Professional Documents

Culture Documents

VFD Systems Available To Vary The Speed

VFD Systems Available To Vary The Speed

Uploaded by

yogacruiseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VFD Systems Available To Vary The Speed

VFD Systems Available To Vary The Speed

Uploaded by

yogacruiseCopyright:

Available Formats

Systems available to vary the Speed

A VFD is basically an electrical circuit, which is connected between a supplying network and a motor. Unlike a Direct-On-Line (DOL) operated motor, the speed of which is fixed to the frequency of the supplying AC network, the main purpose of a VFD is to provide the motor with an AC supply voltage / AC current of variable frequency, enabling a variable motor speed and torque. In general, a state-of-the-art VFD consists of a rectifier section, a DC-link section and an inverter section. The rectifier section rectifies the supplying AC network voltage of fixed frequency (usually 50 or 60Hz) into a DC voltage / DC current, which then, in the inverter section of the VFD, will be transformed into an AC voltage / AC current of variable amplitude and frequency.

Types variable frequency systems available

A. Low voltage drives B. Medium voltage drives /in tommorows article/ C. High voltage drives /in tommorows article/ When talking about Variable Frequency Drives (VFDs), one has to distinguish between Low Voltage VFDs (up to 690V motor voltage) and Medium Voltage VFDs (above 1kV motor voltage). Typically the economically reasonable power ranges are: for LV-VFDs is up to 500 Hp for MV-VFDs is upto 1000 Hp and for HT VFDs is above 1000 H.P . This system is to reduce THD and transmission loss.

A. Application of LV VFDs In Sugar Industry Introduction

Inially LV-VFDs were introduced into the market in the late 60s only The benefits of LV-VFDs in those days were basically the same as today ie. energy savings, improved process control, less maintenance cost. However, these benefits were to some extent, compensated by the drawbacks such as low power factor issues, harmonic distortion, torque pulsations and reliability problems. These problems have now been basically eliminated allowing the advantages of a LV-VFD system to clearly dominate. This opened the doors for LV-VFDs to enter in many industries such as oil & gas petrochemical,power, water & sewage water pumping, metals, minerals & mining, marine and Sugar plant etc to name just a few. This is mainly for the controlled and economical transport of liquids, gas and solid.

In the sugar industry, a lot of applications are suited for operation with a LV-VFD instead of the conventional driving methods such as: 1. 2. 3. 4. 5. 6. 7. 8. 9. Cane Carrier Drive, Feeder Table Drive, Milling Plant Drive, Raw juice Pumps, Sulphited Juice Pumps, Molasses Pumps, Injection Pumps, Cooling Tower Pumps and Centrifugals for a Sugar Curing and Chemical Dosing pump.

You might also like

- Variable Frequency DriveDocument26 pagesVariable Frequency Driveashwinichodisetti_3775% (8)

- H-Bridge 5 Level Inverter Using PWM TechniqueDocument31 pagesH-Bridge 5 Level Inverter Using PWM TechniqueKolan Vamshi Kiran Reddy100% (1)

- Audio - Introduction To Sound Recording - 2004 (Advanced) PDFDocument828 pagesAudio - Introduction To Sound Recording - 2004 (Advanced) PDFbelvedere01No ratings yet

- Medium Voltage Drives in The Sugar Industry - SIT 2005 PDFDocument11 pagesMedium Voltage Drives in The Sugar Industry - SIT 2005 PDFkalos stratiotesNo ratings yet

- Technical Seminar On VFDDocument17 pagesTechnical Seminar On VFDRadhika Priyadarshini100% (7)

- Figure No. 1 Variable Frequency DriveDocument38 pagesFigure No. 1 Variable Frequency DriveAshutosh SoniNo ratings yet

- VFD 1Document17 pagesVFD 1Sujatha GoliNo ratings yet

- Figure No. 1 Variable Frequency DriveDocument38 pagesFigure No. 1 Variable Frequency Drivet_aditya2506No ratings yet

- Variable Frequency DriveDocument8 pagesVariable Frequency DriveNAYEEM100% (1)

- Facts at Your Fingertips: Variable Frequency DrivesDocument1 pageFacts at Your Fingertips: Variable Frequency Drivesagrocel_bhv5591No ratings yet

- Variable Frequency Drive: Seminar ReportDocument7 pagesVariable Frequency Drive: Seminar ReportPavan KamatNo ratings yet

- Component and Types of VFDDocument11 pagesComponent and Types of VFDArsalan Danish100% (1)

- Variable Frequency DrivesDocument17 pagesVariable Frequency DrivesAshok SutharNo ratings yet

- Regarding Selection - WORD 97 FORMATDocument22 pagesRegarding Selection - WORD 97 FORMATSurya Prakash SinhaNo ratings yet

- Variable Frequency Drive (VFD)Document8 pagesVariable Frequency Drive (VFD)vishnurajpattambi100% (1)

- Comparison of PWM VFDs Versus Resonant Link Converters For Oilfield ESP Duty. PaDocument27 pagesComparison of PWM VFDs Versus Resonant Link Converters For Oilfield ESP Duty. Pajhon mambyNo ratings yet

- Variable Frequency Drive Navigation Search: From Wikipedia, The Free EncyclopediaDocument9 pagesVariable Frequency Drive Navigation Search: From Wikipedia, The Free EncyclopediaMadhar ShaNo ratings yet

- Variable Frequency DriveDocument9 pagesVariable Frequency DriveOsama SalemNo ratings yet

- Full Paper P-031Document9 pagesFull Paper P-031SUBRATA BISWASNo ratings yet

- VFDDocument151 pagesVFDMUHAMMAD UZAIR100% (1)

- VFD QuestionariesDocument3 pagesVFD QuestionariesChandra SekarNo ratings yet

- Power Quality: M V S I o V F DDocument5 pagesPower Quality: M V S I o V F DHari Krishna.MNo ratings yet

- Benefits of VSD SystemsDocument7 pagesBenefits of VSD Systemsalx 100No ratings yet

- Why Use Bypass in Variable Frequency Drive SystemDocument6 pagesWhy Use Bypass in Variable Frequency Drive Systemmani_208eeNo ratings yet

- VFD-types, Working, Soft-Starter, Market Scope.: Dharnish Kumar V G Abhyas InternshipDocument11 pagesVFD-types, Working, Soft-Starter, Market Scope.: Dharnish Kumar V G Abhyas InternshipdharnishNo ratings yet

- Cables VFD MotorDocument19 pagesCables VFD MotorMarius RotaruNo ratings yet

- Cables VFD-motorDocument19 pagesCables VFD-motorMarius RotaruNo ratings yet

- Electric - Propulsion Imtech DieselElSys Rev05Document10 pagesElectric - Propulsion Imtech DieselElSys Rev05moiseian100% (1)

- ThrusterDocument32 pagesThrusterkarthik rajuNo ratings yet

- Actuators 01 00012 PDFDocument9 pagesActuators 01 00012 PDFYuones PanahiNo ratings yet

- Accessories For Frequency Inverter 1dd65Document7 pagesAccessories For Frequency Inverter 1dd65appinassociatesNo ratings yet

- 101 About Semiconductor DevicesDocument10 pages101 About Semiconductor DevicesshashankrajoriaNo ratings yet

- Variable Frequency DriveDocument3 pagesVariable Frequency DriveRohitash NitharwalNo ratings yet

- VVVFD 2Document25 pagesVVVFD 2syed42210No ratings yet

- Speed Control of Multilevel Inverter-Based Induction Motor Using V/F MethodDocument13 pagesSpeed Control of Multilevel Inverter-Based Induction Motor Using V/F MethodIzza AnshoryNo ratings yet

- A Medium Frequency Transformer-Based Wind Energy Conversion System Used For Current Source Converter Based Offshore Wind FarmDocument4 pagesA Medium Frequency Transformer-Based Wind Energy Conversion System Used For Current Source Converter Based Offshore Wind FarmKurushNishanthNo ratings yet

- Project Manual VLT 2800 ENGDocument171 pagesProject Manual VLT 2800 ENGKrzysiek PodsiadłoNo ratings yet

- The Application of Variable Frequency Drive As An Efficient Control Element in Cement IndustryDocument7 pagesThe Application of Variable Frequency Drive As An Efficient Control Element in Cement IndustryНемања Катић100% (1)

- Small Variable-Frequency DriveDocument11 pagesSmall Variable-Frequency DriveYasir ButtNo ratings yet

- Purpose of Variable Frequency DrivesDocument25 pagesPurpose of Variable Frequency DrivesGaurav MobarNo ratings yet

- VFDsDocument20 pagesVFDsHaris ShahidNo ratings yet

- Global VFD Solutions White Paper 2020Document10 pagesGlobal VFD Solutions White Paper 2020Felipe GustavoNo ratings yet

- Variable Frequency DriveDocument26 pagesVariable Frequency DriveAshish KatochNo ratings yet

- Variable Frequency DriveDocument4 pagesVariable Frequency Drivearavind_k104No ratings yet

- Sliding-Mode-Control-Based Boost Converter For High-Voltage-Low-Power ApplicationsDocument9 pagesSliding-Mode-Control-Based Boost Converter For High-Voltage-Low-Power Applicationst.benaissaNo ratings yet

- Introduction HVDCDocument23 pagesIntroduction HVDCmodanto100% (1)

- Variables EqiposDocument70 pagesVariables EqiposGonzalo FuentesNo ratings yet

- Project DocumentDocument50 pagesProject DocumentVijay B VijayNo ratings yet

- F A C T o R S & P H e N o M e N A: Power System Technology NavigatorDocument47 pagesF A C T o R S & P H e N o M e N A: Power System Technology Navigatormanishtyagi09No ratings yet

- VFD 14Document1 pageVFD 14Kiruba EathirajNo ratings yet

- Variable Frequency DrivesDocument46 pagesVariable Frequency DrivesCubix AutomationNo ratings yet

- Variable Speed DrivesDocument16 pagesVariable Speed Drivesfaizan123khanNo ratings yet

- HVDC Plus Basics and PrincipleDocument24 pagesHVDC Plus Basics and PrincipleNtomboxolo BuzaniNo ratings yet

- Pump Applications Using VFDS: Are Vfds Worth It For Pump Applications? Have They Been Oversold To The Market?Document29 pagesPump Applications Using VFDS: Are Vfds Worth It For Pump Applications? Have They Been Oversold To The Market?123sam456No ratings yet

- Methods for Increasing the Quality and Reliability of Power System Using FACTS DevicesFrom EverandMethods for Increasing the Quality and Reliability of Power System Using FACTS DevicesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- High Voltage Direct Current Transmission: Converters, Systems and DC GridsFrom EverandHigh Voltage Direct Current Transmission: Converters, Systems and DC GridsNo ratings yet

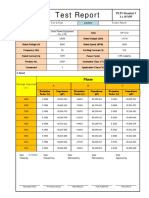

- EDG TestDocument6 pagesEDG Testyogacruise100% (1)

- Boiler Feed Pump KSBDocument9 pagesBoiler Feed Pump KSByogacruiseNo ratings yet

- Protection Relay of Generator TestDocument6 pagesProtection Relay of Generator Testyogacruise100% (2)

- Calculation Sheet of Bus Protection Unit 3 FinalDocument17 pagesCalculation Sheet of Bus Protection Unit 3 Finalyogacruise100% (1)

- Refractory Repair and ProcedureDocument3 pagesRefractory Repair and Procedureyogacruise50% (2)

- Ge DGCM Field Rtu CatalogDocument12 pagesGe DGCM Field Rtu CatalogyogacruiseNo ratings yet

- Tan Delta-FDocument1 pageTan Delta-FyogacruiseNo ratings yet

- Manhole On Weld SeamDocument1 pageManhole On Weld SeamyogacruiseNo ratings yet

- If The Misalignment Between The Head and Shell in A Pressure Vessel Exceeds The ASME Requirement1Document8 pagesIf The Misalignment Between The Head and Shell in A Pressure Vessel Exceeds The ASME Requirement1yogacruiseNo ratings yet

- Expansion Bellows Leak RepairDocument1 pageExpansion Bellows Leak RepairyogacruiseNo ratings yet

- 3 Heating Load Calculation: 3.1 Heat Transmission LossDocument14 pages3 Heating Load Calculation: 3.1 Heat Transmission LossyogacruiseNo ratings yet

- WUXI HUAGUANG BOILER CO., LTD. (无锡华光锅炉股份有限公司) : Wang Fu Jun Zhao Xiao Li Zhang Wei Min Wang Fu Jun Tang Xing LiangDocument4 pagesWUXI HUAGUANG BOILER CO., LTD. (无锡华光锅炉股份有限公司) : Wang Fu Jun Zhao Xiao Li Zhang Wei Min Wang Fu Jun Tang Xing LiangyogacruiseNo ratings yet

- If Steam Drum Under Vacuum Then What Will HappenDocument2 pagesIf Steam Drum Under Vacuum Then What Will HappenyogacruiseNo ratings yet

- Commissioning of A FurnaceDocument2 pagesCommissioning of A FurnaceyogacruiseNo ratings yet

- WPS and PQRDocument2 pagesWPS and PQRyogacruiseNo ratings yet

- API 571 Required SupportDocument4 pagesAPI 571 Required Supportyogacruise100% (1)

- Repair Wps LgiDocument6 pagesRepair Wps LgiyogacruiseNo ratings yet

- Shut-In and Start-Up Start-Up: Transient FlowDocument2 pagesShut-In and Start-Up Start-Up: Transient FlowyogacruiseNo ratings yet

- Rubber Lining Temperature LimitDocument1 pageRubber Lining Temperature LimityogacruiseNo ratings yet

- Role of Corrosion Engineer at A Petrochemical PlantDocument2 pagesRole of Corrosion Engineer at A Petrochemical PlantyogacruiseNo ratings yet

- Balancing Specialist: Subject: Basic Balancing (4 Hours)Document3 pagesBalancing Specialist: Subject: Basic Balancing (4 Hours)yogacruiseNo ratings yet

- SW-HF 5.1 5005 SERVICE GUIDE (Updated) PDFDocument30 pagesSW-HF 5.1 5005 SERVICE GUIDE (Updated) PDFLingurariu BogdanNo ratings yet

- Zxdu68 B201 DC PDFDocument42 pagesZxdu68 B201 DC PDFronnymareNo ratings yet

- Data Sheet: Stereo Cassette Head Preamplifier and EqualizerDocument17 pagesData Sheet: Stereo Cassette Head Preamplifier and EqualizerLuciana OhiraNo ratings yet

- Galleon II: 1KVA/1.5KVA/2KVA/3KVADocument2 pagesGalleon II: 1KVA/1.5KVA/2KVA/3KVAWil LiamNo ratings yet

- Datasheet MPI-540-v1 GBDocument7 pagesDatasheet MPI-540-v1 GBBenet George VadakkemulanjanalNo ratings yet

- 8200T-Audiolab Service Manual.V01.2011.06.10Document26 pages8200T-Audiolab Service Manual.V01.2011.06.10krymarioNo ratings yet

- VFD Systems Available To Vary The SpeedDocument2 pagesVFD Systems Available To Vary The SpeedyogacruiseNo ratings yet

- HCD GTX88 86159Document104 pagesHCD GTX88 86159florinpetreusNo ratings yet

- Nehs06780001 - Multimeter OperationDocument8 pagesNehs06780001 - Multimeter OperationMontell JordanNo ratings yet

- Fiche lpr35 RTM 2022Document6 pagesFiche lpr35 RTM 2022Arkadiusz WłodarczakNo ratings yet

- TAS5733L - Digital Input Audio Power Amplifier With EQ and 3-Band AGLDocument68 pagesTAS5733L - Digital Input Audio Power Amplifier With EQ and 3-Band AGLPREVARANTNo ratings yet

- DRH 300Document20 pagesDRH 300Huythuong NguyenNo ratings yet

- Audt30 EngDocument162 pagesAudt30 EngDario SanchezNo ratings yet

- Lecture 4 Diode Circuits NewDocument76 pagesLecture 4 Diode Circuits NewShari Bin MappiasiNo ratings yet

- UTC2822 DatasheetDocument5 pagesUTC2822 Datasheetlucas sousaNo ratings yet

- 7SR10 - Overcurrent Earth Fault Catalogue SheetDocument14 pages7SR10 - Overcurrent Earth Fault Catalogue SheetFrancisco MartinezNo ratings yet

- Leroy Somer Alternator Datasheet 5672i - enDocument12 pagesLeroy Somer Alternator Datasheet 5672i - enFaheem AkramNo ratings yet

- A Novel Audio Power Amplifier Topology PDFDocument26 pagesA Novel Audio Power Amplifier Topology PDFelekossNo ratings yet

- MAX7400/MAX7403/MAX7404/MAX7407Document12 pagesMAX7400/MAX7403/MAX7404/MAX7407xyalfaxyzNo ratings yet

- Demand ControllerDocument64 pagesDemand ControllerAboy CandoNo ratings yet

- Crown Amplifiers Catalog PDFDocument68 pagesCrown Amplifiers Catalog PDFArjay DomisiwNo ratings yet

- 6310 ABC KyoritsuDocument19 pages6310 ABC Kyoritsusergio_oscuraNo ratings yet

- Rockford Fosgate Punch 400.4 ManualDocument60 pagesRockford Fosgate Punch 400.4 ManualTiago Henrique Dias DantasNo ratings yet

- SL5018P - Narrowband FM IfDocument6 pagesSL5018P - Narrowband FM IfDefaultAnomolyNo ratings yet

- Analysis of Total Harmonic DistortionDocument5 pagesAnalysis of Total Harmonic DistortionME SOUNDNo ratings yet

- Tpa 3113 D2Document33 pagesTpa 3113 D2Cesar Perez CamposNo ratings yet

- p3g30 32 en M j006 Ansi ManualDocument456 pagesp3g30 32 en M j006 Ansi ManualAtiqun NabiNo ratings yet

- A AG G - D D779 90 00 0: Service ManualDocument34 pagesA AG G - D D779 90 00 0: Service ManualSilomo-saka MambaNo ratings yet