 EXC/XC-W/SD 2010: Spare Parts Manual: EngineMikel Etxeberria ErrazkinNo ratings yet

- DG Sets (Stationary Engines)Document7 pagesDG Sets (Stationary Engines)கோவி கோபால் ஆர்ட்ஸ்100% (1)

- 655CFM Compressor PDSDocument1 page655CFM Compressor PDShendra Pryal100% (1)

- Section 1: IndexDocument124 pagesSection 1: IndexAhmed Kaoud SakrNo ratings yet

- PC 200 Fuel Filter KitDocument16 pagesPC 200 Fuel Filter KitSandip Maiti100% (1)

- JCB432ZXDocument10 pagesJCB432ZXpangapuvvuNo ratings yet

- HM400 3M0 PDFDocument20 pagesHM400 3M0 PDFFakhrur RizkyNo ratings yet

- Sunway Sunflex Catalog 1 Piece TypeDocument66 pagesSunway Sunflex Catalog 1 Piece TypeAna Plaza GriffithsNo ratings yet

- Canvass Form: 4/2/2018 Equipment BDZ-006 Project Shantui SD13 Engine Req # 112408 SC8D143G2B1Document3 pagesCanvass Form: 4/2/2018 Equipment BDZ-006 Project Shantui SD13 Engine Req # 112408 SC8D143G2B1Joemar ReveloNo ratings yet

- 05 HD785-7 Engine 12V140-2 Presentation Part1Document9 pages05 HD785-7 Engine 12V140-2 Presentation Part1Satria Fajri100% (1)

- Ajce Catalogue (Eng)Document4 pagesAjce Catalogue (Eng)Tabacaru Liviu Catalin- RKU UNIONNo ratings yet

- 6.0-P.pf1 Hydrostatic Sensor Paver - APPOLO 550Document4 pages6.0-P.pf1 Hydrostatic Sensor Paver - APPOLO 550anoopsurendran100% (1)

- 01 D155 IntroductionDocument22 pages01 D155 IntroductionMichael DavenportNo ratings yet

- VMT 860 Brochure Issue 2Document16 pagesVMT 860 Brochure Issue 2Florin Paraschivescu100% (1)

- DozerDocument4 pagesDozerbipin kumarNo ratings yet

- Cummins Service SY120 & SY210 & SY215Document1 pageCummins Service SY120 & SY210 & SY215satyam gangeleNo ratings yet

- Spesifikasi Vibro Compactor HAMM 3410Document2 pagesSpesifikasi Vibro Compactor HAMM 3410MuqorobinNo ratings yet

- JCB Trial Protocol PDFDocument3 pagesJCB Trial Protocol PDFRizvan QureshiNo ratings yet

- 2dx Backhoe LoaderDocument8 pages2dx Backhoe LoaderKarpun PeguNo ratings yet

- Ex110 5Document7 pagesEx110 5adi078No ratings yet

- Digmax Parts CatalogeDocument630 pagesDigmax Parts CatalogeChirag BansalNo ratings yet

- D6H LGP Crawler Dozer SpecDocument2 pagesD6H LGP Crawler Dozer SpecLasitha Wi100% (1)

- HITACHI - Clamshell Telescopic Arm KA-En072Document4 pagesHITACHI - Clamshell Telescopic Arm KA-En072fvmattosNo ratings yet

- Conveyor Pulleys PDFDocument8 pagesConveyor Pulleys PDFDhirendraRaviNo ratings yet

- Mines Act 1952Document33 pagesMines Act 1952DhirendraRaviNo ratings yet

- Vihangam Yoga - Divya Jeevan KathaDocument88 pagesVihangam Yoga - Divya Jeevan KathaAMIT MORE83% (6)

- Skeptimedia Cure Cancer The Natural Way?: 6 September 2010. One of The Most Common Medical Scams Is The "Document4 pagesSkeptimedia Cure Cancer The Natural Way?: 6 September 2010. One of The Most Common Medical Scams Is The "DhirendraRaviNo ratings yet

- Miscible Blend & ImMisible BlendDocument18 pagesMiscible Blend & ImMisible BlendHamzahSardarNo ratings yet

- Midterm Exam in P.E 1Document3 pagesMidterm Exam in P.E 1Condrad Casido0% (1)

- Comparing Effectiveness of Family Planning Methods: How To Make Your Method More EffectiveDocument1 pageComparing Effectiveness of Family Planning Methods: How To Make Your Method More EffectiveGabrielle CatalanNo ratings yet

- JD ExamDocument2 pagesJD ExamCarmen T. TamacNo ratings yet

- Pemurnian EnzimDocument54 pagesPemurnian EnzimwulanNo ratings yet

- Ijiset V2 I12 50Document11 pagesIjiset V2 I12 50AndiNo ratings yet

- Exercises 1Document4 pagesExercises 1Xena Nurraini Anun CakranegaraNo ratings yet

- Fred Review 16Document8 pagesFred Review 16Justin HsuNo ratings yet

- MonitersDocument25 pagesMonitersJaveed AhamedNo ratings yet

- Multiple SclerosisDocument45 pagesMultiple Sclerosispriyanka bhowmikNo ratings yet

- Critikon Dinamap Compact - Service Manual 2Document78 pagesCritikon Dinamap Compact - Service Manual 2Ayaovi JorlauNo ratings yet

- VPS Impression MaterialsDocument55 pagesVPS Impression MaterialsalhaleemNo ratings yet

- Accelerated Storage, Shelf Life and Color of Mango PowderDocument19 pagesAccelerated Storage, Shelf Life and Color of Mango PowderAmandaInggitaNo ratings yet

- Apollo 7 Air-To-Ground Voice TranscriptionDocument1,188 pagesApollo 7 Air-To-Ground Voice TranscriptionBob AndrepontNo ratings yet

- Sample History Dissertation AbstractDocument4 pagesSample History Dissertation AbstractIDon'TWantToWriteMyPaperSingapore100% (1)

- Gpi ProjectDocument60 pagesGpi Projectrushikesh kakadeNo ratings yet

- Ntroduction: Dr. Hammad Iqbal SheraziDocument14 pagesNtroduction: Dr. Hammad Iqbal SherazisamoleNo ratings yet

- Cronica Report Malcolm McLeanDocument2 pagesCronica Report Malcolm McLeanomar andres rodriguez veraNo ratings yet

- Homeostasis Lab PDFDocument2 pagesHomeostasis Lab PDFSip BioNo ratings yet

- Course Syllabus: L&S 126 Strategy Formulation First Semester SY 2012 - 2013 Instructors & ScheduleDocument5 pagesCourse Syllabus: L&S 126 Strategy Formulation First Semester SY 2012 - 2013 Instructors & ScheduleJullie Kaye Frias DiamanteNo ratings yet

- STM Unit-1,2,3 PDFDocument88 pagesSTM Unit-1,2,3 PDFsaranyaNo ratings yet

- Q2 - Lesson 6 Student Listening Complete The Notes Below. Write Numbers and / or No More Than Three Words For Each AnswerDocument7 pagesQ2 - Lesson 6 Student Listening Complete The Notes Below. Write Numbers and / or No More Than Three Words For Each AnswerLương Huệ PhươngNo ratings yet

- Freedom - Pharrell WilliamsDocument2 pagesFreedom - Pharrell WilliamsFaiz Hafizy IINo ratings yet

- Back To School LiturgyDocument2 pagesBack To School LiturgyChristopher C HootonNo ratings yet

- Lecture 12Document11 pagesLecture 12hafsaah46No ratings yet

- Notes of Cost (Microeconomics)Document10 pagesNotes of Cost (Microeconomics)Nishant DoshiNo ratings yet

- Basic Surgical InstrumentsDocument31 pagesBasic Surgical Instrumentskameru_25No ratings yet