Professional Documents

Culture Documents

Scuba Leaflet

Scuba Leaflet

Uploaded by

Kaa NidOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scuba Leaflet

Scuba Leaflet

Uploaded by

Kaa NidCopyright:

Available Formats

scuba

perfectly evolved

for the

Luxfer's revolutionary lightweight scuba cylinders have been developed to combine optimum safety with outstanding performance and durability even in the toughest underwater conditions.

BENEFITS INCLUDE:

safe

The responsible divers guide to cylinder care!

good deep care

take

REMEMBER!

of your cylinder

before filling

For

! !

Although Luxfer's Scuba cylinders have been designed to exceed stringent performance and safety standards, it's up to you to ensure that your cylinder is always kept in peak condition by carefully following Luxfer's recommendations for continued care and maintenance.

! ! ! !

By taking care of your cylinder you'll be rewarded with many years of safe, trouble-free service Protect it from damage and never abuse or modify it Neglecting the cylinder could result in irreversible deterioration and a potential threat to personal safety Wash your cylinder in fresh water and dry after each use.

new cylinders

for

! ! !

continued use of the cylinder

Check that the cylinder is within its re-test period (see BSEN1802:2002) NEVER fill a cylinder that's outside its re-test period Visually examine the cylinder for evidence of damage from previous use or transportation. If in doubt (ie the cylinder shows signs of ANY damage) take it to a re-test station for an expert opinion and/or hydro-testing

filling

! ! !

Before you connect the cylinder to the compressor ALWAYS verify the rated filling pressure NEVER fill the cylinder or allow it to be filled beyond the maximum rated working pressure (PW) shown on the cylinder neck If you suspect or hear a hissing sound - stop filling immediately. NEVER fill or use a cylinder that is leaking. The cylinder must be taken to an approved re-test station for a thorough examination. Never try to tighten the valve if leaking around the cylinder neck ALWAYS check for leaks after filling and before use by immersing the cylinder into a tank or container of water. Take enough time to thoroughly check for even the smallest escaping bubble! It is strongly recommended that extreme care is taken to avoid any moisture transfer into your diving cylinder or buoyancy aid during filling. Buoyancy aids should not be filled from a diving cylinder.

Ensure that your cylinder is fitted with a compatible valve and associated components When using oxygen-enriched air, oxygen or nitrox mixtures, ensure that the cylinder is fitted with an oxygen or nitrox-compatible valve assembled with an oxygencompatible o-ring and lubricant Establish that the filling facility is suitable for providing a controlled oxygen-enriched air-fill, which must be totally free from oil carry-over and loose particulate If there's no assurance that the valve, o-ring and lubricant used is oxygen compatible or that the filling conditions conform, Luxfer recommend that you don't fill the cylinder until oxygen suitability is confirmed If you choose a standard air-fill only but decide to switch to an oxygen-enrich fill at a later date, remember to ensure that your cylinder is oxygen-clean and that your valve and associated accessories are oxygencompatible and clean.

! !

Clean internal surface and good corrosion resistance - the ideal combination for stored breathing gases! Exceptional strength and durability! Flat base for upright storage without a boot! Lightweight and easy to carry! High quality external surface finish!

before you dive!

Its vitally important that you read and understand these guidelines before you fill or use your Luxfer Cylinder! Keep this leaflet safe for future reference.

Determine if the cylinder shows external corrosion from poor storage, particularly after lengthy storage. If corrosion is evident, take the cylinder to a re-test station for an expert opinion and/or hydro-testing An appropriate valve (with the correct thread) should be torqued into the cylinder using calibrated torque wrenches with correctly fitting engagement heads. Torquing of valves should be in line with ENISO 13341:1997 for aluminium parallel threads.

careandmaintenance of your new cylinder

safety on the move

Keep your cylinder in top condition by following these common-sense guidelines:

important markings

The markings stamped on the neck of your cylinder contain important information which should be referred to when re-testing or filling.

Thread Specification indicates the cylinder thread type and size. It is important to ensure the correct valve is used with your cylinder

cleaning and storage

!

After use, thoroughly wash the outside and boot assembly with clean water containing mild soap or detergent, rinse off and wipe dry with a towel. It is advisable to remove the cylinder from its backpack and the boot for regular cleaning Keep the threads and cylinder interior dry and free from contamination of any sort ALWAYS ensure your cylinder maintains a slight positive pressure up to 20 bar NEVER store the cylinder on bare concrete or any surface that may hold moisture Cylinders used as part of a bouyancy aid must be washed in fresh water and thoroughly dried after each use.

testing check list

! !

ALWAYS ensure your cylinder is re-tested within the prescribed period for the UK and EEC (BSEN1802:2002) ALWAYS ensure that the cylinder attachments are maintained, serviced, inspected and handled in strict accordance with the manufacturers instructions.

warning!

! !

NEVER alter or obscure the cylinder markings! NEVER fill or partially fill your cylinder with Oxygen, Oxygen mixtures or Nitrox unless the cylinder and valve have been properly cleaned and maintained for these mixtures!

Distributed by:

Test Pressure shows the pressure that the cylinder should be tested to. NOT to be exceeded

10

! ! ! !

Always secure your cylinder safely when in transit a dry wooden box or sturdy cardboard container is ideal Prevent the cylinder from rolling about - any impact could damage the shell by indenting, scratching, gouging, scoring or chipping off protective paint finishes Do NOT throw the cylinder onto sand or ground - it may impact against a hidden hard object that could cause damage Take care to avoid dropping your cylinder as well as damaging an empty cylinder, dropping a charged cylinder could shear the valve Prevent the cylinder from being exposed to direct sunlight or where the sun is directed through windows or clear glass roofing. Keep your cylinder cool. Filled cylinders that become warm (up to 60C) could result in breathing difficulties due to the temperature of the contained gas. Never expose your cylinder to temperatures in excess of 60C.

2 3 4

Country of Manufacture Cylinder Manufacturer

! ! ! !

repair

!

If the painted surface is damaged do not ignore it! Clean the area with fine wire wool and touch up the damage with a room-temperature air-drying aluminium primer followed by a room temperature drying gloss paint. Do not use paints with a curing temperature above ambient. For further information contact the manufacturer Do not attempt to remove a damaged paint surface with abrasive wheels, files, shot-blasting or aggressive chemicals. This may reduce the wall thickness making the cylinder unsafe for pressure storage Do not leave valves open after use. This allows moist-air intake that can cause internal corrosion If using stainless steel fixtures as a backpack clamp - coat with a suitable plastic to insulate from the aluminium.

Please fill out the details below and keep as a reference when re-testing or filling your cylinder. Date Purchased Purchased From Cylinder Serial No Cylinder Capacity Charged Pressure Test Pressure Original Test Date Thread Size

14

Cylinder Type Number and Serial Number this number is recorded by Luxfer so that the entire manufacturing history of your cylinder can be traced

5

Service Pressure indicates the pressure which can develop inside the cylinder at the temperature shown. It should NOT to be confused with the working pressure (PW)

11

1 2 3 4

Mark of Conformity to the Pressure Equipment Directive 97/23/EC & Notified Body Identification Number

12

5 6

Alloy of Construction Design Minimum Wall Thickness Empty Weight of Cylinder Only (kg) Minimum Water Capacity (litres) Test Date shows when your cylinder was first tested, with the year followed by the month or quarter of the test year shown in a circle

13

Your life depends on your cylinder so always treat it with care and respect!

! !

This leaflet is a general Guide to the use & care of your Luxfer Scuba Cylinder. If you have bought this cylinder as a single item only (ie. no valve fitted), you must also refer to Luxfers PED Customer Information Sheet. If you bought this cylinder as part of a Scuba equipment assembly (ie. valve fitted etc.) you must also refer to the equipment assemblers PED Customer Information Sheet.

10 6 7 8 13 11 12

7 8 9

Customer/Trade Name (on reverse of cylinder) for whom the cylinder was originally made (optional).

14

Luxfer Gas Cylinders, Colwick, Nottingham, NG4 2BH, UK. www.luxfercylinders.com

Luxfer 2002

Working Pressure shows the pressure that the cylinder should be filled to. NOT to be exceeded

You might also like

- Show: Bunheads By: Amy Sherman-Palladino Scene Type: Serio-Comic Character: BooDocument17 pagesShow: Bunheads By: Amy Sherman-Palladino Scene Type: Serio-Comic Character: BooChristina CannillaNo ratings yet

- Öhlins General Workshop Manual PDFDocument61 pagesÖhlins General Workshop Manual PDFryden100% (1)

- Science: Quarter 2 - Module 7: "Beneficial or Harmful?"Document20 pagesScience: Quarter 2 - Module 7: "Beneficial or Harmful?"Freya Joy Mercado - Santos91% (11)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Front View: Wire Rope DrumDocument2 pagesFront View: Wire Rope DrumDave Vendivil SambranoNo ratings yet

- Sugar Plant Energy ConservationDocument24 pagesSugar Plant Energy Conservationtsrinivasan5083100% (5)

- Muller CoDocument12 pagesMuller CoRamSalunkheNo ratings yet

- Bulletin 4002 O&M Manual For CL-16-26-56 Revised 10-15-2014Document15 pagesBulletin 4002 O&M Manual For CL-16-26-56 Revised 10-15-2014Docente 361 UMECITNo ratings yet

- Liquid Nitrogen Tank Operating ManualDocument25 pagesLiquid Nitrogen Tank Operating Manualedgardiaz5519No ratings yet

- Compressed Gas Cylinders Safety ChecklistDocument4 pagesCompressed Gas Cylinders Safety ChecklistKhairul AmilinNo ratings yet

- Compressed Gas Cylinder StorageDocument4 pagesCompressed Gas Cylinder StorageNoel Weng100% (1)

- Guide-to-Compressed-or-Liquefied-Gases-in-Laboratories ACETYLENEDocument10 pagesGuide-to-Compressed-or-Liquefied-Gases-in-Laboratories ACETYLENEvermaravi11449922No ratings yet

- Unfired Pressure Vessels: Occupational Health & Optometry SafetyDocument29 pagesUnfired Pressure Vessels: Occupational Health & Optometry SafetyPatricia Zabala AnimasNo ratings yet

- Using Your Albany PumpDocument5 pagesUsing Your Albany PumpmehdiNo ratings yet

- Handbook Sealweld Valvulas de ProcesoDocument92 pagesHandbook Sealweld Valvulas de Procesofelipe castellanosNo ratings yet

- WALLACH LL100 TWO TRIGGER CRYOSURGICAL UNIT For N2O Instructions For UseDocument8 pagesWALLACH LL100 TWO TRIGGER CRYOSURGICAL UNIT For N2O Instructions For UsePierre Richard MompremierNo ratings yet

- Series 39 Inline Check Valve: Installation, Operation, and Maintenance ManualDocument4 pagesSeries 39 Inline Check Valve: Installation, Operation, and Maintenance ManualLalo SepulvedaNo ratings yet

- TRUE Spec Series Heated CabinetDocument7 pagesTRUE Spec Series Heated Cabinetansarymohamed29No ratings yet

- Enimex - BVFL - GB PDFDocument6 pagesEnimex - BVFL - GB PDFAlienshowNo ratings yet

- Safety in Handlig Gas CylindersDocument2 pagesSafety in Handlig Gas CylindersKrish VetriselvamNo ratings yet

- Catalina Valve Insertion InstructionsDocument3 pagesCatalina Valve Insertion InstructionsCarlos Arturo Martinez SalcedoNo ratings yet

- Prevent MaintenanceDocument15 pagesPrevent Maintenancemecanico_ipnNo ratings yet

- Double Disc Check Valve: Job NameDocument10 pagesDouble Disc Check Valve: Job NameAditya RochmansyahNo ratings yet

- Information Sheet 6.1.4 Backfire and FlashbackDocument4 pagesInformation Sheet 6.1.4 Backfire and FlashbackJerryson CabriasNo ratings yet

- Ahstco Product CatalogDocument79 pagesAhstco Product CatalogPeerasut ChaisrimaneepanNo ratings yet

- Portable Gasoline Trash Pump: Model 761204 2" Intake/Outlet 7HP Mode L 761205 4" Intake/Outlet 14HPDocument15 pagesPortable Gasoline Trash Pump: Model 761204 2" Intake/Outlet 7HP Mode L 761205 4" Intake/Outlet 14HPtubjackieNo ratings yet

- Compressed Gas Cryogenic Liquid Cylinder SafetyDocument5 pagesCompressed Gas Cryogenic Liquid Cylinder SafetyHebron DawitNo ratings yet

- Cylinders InfoDocument34 pagesCylinders InfoBhavani BudiNo ratings yet

- STXX28 OperatorsManualDocument8 pagesSTXX28 OperatorsManualم.نور المشاقبةNo ratings yet

- CGC SafetyDocument9 pagesCGC SafetySOLY_POP_10No ratings yet

- Valve Manual 2012Document2 pagesValve Manual 2012António VCNo ratings yet

- Safe Use of Cylinder Gases: ©consultnet LimitedDocument29 pagesSafe Use of Cylinder Gases: ©consultnet LimitedAhmad Mensa100% (1)

- Manual FCS-C5000 V1.2 ENDocument31 pagesManual FCS-C5000 V1.2 ENMilo WartenbergNo ratings yet

- Vaas Automation PVT LTD: 90 Series Installation, Operating & Maintenance ManualDocument5 pagesVaas Automation PVT LTD: 90 Series Installation, Operating & Maintenance ManualDanielle JohnsonNo ratings yet

- Compressed Gas Safety: Program Objective Purpose and ScopeDocument3 pagesCompressed Gas Safety: Program Objective Purpose and ScopeAjani CherenfantNo ratings yet

- Alum SCUBA Safety Alert 2010sepDocument2 pagesAlum SCUBA Safety Alert 2010sepbcarr74469No ratings yet

- Cylinder Break in InstallDocument1 pageCylinder Break in Install陳俊欽No ratings yet

- Compressed Gas Cylinders PowerPointDocument20 pagesCompressed Gas Cylinders PowerPointRajanbabuNo ratings yet

- Cylinder Leakage Tester 2 - Gauge Vse2020.V3: 1. SafetyDocument2 pagesCylinder Leakage Tester 2 - Gauge Vse2020.V3: 1. Safetyhotmaail4No ratings yet

- Manual 1956 PN 09-1013 VF-61Document3 pagesManual 1956 PN 09-1013 VF-61fabiosparkNo ratings yet

- Compressed Gas Cylinder SafetyDocument36 pagesCompressed Gas Cylinder Safetyelvis hidalgoNo ratings yet

- EHS Moment - Compressed Gases - Inspection of Gas Cylinder - 12 Oct 23Document2 pagesEHS Moment - Compressed Gases - Inspection of Gas Cylinder - 12 Oct 23sanalkumar24No ratings yet

- HABONIMDocument18 pagesHABONIMHema IbraNo ratings yet

- Liquid Cylinder Owners ManualDocument25 pagesLiquid Cylinder Owners Manualshan757No ratings yet

- Compressed Gas Cylinder SafetyDocument36 pagesCompressed Gas Cylinder Safetyagrocel_bhv5591No ratings yet

- Compressed Gas SafetyDocument20 pagesCompressed Gas SafetyMd Rafat ArefinNo ratings yet

- Service Lefty 2011 PBR-XLR Eng - 2Document8 pagesService Lefty 2011 PBR-XLR Eng - 2geert janNo ratings yet

- UatDocument108 pagesUatdhirendraNo ratings yet

- Compressed Gas Cylinders Safety: StorageDocument3 pagesCompressed Gas Cylinders Safety: StorageHebron DawitNo ratings yet

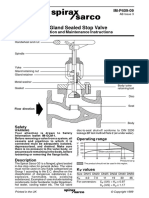

- G3 Gland Sealed Stop Valve-Installation Maintenance Manual PDFDocument2 pagesG3 Gland Sealed Stop Valve-Installation Maintenance Manual PDFchanNo ratings yet

- User-Maintenance Manual: Double Flanged Butterfly ValvesDocument27 pagesUser-Maintenance Manual: Double Flanged Butterfly ValvesKYAWNo ratings yet

- Manual Filtros Dynamic Series Rainbow Pentair InglesDocument2 pagesManual Filtros Dynamic Series Rainbow Pentair InglesIrvin Enrique Solano SalvadorNo ratings yet

- Needle Valve Maintenance Instructions - Alco Valves PM-221Document5 pagesNeedle Valve Maintenance Instructions - Alco Valves PM-221AzaelNo ratings yet

- TBV Series 21 20 Cryogenic Flanged Ball ValveDocument5 pagesTBV Series 21 20 Cryogenic Flanged Ball ValveJosip PobranNo ratings yet

- Fluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualDocument12 pagesFluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualmehtahemalNo ratings yet

- LP Gas Basic Filling Procedures Gen Info 1Document10 pagesLP Gas Basic Filling Procedures Gen Info 1handoyo_eko20017573No ratings yet

- Dnvps Line Sampler: (Marpol Annex Vi-Compliant)Document6 pagesDnvps Line Sampler: (Marpol Annex Vi-Compliant)dassi99No ratings yet

- 16MVA Transformer SCH - O&M Manual PDFDocument107 pages16MVA Transformer SCH - O&M Manual PDFpawanNo ratings yet

- PT 102662 Iom UsDocument5 pagesPT 102662 Iom UsMo ZeroNo ratings yet

- Iom WKM 310FDocument4 pagesIom WKM 310FNasir NaqviNo ratings yet

- Gas Cylinders and GasesDocument5 pagesGas Cylinders and Gasesjose_mario1128No ratings yet

- Guidelines For Oxygen CylindersDocument9 pagesGuidelines For Oxygen CylindersAshish TiwariNo ratings yet

- Atmospheric Relief Valve ManualDocument12 pagesAtmospheric Relief Valve ManualTarun ChandraNo ratings yet

- RLSB90 LManualDocument12 pagesRLSB90 LManualacea.liambNo ratings yet

- Verrier Elwin, Sarat Chandra Roy - The Agaria (1992, Oxford University Press, USA)Document383 pagesVerrier Elwin, Sarat Chandra Roy - The Agaria (1992, Oxford University Press, USA)ravibaswaniNo ratings yet

- Stanford Health Care Antimicrobial Dosing Reference GuideDocument7 pagesStanford Health Care Antimicrobial Dosing Reference GuideKarl Martin PinedaNo ratings yet

- Chapter 1 DhatuDocument6 pagesChapter 1 Dhatusbec96860% (1)

- NT115UsersMan EngDocument48 pagesNT115UsersMan EngThai Binh MinhNo ratings yet

- TDE9540 09 WhitePaperDocument56 pagesTDE9540 09 WhitePaperdarkoskr84No ratings yet

- Example The Inductance of A SolenoidDocument3 pagesExample The Inductance of A SolenoidMuhamad YusupNo ratings yet

- Eleven Rack User GuideDocument130 pagesEleven Rack User GuideGeocasta AbaddonNo ratings yet

- KrisbowDocument12 pagesKrisbowGhirah ArrahmanNo ratings yet

- Sentiment Analysis With NLP Deep LearningDocument8 pagesSentiment Analysis With NLP Deep LearningAnkush ChajgotraNo ratings yet

- Hotel Minimum ReqDocument28 pagesHotel Minimum ReqAnusha AshokNo ratings yet

- High Altitude Aeronautical Platform Systems (Presentation)Document30 pagesHigh Altitude Aeronautical Platform Systems (Presentation)Mahenoor SiddiquiNo ratings yet

- Kyocera Fs-1020d Service ManualDocument109 pagesKyocera Fs-1020d Service ManualvonBoomslangNo ratings yet

- Common Female Ancestor Test 2: African L2 Haplogroups Pereira Et Al (2001)Document7 pagesCommon Female Ancestor Test 2: African L2 Haplogroups Pereira Et Al (2001)Mwiinga JnrNo ratings yet

- MG500 Service Training PDFDocument22 pagesMG500 Service Training PDFJav SeNo ratings yet

- Determining The Susceptibility of Stainless Steels and Related Nickel-Chromium-Iron Alloys To Stress-Corrosion Cracking in Polythionic AcidsDocument3 pagesDetermining The Susceptibility of Stainless Steels and Related Nickel-Chromium-Iron Alloys To Stress-Corrosion Cracking in Polythionic AcidsIvan AlanizNo ratings yet

- Hands On pGALS Complete PDF 17 6 08Document8 pagesHands On pGALS Complete PDF 17 6 08Fakhre IbrahimNo ratings yet

- LT-181H SeriesDocument3 pagesLT-181H SeriesCenti MeterNo ratings yet

- High Efficiency Single Synchronous Buck PWM Controller: RT8240A/B/CDocument17 pagesHigh Efficiency Single Synchronous Buck PWM Controller: RT8240A/B/Ckamil_yilmaz_6No ratings yet

- Final Year Project SPYBOTDocument7 pagesFinal Year Project SPYBOTFaizanAhmedNo ratings yet

- Arc2500rev1 02serviceDocument18 pagesArc2500rev1 02serviceRomlly Voice ElektroNo ratings yet

- Chapter 3 - HypothyroidismDocument59 pagesChapter 3 - HypothyroidismSteffi AraujoNo ratings yet

- Synergy Shuttle ConveyorDocument5 pagesSynergy Shuttle ConveyorTamal Tanu RoyNo ratings yet

- 1 Structural - FunctionalismDocument57 pages1 Structural - FunctionalismCinnamonNo ratings yet

- Vulvovaginal DisordersDocument62 pagesVulvovaginal DisordersMabruk MansoorNo ratings yet

- MSF2231 - SIB Motor Feb 17Document15 pagesMSF2231 - SIB Motor Feb 17Ibrahim RahmatullahNo ratings yet