Professional Documents

Culture Documents

1 s2.0 S0925400507005539 Main

1 s2.0 S0925400507005539 Main

Uploaded by

Bridget GwenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S0925400507005539 Main

1 s2.0 S0925400507005539 Main

Uploaded by

Bridget GwenCopyright:

Available Formats

Available online at www.sciencedirect.

com

Sensors and Actuators B 129 (2008) 106112

Optical bre based humidity sensor using Co-polyaniline clad

Anu Vijayan a, , Madhavi Fuke a , Ranjit Hawaldar b , Milind Kulkarni b , D. Amalnerkar b , R.C. Aiyer a

a

Center for Sensor Studies, Department of Physics, University of Pune, Pune 411007, India b Center for materials for Electronics Technology, Pashan, Pune 411008, India Received 31 March 2007; received in revised form 1 June 2007; accepted 19 July 2007 Available online 2 August 2007

Abstract A humidity sensor of nanostructure Co dispersed in polyaniline deposited as a clad, having quick response of 8 s (2095%RH) and recovery time of 1 min (9520%RH) on bre optical waveguide, is reported, in the range of 20100%RH. The length and thickness of the clad is optimized for better performance on a commercially procured plastic optical bre whose original cladding is removed. The sensor response is reproducible, repeatable and fully reversible. The clad length is optimized to10 mm with thickness 10.38 m, exhibits the best results. Material characterization is done using SEM, XRD and FTIR. 2007 Elsevier B.V. All rights reserved.

Keywords: Plastic optical bre; Co dispersed in polyaniline; Relative humidity

1. Introduction Optical bre based chemical sensors have attracted increasing interest in recent years owing to their inherent characteristics such as immunity to electrical noise, ease of miniaturization, the possibility of real time monitoring and remote sensing. An additional advantage in comparison with electrical sensors is they do not need more electrical contacts that could be damaged by the analyte. These features make them a powerful tool for environmental and industrial process monitoring. Optical bres have very high sensitivity to external perturbation which makes them a potential candidate for realizing sensing in optical domain [1]. Today the optical sensing technology is used to measure nearly all of the parameters of interest and very large number of chemical species as well. Humidity sensors have gained importance in recent years because of the need to monitor and control environmental relative humidity (RH) in various industrial processes [2] particularly in various chemical processes, such as in food, electronics,

Corresponding author. E-mail addresses: anup@physics.unipune.ernet.in (A. Vijayan), rca@physics.unipune.ernet.in (R.C. Aiyer). 0925-4005/$ see front matter 2007 Elsevier B.V. All rights reserved. doi:10.1016/j.snb.2007.07.113

textile, pharmaceutical industries. Research has been carried out on various trans-domain systems to explore the possibility of utilizing them as sensors. Different electrical and optical humidity sensors for such applications have been reported in literature [35]. The conventional materials used for sensing the humidity are electrolytic metal oxides, alumina thin lms, and ceramics [6]. Porous ceramics or polymer lms are used in commercially available humidity sensors. Planar optical waveguide with screen printed thick lms of semiconducting oxides is reported by Ansari et al. [7] Presently polymers are identied as better candidates for practical applications; since they are compatible to oxides and ceramics and also they can be used at room temperature [8,9] Nanocrystalline materials have also been a subject of intense research in the recent years due to the unusual properties exhibited by them and also new physics generated by these systems. The humidity sensing using nanocomposites have been reported in the literature [10,11]. The synthesis of nanocrystalline nickel oxide by controlled oxidation of Nickel nanoparticles and their humidity sensing properties are discussed by Das et al. [10], whereas Pal et al. [11] have explored the possibilities of using nanocomposites containing silver particles grown within a glass barium titanate composite by the ion exchange followed by reduction technique, for humidity sensing. Humidity monitoring

A. Vijayan et al. / Sensors and Actuators B 129 (2008) 106112

107

sensor with fast response-less than a couple seconds and high sensitivity based on the leaky plastic optical bre structure was fabricated [12]. An evanescent-wave optical bre humidity sensor using CoCl2 doped thin polymer lm coated on the bare bre core is reported by Khijwania et al. [13]. Nano-like magnesium oxide lms were studied as optical bre humidity sensor by Shukla et al. [14]. A highly sensitive optical humidity probe based on reectance measurements has been made using Naon(R)crystal violet (CV) lms. This sensor can be used to calibrate relative humidity in the range of 00.25% with a detection limit of 0.018%RH and exhibits low hysteresis. [15] In comparison with the other sensors, the sensor developed here is for a range of 2095 having good repeatability, reproducibility and fast response time. The transmission properties of nanocomposites lms are reported to change with water adsorption which leads to a change in their refractive index. As the evanescent tail has only a small fraction of power, a longer portion of bre is needed to be coated to have an effective interaction of light with the analyte and hence a detectable change at the output. Bending the bre transfers power from the guided modes to the leaky modes, providing more power to interact with the analyte in the sensing region. This results in high sensitivity with a very small interaction length [16,17]. To the best of our knowledge the nano-polyaniline or its nanocomposites was not found to be reported as humidity sensing materials. The aim of this paper is to realize a plastic optical bre relative humidity sensor with better sensitivity and sufciently large operational range. An evanescent wave bre optic humidity sensor is constructed by depositing Co nanoparticles dispersed in polyaniline over an exposed core region of a multimode bre. The sensing mechanism is based on evanescent eld interaction with the coating of the nanocomposites. As the electromagnetic wave in the form of incident light guided propagates through the sensing region, the optical power in evanescent tail of the propagating mode is absorbed with the change in the environmental parameter, i.e. humidity. This results in a modulated output from the bre, which is used as the criterion for detecting and determining the relative humidity in the surrounding environment. 2. Experimental Spherical Co nanoparticles of average size 3050 nm with polyaniline are synthesized by using chemical synthesis. In a typical synthetic procedure, 50 ml of cobalt nanoparticle solution was diluted with 50 ml of toluene. To this was then added 0.265 ml of aniline, 1.26 g of para-toluene sulfonic acid (PTSA) and 0.63 ammonium persulfate in 2 ml water with 48 ml of methanol. The solution so formed was further used for experimentation. To fabricate the sensor, plastic optical bre is used. The evanescent wave is to be used so the cladding of the plastic optical bre was removed from the central portion of the bre, where the humidity sensitive lm is then coated by dip coating carefully. To conrm the sensing property of the plastic optical bre with 1 mm diameter and a length 17.5 cm, the material was

coated onto the central portion of the optical bre. The length of the clad is optimized to get maximum possible sensitivity. Then for the optimized length of 10 mm, thickness of the lms is varied from 10.38 to 26.03 m. The bre used for sensing was bent to a U shape with a bent radius of 7 mm taking into considerations the penetration depth considerations as reported by Gupta et al. [16] and Khijwania et al. [13]. The plastic optical bre has a polymethylmethacrylate (PMMA) core approximately 980 m thickness, with 20 m thick cladding made of uoride containing carbon polymer. The refractive indices of the core and cladding are 1.492 and 1.417, respectively. The total diameter of the plastic optical bre is 2.2 mm with PVC protecting sheath. The bre end is wet polished with 600-grain sandpaper for predetermined time to maximize the optical power coupling to the plastic optical bre. The ends of the plastic optical bre are connected to a transmitter and receiver. Siemens plastic bre components (PFC) emitters and detectors are used, which are low cost components. SFH 450 emitter diode having a peak emission wavelength of 950 nm, infrared is used as transmitter. A phototransistor SFH350 (responsivity of 0.3 A/ W) is used as a detector. The advantage of the Siemens PFCs is the housing aperture into which a plastic optical bre is introduced without having to remove the cladding, with an additional benet of directly centering the bre onto the transmitter and detector. A +5 V power supply is used to power the transmitter and the detector. The experimental setup is realized as shown in Fig. 1 (a dome of 1.5 l capacity) used for RH measurement, which are adjusted by proper inlet of wet/dry air at room temperature (30 C). The humidity in the chamber is controlled by injecting humid or dry air through a nozzle. The transmitted output light intensity is measured with respect to relative humidity for length and thickness variations. After optimizing the length of cladding the thickness was optimized. The change in the RH% is measured directly, using a precalibrated hygrometer (DIEHLThermotron Hygro). The output voltage of the receiver (detector) as a result of change in humidity is measured using a Rishcom digital multimeter. 3. Structural characterization X-ray diffraction was performed with a Philips X-Ray diffractometer with Cu K as the radiating wavelength. The Fourier

Fig. 1. Experimental setup for measurement of relative humidity.

108

A. Vijayan et al. / Sensors and Actuators B 129 (2008) 106112

Fig. 2. XRD spectra of Co nanocomposites dispersed in polyaniline.

transform infrared (FTIR) spectra of the samples were recorded on a Perkin-Elmer-Spectrum 2000 spectrophotometer operated between 400 and 4000 cm1 in a KBr medium. The powder morphology of the composites in the form of lm was investigated with an analytical scanning electron microscope JOEL JSM 6360A. 4. Results and discussion The XRD pattern (Fig. 2) reveals the partial crystalline nature of the polymer due to the presence of sharp peaks between 2 values 20 and 40 . Sharp peaks are observed at 21.0, 23.8 and 25.0 2values implying the presence of a rigid chain and ordered structure resulting in partial crystallinity. The characteristic peak of Co2 O3 at 2 values of 31.12 , due to (0 0 2) plane of Co2 O3 ; CoO at 2 values of 42.38 , due to (2 0 0) plane of CoO; Co at 2 values of 44.65 , due to (1 1 1) plane and -Co

at 2 values of 47.54 , due to (1 0 1) plane of -Co are seen in the pattern. Cox Oy phases clearly show oxidation of Co on dispersion in polyaniline due to the addition of ammonium persulfate which is a strong oxidizing agent. The SEM micrographs of the lms of various thicknesses are as in Fig. 3. The grains as well as ower like structures are observed. At higher magnication globular like aspect consistent with the instantaneous nucleation of the material is observed. With increasing thickness lms show changes in morphology. For lower thicknesses (10.38, 17.26, and 21.08 m) porosity is seen (Fig. 3ac) whereas for higher thickness the composite shows agglomeration of polymer. Such composites are likely to facilitate adsorption of water vapours because of the pores. Rods and spherical shaped Co is seen in lower thicknesses, later on formed bigger rods and then looked like wires, which changed to platelets. (Fig. 3df) An FTIR spectrum of Co nanocomposites dispersed in polyaniline is as shown in Fig. 4. The peak observed (Fig. 4) at 814.41 cm1 is the characteristic of paradistributed aromatic rings indicating polymer formation. C H in plane and C H out of plane, bending vibrations appear at 1126.8 and 685.34 cm1 , respectively. Aromatic C N stretching indicating appearance of the secondary aromatic amine group is observed at 1303.29 cm1 . Of particular interest are the bands in the vicinity of 1459.19 and 1601.84 cm1 corresponding to the benzoid ring and quinoid ring modes, respectively. The presence of these bands clearly shows that the polymer is composed of insulating and conducting phase of the polymer. Band at 3409.59 cm1 is assigned to N H stretching vibrations. Presence of all these characteristics bands conrms that the polymer is in the conducting ES phase. The metal oxygen stretching frequency of CoO is at 568 cm1 . Here the optical bre is made up of PMMA and hence shows response to humidity, that is negligible with respect to

Fig. 3. Scanning electron micrograph (SEM) of Co nanocomposites dispersed in polyaniline.

A. Vijayan et al. / Sensors and Actuators B 129 (2008) 106112

109

Fig. 5. Variation of length of cladding on the optical bre. Fig. 4. FTIR spectra of Co nanocomposites dispersed in polyaniline. Table 1 Region wise sensitivity for length variation Length (mm) 2 4 6 8 10 11 13 15 Region 1 (mV/%RH) 2.09(8858) 1.94(8881) 1.94(8855) 2.67(8876) 3.406(8880) 0.23(8881) 0.195(8870) 0.05(8870) Region 2 (mV/%RH) 2.09(5728) 2.64(8054) 1.69(5438) 2.79(7544) 2.002(8035) 0.31(8062) 0.195(7055) 0.024(7050) Region 3 (mV/%RH) 0.45(2720) 0.55(5320) 0.93(3720) 0.34(4320) 0.749(3420) 0.41(6120) 0.544(5523) 0.342(5023)

the sensitivity of the coated optical bre with Co and polyaniline nanocomposites and the trend is exactly opposite. Hence for all the experiments, the sensing by the optical bre is neglected and the sensing by the nanocomposites is only taken into consideration. The sensor, as indicated above, is based on the phenomenon of the evanescent wave adsorption where a small portion of the optical power in the guided modes, extended to the cladding region, interacts with the coated sensing lm of Co dispersed in polyaniline nanocomposites. Bending of the bre leads to an outward shift in the peak intensity of the light travelling in bre, this in turn leads to a larger portion of the optical power available in the sensing region to interact with the mediating reagent in the coated lm. The bre has a core refractive index of 1.492 which is higher than the refractive index of the coated lm used; 1.473 for thickness of 26.03 m, and decreases to lower values

Table 2 Region wise sensitivity for different thickness Thickness ( m) 10.38 17.26 21.08 23.57 26.03 Refractive index of lm 1.473 1.45 1.42 1.38 1.35

with the thicknesses as given in Table 1 as measured by Abeles method, resulting in more leaky or radiation eld in the cladding which maintains the total internal reection in the cladding. This connes more and more power in the waveguide. With increase in the humidity the refractive index of the nanocomposites further decreases and continues to decrease further with increase in humidity of the chamber, conning more light in the waveguide. Thus, output power is increased as the humidity is increased as observed in the gure effectively increasing the sensitivity Table 2. Different experiments for length and thickness variation are done. Fig. 5 shows the humidity response for variation in the length of the coated clad. These lengths are varied from 2 to 15 mm. As per these variations the clad with 10 mm length shows maximum sensitivity. The sensitivity decreased with increasing lengths and hence 10 mm was considered as an optimal length .The increase in sensitivity with length of cladding may be due to the availability of large interacting area. This will obviously cause larger amount of hydroxyl ion adsorption by clad enhancing the changes in optical properties resulting in higher sensitivity. The overall sensitivity of the sensor increases up to 10 mm clad length giving maximum connement to the transmitting laser beam and later on decreasing giving low response with increasing length. At higher lengths the cladding material might be absorbing the transmitted light in addition to the obvious losses offered by the bre which decreases the intensity. Using this optimized length further experimentation for thickness variation (10.3826.03 m) is done. As the relative humidity increases, the sensitivity increases for the different

Region 1 (mV/%RH) 3.406(8880) 0.214(8876) 2.783(8868) 1.727(8872) 1.465(8864)

Region 2 (mV/%RH) 2.002(8035) 1.221(7554) 1.225(6738) 1.283(7154) 1.125(6334)

Region 3 (mV/%RH) 0.749(3420) 0.522(5320) 1.231(3720) 0.762(5320) 0.512(3320)

110

A. Vijayan et al. / Sensors and Actuators B 129 (2008) 106112

Fig. 6. Thickness variation of nanocomposite clad on optical bre.

thicknesses as shown in Fig. 6. Thickness of 10.38 m shows a maximum sensitivity of 3.406 mV/%RH for 10 mm length. This plot of thickness of 10.38 m obeys the gas square law. It is obvious that with increasing thickness the content of Co in the lm is correspondingly increasing. This results in the decrease of the refractive index of the lm with increasing thickness, which decreases the output Fig. 7. From the SEM image of lower thicknesses of 10.38, 17.26 and 21.08 m, it is evident that the clad is more porous, hence offers more sites for interaction of water molecules offering maximum sensitivity, whereas for higher thicknesses it has not much voids giving lower sensitivity for humidity. The sensitivity curve shows different slopes, giving three different humidity regions. The sensor shows lower sensitivity of 0.749 mV/%RH for range (2034%RH) whereas the sensitivity of the second region (3580%RH) is 2.002 mV/%RH. The highest sensitivity is shown by the third region (8092%RH) is 3.406 mV/%RH.

The sensing occurs due to the adsorption of water molecules on the surface of the lm. The dissociation of water molecule can be considered as surface reaction leading to the formation of surface oxides. This effectively changes the boundary conditions at cladding-guide interface increasing the beam connement in the guide. Therefore, the output intensity through the cladded guide increases. However, three regions in sensitivity curves indicate different dominant phenomena in the process. At a low humidity (region 1) when adsorption starts on the surface, a layer of hydroxyl groups is formed. The water molecules are chemisorbed through a dissociative mechanism by which two hydroxyls per water molecules are formed. In intermediate RH range, monolayers of water molecules will be adsorbed along sites available on the thickness of the lm. Here light transmitted through the bre gets more conned than in the lower humidity region. At higher RH (region 3) water adsorption by the cladding becomes multilayer adsorption in the pores of the cladding and the water molecules will be penetrating deeper up to the cladding guide interface. The refractive index of the clad further decreases resulting in more connement of light in the bre and hence output transmitted is maximum thus giving highest sensitivity. The Co nanoparticles are attached to the polymer chain by weak Vander Waals forces of attraction. The increase or decrease in output with humidity can also be attributed to the mobility of the Co nanoparticles. Under dry conditions the polymer chains tend to curl up into a compact, coil form restricting the mobility of the Co particles. On the other hand, at high humidity, polymer adsorbs water molecules and gets hydrated uncurling of the compact, coil form into straight chains that are aligned with respect to one another. Physisorption or chemisorption will change two parameters effectively viz. electrical conductivity and refractive index of the material. In this case the refractive index of the material of the clad changes with the relative humidity. The charge transfer or proton ion formation gives an increase in conductivity while the presence of water

Fig. 7. Variation of humidity for increasing and decreasing cycle of a typical sample for 10.38 m, 10 mm length.

Fig. 8. Variation from cycle to cycle of a typical sample for10.38 m thickness and 10 mm length.

A. Vijayan et al. / Sensors and Actuators B 129 (2008) 106112

111

Acknowledgement One of the authors, Anu Vijayan wishes to acknowledge ISRO authorities for providing nancial support. References

[1] H. C. Hesse, East German Patent 106 (1974) 86. [2] B.M. Kulwicki, Humidity sensors, J. Am. Chem. Soc. 74 (4) (1991) 697708. [3] S. Otuski, K. Adachi, T. Taguchi, A novel ber-optic gas sensing conguration using extremely curved optical bers and an attempt for optical humidity detection, Sens. Actuators, B 53 (1998) 9196. [4] A.P. Russell, K.S. Fletcher, Optical sensor for the determination of moisture, Anal. Chim. Acta 170 (1985) 209216. [5] C. Barian, I.R. Matis, F.J. Arregui, M. Lopez-Amo, Optical ber humidity sensor based on a tapered coated with agarose gel, Sens. Actuators, B 69 (2000) 127131. [6] C.-D. Feng, S.-L. Sun, H. Wang, C.U. Segre, J.R. Stetter, Humidity sensing properties of Naon and solgel derived SiO2 /Naon composite thin lms, Sens. Actuators, B 40 (1997) 217222. [7] Z.A. Ansari, R.N. Karekar, R.C. Aiyer, Humidity sensor using planar optical waveguides with claddings of various oxide materials, Thin Solid Films 305 (1997) 330335. [8] Y. Li, M.J. Yang, N. Camaioni, G. Casalbore-Miceli, Humidity sensors based on polymer solid electrolytes: investigation on the capacitive and resistive devices construction, Sens. Actuators, B 77 (2001) 625. [9] C.W. Lee, Y. Kim, S.W. Joo, M.S. Gomg, Resistive humidity sensor using polyelectrolytes based on new-type mutually cross-linkable copolymers, Sens. Actuators, B 88 (2003) 21. [10] D. Das, M. Pal, E. Di Bartolomeo, E. Traversa, D. Chakravorthy, Synthesis of nanocrystalline nickel oxide by controlled oxidation of nickel nanoparticles and their humidity sensing properties, J. Appl. Phys. 88 (2000) 68566860. [11] B.N. Pal, T.K. Kundu, S. Banerjee, D. Chakravorthy, Humidity sensing by nanocomposites of silver in silicate glass ceramics, J. Appl. Phys. 93 (2003) 42014206. [12] Shinzo Muto, Osamu Suzuki, Takashi Amano, Masayuki Morisawa, A plastic optical bre sensor for real-time humidity monitoring, Meas. Sci. Technol. 14 (2003) 746750. [13] S.K. Khijwania, L.S. Kirthi, P. Jagdish, An evanescent-wave optical bre relative humidity sensor with enhanced sensitivity, Sens. Actuators, B 104 (2005) 217222. [14] S.K. Shukla, G.K. Paraskar, A.P. Mishra, Puneet Mishra, B.C. Yadav, R.K. Shukla, L.M. Bali, G.C. Dubey, Nano-like magnesium oxide lms and its signicance in optical bre humidity sensor, Sens. Actuators, B 98 (2004) 511. [15] H. Dacres, R. Narayanaswamy, Highly sensitive optical humidity probe, Talanta 69 (3) (2006) 631636. [16] B.D. Gupta, H. Dodeja, A.K. Tomar, Fiber optic evanescent absorption sensor based on U-shaped probe, Opt. Quantum Electron. 28 (1996) 16291639. [17] S.K. Khijwania, B.D. Gupta, Fiber optic evanescent eld sensor: effect of ber parameters and geometry of the probe, Opt. Quantum Electron. 31 (1999) 625636. [18] Narsimha Parvatikar, Shilpa Jain, C.M. Kanamadi, B.K. Chougule, S.V. Bhoraskar, M.V.N. Ambika Prasad, humidity sensing and electrical properties of polyaniline/cobalt oxide composite, J. Appl. Polym. Sci. 103 (2007) 653658.

Fig. 9. RH response of different samples for 10.38 m thickness and 10 mm length.

molecules in the lm contributes towards the change in refractive index. The measurement of either parameter will give the response to the ambient in which the material is present [18]. Hysteresis, dened as the maximum difference in the two outputs (increasing and decreasing cycle) at the same RH level is observed to be nearly 4% for all of the thicknesses. The hysteresis at lower humidity is a result of slow desorption of the water from the pores of the capillary. At higher humidity, the capillary condensation occurs and forms a meniscus over the capillaries of the lm, which attributes to hysteresis and nonlinearity in the response. The repeatability and reproducibility of the optical humidity sensor using Co polyaniline nanocomposites was found to be very encouraging for all the thicknesses and results for 10.38 m thickness is shown in Figs. 8 and 9, respectively. About 3% uncertainties from cycle to cycle and uncertainty of about 4% from sample to sample is observed Figs. 8 and 9 indicate better repeatability and reproducibility. The sensor shows quick response of 8 s (2095%RH), recovery time of 1 min (9520%RH). In this case the response is quite fast and recovery is slow. This sensor is presently expected to be used for air ambient (i.e. normal atmosphere gases and about 30 C (5 C)). Some experiments for gases like ammonia, CO, CO2 and H2 were performed but the sensor showed no much response to these gases. 5. Conclusions Co nanostructure dispersed in polyaniline is successfully used as a humidity sensitive clad with optimized length of 10 mm and thickness of 10.38 m in the broad range of 2095% of RH with ease of fabrication with low cost having fast response and three sensitivity segments. The sensor reveals response time of 8 s (2095%RH), recovery time of 1 min (9540%RH) which is very fast.

Biographies

Anu Vijayan received MPhil in physics in Study of solid propellant and study of deposition of Al2 O3 under various humidity and temperature conditions, from Pune University in 2005, and is pursuing her PhD in the area of physical

112

A. Vijayan et al. / Sensors and Actuators B 129 (2008) 106112 based sensors, thin lm transistors, nanocomposites and polymers for electronics applications. Dr. Kulkarni has published about 25 research papers in international journals of high repute. Dr.Dinesh Amalnerkar obtained his PhD degree with specialization in physical chemistry from National Chemical Laboratory (NCL), Pune, India, in 1982. Currently, he is the Director of C-MET, Pune. He has published around 80 papers in peer-reviewed international journals, won 7 awards for oral/poster presentations in various national/international symposia. There are 13 Indian patents & 2 technology transfers to his credit. He has contributed a chapter in a book entitled Thick Film Sensors published by Elsevier. Recently, he has worked as a Brain-Pool Visiting Scientist at Korea Research Institute of Chemical Technology, Daejon, Korea. Prof. R.C. Aiyer graduated from the Pune University with BSc in physics, and an MSc in electronics and received her PhD in physics from Pune University in 1979, and is currently working as a professor of physics university of Pune, India. Her research interests are sensors, microwaves, laser applications, resonators and non-linear optical properties of quantum dots.

and chemical sensors. Main area of interest is optical waveguide based humidity and gas sensing. Madhavi Fuke obtained her MSc degree in physics from Amravati University in 2005 and is pursuing her MPhil in the area of optical sensors, basically for polymer based sensors for humidity. Ranjit Hawaldar obtained his BSc and MSc degrees in chemistry from Pune University in 2000 and 2002, respectively. Now he is a PhD student in materials science with the Department of Physics, University of Pune and a project staff at Centre for Materials for Electronics Technology, C-MET, Pune. His research interests focus on synthesis of capped and uncapped nanoparticles from the standpoint of E3 (electronics, energy & environment) related applications. Dr. Milind V. Kulkarni obtained his MSc degree in polymer chemistry from Shivaji University, Kolhapur in 1996, with rst rank. He received his PhD degree in 2002 from University of Pune, Pune, India, by working on Synthesis, Characterization and Application of Conducting Polyanilines as Chemical Sensors. Presently he is working as Scientist-C in Centre for Materials for Electronics Technology (C-MET), Pune. His main elds of current scientic interest are synthesis and characterization of conducting/electroactive polymers, polymer

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Kitty: The Little White Kitten Crochet PatternDocument10 pagesKitty: The Little White Kitten Crochet Patternd-fbuser-29715938996% (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Self-Induced Transparency Bragg Solitons in A Nonlinear Photonic Bandgap StructureDocument6 pagesSelf-Induced Transparency Bragg Solitons in A Nonlinear Photonic Bandgap StructureBridget GwenNo ratings yet

- Physical Model of Lateral Pin Photodiode Gated by A Transparent Electrode Fabricated On Soi FilmDocument6 pagesPhysical Model of Lateral Pin Photodiode Gated by A Transparent Electrode Fabricated On Soi FilmBridget GwenNo ratings yet

- Bragg-Angle Diffraction in Slant Gratings Fabricated by Single-Beam Interference LithographyDocument4 pagesBragg-Angle Diffraction in Slant Gratings Fabricated by Single-Beam Interference LithographyBridget GwenNo ratings yet

- Opj20120100006 23668886Document6 pagesOpj20120100006 23668886Bridget GwenNo ratings yet

- Investigation of The Optical Properties of CDBR: Hamdollah Salehi, Nastaran AsarehDocument4 pagesInvestigation of The Optical Properties of CDBR: Hamdollah Salehi, Nastaran AsarehBridget GwenNo ratings yet

- Crystal Lattices: 2.1 The LatticeDocument10 pagesCrystal Lattices: 2.1 The LatticeBridget GwenNo ratings yet

- 82sengupta DDocument4 pages82sengupta DBridget GwenNo ratings yet

- SPE-177971-MS - Processing Formation Test Data To Reduce The Risk Inherent in Capturing Representative Samples in Zones With Highly Varying PermeabilitiesDocument13 pagesSPE-177971-MS - Processing Formation Test Data To Reduce The Risk Inherent in Capturing Representative Samples in Zones With Highly Varying PermeabilitiesSamanta MirandaNo ratings yet

- Velocity-Outdoor Catalog 2019Document148 pagesVelocity-Outdoor Catalog 2019robertoelripNo ratings yet

- INFO 4650 Prototype - Course OutlineDocument7 pagesINFO 4650 Prototype - Course OutlineMax PerronNo ratings yet

- Applying Theorems On Triangle Inequalities (Exterior Angle Inequality Theorem)Document3 pagesApplying Theorems On Triangle Inequalities (Exterior Angle Inequality Theorem)leonardoalbor05No ratings yet

- MBA Syllabus 2021 NewDocument245 pagesMBA Syllabus 2021 Newarchana97anilNo ratings yet

- Botanical Inks Plant-to-Print DyesDocument276 pagesBotanical Inks Plant-to-Print DyesNoémi Gyimóthy100% (3)

- TMV Trading PricelistDocument8 pagesTMV Trading Pricelistronald s. rodrigoNo ratings yet

- Needs AnalysisDocument11 pagesNeeds AnalysisPrincess Francisco100% (1)

- RUBRICS For ACTIVITY MIL - Camera ShotsDocument2 pagesRUBRICS For ACTIVITY MIL - Camera ShotsJaeneth SimondoNo ratings yet

- Saep 1160Document13 pagesSaep 1160Durga Jagan Puppala100% (1)

- Cven 444: Structural Concrete Design: Class ProjectDocument12 pagesCven 444: Structural Concrete Design: Class Projectmasadi1991No ratings yet

- Sana Younas UpdatedDocument4 pagesSana Younas Updatedsana qamarNo ratings yet

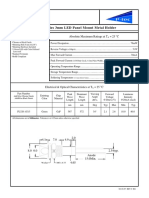

- PL320 Series 3mm LED Panel Mount Metal Holder: Features Absolute Maximum Ratings at T 25 °CDocument1 pagePL320 Series 3mm LED Panel Mount Metal Holder: Features Absolute Maximum Ratings at T 25 °CJajang JajaNo ratings yet

- The Significance of Yoga TantraDocument358 pagesThe Significance of Yoga TantraAnurag Chand100% (3)

- Law of Torts: H.P National Law University, ShimlaDocument11 pagesLaw of Torts: H.P National Law University, Shimlakunal mehtoNo ratings yet

- Drum Dryers: Wan Ramli Wan DaudDocument15 pagesDrum Dryers: Wan Ramli Wan DaudYanuarRamadhanNo ratings yet

- Holocaust Essay Thesis StatementDocument6 pagesHolocaust Essay Thesis Statementmmwsmltgg100% (2)

- COLREG2014Document3 pagesCOLREG2014jean.bitereNo ratings yet

- Stokan 7 - 13 SeptemberDocument25 pagesStokan 7 - 13 SeptemberNovianti Sri WahyuniNo ratings yet

- Prayer For The Elderly and GrandparentsDocument2 pagesPrayer For The Elderly and GrandparentsRomain Garry Evangelista LazaroNo ratings yet

- Laptop Price List-Afresh笔记本Document6 pagesLaptop Price List-Afresh笔记本Miriam BarahonaNo ratings yet

- Determination of Molecular Weight Through Boiling Point ElevationDocument1 pageDetermination of Molecular Weight Through Boiling Point ElevationremNo ratings yet

- DVT Case StudyDocument3 pagesDVT Case StudyCrystal B Costa78No ratings yet

- KP Universities Act 2016Document37 pagesKP Universities Act 2016Noor MalikNo ratings yet

- Renewable Energy Romania Report and Opportunities in RomaniaDocument10 pagesRenewable Energy Romania Report and Opportunities in RomaniaAlly CumvreaueuNo ratings yet

- Sustamid PA6GOLDocument1 pageSustamid PA6GOLPatrick BaridonNo ratings yet

- 25 191 1 PB PDFDocument11 pages25 191 1 PB PDFRaihatil UmmiNo ratings yet

- Java Lab (Mca) SyllabusDocument2 pagesJava Lab (Mca) SyllabusAMAN PANDEY 22SCSE2030634No ratings yet

- Stationary Compressors: Principal Data: LE 2-20/ 10 Bar/ 50 HZDocument5 pagesStationary Compressors: Principal Data: LE 2-20/ 10 Bar/ 50 HZAljamali AlhofashiNo ratings yet