Professional Documents

Culture Documents

Control Valve Packing: Number of Packing Rings

Control Valve Packing: Number of Packing Rings

Uploaded by

partho143Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control Valve Packing: Number of Packing Rings

Control Valve Packing: Number of Packing Rings

Uploaded by

partho143Copyright:

Available Formats

Cashco Packing

Control Valve Packing

Packing is a sealing system which normally consists of a deformable material such as TFE, graphite, asbestos, Kalrez, etc. Usually the material is in the form of solid or split rings contained in a packing box. Packing material is compressed to provide an effective pressure seal between the uid in the valve body and the outside atmosphere. At one time it was believed that the more packing you had in a control valve the better it would seal. Since FUGITIVE EMISSIONS has become a concern, extensive studies have been made which have shown that better sealing can be obtained by minimizing the number of packing rings. New standards are being developed to which manufacturers will be asked to test their control valves. Test results from using these standards will allow a user to predict with some certainty how well a particular valve and packing combination will hold up. Denitions Consolidation: Packing consolidation is the shortening of a packing stack under load due to the elimination of voids in, between, and around the packing rings. This causes a reduction in packing stress (Radial Load) and consequently an increase in leakage. Consolidation can occur when the packing wears, cold ows, is subjected to thermal gradients, or if a nonuniform stress distribution in the packing exists. Extrusion: When packing is loaded to its proper stress level it has a tendency to cold ow and will extrude between the stem and the follower. Any increase in temperature will increase the tendency of the packing to cold ow. PTFE is very susceptible to this because the hotter it is the quicker it will cold ow and because PTFE has an expansion rate roughly ten times that of carbon steel. As the packing tries to expand in the xed volume of the packing gland, extrusion will occur. This material loss due to extrusion will relieve the axial stress, which relaxes the radial stress and results in a loss of seal. Migration: Packing migration occurs when a portion of the packing is caught by a rough stem and is removed from the packing box as the stem slides in and out of the packing box. (Applies only to Linear Valves.) Packing System Design Principles 1. In order to minimize stem friction and wear on the packing, the stem surface nish should be in the 8 to 16 RMS range. 2. The stem of the valve should be held concentric with the packing bore. This helps to uniformly compress the packing. This is best accomplished by guiding the stem at the top and the bottom of the packing bore. 3. To minimize packing extrusion under load, the inner diameter of packing spacers should be held as close to the stem diameter as possible. Anti-extrusion washers can also be helpful in minimizing extrusion. 4. It is desirable to use a wiping mechanism. The stem-wiping device should be at least a stroke distance away from the packing to prevent damage to the stem and packing by dragging particles and deposits into the packing area. Live-Loaded Packing Arrangements

http://www.maintenanceresources.com/referencelibrary/controlvalves/cashcopacking.htm[21/02/2011 9:54:57 AM]

Cashco Packing

Internal Live-Loading

External Live-Loading

Spring-Loaded Packing

Jammed Packing

http://www.maintenanceresources.com/referencelibrary/controlvalves/cashcopacking.htm[21/02/2011 9:54:57 AM]

Cashco Packing

The live-loading packing spring is replaced by a xed spacer of the same material as the trim material. Dual Packing

Pressure inside the valve is alternately greater than or less than (i.e. vacuum) ambient pressure. Dual Packing With Leak-Off Connection

http://www.maintenanceresources.com/referencelibrary/controlvalves/cashcopacking.htm[21/02/2011 9:54:57 AM]

Cashco Packing

Valve has a 1/4" (6mm) NPT tapped opening on its bonnet. Complete with removable steel plug for all body materials. The opening is located between primary and secondary packing sets when the valve is equipped with dual packing.

Internally Pressurized Bellows Stem Seal

Although it is the most expensive way in which to seal off the bonnet assembly from escaping uids, it is also the most effective way of handling lethal, toxic, explosive, and corrosive uids. As we head toward "ZERO EMISSIONS" control requirements, the bellows seal will become more popular.

Control Valve Concepts / Actuator Operating Modes / Positioners / Positioner and Controller Operating Modes / Flow Characteristics / Seat Leakage / Helpful Hints / Cashco Terminology / Advanced Topics

Copyright Maintenance Resources, Inc.

http://www.maintenanceresources.com/referencelibrary/controlvalves/cashcopacking.htm[21/02/2011 9:54:57 AM]

Cashco Packing

Phone: 812.877.7119 Fax: 812.877.7116 E-Mail: info@maintenanceresources.com Via Mail: 1983 North Hunt Street Terre Haute, IN 47805

http://www.maintenanceresources.com/referencelibrary/controlvalves/cashcopacking.htm[21/02/2011 9:54:57 AM]

You might also like

- JEHLE RENY Solutions To Selected ExercisesDocument38 pagesJEHLE RENY Solutions To Selected ExercisesSyed Yusuf Saadat100% (7)

- Customer Storage and Handling GuidelineDocument10 pagesCustomer Storage and Handling GuidelineVũ Thế Anh100% (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- HMIWebDisplayBuildingGuide EngDocument181 pagesHMIWebDisplayBuildingGuide Engpartho143100% (2)

- PackerDocument9 pagesPackerMahesh sinhaNo ratings yet

- Packing of Control Valves PresentationDocument58 pagesPacking of Control Valves PresentationMuhammadAsim100% (1)

- CHE Facts 1211Document1 pageCHE Facts 1211kumar_chemicalNo ratings yet

- What Is A Gasket?Document3 pagesWhat Is A Gasket?Rajesh GajjamNo ratings yet

- Uses of PackersDocument13 pagesUses of Packersmohamed_sahnoun_enisNo ratings yet

- Storage Tank Venting For ConservationDocument9 pagesStorage Tank Venting For Conservationkenoly123No ratings yet

- P&S 2005 - Packing Q&ADocument2 pagesP&S 2005 - Packing Q&ABrandonNo ratings yet

- EO Penetration in PolyethyleneDocument8 pagesEO Penetration in PolyethyleneSurendar KesavanNo ratings yet

- CECA - Adsorbents Handling ProceduresDocument15 pagesCECA - Adsorbents Handling ProceduresRonald SzafirskiNo ratings yet

- What Is Valve Packing Valve Packing Materials Their Types and CharacteristicsDocument8 pagesWhat Is Valve Packing Valve Packing Materials Their Types and CharacteristicssatphoenixNo ratings yet

- Column PackingDocument8 pagesColumn PackingAmin IsmailiNo ratings yet

- Vacuum Bagging TechniquesDocument56 pagesVacuum Bagging TechniquesPriyesh SaxenaNo ratings yet

- Reducing Methane Emissions From Compressor Rod Packing SystemsDocument8 pagesReducing Methane Emissions From Compressor Rod Packing Systemsb4sukiNo ratings yet

- Mechanical SealDocument22 pagesMechanical Sealkamal arabNo ratings yet

- Uses of PackersDocument2 pagesUses of PackersVivek ApteNo ratings yet

- Is Thicker Gasket Material Better Than ThinnerDocument2 pagesIs Thicker Gasket Material Better Than ThinnerSteven LiparotoNo ratings yet

- 4.10 Shaft SealingDocument11 pages4.10 Shaft SealingSandi AslanNo ratings yet

- Explosion DoorDocument15 pagesExplosion DoorGaluhNo ratings yet

- Design and Function of Weight-Loaded Pressure / Vacuum VentsDocument2 pagesDesign and Function of Weight-Loaded Pressure / Vacuum Ventsromero2kNo ratings yet

- Mechanicalpacking - Eng.1506.ltr 1Document16 pagesMechanicalpacking - Eng.1506.ltr 1Agustinus KNo ratings yet

- On-Stream Leak Repair Techniques - Part 2Document2 pagesOn-Stream Leak Repair Techniques - Part 2qaisarabbas9002100% (1)

- Anexo 9 Puraspec 7151Document7 pagesAnexo 9 Puraspec 7151Edgar Hector GarciaNo ratings yet

- Gland Packings PumpDocument13 pagesGland Packings PumpJitu Jena100% (1)

- Specifying Slide Gate ValveDocument4 pagesSpecifying Slide Gate ValvesahirprojectsNo ratings yet

- Read Online Textbook Additive Manufacturing For The Aerospace Industry Francis Froes Rodney Boyer Ebook All Chapter PDFDocument22 pagesRead Online Textbook Additive Manufacturing For The Aerospace Industry Francis Froes Rodney Boyer Ebook All Chapter PDFjudith.austin357100% (6)

- Intalox® Ultra™ Random Packing - Pushing The EnvelopeDocument4 pagesIntalox® Ultra™ Random Packing - Pushing The Envelope徐孝民No ratings yet

- GlandDocument2 pagesGlandSyeda ZahraNo ratings yet

- 55 Emerson Catalog PDFDocument82 pages55 Emerson Catalog PDF050678No ratings yet

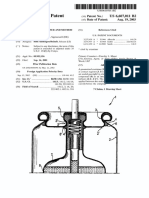

- U/ /////////I It //////////// ///.////: (12) United States Patent (10) Patent No.: US 6,607,011 B2Document4 pagesU/ /////////I It //////////// ///.////: (12) United States Patent (10) Patent No.: US 6,607,011 B2ererNo ratings yet

- Breather Valves2Document12 pagesBreather Valves2prashant_dc_in100% (1)

- Seal Leakage of Ball Valves StemDocument7 pagesSeal Leakage of Ball Valves StemBruno ManzettiNo ratings yet

- Inflatable Packers For Grouting: Figure 1 - Fixed End Inflatable Packer Figure 2 - Moving End Inflatable PackerDocument7 pagesInflatable Packers For Grouting: Figure 1 - Fixed End Inflatable Packer Figure 2 - Moving End Inflatable PackerYahya Ah100% (1)

- Seal Plans That I UseDocument9 pagesSeal Plans That I Usedhanu_aquaNo ratings yet

- Pressure VesselsDocument19 pagesPressure VesselsNikhil Deshpande100% (1)

- Stuffing BoxesDocument4 pagesStuffing BoxesrezaNo ratings yet

- Foam PourerDocument6 pagesFoam Pourerparo78joyNo ratings yet

- PackingDocument8 pagesPackingmohammed hamzaNo ratings yet

- 7.2.24 - Breather ValvesDocument28 pages7.2.24 - Breather Valvessav33No ratings yet

- Types Packing of Distillation Column by Huda ShahDocument7 pagesTypes Packing of Distillation Column by Huda ShahHuda ShahNo ratings yet

- 3M COMPLY 1233LF Vacum Bowie Dick TESTDocument4 pages3M COMPLY 1233LF Vacum Bowie Dick TESTpabloNo ratings yet

- Distillations From The WholeDocument5 pagesDistillations From The WholeJesus MoralesNo ratings yet

- GasketsDocument8 pagesGasketsRaj SharmaNo ratings yet

- Valve Maintenance Packing Replacement 170129023327 PDFDocument36 pagesValve Maintenance Packing Replacement 170129023327 PDFRamalingam PrabhakaranNo ratings yet

- Featured Snippet From The Web: Pump PackingDocument1 pageFeatured Snippet From The Web: Pump PackingSol PolNo ratings yet

- Eh Sealpot WPDocument10 pagesEh Sealpot WPAditya BulusuNo ratings yet

- Cargo 4aDocument44 pagesCargo 4aumut tunalıNo ratings yet

- 1.1. Autoclave Manufacturing ProcedureDocument2 pages1.1. Autoclave Manufacturing ProcedureAfifa SaifNo ratings yet

- Advantages of Membrane TechnologyDocument5 pagesAdvantages of Membrane TechnologyGopalNo ratings yet

- Guide To Vacuum BaggingDocument3 pagesGuide To Vacuum BaggingYazan ArabyNo ratings yet

- B3610 2 Design Considerations For Containment and Ventilation USDocument15 pagesB3610 2 Design Considerations For Containment and Ventilation USProveedora de servicios y suministros PSSNo ratings yet

- Chemical PumpsDocument4 pagesChemical PumpsRoozbeh PNo ratings yet

- Box Culvert Joint SealantDocument6 pagesBox Culvert Joint SealantgemotorresNo ratings yet

- Ambalaje 3Document5 pagesAmbalaje 3Cristina AlexandraNo ratings yet

- 1.6 Inert Gas SystemDocument8 pages1.6 Inert Gas SystemAbcdNo ratings yet

- Types of Trays The Packing MaterialDocument5 pagesTypes of Trays The Packing MaterialalyNo ratings yet

- Shaft SealsDocument4 pagesShaft SealsmarsulexNo ratings yet

- TI-84CE Graphing CalculatorDocument4 pagesTI-84CE Graphing Calculatorpartho143No ratings yet

- Urinalysis and Body Fluids: Unit 2 Session 5Document4 pagesUrinalysis and Body Fluids: Unit 2 Session 5partho143No ratings yet

- Space Motion of RocketsDocument14 pagesSpace Motion of Rocketspartho143No ratings yet

- Management of ChangeDocument2 pagesManagement of Changepartho143No ratings yet

- Class11 - Digestion and Absorption Assignment (2018-2019)Document1 pageClass11 - Digestion and Absorption Assignment (2018-2019)partho143No ratings yet

- Job Application (Includes Both)Document3 pagesJob Application (Includes Both)partho143No ratings yet

- Add, Edit, Delete and Run Access Queries With VBADocument5 pagesAdd, Edit, Delete and Run Access Queries With VBApartho143No ratings yet

- 04 SET MagnetismDocument5 pages04 SET Magnetismpartho143No ratings yet

- Mind Map RubricDocument1 pageMind Map Rubricpartho143No ratings yet

- Guide To OPCDocument9 pagesGuide To OPCpartho143No ratings yet

- Beginners PianoDocument25 pagesBeginners Pianopartho143100% (1)

- RD WR - AspDocument2 pagesRD WR - Asppartho143No ratings yet

- 023 BP RefiningDocument27 pages023 BP Refiningpartho143No ratings yet

- Interactive Excel Spreadsheet: CHM 102/sinexDocument12 pagesInteractive Excel Spreadsheet: CHM 102/sinexpartho143No ratings yet

- Add or Remove A Macro From CodeDocument2 pagesAdd or Remove A Macro From Codepartho143No ratings yet

- Generate A Model Tab: PsDocument6 pagesGenerate A Model Tab: Pspartho143No ratings yet

- Linear and Nonlinear Regression in Mathcad: Scalar CaseDocument3 pagesLinear and Nonlinear Regression in Mathcad: Scalar Casepartho143No ratings yet

- Finding Roots of Scalar Functions Using in MathcadDocument2 pagesFinding Roots of Scalar Functions Using in Mathcadpartho143No ratings yet

- Finding Roots of Polynomials Using Mathcad: PolyrootsDocument1 pageFinding Roots of Polynomials Using Mathcad: Polyrootspartho143No ratings yet

- Using Excel For Handling, Graphing, and Analyzing Scientific DataDocument2 pagesUsing Excel For Handling, Graphing, and Analyzing Scientific Datapartho143No ratings yet

- Sample VariationDocument8 pagesSample Variationpartho143No ratings yet

- Developer's Guide To Excelets/SinexDocument1 pageDeveloper's Guide To Excelets/Sinexpartho143No ratings yet

- Click Here: Developer's Guide To Excelets/SinexDocument3 pagesClick Here: Developer's Guide To Excelets/Sinexpartho143No ratings yet

- ER420 - MS of G.I Pipe Crossing - r0Document12 pagesER420 - MS of G.I Pipe Crossing - r0Wr ArNo ratings yet

- Experimental Investigation On The Effects of Process Parameters of GMAW and Transient Thermal Analysis of AISI321 SteelDocument16 pagesExperimental Investigation On The Effects of Process Parameters of GMAW and Transient Thermal Analysis of AISI321 SteelumisaaadahNo ratings yet

- 001-Chennakeshava Temple, SomanathapuraDocument12 pages001-Chennakeshava Temple, SomanathapuraraajagopalNo ratings yet

- Brief History of BoholDocument12 pagesBrief History of BoholJimmy Makiling PamugasNo ratings yet

- Lab Report DensityDocument3 pagesLab Report Densityapi-317559664No ratings yet

- Electronics Technician 10-2015 Room AssignmentDocument7 pagesElectronics Technician 10-2015 Room AssignmentPRC BaguioNo ratings yet

- Argumentative Sample Essays 1Document7 pagesArgumentative Sample Essays 1ֆɦɛʀաɨռ ֆǟʀʄʀǟʐNo ratings yet

- M6 Lesson 6 Check in ActivityDocument7 pagesM6 Lesson 6 Check in Activitynina erth gonzalesNo ratings yet

- 01-01-2021 GOC2 English ADocument39 pages01-01-2021 GOC2 English APrabhakar BandaruNo ratings yet

- CW9 Identifying Functions 5Document2 pagesCW9 Identifying Functions 5Xavier BurrusNo ratings yet

- Operator's Manual - 6'' Echo Sounder - LS-6100Document47 pagesOperator's Manual - 6'' Echo Sounder - LS-6100Adeilson AlmoaiaNo ratings yet

- The Sutra on the Eight Realizations of Great Beings(八大人觉经·中英对照) PDFDocument19 pagesThe Sutra on the Eight Realizations of Great Beings(八大人觉经·中英对照) PDFAnonymous NQfypLNo ratings yet

- CrystallizersDocument14 pagesCrystallizersAbhishekAyareNo ratings yet

- Laser Markable Label Material: Technical Data January 1, 1999Document3 pagesLaser Markable Label Material: Technical Data January 1, 1999jonathan6657No ratings yet

- Kelompok 10 - 1-s2.0-S002364381730004X-mainDocument4 pagesKelompok 10 - 1-s2.0-S002364381730004X-mainAngelina NitaNo ratings yet

- Diagnosis and Screening of Brugada SyndromeDocument11 pagesDiagnosis and Screening of Brugada SyndromeWinardi NursyidahNo ratings yet

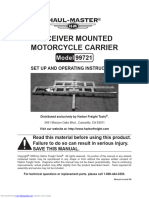

- Receiver Mounted Motorcycle Carrier: Set Up and Operating InstructionsDocument8 pagesReceiver Mounted Motorcycle Carrier: Set Up and Operating InstructionsVeljko KercevicNo ratings yet

- Environmental DeterminismDocument7 pagesEnvironmental DeterminismSafdar HussainNo ratings yet

- Medical Oxygen Generator FlyerDocument2 pagesMedical Oxygen Generator FlyertahatekriNo ratings yet

- INSTA PT 2023 Exclusive Geography PDFDocument55 pagesINSTA PT 2023 Exclusive Geography PDFAnushkaNo ratings yet

- (Urban and Industrial Environments) Andrew Karvonen - Politics of Urban Runoff - Nature, Technology, and The Sustainable City-The MIT Press (2011)Document307 pages(Urban and Industrial Environments) Andrew Karvonen - Politics of Urban Runoff - Nature, Technology, and The Sustainable City-The MIT Press (2011)Florina PtlNo ratings yet

- Elementary Electronics 1969-11-12Document100 pagesElementary Electronics 1969-11-12Jim ToewsNo ratings yet

- Las Science 9 Melc 7 q2 Week-7Document7 pagesLas Science 9 Melc 7 q2 Week-7LINDSY MAE SULA-SULANo ratings yet

- BSMLS2A - Candelasa - Activity 2 - BiochemistryDocument3 pagesBSMLS2A - Candelasa - Activity 2 - BiochemistryJohn CandelasaNo ratings yet

- AQUAVARI - Kinetic Air Valve WeightsDocument47 pagesAQUAVARI - Kinetic Air Valve WeightssandeshNo ratings yet

- Bhadbhut Barrage Project Across Naramada RiverDocument14 pagesBhadbhut Barrage Project Across Naramada RiverPalashXVNo ratings yet

- Weld Crawler BrochureDocument2 pagesWeld Crawler BrochureEdgardo José Tamaronis LeonettNo ratings yet

- Electrical Wirings-Ground FloorDocument1 pageElectrical Wirings-Ground FloordrajkumarceNo ratings yet

- GardeningDocument2 pagesGardeningAlice DwyerNo ratings yet