Professional Documents

Culture Documents

Machine / Plant Checklist Technology Studies: Term 1

Machine / Plant Checklist Technology Studies: Term 1

Uploaded by

gaanneshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machine / Plant Checklist Technology Studies: Term 1

Machine / Plant Checklist Technology Studies: Term 1

Uploaded by

gaanneshCopyright:

Available Formats

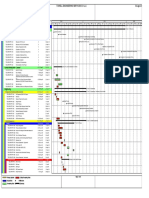

MACHINE / PLANT CHECKLIST

Machine Location INJECTION MOULDER Blank (Highlight & insert Room)

TECHNOLOGY STUDIES

School Name

Blank (Highlight this cell)

Blank (Highlight this cell and insert machine name) Person Responsible Blank (Highlight this cell & insert name)

WEEK WEEK WEEK WEEK WEEK WEEK WEEK WEEK WEEK

Barc Year Blank

WEEK WEEK

Term 1

End of week date

10

11

DAILY In addition to programmed regular maintenance teachers are expected to conduct Routine Surveillance of each machine before student use

Visual check of mains Electrical Switches, Wiring and/or Conduit (Cracks, broken controls etc.) Arrange for immediate repair of any faults If the unit operates from a 240V power outlet it must be RCD protected. Any portable RCD must have current compliance tag attached Visually check that the thermostat indicator light is operating Verify all Guards are secure and operate correctly Ensure workspaces and walk-ways are clear and unobstructed and that no slip-hazards are present Confirm availability and condition of Personal Protective Equipment Notes Notes Notes Notes Notes Notes Notes Notes Notes Notes Notes

WEEKLY CHECKS

Conduct close inspection for damage to Switch Gear Test operation of Switch Gear (Proper function of switch controls) Check the security of the hopper ensuring that the lid is attached (if fitted) and remove any build of foreign material.. Check that the table mechanism (rack and pinion) operates smoothly Lubricate lightly according to manufacturers specification

Tick each cell as WEEKLY CHECKS are made

Use a letter N to indicate if the MACHINE is NOT USED during that week

WEEKLY TASKS sign off

/var/www/apps/conversion/tmp/scratch_1/133883788.doc

MACHINE / PLANT CHECKLIST

Machine Location INJECTION MOULDER Blank (Highlight & insert Room)

TECHNOLOGY STUDIES

School Name

Blank (Highlight this cell)

Blank (Highlight this cell and insert machine name) Person Responsible Blank (Highlight this cell & insert name)

WEEK WEEK WEEK WEEK WEEK WEEK WEEK WEEK WEEK

Barc Year Blank

WEEK WEEK

Term 2

End of week date

10

11

DAILY In addition to programmed regular maintenance teachers are expected to conduct Routine Surveillance of each machine before student use

Visual check of mains Electrical Switches, Wiring and/or Conduit (Cracks, broken controls etc.) Arrange for immediate repair of any faults If the unit operates from a 240V power outlet it must be RCD protected. Any portable RCD must have current compliance tag attached Visually check that the thermostat indicator light is operating Verify all Guards are secure and operate correctly Ensure workspaces and walk-ways are clear and unobstructed and that no slip-hazards are present Confirm availability and condition of Personal Protective Equipment Notes Notes Notes Notes Notes Notes Notes Notes Notes Notes Notes

WEEKLY CHECKS

Conduct close inspection for damage to Switch Gear Test operation of Switch Gear (Proper function of switch controls) Check the security of the hopper ensuring that the lid is attached (if fitted) and remove any build of foreign material.. Check that the table mechanism (rack and pinion) operates smoothly Lubricate lightly according to manufacturers specification

Tick each cell as WEEKLY CHECKS are made

Use a letter N to indicate if the MACHINE is NOT USED during that week

WEEKLY TASKS sign off

/var/www/apps/conversion/tmp/scratch_1/133883788.doc

MACHINE / PLANT CHECKLIST

Machine Location INJECTION MOULDER Blank (Highlight & insert Room)

TECHNOLOGY STUDIES

School Name

Blank (Highlight this cell)

Blank (Highlight this cell and insert machine name) Person Responsible Blank (Highlight this cell & insert name)

WEEK WEEK WEEK WEEK WEEK WEEK WEEK WEEK WEEK

Barc Year Blank

WEEK WEEK

Term 3

End of week date

10

11

DAILY In addition to programmed regular maintenance teachers are expected to conduct Routine Surveillance of each machine before student use

Visual check of mains Electrical Switches, Wiring and/or Conduit (Cracks, broken controls etc.) Arrange for immediate repair of any faults If the unit operates from a 240V power outlet it must be RCD protected. Any portable RCD must have current compliance tag attached Visually check that the thermostat indicator light is operating Verify all Guards are secure and operate correctly Ensure workspaces and walk-ways are clear and unobstructed and that no slip-hazards are present Confirm availability and condition of Personal Protective Equipment Notes Notes Notes Notes Notes Notes Notes Notes Notes Notes Notes

WEEKLY CHECKS

Conduct close inspection for damage to Switch Gear Test operation of Switch Gear (Proper function of switch controls) Check the security of the hopper ensuring that the lid is attached (if fitted) and remove any build of foreign material.. Check that the table mechanism (rack and pinion) operates smoothly Lubricate lightly according to manufacturers specification

Tick each cell as WEEKLY CHECKS are made

Use a letter N to indicate if the MACHINE is NOT USED during that week

WEEKLY TASKS sign off

/var/www/apps/conversion/tmp/scratch_1/133883788.doc

MACHINE / PLANT CHECKLIST

Machine Location INJECTION MOULDER Blank (Highlight & insert Room)

TECHNOLOGY STUDIES

School Name

Blank (Highlight this cell)

Blank (Highlight this cell and insert machine name) Person Responsible Blank (Highlight this cell & insert name) Year Blank

Barc

Term 4

End of week date

WEEK

WEEK

WEEK

WEEK

WEEK

WEEK

WEEK

WEEK

WEEK

WEEK

WEEK

10

11

DAILY In addition to programmed regular maintenance teachers are expected to conduct Routine Surveillance of each machine before student use

Visual check of mains Electrical Switches, Wiring and/or Conduit (Cracks, broken controls etc.) Arrange for immediate repair of any faults If the unit operates from a 240V power outlet it must be RCD protected. Any portable RCD must have current compliance tag attached Visually check that the thermostat indicator light is operating Verify all Guards are secure and operate correctly Ensure workspaces and walk-ways are clear and unobstructed and that no slip-hazards are present Confirm availability and condition of Personal Protective Equipment Notes Notes Notes Notes Notes Notes Notes Notes Notes Notes Notes

WEEKLY CHECKS

Conduct close inspection for damage to Switch Gear Test operation of Switch Gear (Proper function of switch controls) Check the security of the hopper ensuring that the lid is attached (if fitted) and remove any build of foreign material.. Check that the table mechanism (rack and pinion) operates smoothly Lubricate lightly according to manufacturers specification

Tick each cell as WEEKLY CHECKS are made

Use a letter N to indicate if the MACHINE is NOT USED during that week

WEEKLY TASKS sign off

/var/www/apps/conversion/tmp/scratch_1/133883788.doc

MACHINE / PLANT CHECKLIST

Machine Location INJECTION MOULDER Blank (Highlight & insert Room)

Date Sign Off at end of Check the availability of spare parts Lubricate all points in accordance with the manufacturer's specification Check operation of the thermostat. Protect all bare metal surfaces before Term Shutdown (CRC, WD40, RP7 of similar)

TECHNOLOGY STUDIES

School Name

Blank (Highlight this cell)

Blank (Highlight this cell and insert machine name) Person Responsible Blank (Highlight this cell & insert name)

/ T1 / T2 / T3 / T4

Barc Year Blank

Date

END OF TERM CHECKS

END OF SEMESTER CHECKS

/

Sem 1

/

Sem 2

Sign Off at end of Clear away all dust and waste from inside and around housings, cabinets etc Check security of all Fixed Guards Check the injection control lever (rack and pinion) if fitted for smooth operation repair or replace if damaged.. Check the security of Machine Mountings to the floor, wall or base block

ANNUAL CHECKS

Check condition of 50mm line markings defining Operator Zones and Access Walkways Review Safety Operating Procedure and update if necessary Check that the electrical power cables have been RCD tested and tagged. (If not hard wired)

/var/www/apps/conversion/tmp/scratch_1/133883788.doc

MACHINE / PLANT CHECKLIST

Machine Location INJECTION MOULDER Blank (Highlight & insert Room)

TECHNOLOGY STUDIES

School Name

Blank (Highlight this cell)

Blank (Highlight this cell and insert machine name) Person Responsible Blank (Highlight this cell & insert name) Year Blank

Barc

MAINTENANCE RECORD MACHINE / EQUIPMENT

Date Regular servicing as per Maintenance Checklist / Major or Minor repairs Maintenance performed by Company / Business / Individual Time Taken Cost Tag-out (If Required) Tag Removed & Checked by

OHS&W Regulations 1995 Record keeping 3.2.44 Section (b) and (c): (b) keep those records for at least five years or, if an approved code of practice specifies a different period, for that period; and (c) except where the plant is being sold for scrap or spare parts for other plant - ensure that those records are transferred to any person who purchases or otherwise acquires the plant (other than on hire or lease) from the owner.

/var/www/apps/conversion/tmp/scratch_1/133883788.doc

You might also like

- Loop Check PresentationDocument39 pagesLoop Check Presentationsaqib javaid100% (6)

- Illustrated Parts Catalog Mooney M20RDocument495 pagesIllustrated Parts Catalog Mooney M20RBruno BrazNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- D Type Manual Eng v20Document87 pagesD Type Manual Eng v20ammelino67% (3)

- 21 CFR Part 11 Complete Guide To International Computer Validation Compliance PDFDocument287 pages21 CFR Part 11 Complete Guide To International Computer Validation Compliance PDFZigma Delta100% (2)

- Melfa Basic VDocument516 pagesMelfa Basic VAnderson Gomez Castro67% (3)

- Electrician Practical Skills Assessment Candidate GuideDocument8 pagesElectrician Practical Skills Assessment Candidate GuideSaravanan Rasaya100% (1)

- Haer Hazardous Area Equipment RegisterDocument3 pagesHaer Hazardous Area Equipment Registerselvan110663No ratings yet

- 004 Annexure D Job Safety SAnalysis JSADocument3 pages004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- API 580 Questions ModDocument18 pagesAPI 580 Questions ModDeepak100% (1)

- Machine / Plant Checklist Technology Studies: Term 1Document6 pagesMachine / Plant Checklist Technology Studies: Term 1spkumarthNo ratings yet

- Job Plan: Lead Craft Condition For Work Crafts Department Craft QTYDocument3 pagesJob Plan: Lead Craft Condition For Work Crafts Department Craft QTYMohsin YasinNo ratings yet

- SLPG - HT Motor-4yDocument4 pagesSLPG - HT Motor-4yAshraf MohammedNo ratings yet

- Thermographic Scanning of Electrical Equipment Kindly Put A Mark in The Box If This Is Included andDocument3 pagesThermographic Scanning of Electrical Equipment Kindly Put A Mark in The Box If This Is Included andCollen Noel MabasaNo ratings yet

- Planned Preventive Maintenance Task Sheet: PPM No PPM Equipment Electric Plate Asset Code Frequency YearlyDocument1 pagePlanned Preventive Maintenance Task Sheet: PPM No PPM Equipment Electric Plate Asset Code Frequency YearlyMdrahaman MithuNo ratings yet

- SLPG - DC Ups-3mDocument2 pagesSLPG - DC Ups-3mAshraf MohammedNo ratings yet

- 4.k Preventive Maintenance - MV SWGDocument4 pages4.k Preventive Maintenance - MV SWGFreijNo ratings yet

- Planned Preventive Maintenance Task Sheet: PPM No PPM Equipment Dish Washer Frequency QuarterlyDocument1 pagePlanned Preventive Maintenance Task Sheet: PPM No PPM Equipment Dish Washer Frequency QuarterlyMdrahaman Mithu100% (2)

- Sop AntennaDocument27 pagesSop AntennaAltezza AtehNo ratings yet

- Ground, Fault, Circuit Interrupters (GFCI)Document46 pagesGround, Fault, Circuit Interrupters (GFCI)Abdul Hameed OmarNo ratings yet

- 1Y Low Voltage Board MaintenanceDocument2 pages1Y Low Voltage Board MaintenanceOGBONNAYA MARTINSNo ratings yet

- Commn. Check ListDocument8 pagesCommn. Check ListsbpathiNo ratings yet

- Electrical Preventive Maintenance of Air Circuit BreakersDocument4 pagesElectrical Preventive Maintenance of Air Circuit BreakersRobert Galarza100% (1)

- Method Statement For The Installation of TransformerDocument11 pagesMethod Statement For The Installation of TransformerShaikh Ahamed100% (2)

- Visual and Technical Checking of Instrumentation and Control SystemDocument13 pagesVisual and Technical Checking of Instrumentation and Control SystemzhangyiliNo ratings yet

- Lock Out Tag OutDocument47 pagesLock Out Tag OutAldrien Cabinte100% (1)

- Method Statement For Installation-Mv MCC and MotorsDocument3 pagesMethod Statement For Installation-Mv MCC and MotorsAldrige Tatenda VengesaiNo ratings yet

- Work Instruction Electrical Continuity and Insulation Resistance TestDocument2 pagesWork Instruction Electrical Continuity and Insulation Resistance TestDushanthaNo ratings yet

- Test Befor Touch ProcedireDocument1 pageTest Befor Touch ProcedireMrutyunjay Dilip PatilNo ratings yet

- Comprehensive Electrical System Maintenance ChecklistsDocument12 pagesComprehensive Electrical System Maintenance ChecklistsFarrukh Nadeem100% (1)

- Testing and Commissioning of Fire Alarm SystemDocument10 pagesTesting and Commissioning of Fire Alarm SystemRobin Oidem CaniedoNo ratings yet

- Electrical CommissioningDocument19 pagesElectrical CommissioningLuis EnriqueNo ratings yet

- Best Editable Construction QHSE Documentation PortalDocument4 pagesBest Editable Construction QHSE Documentation PortalVishnuraj RNo ratings yet

- 1 1 9 E T 9 7 E N: Operator For Overhead and Sectional DoorsDocument26 pages1 1 9 E T 9 7 E N: Operator For Overhead and Sectional DoorsDavidNo ratings yet

- Parts of The Analog MultitesterDocument4 pagesParts of The Analog MultitesterDestiny canacanNo ratings yet

- SLPG - Emergency Light Fixture-1yDocument2 pagesSLPG - Emergency Light Fixture-1yAshraf MohammedNo ratings yet

- Industrial Process Control Lab: Student's Lab ReportDocument5 pagesIndustrial Process Control Lab: Student's Lab ReportNoumanShabbirNo ratings yet

- Lockout Tagout TrainingDocument33 pagesLockout Tagout Trainingbalamurugan sNo ratings yet

- Commissioning High Voltage EquipmentDocument13 pagesCommissioning High Voltage EquipmentJesus RodriguezNo ratings yet

- Image Sp100Document99 pagesImage Sp100Almacen SertecNo ratings yet

- Aislamiento de TransformadoresDocument6 pagesAislamiento de TransformadoresDenisse GarciaNo ratings yet

- Elite Precommissioning Procedures and Formats For SS Bay EquipmentDocument92 pagesElite Precommissioning Procedures and Formats For SS Bay EquipmentSurya Mvs100% (1)

- Safe Work Method Statement For Testing & Commissioning of DX Split UnitsDocument5 pagesSafe Work Method Statement For Testing & Commissioning of DX Split Unitsvin ssNo ratings yet

- Crawler Cranes: Primary HazardsDocument5 pagesCrawler Cranes: Primary HazardsChorida Dita RahmaniaNo ratings yet

- Commissioning: Commissioning High Voltage EquipmentDocument14 pagesCommissioning: Commissioning High Voltage Equipment2091979No ratings yet

- PPM ElectricDocument10 pagesPPM ElectricAbdullahSharifNo ratings yet

- KewtechKT75 ManualDocument31 pagesKewtechKT75 ManualtiongchungkongNo ratings yet

- PTW LOTO-TrainingDocument29 pagesPTW LOTO-TrainingDanish AliNo ratings yet

- Recap: Ppe: Uettdrvc25Document11 pagesRecap: Ppe: Uettdrvc25Trained UpNo ratings yet

- T&C of Fire Supression SystemDocument5 pagesT&C of Fire Supression Systemamg007100% (1)

- LOCKOUTDocument33 pagesLOCKOUTLINTON KENNY RAMIREZ LARROSANo ratings yet

- Inverter Check Kit DimDocument10 pagesInverter Check Kit DimdanielarteagaNo ratings yet

- Maintenance of Switchboard Safety SystemsDocument2 pagesMaintenance of Switchboard Safety SystemsNarine100% (1)

- Inverter-Check-Kit Dim PDFDocument10 pagesInverter-Check-Kit Dim PDFJean PaulNo ratings yet

- APFC O&M ManualDocument54 pagesAPFC O&M ManualTarun Godiyal100% (2)

- 06-14586 Drema IOM CalorifiersDocument65 pages06-14586 Drema IOM CalorifiersDavid CurkanNo ratings yet

- LAVT & NGR Cubicles Pre & Commissioning Activities Including Tools RequiredDocument2 pagesLAVT & NGR Cubicles Pre & Commissioning Activities Including Tools Requiredrhoney0120% (1)

- PSV TestingDocument26 pagesPSV Testingmanoj thakkar100% (1)

- 28 The Facility Files 3 12Document1 page28 The Facility Files 3 12sajuhereNo ratings yet

- Msra - 999Document2 pagesMsra - 999Mahmoud IdrisNo ratings yet

- Testing & Commissioning of CCUDocument2 pagesTesting & Commissioning of CCUamg007100% (1)

- MGT 214 - Module 2Document25 pagesMGT 214 - Module 2Muhammad FaisalNo ratings yet

- Owners Operators Guide 737ngDocument21 pagesOwners Operators Guide 737ngJemoederiseenhoer100% (3)

- The University of The West Indies Open Campus: MGMT 2026 - Problem Sheet AssignmentDocument4 pagesThe University of The West Indies Open Campus: MGMT 2026 - Problem Sheet AssignmentslayerdaveNo ratings yet

- EN ISO 13857 (2008) (E) CodifiedDocument5 pagesEN ISO 13857 (2008) (E) CodifiedAlcivone Colet0% (1)

- Maintenance StrategyDocument19 pagesMaintenance StrategyKumar Ganesh67% (3)

- GRCADocument14 pagesGRCAjuan gaston estoupNo ratings yet

- Lincoln Precision Tig275Document6 pagesLincoln Precision Tig275Sayed Abo ElkhairNo ratings yet

- 4299-00-69-00-3001 - 2 (Code 10) Project Quality PlanDocument84 pages4299-00-69-00-3001 - 2 (Code 10) Project Quality PlanvisakanNo ratings yet

- Epanet Analysis of Unilag Water Distribution Network-LibreDocument16 pagesEpanet Analysis of Unilag Water Distribution Network-Libreamhosny64No ratings yet

- Internship Report On Servis Industry LimitedDocument60 pagesInternship Report On Servis Industry LimitedFarhan AliNo ratings yet

- API Standard ValveDocument30 pagesAPI Standard ValveSreenivasulu TalariNo ratings yet

- Sourcing - RFIDocument20 pagesSourcing - RFIMohamed Hussein100% (1)

- Tcs Eis Case Study BPCLDocument4 pagesTcs Eis Case Study BPCLsumitkr_20181No ratings yet

- Just in Time and Lean OperationDocument25 pagesJust in Time and Lean Operation버니 모지코No ratings yet

- Suffolk Times Classifieds and Service Directory: July 27, 2017Document14 pagesSuffolk Times Classifieds and Service Directory: July 27, 2017TimesreviewNo ratings yet

- Computer Based Information System AuditDocument4 pagesComputer Based Information System AuditAdin IhtiNo ratings yet

- Owner & Client Service AgreementsDocument17 pagesOwner & Client Service AgreementsButac ArchitectsNo ratings yet

- Overview VES Visual Enterprise SolDocument10 pagesOverview VES Visual Enterprise SolmspranavNo ratings yet

- Introduction To Structural Health Monitoring: January 2006Document26 pagesIntroduction To Structural Health Monitoring: January 2006shahriar satil martinNo ratings yet

- Cicol NT SlurryDocument3 pagesCicol NT SlurryTori SmallNo ratings yet

- Stainless Steel Surface FinishesDocument5 pagesStainless Steel Surface FinishesOlgalycos100% (1)

- Catalogo Sanz Mayo 2014Document52 pagesCatalogo Sanz Mayo 2014deisy ortega100% (1)

- EPCC For Multi Purpose Tank Project (Refloat)Document8 pagesEPCC For Multi Purpose Tank Project (Refloat)Benasher IbrahimNo ratings yet

- IT Term PaperDocument26 pagesIT Term PaperSaheb Jeet SinghNo ratings yet

- What Are SAP End User ManualDocument2 pagesWhat Are SAP End User ManualshravaninathreddyNo ratings yet

- Fastrack FM 94.3 The Station For The Move On GenerationDocument7 pagesFastrack FM 94.3 The Station For The Move On GenerationtbongirwarNo ratings yet

- IDT Legacy WorkflowsDocument32 pagesIDT Legacy WorkflowsaliNo ratings yet