Professional Documents

Culture Documents

Installation Guide: TH8320ZW1000

Installation Guide: TH8320ZW1000

Uploaded by

IBJSC.comCopyright:

Available Formats

You might also like

- SH367309 Ev1.2aDocument92 pagesSH367309 Ev1.2aThien Dinh86% (7)

- LG IS3 ManualDocument137 pagesLG IS3 ManualEugenio Francisco Martínez Mora70% (10)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Heat KingDocument28 pagesHeat KingWayne Grey100% (3)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Carrier Commercial Systems 2008 List Prices: 30Rb Air Cooled ChillersDocument13 pagesCarrier Commercial Systems 2008 List Prices: 30Rb Air Cooled ChillersvickersNo ratings yet

- Energy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134aDocument30 pagesEnergy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134atechnokakiNo ratings yet

- Tutorial - Ground MatDocument76 pagesTutorial - Ground MatThiago Breno Menezes da Silva100% (1)

- Manual de Servicio Monitor LCD Dell E190SfDocument59 pagesManual de Servicio Monitor LCD Dell E190SfAntonio Chavez100% (1)

- File 2 10Document8 pagesFile 2 10camelod555No ratings yet

- Installation Guide: Focuspro Wi-Fi Th6000 Series Programmable ThermostatDocument36 pagesInstallation Guide: Focuspro Wi-Fi Th6000 Series Programmable ThermostatLynnNo ratings yet

- Thermostat ManualDocument24 pagesThermostat ManualbschvyNo ratings yet

- Aoe 12V4000L62 Ratings and Emissions 1: Technical Description TB 46204 F 50Document7 pagesAoe 12V4000L62 Ratings and Emissions 1: Technical Description TB 46204 F 50mgewaliNo ratings yet

- Ficha Tecnica GensetDocument4 pagesFicha Tecnica GensetselvamejiaNo ratings yet

- Installation Guide: Non-Programmable Digital ThermostatDocument16 pagesInstallation Guide: Non-Programmable Digital ThermostatBojan BjelajacNo ratings yet

- HR E577rDocument6 pagesHR E577rAnton RenaldoNo ratings yet

- The European Products Catalogue 2013Document237 pagesThe European Products Catalogue 2013anon_558925735No ratings yet

- Catalog LG (Diferite Temperaturi)Document161 pagesCatalog LG (Diferite Temperaturi)Alin Petre0% (1)

- 1 Aoe 8V4000L62 Ratings and Emissions: Technical Description TB 46202 F 50Document7 pages1 Aoe 8V4000L62 Ratings and Emissions: Technical Description TB 46202 F 50mgewaliNo ratings yet

- 30HXC CNDocument12 pages30HXC CNtechnokakiNo ratings yet

- Service: ManualDocument54 pagesService: ManualElseven AkifNo ratings yet

- Consolidated Capital SpareDocument9 pagesConsolidated Capital SparevenkateshbitraNo ratings yet

- 2VV - Baterie Apa 2VV VOK01 CircularaDocument6 pages2VV - Baterie Apa 2VV VOK01 CircularaCristian JianuNo ratings yet

- 210 Technical SpecificationDocument28 pages210 Technical SpecificationquaressNo ratings yet

- G3516 (975 Ekw 1218 kVA)Document7 pagesG3516 (975 Ekw 1218 kVA)Antwon CharlesNo ratings yet

- AHU InstructionDocument12 pagesAHU Instructionforevertay2000No ratings yet

- SCOH-K Tech Guide 0705Document48 pagesSCOH-K Tech Guide 0705Emir OmerdicNo ratings yet

- P 4740100 InstallDocument13 pagesP 4740100 InstallAshraf Adel Nashed ZakiNo ratings yet

- Model: T1540 Diesel GensetDocument5 pagesModel: T1540 Diesel Gensetengnajeeb75No ratings yet

- Service Manual: Ironing Board HL 5420Document3 pagesService Manual: Ironing Board HL 5420pukymottoNo ratings yet

- Heat Exchangers PDFDocument10 pagesHeat Exchangers PDFtdecebalusNo ratings yet

- York Cat LC 2012 enDocument148 pagesYork Cat LC 2012 enMary Andrews100% (1)

- Bulletin 900-Tc: Single-Loop Electronic Temperature/Process ControllersDocument30 pagesBulletin 900-Tc: Single-Loop Electronic Temperature/Process ControllersAriel Pedro Nina ANo ratings yet

- Victoria Tech ManualDocument56 pagesVictoria Tech ManualOarga CalinNo ratings yet

- Thremostat ManualDocument60 pagesThremostat ManualfranNo ratings yet

- Service & Maintenance ManualDocument44 pagesService & Maintenance ManualAnonymous 2iQ1B59No ratings yet

- Model: T2100 Diesel GensetDocument5 pagesModel: T2100 Diesel Gensetengnajeeb75No ratings yet

- Honeywell RTH8500 Series Quick Installation Guide PDFDocument60 pagesHoneywell RTH8500 Series Quick Installation Guide PDFbandihootNo ratings yet

- IMI CD3 MCU Tech Manual PDFDocument48 pagesIMI CD3 MCU Tech Manual PDFJoe BloggsNo ratings yet

- 2020 2220 ManualDocument15 pages2020 2220 Manualalfredo perezNo ratings yet

- 3/2 Directional ValveDocument9 pages3/2 Directional ValveMohan ArumugavallalNo ratings yet

- Pro 1000-2000Document20 pagesPro 1000-2000cisar29No ratings yet

- Uk Product CatalogueDocument94 pagesUk Product CataloguePersefoniaNo ratings yet

- Single Duct UnitsDocument30 pagesSingle Duct UnitsMike AristaNo ratings yet

- 6ALBR5233JQODocument23 pages6ALBR5233JQOpinticaniulian9042No ratings yet

- fp50 fp100 fp200Document10 pagesfp50 fp100 fp200ducmanh83No ratings yet

- M 11029 PDFDocument14 pagesM 11029 PDFquiphanvanNo ratings yet

- Kalorimetar Data Sheet UH50 - UH106 101kDocument15 pagesKalorimetar Data Sheet UH50 - UH106 101kbobesponjakockaloneNo ratings yet

- Steffes 5100 Tech Data SheetDocument4 pagesSteffes 5100 Tech Data SheetcringsredNo ratings yet

- Siemens - Tyco V23084 C2001 A303Document5 pagesSiemens - Tyco V23084 C2001 A303meda меда100% (1)

- AHUDocument5 pagesAHUksahunkNo ratings yet

- 50KVA RevDocument2 pages50KVA RevMansoor AhmadNo ratings yet

- 60 MW GE Frame 7B+ Gas Turbine Generator Package PG 7801BDocument5 pages60 MW GE Frame 7B+ Gas Turbine Generator Package PG 7801BvcharlesNo ratings yet

- Walvoil Cartridge Ventielen HICDocument20 pagesWalvoil Cartridge Ventielen HICddNo ratings yet

- Linea 24 and 28 Installation and Servicing InstructionsDocument64 pagesLinea 24 and 28 Installation and Servicing Instructionskhairul_ezadNo ratings yet

- 520 - MPC Plate Chiller BulletinDocument4 pages520 - MPC Plate Chiller BulletinThanh Van LeNo ratings yet

- Manejadora Adp Lennox PDFDocument15 pagesManejadora Adp Lennox PDF45saulNo ratings yet

- Dcg95v 100Document6 pagesDcg95v 100nmclaugh0% (1)

- OlkDocument16 pagesOlkcristianNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Power Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryFrom EverandPower Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Dino-Lite Premier AM7013MZTSDocument4 pagesDino-Lite Premier AM7013MZTSIBJSC.comNo ratings yet

- Dino-Lite Premier AD7013MTLDocument4 pagesDino-Lite Premier AD7013MTLIBJSC.comNo ratings yet

- Smarthome Catalog Vol. 131Document68 pagesSmarthome Catalog Vol. 131IBJSC.comNo ratings yet

- Catalog of Flexicon Flexible Conduit Solutions For Hazardous AreasDocument17 pagesCatalog of Flexicon Flexible Conduit Solutions For Hazardous AreasIBJSC.comNo ratings yet

- RelayTestJumpApps BFA5CDF49F46CDocument1 pageRelayTestJumpApps BFA5CDF49F46CIBJSC.comNo ratings yet

- Calibration Check Waterproof pH/mV/ºC Meter: Sales and Technical Service ContactsDocument16 pagesCalibration Check Waterproof pH/mV/ºC Meter: Sales and Technical Service ContactsIBJSC.comNo ratings yet

- Instruction Manual: Portable Waterproof Leather & Paper PH MeterDocument2 pagesInstruction Manual: Portable Waterproof Leather & Paper PH MeterIBJSC.comNo ratings yet

- Kyoritsu2040 UsermanualDocument2 pagesKyoritsu2040 UsermanualIBJSC.comNo ratings yet

- HD Megapixel Wireless Network Pan/Tilt Surveillance CameraDocument2 pagesHD Megapixel Wireless Network Pan/Tilt Surveillance CameraIBJSC.comNo ratings yet

- HD Megapixel Wireless Network Surveillance CameraDocument2 pagesHD Megapixel Wireless Network Surveillance CameraIBJSC.comNo ratings yet

- HI 98127 - HI 98128: Functional Description Ce Declaration of ConformityDocument2 pagesHI 98127 - HI 98128: Functional Description Ce Declaration of ConformityIBJSC.comNo ratings yet

- Printer lithiumIonBatteryMSDSDocument7 pagesPrinter lithiumIonBatteryMSDSIBJSC.comNo ratings yet

- Sony DCR-TRV820 HandycamDocument245 pagesSony DCR-TRV820 Handycamcochr002No ratings yet

- Half-Wave Rectifier Feeding A DC MotorDocument4 pagesHalf-Wave Rectifier Feeding A DC Motorhamza abdo mohamoudNo ratings yet

- RT3661AB-RichTek Sau AS3661AB PDFDocument36 pagesRT3661AB-RichTek Sau AS3661AB PDFeduardskNo ratings yet

- Parametri Si EroriDocument112 pagesParametri Si EroriRobert sebastian BeldescuNo ratings yet

- Class D Amplifier PDFDocument7 pagesClass D Amplifier PDFHoracio Dorantes ReyesNo ratings yet

- Weak InversionDocument33 pagesWeak Inversionrafael_santos_121No ratings yet

- Driver DST 3640 For 31 KG CMDocument18 pagesDriver DST 3640 For 31 KG CMWWW.150775.BUGME.PWNo ratings yet

- A.1.3 Modbus Measured Variables With The Function Codes 0x03 and 0x04Document6 pagesA.1.3 Modbus Measured Variables With The Function Codes 0x03 and 0x04David VallejoNo ratings yet

- Safety Precautions in ElectronicsDocument16 pagesSafety Precautions in ElectronicsChezzzzyNo ratings yet

- BQ4010Document11 pagesBQ4010易行胜No ratings yet

- Assignment 1: Electrical Machines-Ii (Elpc402)Document1 pageAssignment 1: Electrical Machines-Ii (Elpc402)Abishek BhardwajNo ratings yet

- F3 PWM Controller: Ice3Bs03LjgDocument25 pagesF3 PWM Controller: Ice3Bs03LjgАндрей КирюхинNo ratings yet

- Dip05 2a72 21LDocument2 pagesDip05 2a72 21Lm0gaNo ratings yet

- Chapter 4.0 Sensor and Signal ConditioningDocument49 pagesChapter 4.0 Sensor and Signal ConditioningDawit MengisteabNo ratings yet

- Practical Electronic Design For Experimenters Louis E Frenzel Download PDF ChapterDocument51 pagesPractical Electronic Design For Experimenters Louis E Frenzel Download PDF Chapterrobert.sanyaro720100% (11)

- Table of Relay Outputs With tYPE 1-2-3-4-13 (Variable Speed Control)Document2 pagesTable of Relay Outputs With tYPE 1-2-3-4-13 (Variable Speed Control)راجيرحمةربهNo ratings yet

- Lecture 12 (EPSP)Document28 pagesLecture 12 (EPSP)JaleesNo ratings yet

- Electrical Test EquipmentsDocument17 pagesElectrical Test Equipmentsengrroy100% (1)

- Hileakester Hld-20aDocument8 pagesHileakester Hld-20aFebri Petra SimanungkalitNo ratings yet

- AGC300 AGC300 Rev0Document11 pagesAGC300 AGC300 Rev0raj_ritu_aNo ratings yet

- Generators and Transformers: Prepared by M.Aruna / EeeDocument11 pagesGenerators and Transformers: Prepared by M.Aruna / Eeegssasi100% (1)

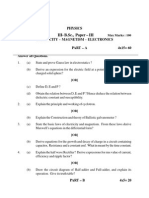

- Physics Paper IIIDocument3 pagesPhysics Paper IIItadepalli patanjaliNo ratings yet

- Electrical Systems DemoDocument45 pagesElectrical Systems Demoronald lazo100% (1)

- GTP Ykp PDFDocument45 pagesGTP Ykp PDFSwarup NayakNo ratings yet

- CH 05 PowerDocument49 pagesCH 05 PowerTriếtCỏNo ratings yet

Installation Guide: TH8320ZW1000

Installation Guide: TH8320ZW1000

Uploaded by

IBJSC.comOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Guide: TH8320ZW1000

Installation Guide: TH8320ZW1000

Uploaded by

IBJSC.comCopyright:

Available Formats

Installation Guide

TH8320ZW1000

Touch-screen Thermostat

This manual covers the TH8320ZW1000.

System Types

Gas, oil, or electric heat with air conditioning Warm air, hot water, high efficiency furnaces, heat pumps, steam, gravity Heat only including power to open and close zone valves (Series 20), and normally open zone valves Heat only with fan Cool only 750 mV heating systems

This thermostat contains a Lithium battery which may contain Perchlorate material. Perchlorate Materialspecial handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate

Need Help?

For assistance with this product please visit http://customer.honeywell.com or call Honeywell Customer Care toll-free at 1-800-468-1502

U.S. Registered Trademark. US Patent No. 6,574,581, 6,975,958, 7,114,554, 7,346,467, 7,636,604, 7,693,582, 7,788,936, 7,845,576, and other patents pending. Copyright 2011 Honeywell International Inc. All rights reserved.

69-2486-03

Installation Guide

Wallplate installation

1. Separate wallplate from thermostat. 2. Mount wallplate as shown below. Grasp top and bottom of wallplate and pull to remove from thermostat.

+ +

M29480

Drill 3/16 holes for drywall. Drill 7/32 holes for plaster.

Wire hole

Mounting screws

Wall anchors

M29481

Must be installed by a trained, experienced technician

Read these instructions carefully. Failure to follow these instructions can damage the product or cause a hazardous condition. CAUTION: ELECTRICAL HAZARD Can cause electrical shock or equipment damage. Disconnect power before beginning installation. MERCURY NOTICE If this product is replacing a control that contains mercury in a sealed tube, do not place the old control in the trash. Contact your local waste management authority for instructions regarding recycling and proper disposal.

69-248603

TH8320ZW1000

Power Requirements

Remove tab.

K

M32428

M32429

Connect the common side of the transformer to C terminal. This connection is mandatory.

The thermostat is shipped from the factory with the coin cell installed. To keep the battery from discharging during shipment and storage, the thermostat is shipped with a plastic tab inserted in the battery holder. This tab must be removed during installation. Simply pull the plastic tab out of the battery tray. Make sure that the battery tray is fully inserted into the thermostat.

Wiring

Remove factory-installed jumper only for two-transformer systems. Push excess wire back into the wall opening. Plug wall opening with non-flammable insulation.

K

M32430 M32431

69-248603

Installation Guide

Wiring

Terminal Designations

Conventional Terminal Letters:

R Rc C Heating power. Connect to secondary side of heating system transformer. Cooling power. Connect to secondary side of cooling system transformer. Common wire from secondary side of cooling transformer (if 2 transformers). 1st stage heat relay. 2nd stage heat relay 1st stage compressor contactor. 2nd stage compressor contactor. Fan relay. Optional THP9045 Wiring Module Terminal [9]

Heat Pump Terminal Letters:

R Rc C Y Y2 Aux G E L

W W2 Y Y2 G K

O/B K

Heating power. Connect to secondary side of heating system transformer. Cooling power. Connect to secondary side of cooling system transformer. Common wire from secondary side of cooling system transformer. 1st stage compressor contactor. 2nd stage compressor contactor. Auxiliary heat relay. Fan relay. Emergency heat relay. Heat pump reset (powered continuously when System is set to Em Heat; system monitor when set to Heat, Cool or Off). Changeover valve for heat pumps. Optional THP9045 Wiring Module Terminal [9]

Wiring guideconventional systems

1H/1C System (1 transformer)

Rc R W Y G C K Power [1] [R+Rc joined by jumper] Heat relay Compressor contactor Fan relay 24VAC common [3] Optional THP9045 Wiring Module Terminal [9]

Heat Only System (Series 20)

Rc R W Y C [R+Rc joined by jumper] Series 20 valve terminal R [1] Series 20 valve terminal B Series 20 valve terminal W 24VAC common [3]

2H/2C System (1 transformer)

Y2 W2 Rc R W Y G C K Cool relay 2 Heat relay 2 Power [1] [R+Rc joined by jumper] Heat relay 1 Cool relay 1 Fan relay 24VAC common [3]

Heat Only System

Rc R W C Power [1] [R+Rc joined by jumper] Heat relay 24VAC common [3]

Optional THP9045 Wiring Module Terminal [9]

See [notes] below

[1] Power supply. Provide disconnect means and overload protection as required. [3] Connection to 24VAC common at the transformer is required. [9] See "Optional THP9045 Wiring Module" on page 14 for more details.

69-248603

TH8320ZW1000

Wiring

Wiring guideheat pump systems

1H/1C Heat Pump (no auxiliary heat)

Rc R O/B Y G C K Power [1] [R+Rc joined by jumper] Changeover valve [5] Compressor relay Fan relay 24VAC common [3] Optional THP9045 Wiring Module Terminal [9]

1H/1C System (2 transformers)

Rc R W Y G C K Power (cooling transformer) [1, 2] Power (heating transformer) [1, 2] Heat relay Compressor contactor Fan relay 24VAC common [3, 4] Optional THP9045 Wiring Module Terminal [9]

2H/1C Heat Pump (with auxiliary heat)

L E Aux Rc R O/B Y G C K Equipment monitor [6, 7] Emergency heat relay [8] Auxiliary heat relay (Heat 2) [8] Power [1] [R+Rc joined by jumper] Changeover valve [5] Compressor relay Fan relay 24VAC common [3] Optional THP9045 Wiring Module Terminal [9]

Heat Only System With Fan

Rc R W G C Power [1] [R+Rc joined by jumper] Heat relay Fan relay 24VAC common [3]

Cool Only System

Rc R Y G C K Power [1] [R+Rc joined by jumper] Compressor contactor Fan relay 24VAC common [3] Optional THP9045 Wiring Module Terminal [9]

2H/2C Heat Pump (no auxiliary heat)

Y2 Rc R O/B Y G C K Compressor 2 relay Power [1] [R+Rc joined by jumper] Changeover valve [5] Compressor 1 relay Fan relay 24VAC common [3] Optional THP9045 Wiring Module Terminal [9]

2H/2C System (2 transformers)

Y2 W2 Rc R W Y G C K Cool relay 2 Heat relay 2 Power (cooling transformer) [1, 2] Power (heating transformer) [1, 2] Heat relay 1 Cool relay 1 Fan relay 24VAC common [3, 4] Optional THP9045 Wiring Module Terminal [9]

See [notes] below

[1] [2] [3] [4] [5] [6] [7] Power supply. Provide disconnect means and overload protection as required. Remove jumper for 2 transformer systems. Connection to 24VAC common at the transformer is required. Common connection must come from cooling transformer. O/B set to control as either O or B in installer setup. If L terminal is used, 24VAC common (terminal C) must be connected. Heat pump reset (powered continuously when thermostat is set to Em. Heat; system monitor when set to Heat, Cool, or Off). [8] Install field jumper between Aux and E terminals if there is no emergency heat relay.

[9] See "Optional THP9045 Wiring Module" on page 14 for more details.

69-248603

Installation Guide

Mount thermostat

Align pins on back of thermostat with slots in wallplate, then push gently until thermostat snaps into place.

M32435

Set date and time

Press st to set date Press st to set month Press st to set year

TUE

Press st to set time

TUE

15

2006

DONE

6

DONE

1:00 PM

M29485

Press DONE to save changes.

Press DONE to save and exit.

Installer setup

1. Press SYSTEM. 2. Press and hold these two buttons until the display changes.

SYSTEM

HEAT

6:00aM

CANCEL

TUE

FAN AUTO

Inside

70

3. Change settings as required (see pages 7-9).

HOLD

DONE

SYSTEM

HEAT

6:00aM

SCHED

0120

DONE

20

M32417

69-248603

TH8320ZW1000

Installer setup

Function Setting

0120

DONE

20

DONE

0120

20

M32427

Press st to select function

Press st to change setting

Press DONE to exit & save settings.

Setup functions

0120 0130 0140 0150 0160 0165 0170 Year (first two digits) Year (second two digits) Month Date Schedule format Restore Energy Saving Schedule System type

Settings & Options (factory default in bold)

20 (2000-2078) 21 (2101-2178) 10 (2010) [Other options: 00-99] 6 15 0 4 0 1 1 2 3 4 5 6 7 8 9 10 11 12 [Other options: 1-12] [Other options: 1-31] Nonprogrammable Programmable No Yes 1 heat/1 cool conventional 1 heat/1 cool heat pump (no aux. heat) Heat only (2-wire systems) Heat only with fan Hot water Series 20 system (power to open & close zone valves/normally open zone valves) Cool only 2 heat/1 cool heat pump (with aux. heat) 2 heat/2 cool multistage conventional 2 heat/1 cool multistage conventional 1 heat/2 cool multistage conventional 2 heat/2 cool heat pump (no aux. heat) 3 heat/2 cool heat pump (with aux. heat) Gas/Oil heat (equipment controls heating fan) Electric furnace (thermostat controls heating fan) O terminal controls valve in cooling B terminal controls valve in heating Recommended for most compressors [Other options: 1, 2, 4, 5 or 6 CPH] Recommended for most compressors [Other options: 1, 2, 4, 5 or 6 CPH]

0180 0190 0220 0230 0240

Fan control (heating) Changeover valve (O/B terminal) 1st stage compressor cycle rate 2nd stage compressor cycle rate 1st stage heat cycle rate (CPH = cycles per hour) 5 1 3 9

0 1 0 1 3 3

Gas or oil furnaces of less than 90% efficiency Steam or gravity systems Hot water systems & furnaces of 90%+ efficiency Electric furnaces [Other options: 2, 4, 6, 7, 8, 10, 11, 12 CPH] Continued on next page

69-248603

Installation Guide

Installer setup

Setup functions

0250 2nd stage heat cycle rate (CPH) 5 1 3 9 5 1 3 9 9 1 3 5 0 1 0 1 3 0 1 1 0 0500 Furnace filter change reminder 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 0 1 0 1 2

Settings & Options (factory default in bold)

Gas or oil furnaces of less than 90% efficiency Steam or gravity systems Hot water systems & furnaces of 90%+ efficiency Electric furnaces [Other options: 2, 4, 6, 7, 8, 10, 11, 12 CPH] Gas or oil furnaces of less than 90% efficiency Steam or gravity systems Hot water systems & furnaces of 90%+ efficiency Electric furnaces [Other options: 2, 4, 6, 7, 8, 10, 11, 12 CPH] Electric emergency heat Steam or gravity systems Hot water systems & furnaces of 90%+ efficiency Gas or oil furnaces of less than 90% efficiency [Other options: 2, 4, 6, 7, 8, 10, 11, 12 CPH] Backlight on for approx. 45 seconds after keypress Backlight always on low intensity, full bright after keypress (requires 24VAC connection) Manual changeover (Heat/Cool/Off) Automatic changeover (Heat/Cool/Auto/Off) Heat/cool temperature 3F apart (1.5C) [Other options: 2-9 (2F to 9F/1C to 5C)]) Fahrenheit Celsius Auto-change to daylight savings time (through 2007, and for areas that do not use the new 2008 DST calendar) Daylight savings time is turned off Off 10-day run time (about 1 month) 30-day run time (about 3 months) 60-day run time (about 6 months) 90-day run time (about 9 months) 120-day run time (about 1 year) 180-day run time (about 1.5 years) 270-day run time (about 2 years) 365-day run time (about 3 years) 30 calendar days 60 calendar days 90 calendar days 120 calendar days 180 calendar days 365 calendar days Counts both heat and cool Counts cool only Disabled 365 days 730 days Continued on next page

0260

3rd stage heat cycle rate (CPH)

0270

Emergency heat cycle rate (CPH)

0280

Continuous Backlight Manual/Auto changeover Auto changeover deadband Temperature display Daylight savings

0300 0310 0320 0330

0502 0520

Furnace filter for Run time UV Lamp Replacement Reminder

69-248603

TH8320ZW1000

Installer setup

Setup functions

0530 0540 0580 0600 0610 0615 0616 0640 0650 Adaptive Intelligent Recovery Program periods Compressor protection Heat temperature range stop Cool temperature range stop Energy Saving Heat Setpoint Energy Saving Cooling Setpoint Clock format Extended fan timer (heat) Extended fan timer (cool) Keypad lock

Settings & Options (factory default in bold)

1 0 4 2 5 90 50 65 78 12 24 0 90 0 90 0 1 2 2 1 3 2 1 3 0 0 1 On Off 4 program periods (Wake, Leave, Return, Sleep) 2 program periods (Wake, Sleep) 5 minute compressor off time [Other options: 0, 1, 2, 3 or 4-minute off time] Max. heat temperature setting is 90F (32C) [Other options: 40-89F (4C to 32C)] Min. cool temperature setting is 50F (10C) [Other options: 51-99F (11C to 37C)] 65F (18.5C) 40-90F (4.5C to 32C) 78F (25.5C) 50-99F (10C to 37C) 12-hour time (i.e., 3:30 pm) 24-hour time (i.e., 15:30) Off Fan runs for 90 seconds after call for heat ends [Other options: 30, 60, 120] Off Fan runs for 90 seconds after call for cooling ends [Other options: 30, 60, 120] Keypad unlocked (fully functional) Partially locked (access to temperature settings only) Fully locked Standard temperature control (recommended) Choose if room is warmer than set temperature Choose if room does not reach set temperature Standard temperature control (recommended) Choose if room is cooler than set temperature Choose if room does not reach set temperature Thermostat displays actual room temperature [Other options: -3, -2, -1, 1, 2, 3F offset (-1.5C to 1.5C)] No reset Reset installer options (including Z-Wave inclusion) & program schedule to factory default (only date and time settings are retained) Remove Add Idle Send Node

0660

0670

0680

Heat temperature control Cool temperature control Temperature display offset Reset

0690

0700 0710

rf10 rf20

Z-Wave Network Connection Z-Wave Node Connection

0 1 0 1

69-248603

Installation Guide

Installer system test

During installer setup, press t repeatedly until Test appears. Test number System status

0120

DONE

20

1

TEST

DONE

0

Press t to change status

M29488

Press DONE to terminate testing.

Press t to select test

System test 1 Cooling system

System status 0 1 2 0 1 0 1 2 Compressor and fan turn off Compressor and fan turn on Second stage compressor turns on Fan turns off Fan turns on Heat and fan turn off Heat turns on (fan on if Function 0170 is set for heat pump, or if Function 0180 is set to 1) Second stage heat turns on Em Heat and fan turn off Em Heat and fan turn on Second stage heat turns on (Auxiliary heat)

2 3

Fan system Heating system

Emergency heating system

0 1 2

CAUTION: EQUIPMENT DAMAGE HAZARD. Compressor protection is bypassed during testing. To prevent equipment damage, avoid cycling the compressor quickly.

Z-Wave enrollment

1. To join a Z-Wave network, set the Z-Wave controller to INCLUDE mode.

2.

Select 1 to add thermostat to Z-Wave network.

F 10

DONE

0

M32423A

69-248603

10

TH8320ZW1000

Z-Wave enrollment

Wait

F 10

M32422

3.

To remove the thermostat from the Z-Wave network select 0.

14

F 10

DONE

M32424A

F 10

M32425

11

69-248603

Installation Guide

Z-Wave enrollment

4.

To share the thermostat Node information with additional Z-Wave devices select 1.

F20

DONE

0

M32421

Z-Wave messages

Add/ Remove The thermostat can be included or excluded from the Z-Wave network. This action requires the controller set in inclusion mode. The device is included to the Z-Wave network after sending the node information to the controller. The controller is responsible for assigning the home ID and device ID to the included device. Association The thermostat can be associated with other devices in the system. Being associated means that the thermostat is able to send messages directly to any other device. During the association process the return route is acquired from the primary controller. The thermostat then uses this return route to access the distant node. Enter/leave power saving mode When requested from the Z-Wave controller, the thermostat adjusts its setpoint in order to decrease the power consumption of the HVAC equipment. In addition, using an Internet gateway enables the person to control the thermostat remotely through the Internet. Fan Switch The thermostat can send the message containing the actual fan switch position. Fan Switch change The other devices are able to change the fan switch of the thermostat. After the message is received, the fan switch is changed to the desired value (if this value is possible). For the thermostat the possible values are On, Auto and Circ. Indoor temperature The thermostat sends the indoor temperature using the Multilevel Sensor command class. Report upon GET request Upon request (GET command) the thermostat sends the corresponding report. Setpoint Value The thermostat can send the message containing the actual setpoint value based on setpoint change.

69-248603

12

TH8320ZW1000

Z-Wave messages

Setpoint change Other Z-Wave devices are able to modify the setpoint of the thermostat. The absolute value can be sent by the controller and thermostat will change the setpoint to this value. System Switch The thermostat can send the message containing the actual system switch based on system switch change. System switch change Other devices (controllers) are able to change the system switch of the thermostat. After the message is received by the thermostat, the system switch is changed to desired value (if this value is seven). Seven possible switch modes are available for the thermostat: Heat / Cool / Off / Auto / Energy Saving Heat / Energy Saving Cool / Em Heat. The number of allowed system switch selection depends on the actual configuration of the thermostat. The thermostat uses "Thermostat Mode Supported" report command class to tell other devices the actually supported system switch modes. Thermostat Fan State The thermostat can send the message containing the actual state of fan based on fan state change. The Fan state can be either "Auto" or "On". Thermostat Operating State The thermostat can send the message containing the actual state of the HVAC equipment based on equipment state change. The thermostat provides the following operating states: Idle - no equipment on Heating - heating equipment on Cooling - cooling equipment on Pending Heat - minimum off time applied to protect the heat pump compressor Pending Cool - minimum off time applied to protect the heat pump compressor Time/Date The thermostat can send the message containing the actual Time and Date. Time/Date change The time and date is able to be changed on the thermostat. After the report is received, the time and/or date is changed to the desired value (if this value is possible). Unsolicited Report Message Sending the message is possible only if the thermostat is associated with any other node. The thermostat will send the message using assigned node ID and return route.

13

69-248603

Installation Guide

Special functions

Auto Changeover (Setup Function 0300): When set to Auto, the thermostat automatically selects heating or cooling depending on the indoor temperature. Heat and cool settings must be at least 2 degrees apart. Adaptive Intelligent Recovery (Setup Function 0530): Allows the thermostat to learn how long the furnace and air conditioner take to reach programmed temperature settings, so the temperature is reached at the scheduled time. Compressor Protection (Setup Function 0580): Forces the compressor to wait a few minutes before restarting, to prevent damage. During this time, the message Wait is on the display.

Accessories & replacement parts

Please contact your distributor to order replacement parts.

Cover plate* ............................................................ Part Number 32003796-001 *(Use to cover marks left by old thermostats.)

Specifications

Temperature Ranges Heat: 40 to 90F (4.5 to 32C) Cool: 50 to 99F (10 to 37C) Operating Ambient Temperature 0 to 120F (-18 to 48.9C) Shipping Temperature -30 to 150F (-34 to 66C) Operating Relative Humidity 5% to 90% (non-condensing) Physical Dimensions 4-23/25 H x 6-2/5 W x 1-19/46 D 125 mm H x 166 mm W x 36 mm D Electrical Ratings Terminal W Heating (Powerpile) W2 Heating Y Cooling Y2 Cooling Aux Auxiliary heat O/B Changeover E Emergency heat L Heat pump reset Voltage (50/60Hz) 20-30 Vac 750 mV DC 20-30 Vac 20-30 Vac 20-30 Vac 20-30 Vac 20-30 Vac 20-30 Vac 20-30 Vac Running Current 0.02-1.0 A 100 mA DC 0.02-0.6 A 0.02-1.0 A 0.02-0.6 A 0.02-1.0 A 0.02-0.6 A 0.02-1.0 A 0.02-0.6 A

Optional THP9045 Wiring Module

The THP9045 Wiring Module is designed to be used with applicable thermostats in 1 Heat/1 Cool retrofit applications where only 4 wires are available. The K terminal on the thermostat can be used to operate both the fan and compressor on a single wire, and the module is designed to receive the signal from the K terminal, split that signal and reroute it to operate the compressor, and/or fan for normal operation. See the THP9045 manual for further details.

69-248603

14

TH8320ZW1000

Regulatory information

FCC Compliance Statement (Part 15.19) (USA only) This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: 1) This device may not cause harmful interference, and 2) This device must accept any interference received, including interference that may cause undesired operation. FCC Warning (Part 15.21) (USA only) Changes or modifications not expressly approved by the party responsible for compliance could void the users authority to operate the equipment. FCC Interference Statement (Part 15.105 (b)) (USA only) This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one of the following measures: Reorient or relocate the receiving antenna. Increase the separation between the equipment and receiver. Connect the equipment into an outlet on a circuit different from that to which the receiver is connected. Consult the dealer or an experienced radio/TV technician for help. Section 7.1.2 of RSS-GEN Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type and maximum (or lesser) gain approved for the transmitter by Industry Canada. To reduce potential radio interference to other users, the antenna type and its gain should be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary for successful communication. Section 7.1.3 of RSS-GEN This Device complies with Industry Canada License-exempt RSS standard(s). Operation is subject to the following two conditions: 1) this device may not cause interference, and 2) this device must accept any interference, including interference that may cause undesired operation of the

device.

15

69-248603

Z-Wave is a registered trademark of Zensys, Inc. and/or its subsidiaries.

Automation and Control Solutions Honeywell International Inc. 1985 Douglas Drive North Golden Valley, MN 55422 http://customer.honeywell.com Honeywell Limited-Honeywell Limite 35 Dynamic Drive Toronto, Ontario M1V 4Z9

U.S. Registered Trademark. US Patent No. 6,574,581, 6,975,958, 7,114,554, 7,346,467, 7,636,604, 7,693,582, 7,788,936, 7,845,576, and other patents pending. 2011 Honeywell International Inc. 69-248603 M.S. Rev. 05-11 Printed in U.S.A.

You might also like

- SH367309 Ev1.2aDocument92 pagesSH367309 Ev1.2aThien Dinh86% (7)

- LG IS3 ManualDocument137 pagesLG IS3 ManualEugenio Francisco Martínez Mora70% (10)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Heat KingDocument28 pagesHeat KingWayne Grey100% (3)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Carrier Commercial Systems 2008 List Prices: 30Rb Air Cooled ChillersDocument13 pagesCarrier Commercial Systems 2008 List Prices: 30Rb Air Cooled ChillersvickersNo ratings yet

- Energy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134aDocument30 pagesEnergy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134atechnokakiNo ratings yet

- Tutorial - Ground MatDocument76 pagesTutorial - Ground MatThiago Breno Menezes da Silva100% (1)

- Manual de Servicio Monitor LCD Dell E190SfDocument59 pagesManual de Servicio Monitor LCD Dell E190SfAntonio Chavez100% (1)

- File 2 10Document8 pagesFile 2 10camelod555No ratings yet

- Installation Guide: Focuspro Wi-Fi Th6000 Series Programmable ThermostatDocument36 pagesInstallation Guide: Focuspro Wi-Fi Th6000 Series Programmable ThermostatLynnNo ratings yet

- Thermostat ManualDocument24 pagesThermostat ManualbschvyNo ratings yet

- Aoe 12V4000L62 Ratings and Emissions 1: Technical Description TB 46204 F 50Document7 pagesAoe 12V4000L62 Ratings and Emissions 1: Technical Description TB 46204 F 50mgewaliNo ratings yet

- Ficha Tecnica GensetDocument4 pagesFicha Tecnica GensetselvamejiaNo ratings yet

- Installation Guide: Non-Programmable Digital ThermostatDocument16 pagesInstallation Guide: Non-Programmable Digital ThermostatBojan BjelajacNo ratings yet

- HR E577rDocument6 pagesHR E577rAnton RenaldoNo ratings yet

- The European Products Catalogue 2013Document237 pagesThe European Products Catalogue 2013anon_558925735No ratings yet

- Catalog LG (Diferite Temperaturi)Document161 pagesCatalog LG (Diferite Temperaturi)Alin Petre0% (1)

- 1 Aoe 8V4000L62 Ratings and Emissions: Technical Description TB 46202 F 50Document7 pages1 Aoe 8V4000L62 Ratings and Emissions: Technical Description TB 46202 F 50mgewaliNo ratings yet

- 30HXC CNDocument12 pages30HXC CNtechnokakiNo ratings yet

- Service: ManualDocument54 pagesService: ManualElseven AkifNo ratings yet

- Consolidated Capital SpareDocument9 pagesConsolidated Capital SparevenkateshbitraNo ratings yet

- 2VV - Baterie Apa 2VV VOK01 CircularaDocument6 pages2VV - Baterie Apa 2VV VOK01 CircularaCristian JianuNo ratings yet

- 210 Technical SpecificationDocument28 pages210 Technical SpecificationquaressNo ratings yet

- G3516 (975 Ekw 1218 kVA)Document7 pagesG3516 (975 Ekw 1218 kVA)Antwon CharlesNo ratings yet

- AHU InstructionDocument12 pagesAHU Instructionforevertay2000No ratings yet

- SCOH-K Tech Guide 0705Document48 pagesSCOH-K Tech Guide 0705Emir OmerdicNo ratings yet

- P 4740100 InstallDocument13 pagesP 4740100 InstallAshraf Adel Nashed ZakiNo ratings yet

- Model: T1540 Diesel GensetDocument5 pagesModel: T1540 Diesel Gensetengnajeeb75No ratings yet

- Service Manual: Ironing Board HL 5420Document3 pagesService Manual: Ironing Board HL 5420pukymottoNo ratings yet

- Heat Exchangers PDFDocument10 pagesHeat Exchangers PDFtdecebalusNo ratings yet

- York Cat LC 2012 enDocument148 pagesYork Cat LC 2012 enMary Andrews100% (1)

- Bulletin 900-Tc: Single-Loop Electronic Temperature/Process ControllersDocument30 pagesBulletin 900-Tc: Single-Loop Electronic Temperature/Process ControllersAriel Pedro Nina ANo ratings yet

- Victoria Tech ManualDocument56 pagesVictoria Tech ManualOarga CalinNo ratings yet

- Thremostat ManualDocument60 pagesThremostat ManualfranNo ratings yet

- Service & Maintenance ManualDocument44 pagesService & Maintenance ManualAnonymous 2iQ1B59No ratings yet

- Model: T2100 Diesel GensetDocument5 pagesModel: T2100 Diesel Gensetengnajeeb75No ratings yet

- Honeywell RTH8500 Series Quick Installation Guide PDFDocument60 pagesHoneywell RTH8500 Series Quick Installation Guide PDFbandihootNo ratings yet

- IMI CD3 MCU Tech Manual PDFDocument48 pagesIMI CD3 MCU Tech Manual PDFJoe BloggsNo ratings yet

- 2020 2220 ManualDocument15 pages2020 2220 Manualalfredo perezNo ratings yet

- 3/2 Directional ValveDocument9 pages3/2 Directional ValveMohan ArumugavallalNo ratings yet

- Pro 1000-2000Document20 pagesPro 1000-2000cisar29No ratings yet

- Uk Product CatalogueDocument94 pagesUk Product CataloguePersefoniaNo ratings yet

- Single Duct UnitsDocument30 pagesSingle Duct UnitsMike AristaNo ratings yet

- 6ALBR5233JQODocument23 pages6ALBR5233JQOpinticaniulian9042No ratings yet

- fp50 fp100 fp200Document10 pagesfp50 fp100 fp200ducmanh83No ratings yet

- M 11029 PDFDocument14 pagesM 11029 PDFquiphanvanNo ratings yet

- Kalorimetar Data Sheet UH50 - UH106 101kDocument15 pagesKalorimetar Data Sheet UH50 - UH106 101kbobesponjakockaloneNo ratings yet

- Steffes 5100 Tech Data SheetDocument4 pagesSteffes 5100 Tech Data SheetcringsredNo ratings yet

- Siemens - Tyco V23084 C2001 A303Document5 pagesSiemens - Tyco V23084 C2001 A303meda меда100% (1)

- AHUDocument5 pagesAHUksahunkNo ratings yet

- 50KVA RevDocument2 pages50KVA RevMansoor AhmadNo ratings yet

- 60 MW GE Frame 7B+ Gas Turbine Generator Package PG 7801BDocument5 pages60 MW GE Frame 7B+ Gas Turbine Generator Package PG 7801BvcharlesNo ratings yet

- Walvoil Cartridge Ventielen HICDocument20 pagesWalvoil Cartridge Ventielen HICddNo ratings yet

- Linea 24 and 28 Installation and Servicing InstructionsDocument64 pagesLinea 24 and 28 Installation and Servicing Instructionskhairul_ezadNo ratings yet

- 520 - MPC Plate Chiller BulletinDocument4 pages520 - MPC Plate Chiller BulletinThanh Van LeNo ratings yet

- Manejadora Adp Lennox PDFDocument15 pagesManejadora Adp Lennox PDF45saulNo ratings yet

- Dcg95v 100Document6 pagesDcg95v 100nmclaugh0% (1)

- OlkDocument16 pagesOlkcristianNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Power Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryFrom EverandPower Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Dino-Lite Premier AM7013MZTSDocument4 pagesDino-Lite Premier AM7013MZTSIBJSC.comNo ratings yet

- Dino-Lite Premier AD7013MTLDocument4 pagesDino-Lite Premier AD7013MTLIBJSC.comNo ratings yet

- Smarthome Catalog Vol. 131Document68 pagesSmarthome Catalog Vol. 131IBJSC.comNo ratings yet

- Catalog of Flexicon Flexible Conduit Solutions For Hazardous AreasDocument17 pagesCatalog of Flexicon Flexible Conduit Solutions For Hazardous AreasIBJSC.comNo ratings yet

- RelayTestJumpApps BFA5CDF49F46CDocument1 pageRelayTestJumpApps BFA5CDF49F46CIBJSC.comNo ratings yet

- Calibration Check Waterproof pH/mV/ºC Meter: Sales and Technical Service ContactsDocument16 pagesCalibration Check Waterproof pH/mV/ºC Meter: Sales and Technical Service ContactsIBJSC.comNo ratings yet

- Instruction Manual: Portable Waterproof Leather & Paper PH MeterDocument2 pagesInstruction Manual: Portable Waterproof Leather & Paper PH MeterIBJSC.comNo ratings yet

- Kyoritsu2040 UsermanualDocument2 pagesKyoritsu2040 UsermanualIBJSC.comNo ratings yet

- HD Megapixel Wireless Network Pan/Tilt Surveillance CameraDocument2 pagesHD Megapixel Wireless Network Pan/Tilt Surveillance CameraIBJSC.comNo ratings yet

- HD Megapixel Wireless Network Surveillance CameraDocument2 pagesHD Megapixel Wireless Network Surveillance CameraIBJSC.comNo ratings yet

- HI 98127 - HI 98128: Functional Description Ce Declaration of ConformityDocument2 pagesHI 98127 - HI 98128: Functional Description Ce Declaration of ConformityIBJSC.comNo ratings yet

- Printer lithiumIonBatteryMSDSDocument7 pagesPrinter lithiumIonBatteryMSDSIBJSC.comNo ratings yet

- Sony DCR-TRV820 HandycamDocument245 pagesSony DCR-TRV820 Handycamcochr002No ratings yet

- Half-Wave Rectifier Feeding A DC MotorDocument4 pagesHalf-Wave Rectifier Feeding A DC Motorhamza abdo mohamoudNo ratings yet

- RT3661AB-RichTek Sau AS3661AB PDFDocument36 pagesRT3661AB-RichTek Sau AS3661AB PDFeduardskNo ratings yet

- Parametri Si EroriDocument112 pagesParametri Si EroriRobert sebastian BeldescuNo ratings yet

- Class D Amplifier PDFDocument7 pagesClass D Amplifier PDFHoracio Dorantes ReyesNo ratings yet

- Weak InversionDocument33 pagesWeak Inversionrafael_santos_121No ratings yet

- Driver DST 3640 For 31 KG CMDocument18 pagesDriver DST 3640 For 31 KG CMWWW.150775.BUGME.PWNo ratings yet

- A.1.3 Modbus Measured Variables With The Function Codes 0x03 and 0x04Document6 pagesA.1.3 Modbus Measured Variables With The Function Codes 0x03 and 0x04David VallejoNo ratings yet

- Safety Precautions in ElectronicsDocument16 pagesSafety Precautions in ElectronicsChezzzzyNo ratings yet

- BQ4010Document11 pagesBQ4010易行胜No ratings yet

- Assignment 1: Electrical Machines-Ii (Elpc402)Document1 pageAssignment 1: Electrical Machines-Ii (Elpc402)Abishek BhardwajNo ratings yet

- F3 PWM Controller: Ice3Bs03LjgDocument25 pagesF3 PWM Controller: Ice3Bs03LjgАндрей КирюхинNo ratings yet

- Dip05 2a72 21LDocument2 pagesDip05 2a72 21Lm0gaNo ratings yet

- Chapter 4.0 Sensor and Signal ConditioningDocument49 pagesChapter 4.0 Sensor and Signal ConditioningDawit MengisteabNo ratings yet

- Practical Electronic Design For Experimenters Louis E Frenzel Download PDF ChapterDocument51 pagesPractical Electronic Design For Experimenters Louis E Frenzel Download PDF Chapterrobert.sanyaro720100% (11)

- Table of Relay Outputs With tYPE 1-2-3-4-13 (Variable Speed Control)Document2 pagesTable of Relay Outputs With tYPE 1-2-3-4-13 (Variable Speed Control)راجيرحمةربهNo ratings yet

- Lecture 12 (EPSP)Document28 pagesLecture 12 (EPSP)JaleesNo ratings yet

- Electrical Test EquipmentsDocument17 pagesElectrical Test Equipmentsengrroy100% (1)

- Hileakester Hld-20aDocument8 pagesHileakester Hld-20aFebri Petra SimanungkalitNo ratings yet

- AGC300 AGC300 Rev0Document11 pagesAGC300 AGC300 Rev0raj_ritu_aNo ratings yet

- Generators and Transformers: Prepared by M.Aruna / EeeDocument11 pagesGenerators and Transformers: Prepared by M.Aruna / Eeegssasi100% (1)

- Physics Paper IIIDocument3 pagesPhysics Paper IIItadepalli patanjaliNo ratings yet

- Electrical Systems DemoDocument45 pagesElectrical Systems Demoronald lazo100% (1)

- GTP Ykp PDFDocument45 pagesGTP Ykp PDFSwarup NayakNo ratings yet

- CH 05 PowerDocument49 pagesCH 05 PowerTriếtCỏNo ratings yet