Professional Documents

Culture Documents

What Is Ohmic Heating

What Is Ohmic Heating

Uploaded by

Ramanujam O SOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Is Ohmic Heating

What Is Ohmic Heating

Uploaded by

Ramanujam O SCopyright:

Available Formats

1. What is ohmic heating?

Ohmic heating is an advanced thermal processing method wherein the food material, which serves as an electrical resistor, is heated by passing electricity through it. Electrical energy is dissipated into heat, which results in rapid and uniform heating. Ohmic heating is also called electrical resistance heating, Joule heating, or electro-heating, and may be used for a variety of applications in the food industry. 2. How is ohmic heating different from conventional thermal processing? During conventional thermal processing, either in cans or aseptic processing systems for particulate foods, significant product quality damage may occur due to slow conduction and convection heat transfer. On the other hand, ohmic heating volumetrically heats the entire mass of the food material, thus the resulting product is of far greater quality than its canned counterpart. It is possible to process large particulate foods (up to 1 inch) that would be difficult to process using conventional heat exchangers. Additionally, ohmic heater cleaning requirements are comparatively less than those of traditional heat exchangers due to reduced product fouling on the food contact surface.

3. What type of products are suitable for ohmic heating? Ohmic heating can be used for heating liquid foods containing large particulates, such as soups, stews, and fruit slices in syrups and sauces, and heat sensitive liquids. The technology is useful for the treatment of proteinaceous foods, which tend to denature and coagulate when thermally processed. For example, liquid egg can be ohmically heated in a fraction of a second without coagulating it. Juices can be treated to inactivate enzymes

without affecting the flavor. Other potential applications of ohmic heating include blanching, thawing, on-line detection of starch gelatinization, fermentation, peeling, dehydration, and extraction. 4. How does ohmic heating inactivate microorganisms? Like thermal processing, ohmic heating inactivates microorganisms by heat. Additional non-thermal electroporation type effects have been reported at low-frequency (5060 Hz), when electrical charges can build up and form pores across microbial cells, however, it is not necessary to claim such effects since heating is the main mechanism. 5. What is the shelf life of an ohmically processed product? The shelf life of ohmically processed foods is comparable to that of canned and sterile, aseptically processed products. 6. Is commercial scale equipment available? Yes. Some major equipment suppliers providing commercial size ohmic heaters for the food industry include Emmepiemme SRL in Piacenza, Italy, and Capenhurst, United Kingdom. An additional major supplier is likely to enter the market in 2006. Information on available capacities of commercial equipment depends on the application, and information may be obtained from the suppliers.

7. Are there any ohmically processed commercial products available on the market? A number of processing plants currently produce sliced, diced, and whole fruit within sauces in various countries, including Italy, Greece, France, Mexico, and Japan. In the

United States, ohmic heating has been used to produce a low-acid particulate product in a can, as well as pasteurized liquid egg. 8. Is ohmic heating environmentally friendly? Yes. This process uses ordinary electricity. No emissions are produced at the point of use. One emerging application of ohmic heating is fruit peeling, which may greatly reduce the use of lye that is common to such operations, and results in environmental benefits. 9. How economical is ohmic heating of foods? An economic analysis conducted at the University of Minnesota in the early 1990s indicated that ohmic heating would be economically viable for premium quality foods. However, costs of ohmic systems have decreased greatly since that time, and the range of products for which ohmic heating is economical has expanded considerably. 10. What regulatory approval is required for commercializing an ohmically processed product? For in-container processing, the requirements are similar to that of traditional thermal processing in the United States. For continuous flow processing with aseptic packaging, the approaches are currently in development in a project funded by the USDA National Integrated Food Safety Initiative. The Food and Drug Administration (FDA) is responsible for evaluating and monitoring the safety of ohmically processed foods, unless the product contains a specified minimum amount of meat and poultry. In such cases, it falls under USDAs purview. 11. Are facilities available for product development before venturing into ohmic heating? An industrial scale ohmic heating pilot plant facility is available at The Ohio State Universitys Department of Food, Agricultural and Biological Engineering. Food processors are invited to take advantage of the expertise of OSU faculty members and facilities to conduct confidential product evaluations for food safety, quality, and shelf life, and to obtain guidance on product development. The resources at OSU can be accessed for a reasonable fee.

You might also like

- Iron in CerealDocument11 pagesIron in CerealNor Amalina IbrahimNo ratings yet

- Usb Powered Colloidal Silver GeneratorDocument14 pagesUsb Powered Colloidal Silver GeneratorVíctor Faucheret100% (1)

- Dark Plasma Theory: Coronas, Spicules and GranulationDocument4 pagesDark Plasma Theory: Coronas, Spicules and GranulationhearthnsoulNo ratings yet

- Application of Cold Plasma Technology in The Food Industry and Its Combination With Other Emerging TechnologiesDocument17 pagesApplication of Cold Plasma Technology in The Food Industry and Its Combination With Other Emerging TechnologiesMAHMOOD SALIH S A L - 16100% (1)

- Review On Recent Applications of Cold Plasma For Food ProductionDocument16 pagesReview On Recent Applications of Cold Plasma For Food Productionshahin100% (1)

- Citric Acid and Kidney StonesDocument2 pagesCitric Acid and Kidney Stonesen.wrong100% (2)

- Ultrasonic Acoustic LevitationDocument38 pagesUltrasonic Acoustic LevitationPS LinnNo ratings yet

- Ralph Juergens' Article - The Electric SunDocument1 pageRalph Juergens' Article - The Electric Sunkrishna2205No ratings yet

- Potassium Deficiency Scam Kills and Maims MillionsDocument7 pagesPotassium Deficiency Scam Kills and Maims MillionsPetar11100% (2)

- Designer BabiesDocument5 pagesDesigner Babiesapi-509365064No ratings yet

- Toxic Response of The Reproductive SystemDocument5 pagesToxic Response of The Reproductive SystemM. JoyceNo ratings yet

- Biodynamic AgricultureDocument3 pagesBiodynamic AgricultureEliane MasonNo ratings yet

- Disinfectant Use in Hospital: Dr. Yogita Mistry GMC, SuratDocument82 pagesDisinfectant Use in Hospital: Dr. Yogita Mistry GMC, SuratChoice OrganoNo ratings yet

- Glyconutrients and MannatechDocument5 pagesGlyconutrients and MannatechJillyStoneyNo ratings yet

- Mineral Mocktail Guide 2022Document17 pagesMineral Mocktail Guide 2022Susana Sánchez Carrillo100% (1)

- Chemistry of HealthDocument20 pagesChemistry of HealthDave BlackNo ratings yet

- Hydrogen JEEDocument77 pagesHydrogen JEERohith Kumar100% (1)

- ARW Hexagon 100610Document52 pagesARW Hexagon 100610Violet Lee100% (1)

- (Cáncer Vs Ácido Cítrico) - Citric Acid Inhibits Fermentation and Kills Cancer in Humans. Mihaela Catalina Stanciu Foundation For LifeDocument210 pages(Cáncer Vs Ácido Cítrico) - Citric Acid Inhibits Fermentation and Kills Cancer in Humans. Mihaela Catalina Stanciu Foundation For Lifepedpix100% (1)

- Kinds of Blood. Differences Between Men and WomenDocument11 pagesKinds of Blood. Differences Between Men and WomenTiagoSantosNo ratings yet

- Goat Under CoconutDocument3 pagesGoat Under Coconutjhoe eliasNo ratings yet

- Garrett BlueDocument11 pagesGarrett BlueAleksa Nataša RančićNo ratings yet

- CHEMALLOY - A New Alloy For The Science StudentDocument2 pagesCHEMALLOY - A New Alloy For The Science StudentPeter Benedikt WeberNo ratings yet

- Colloidal SilverDocument4 pagesColloidal SilverVince MiltonNo ratings yet

- Graphene Paper PDFDocument16 pagesGraphene Paper PDFAlexia Beatriz O S AlmeidaNo ratings yet

- Geyser ReactorDocument25 pagesGeyser Reactorz987456321100% (1)

- Eat Raw Protein Daily: © Kyle Grimshaw-JonesDocument8 pagesEat Raw Protein Daily: © Kyle Grimshaw-JonesAdrian Stan100% (1)

- Mochus The Proto-Philosopher Fos v18n3Document13 pagesMochus The Proto-Philosopher Fos v18n3Bassem KamelNo ratings yet

- Sterilisation-Chemical Methods: Submitted By, C.Gopika Dileep 1 MSC BiotechnologyDocument12 pagesSterilisation-Chemical Methods: Submitted By, C.Gopika Dileep 1 MSC BiotechnologyKarthika Gokulan0% (1)

- Agricultural Extension Education in MPDocument66 pagesAgricultural Extension Education in MPeqbal.sayed@exensys.comNo ratings yet

- Blood Purifier or Blood ElectrificationDocument4 pagesBlood Purifier or Blood ElectrificationJoscelyn Arktos100% (1)

- Use of Potassium Permanganate To Control External InfectionsDocument4 pagesUse of Potassium Permanganate To Control External InfectionsRamy Nambi100% (1)

- Aseous SterilizationDocument12 pagesAseous SterilizationAminu Zainab100% (1)

- The Quintessence of Satanism PDFDocument2 pagesThe Quintessence of Satanism PDFDersuNo ratings yet

- Darcia Borg Fort William First NationDocument8 pagesDarcia Borg Fort William First NationvampirebbqNo ratings yet

- FalgDocument101 pagesFalgshaikh85No ratings yet

- Pulsed Electric Fields For Food Processing TechnologyDocument33 pagesPulsed Electric Fields For Food Processing TechnologyFélix BaezNo ratings yet

- ImmortalityDocument2 pagesImmortalitySSSSSNo ratings yet

- Bicarbonate Increases Tumor PH and Inhibits Spontaneous MetastasesDocument10 pagesBicarbonate Increases Tumor PH and Inhibits Spontaneous MetastasesKATHERINE LUCIA REVOLLAR CASASNo ratings yet

- Protein and Its MythDocument5 pagesProtein and Its MythRaushan BlakeNo ratings yet

- 146 File 50853Document3 pages146 File 50853solmazbaharyNo ratings yet

- Hypochlorous Acid: Harnessing Nature's Germ Killer - Optometry TimesDocument4 pagesHypochlorous Acid: Harnessing Nature's Germ Killer - Optometry Timesrizki yuliani100% (1)

- Acidity: Cure YourselfDocument17 pagesAcidity: Cure Yourselfआदित्य मोदीNo ratings yet

- Us8367120 AseaDocument6 pagesUs8367120 AseapendulaionNo ratings yet

- Metallic NanoparticlesDocument50 pagesMetallic NanoparticlesmireladragomirNo ratings yet

- HEALTHY LIFE EXTENSION - PHYSICAL IMMORTALITY - THE MASS POSSIBILITY by DR JANNI LLOYD - Physical Immortality - The Mass Possibility's BlogDocument20 pagesHEALTHY LIFE EXTENSION - PHYSICAL IMMORTALITY - THE MASS POSSIBILITY by DR JANNI LLOYD - Physical Immortality - The Mass Possibility's BlogGohed BraunNo ratings yet

- Pyramid Materials Notes F19Document7 pagesPyramid Materials Notes F19erehov1No ratings yet

- Food Spoilage and AdditivesDocument14 pagesFood Spoilage and AdditivesChristine Garcia RafaelNo ratings yet

- APPLICATION OF COLD PLASMA IN FOOD INDUSTRY FinalDocument18 pagesAPPLICATION OF COLD PLASMA IN FOOD INDUSTRY Finalprachi mahajanNo ratings yet

- Cause of DiseaseDocument7 pagesCause of Diseaseparacelsus5No ratings yet

- Bio Disc IntroDocument19 pagesBio Disc IntroBrako Jones100% (1)

- Edward LINACRE - Airdrop Irrigation SystemDocument4 pagesEdward LINACRE - Airdrop Irrigation Systemfafsdfdf12100% (1)

- Experimental Comparative Analysis of Clay Pot Refrigeration Using Two Different Designs of PotsDocument6 pagesExperimental Comparative Analysis of Clay Pot Refrigeration Using Two Different Designs of PotsInternational Journal of Latest Research in Engineering and TechnologyNo ratings yet

- Detox Common StepsDocument5 pagesDetox Common StepsfcontacteNo ratings yet

- Bicarbonate Spdium-2260 Paper - FullDocument10 pagesBicarbonate Spdium-2260 Paper - FullDel Valle MauroNo ratings yet

- Bitter Gourd ReportDocument44 pagesBitter Gourd ReportMillenium Ayurveda100% (1)

- CancerDocument7 pagesCancerKailash AcharyaNo ratings yet

- Transport of Oxygen and Carbon DioxideDocument22 pagesTransport of Oxygen and Carbon DioxideAiza Ayaz100% (1)

- Panacea in My Veins: Stem Cell Facts and FictionFrom EverandPanacea in My Veins: Stem Cell Facts and FictionNo ratings yet

- Nuclear Alternative: Redesigning Our Model of the Structure of MatterFrom EverandNuclear Alternative: Redesigning Our Model of the Structure of MatterNo ratings yet

- Fundamentals of Electrical SwitchgearsDocument38 pagesFundamentals of Electrical SwitchgearsRamanujam O SNo ratings yet

- Electrical SafetyDocument43 pagesElectrical SafetyRamanujam O SNo ratings yet

- Automatic Gate ControlDocument9 pagesAutomatic Gate ControlSantosh KumarNo ratings yet

- Basic ElectricityDocument197 pagesBasic ElectricityRamanujam O SNo ratings yet

- Reluktanzmotoren EndDocument16 pagesReluktanzmotoren EndRamanujam O SNo ratings yet

- Anna UniversityDocument1 pageAnna UniversityRamanujam O SNo ratings yet

- Email WrittingDocument2 pagesEmail WrittingSmit VithalaniNo ratings yet

- TNEB ServiceDocument2 pagesTNEB ServicesbpathiNo ratings yet

- Maintenance Presentation1Document47 pagesMaintenance Presentation1prsiva2420034066100% (3)

- Developing Effective Communication Skills - SeemaDocument31 pagesDeveloping Effective Communication Skills - SeemaRamanujam O SNo ratings yet

- Email English 2Document6 pagesEmail English 2Ramanujam O SNo ratings yet

- Email 1Document2 pagesEmail 1Ramanujam O SNo ratings yet

- 12th English Q BankDocument96 pages12th English Q BankJoswa SanthakumarNo ratings yet

- Teamwork 2Document13 pagesTeamwork 2Ramanujam O SNo ratings yet

- Advances in Electronic - Nose Technologies: Authors Name: G.Sujatha, N. Dhivya, K. Ayyadurai and D.ThyagarajanDocument10 pagesAdvances in Electronic - Nose Technologies: Authors Name: G.Sujatha, N. Dhivya, K. Ayyadurai and D.ThyagarajanRamanujam O SNo ratings yet

- Electrical EngineeringDocument896 pagesElectrical Engineeringmetamorp100% (8)

- Planned Maintenance Checklist: Customer Signature/AcknowledgementDocument0 pagesPlanned Maintenance Checklist: Customer Signature/AcknowledgementRamanujam O SNo ratings yet

- Psychosocial Support Activity Sheet No. 2Document2 pagesPsychosocial Support Activity Sheet No. 2Rizza De MesaNo ratings yet

- Month + Teaching Days Unit Total Teaching Periods: Vibgyor High Grade - 2 English Literature Year Plan (AY 2020 - 2021)Document65 pagesMonth + Teaching Days Unit Total Teaching Periods: Vibgyor High Grade - 2 English Literature Year Plan (AY 2020 - 2021)TAPASsenguptaNo ratings yet

- MySQL Cheat Sheet PDFDocument2 pagesMySQL Cheat Sheet PDFEsha ShahNo ratings yet

- Soal Quizziz Buat Sendiri Kelas Xii TTG News ItemDocument6 pagesSoal Quizziz Buat Sendiri Kelas Xii TTG News ItemJorus RukuNo ratings yet

- MTS719# 2u2s2wc-21Document2 pagesMTS719# 2u2s2wc-21glukkerNo ratings yet

- ACDC - Lucina - DatasheetDocument1 pageACDC - Lucina - Datasheetwincad_sgNo ratings yet

- Higher Eng Maths 9th Ed 2021 Solutions ChapterDocument17 pagesHigher Eng Maths 9th Ed 2021 Solutions ChapterAubrey JosephNo ratings yet

- 2SUPMaT2019 - Bacani - Number TheoryDocument109 pages2SUPMaT2019 - Bacani - Number TheoryRomelaBalasotoParamiNo ratings yet

- Thesis PDFDocument120 pagesThesis PDFPrajwal NiraulaNo ratings yet

- 2007-09-29 Every Soldier Is A SensorDocument5 pages2007-09-29 Every Soldier Is A SensorDozerMayneNo ratings yet

- Module 5 in Eed 114: ReviewDocument6 pagesModule 5 in Eed 114: ReviewYvi BenrayNo ratings yet

- Solution of Assignment 5Document5 pagesSolution of Assignment 5Reza Borah100% (1)

- 900FH&1000FH TurbinesDocument12 pages900FH&1000FH TurbinesRyanNo ratings yet

- Tacha's ReusmeDocument2 pagesTacha's ReusmeJames HamptonNo ratings yet

- InfoDocument2 pagesInfofukinbobNo ratings yet

- Dibrugarh AirportDocument30 pagesDibrugarh AirportRafikul RahemanNo ratings yet

- UPS Technical Data Sheet (MS-DD-SAP01-ELE-DS-0015 - Rev2)Document6 pagesUPS Technical Data Sheet (MS-DD-SAP01-ELE-DS-0015 - Rev2)Muhammad YusufNo ratings yet

- Ims555 Grouping Assignment (Ai Deepfakes)Document23 pagesIms555 Grouping Assignment (Ai Deepfakes)NUR A'ISYAH AZIZINo ratings yet

- SK 135 SR 3Document327 pagesSK 135 SR 3Trung Cuong100% (1)

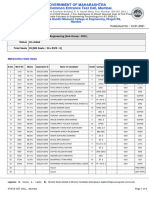

- 2127 - Mahatma Gandhi Missions College of Engineering, Hingoli RD, NandedDocument8 pages2127 - Mahatma Gandhi Missions College of Engineering, Hingoli RD, NandedAjit DeshmukhNo ratings yet

- 4 Quarter Performance Task in Statistics and ProbabilityDocument5 pages4 Quarter Performance Task in Statistics and ProbabilitySHS Panaguiton Emma Marimel HUMSS12-ANo ratings yet

- The Development of Self-Regulation Across Early ChildhoodDocument37 pagesThe Development of Self-Regulation Across Early ChildhoodvickyreyeslucanoNo ratings yet

- Hydraulic Cable Lugs Crimping ToolsDocument6 pagesHydraulic Cable Lugs Crimping ToolsbaolifengNo ratings yet

- 1st Quarter ToolkitDocument6 pages1st Quarter ToolkitDimple BolotaoloNo ratings yet

- ThevoidsummaryDocument6 pagesThevoidsummaryVaibhav Mishra80% (5)

- Corrosion Detection Midterm LessonDocument52 pagesCorrosion Detection Midterm LessonVv ZoidNo ratings yet

- Linear Programming TheoryDocument104 pagesLinear Programming Theorykostas_ntougias5453No ratings yet

- The Relationship Between Dimensions of Love, Personality, and Relationship LengthDocument11 pagesThe Relationship Between Dimensions of Love, Personality, and Relationship LengthjuaromerNo ratings yet

- Data Structures (Sample) Course ReportDocument128 pagesData Structures (Sample) Course Reportsiddardtha666666No ratings yet

- Proces CostingDocument14 pagesProces CostingKenDedesNo ratings yet