Professional Documents

Culture Documents

Format-WORK INSTRUCTION For Heat Treatment Furnace

Format-WORK INSTRUCTION For Heat Treatment Furnace

Uploaded by

Balram JiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Format-WORK INSTRUCTION For Heat Treatment Furnace

Format-WORK INSTRUCTION For Heat Treatment Furnace

Uploaded by

Balram JiCopyright:

Available Formats

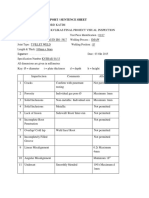

QWI/QC/20 Work Instruction For Hardening Rev. No.

: 01 HAPPY & Tempering, Normalizing & ISO Date :- 27-09-09 FORGINGS LTD. Thermal Annealing Furnace Page : 01 of 01

1 Check the CBFS oil level by measuring depth. 2 Furnace blower to be started. The buttons are in the control panel. After five minute oil pump to be started. Buttons are left hand side of austenitic 3 Furnace (near oil pump units). 4 Austenitic Furnace burner (duly cleaned) light up one by one (Seven burners). 5 Set required temperature on temperature controller according to heat treatment cycle. 6 Loading materials as per heat treatment cycle. 7 Switch on the hydraulic pump buttons are in control panel. 8 After loading push trays one by one. Buttons are in front of austenitic furnace. 9 Soak properly as per heat treatment cycle. 10 Fast cooling blower set timer as per cycle required. The button is exit side of austenitic furnace.

At the time of hardening, heated trays take out from austenitic furnace, put on cradle, 11 timely quenched by pneumatic pusher. Buttons are in panel (Austenitic furnace exit side). Agitation pump immediately start. After quenching tray take out & check quench hardness then transfer to C.T. Furnace 12 for tempering, Temperature maintained as heat treatment Cycle. Please take care that all three circulation fans running continuously, along with water circulation fans too. 13 Polymer % to be checked by Refractor meter & Maintained as heat treatment cycle. 14 Polymer level maintained properly, If less increase by D.M water or polymer. 15 Polymer temperature to be maintained 28 to 40 degree centigrade. At the time of I.S.O thermal annealing & normalizing, the time of cooling & transfer to another furnace maintained as per heat treatment cycle. Approved By Prepared by DGM Metallurgical Quality Control

16

You might also like

- Work Instruction For HMCDocument3 pagesWork Instruction For HMCVasu Raja100% (5)

- Technical Review For ISO 3834Document1 pageTechnical Review For ISO 3834Satish Keskar100% (3)

- Valid SOP: Standard Operating ProceduresDocument10 pagesValid SOP: Standard Operating ProceduresShahid Raza100% (2)

- Forging Audit ChecklistDocument15 pagesForging Audit ChecklistAnkur0% (1)

- Tootan Wala KhoohDocument92 pagesTootan Wala KhoohBalram Ji100% (3)

- Machining In-Process Inspection ChecklistDocument2 pagesMachining In-Process Inspection ChecklistRonnel Leano0% (1)

- Route Card: Material SummaryDocument7 pagesRoute Card: Material SummaryBalram Ji100% (1)

- Standard Testing Procedure - Tensile TestingDocument3 pagesStandard Testing Procedure - Tensile Testingdevendrasingh2021100% (1)

- Welding Machine Calibration ProcedureDocument10 pagesWelding Machine Calibration ProcedureGerman Favela0% (1)

- Poison Test ProcedureDocument2 pagesPoison Test Procedureprashanth93% (15)

- Abnormality Handling - R2Document4 pagesAbnormality Handling - R2Sagar Daund100% (5)

- Mahindra & Mahindra Ltd. Auto Sector Percentage Inspection Points Satisfying Tolerance (PIST)Document2 pagesMahindra & Mahindra Ltd. Auto Sector Percentage Inspection Points Satisfying Tolerance (PIST)shobha shelar67% (3)

- Route Card: Material SummaryDocument7 pagesRoute Card: Material SummaryBalram Ji100% (1)

- CQI.9.Heat Treat System AssessmentDocument51 pagesCQI.9.Heat Treat System AssessmentDung Tran KienNo ratings yet

- WI-QA-02, 13 SOP For SST Operation DT 27th Feb.2019.Document3 pagesWI-QA-02, 13 SOP For SST Operation DT 27th Feb.2019.All in OneNo ratings yet

- Tool History CardDocument1 pageTool History CardIsaiah100% (1)

- Red Bin Analysis-MaceDocument51 pagesRed Bin Analysis-MaceAtul Sharma100% (7)

- CQI 9 Heat Treatment Rev 01Document64 pagesCQI 9 Heat Treatment Rev 01ukavathekar50% (2)

- Daily POKA-YOKE Verification Check SheetDocument8 pagesDaily POKA-YOKE Verification Check SheetsachinNo ratings yet

- 4 M Change ProcedureDocument2 pages4 M Change ProcedureManasi shinde100% (1)

- Standard Machining Tolerance JIS B 0405Document6 pagesStandard Machining Tolerance JIS B 0405fsijestNo ratings yet

- Operator Observance SheetDocument5 pagesOperator Observance SheetEr Avinash Kumar100% (2)

- Cp-005-Calibration of Internal MicrometerDocument5 pagesCp-005-Calibration of Internal MicrometerSUNILNo ratings yet

- Red Bin Analysis ProcedureDocument4 pagesRed Bin Analysis ProcedureVenkatesan92% (12)

- Weld Inspection ReportDocument5 pagesWeld Inspection ReportFord Katim100% (2)

- MIG Welding PWPSDocument1 pageMIG Welding PWPSelectronicmail2ughf6525No ratings yet

- Work Instruction Wire Cut: TitleDocument4 pagesWork Instruction Wire Cut: TitleidenbelleNo ratings yet

- Als 268 03 Issue 03Document27 pagesAls 268 03 Issue 03rollickingdeol50% (6)

- Preventive Maintenance PlanDocument3 pagesPreventive Maintenance PlanBalram Ji86% (7)

- Technical Delivery Condition: Applicable To Parts: Ring WCFN0055Document4 pagesTechnical Delivery Condition: Applicable To Parts: Ring WCFN0055Balram JiNo ratings yet

- 16.work Instruction For VMCDocument1 page16.work Instruction For VMCSAKTHIVEL A50% (4)

- Work Instruction For Bending Rev. 01.01.2013Document3 pagesWork Instruction For Bending Rev. 01.01.2013aymanmalah100% (1)

- Process Validation 1Document1 pageProcess Validation 1tayyab100% (1)

- Heat Treatment ProcedureDocument3 pagesHeat Treatment ProcedureKunal AjgaonkarNo ratings yet

- 1 2 3 - 4M Change Part TagDocument4 pages1 2 3 - 4M Change Part TagIt's me DJNo ratings yet

- WI For DFT MeterDocument4 pagesWI For DFT MeterRahul PoriyaNo ratings yet

- Acceptance CriteriaDocument3 pagesAcceptance Criteriapoongodisk100% (1)

- Acceptence Criteria IMTEDocument12 pagesAcceptence Criteria IMTEdanaka007100% (1)

- Powder Coating ProcedureDocument1 pagePowder Coating Procedurenastyn-1No ratings yet

- Predictive Maintenance: 1 Induction FurnaceDocument14 pagesPredictive Maintenance: 1 Induction Furnacenayan vyasNo ratings yet

- Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)Document3 pagesMetal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)rohitNo ratings yet

- Process Instruction Heat Treatment (Revised 06.11.2017)Document4 pagesProcess Instruction Heat Treatment (Revised 06.11.2017)Deepak kumarNo ratings yet

- Supplier Standardised Process Guide: - Raw Material Testing - RM Processing - ForgingDocument22 pagesSupplier Standardised Process Guide: - Raw Material Testing - RM Processing - ForgingBhavna Acharya100% (1)

- 03 - Oven Calibration ProcedureDocument4 pages03 - Oven Calibration ProcedureSankar Muka0% (1)

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- W10 Work Instructions For WeldingDocument1 pageW10 Work Instructions For WeldingMunazar Hussain100% (3)

- SOP-QAD-001 - Inhouse CalibrationDocument4 pagesSOP-QAD-001 - Inhouse Calibrationdanaka00750% (2)

- Melt Flow Work InstructionDocument1 pageMelt Flow Work Instructionsuresh kumarNo ratings yet

- Process Parameter SheetDocument1 pageProcess Parameter SheetNur AmiraNo ratings yet

- Tus & SatDocument30 pagesTus & SatMadhubalan100% (1)

- Heat Treatment Report FormatDocument4 pagesHeat Treatment Report FormatAnonymous OEUUoKHYR100% (2)

- Iatf ActivitiesDocument6 pagesIatf ActivitiesWizard tube and Engineered componentNo ratings yet

- Weld Visual Report Rev.0Document1 pageWeld Visual Report Rev.0John TerryNo ratings yet

- AE-QA-02 - First Piece Inspection ReportDocument1 pageAE-QA-02 - First Piece Inspection ReportKarthi ThiyagarajanNo ratings yet

- Daily Instrument Check SheetDocument8 pagesDaily Instrument Check SheetRaju RaiNo ratings yet

- PFMEA OF ABB TankDocument12 pagesPFMEA OF ABB Tankrohit mathanker100% (3)

- Kova Fasteners (P) LTD: Sampling PlanDocument1 pageKova Fasteners (P) LTD: Sampling PlanAmandeep SinghNo ratings yet

- 4M Change MatrixDocument1 page4M Change MatrixAnkit SainiNo ratings yet

- Quality Alert FormatDocument1 pageQuality Alert Formatsuresh kumar80% (5)

- Welding Repair ProcedureDocument4 pagesWelding Repair ProcedureRiky SumantriNo ratings yet

- 2X150 Boiler Start InggrisDocument5 pages2X150 Boiler Start InggrisSuprapto DesmosediciNo ratings yet

- Thermal Oil Heater & SystemsDocument4 pagesThermal Oil Heater & SystemsBraulio CvNo ratings yet

- Coal Power Unit StartDocument8 pagesCoal Power Unit StartansudasinghaNo ratings yet

- Electrical Sequence of Operation For A BoilerDocument2 pagesElectrical Sequence of Operation For A BoilerPrecisionetica100% (2)

- Rework Record For Heat Treated Parts: Original Production DetailsDocument1 pageRework Record For Heat Treated Parts: Original Production DetailsBalram Ji100% (2)

- Chap-02 Pair ofDocument9 pagesChap-02 Pair ofBalram JiNo ratings yet

- Handling of InstrumentsDocument10 pagesHandling of InstrumentsBalram JiNo ratings yet

- Oerlikon Checklist 2012Document14 pagesOerlikon Checklist 2012Balram JiNo ratings yet

- PQCS Tube Flange Rough - CuttingDocument1 pagePQCS Tube Flange Rough - CuttingBalram JiNo ratings yet

- Stavax ESRDocument13 pagesStavax ESRBalram JiNo ratings yet

- Sae 1038 - Ø36Document1 pageSae 1038 - Ø36Balram JiNo ratings yet

- Lea - 5SDocument1 pageLea - 5SallanjulesNo ratings yet

- PQCS Tube Flange Rough - ForgingDocument1 pagePQCS Tube Flange Rough - ForgingBalram JiNo ratings yet

- Jominy Formula SheetDocument2 pagesJominy Formula SheetBalram JiNo ratings yet

- Ramya Balaji Alloy Pvt. Limited: Record No.: Date: Page 1 of 1 Title: Code of Conduct For Employees (Staff)Document1 pageRamya Balaji Alloy Pvt. Limited: Record No.: Date: Page 1 of 1 Title: Code of Conduct For Employees (Staff)Balram JiNo ratings yet

- Kmpnai Ko Inayama: Kma-Caari Ka Naama À Idpat-MaomtDocument1 pageKmpnai Ko Inayama: Kma-Caari Ka Naama À Idpat-MaomtBalram JiNo ratings yet

- Shewhart Individuals Control ChartDocument2 pagesShewhart Individuals Control ChartBalram JiNo ratings yet

- Work Instructions - Nickel Spot TestDocument2 pagesWork Instructions - Nickel Spot TestBalram JiNo ratings yet

- Quick Die Change in HammersDocument16 pagesQuick Die Change in HammersBalram JiNo ratings yet

- Job Specification For Recruitment (MACHINE SHOP)Document2 pagesJob Specification For Recruitment (MACHINE SHOP)Balram JiNo ratings yet

- Job Specification For Recruitment (Electrical)Document2 pagesJob Specification For Recruitment (Electrical)Balram JiNo ratings yet

- Why SpiritualityDocument37 pagesWhy SpiritualityBalram JiNo ratings yet

- Job Specification For Recruitment (HEAT SHOP)Document2 pagesJob Specification For Recruitment (HEAT SHOP)Balram JiNo ratings yet

- Job Specification For Recruitment Forging - Page 2Document1 pageJob Specification For Recruitment Forging - Page 2Balram JiNo ratings yet