Professional Documents

Culture Documents

Hazop.1092475 Appendix 30.hazop

Hazop.1092475 Appendix 30.hazop

Uploaded by

Audrey Patrick KallaCopyright:

Available Formats

You might also like

- HAZOP ExampleDocument5 pagesHAZOP ExampleAnonymous QqE5tcEa100% (6)

- HAZOP Study of Methanol, Ethanol, and Water Distillation ColumnDocument7 pagesHAZOP Study of Methanol, Ethanol, and Water Distillation ColumnEng MohammedNo ratings yet

- HAZOP ExerciseDocument8 pagesHAZOP Exercisekefeinzel0% (1)

- Chapter 7 HazopDocument11 pagesChapter 7 HazopMohd Azman Suwandi50% (2)

- HAZOP AnalysisDocument35 pagesHAZOP AnalysisGopi Krish100% (3)

- HAZOP ExerciseDocument12 pagesHAZOP Exerciseshawalina07No ratings yet

- HAZOP ReactorDocument9 pagesHAZOP ReactorChadGayle100% (9)

- Paint Production Process DiagramDocument4 pagesPaint Production Process DiagramQasim SarwarNo ratings yet

- 064126-S-LIS-100-A Valve List - Boiler Pressure PartsDocument6 pages064126-S-LIS-100-A Valve List - Boiler Pressure PartsYusuf Feri FeriansyahNo ratings yet

- Project: Phu My Fertilizer Project Rev. Sheet 41 Client: Petrovietnam of 43Document1 pageProject: Phu My Fertilizer Project Rev. Sheet 41 Client: Petrovietnam of 43Tai Dang Huy100% (1)

- HazopDocument2 pagesHazopapi-292058494100% (1)

- Hazards and Operability (Hazop) Review: Dps Document No.Document143 pagesHazards and Operability (Hazop) Review: Dps Document No.Immanuel100% (1)

- Hazop Example PDFDocument2 pagesHazop Example PDFhappale200286% (7)

- Separation of Liquid Nitrogen and Oxygen by Cryogenic DistillationDocument9 pagesSeparation of Liquid Nitrogen and Oxygen by Cryogenic Distillationzohaib_farooqNo ratings yet

- Problem Statement:: ZZZZZZ Yyyyyy 25 Nov. 2020 Process Plant Safety and Environment XXXXXDocument19 pagesProblem Statement:: ZZZZZZ Yyyyyy 25 Nov. 2020 Process Plant Safety and Environment XXXXXNITIN KUMAR100% (1)

- HAZOP Write UpDocument3 pagesHAZOP Write UpGlacier Ramkissoon100% (1)

- HAZOPDocument34 pagesHAZOPMohammed100% (1)

- HAZOP ProcedureDocument10 pagesHAZOP Proceduresharjeel39100% (3)

- Aerosol Paints Know How Plant Setting FormulationsDocument1 pageAerosol Paints Know How Plant Setting FormulationsAudrey Patrick Kalla67% (3)

- Diagram For Exercise 2: CoolerDocument6 pagesDiagram For Exercise 2: CoolerJoão AlegretiNo ratings yet

- Safety: Table 1: Safe Equipment. Authors: Cango. P, Espinoza. A, Lopez. C. (2019)Document4 pagesSafety: Table 1: Safe Equipment. Authors: Cango. P, Espinoza. A, Lopez. C. (2019)Alexander EspinozaNo ratings yet

- Inherent SafetyDocument50 pagesInherent SafetyChing-Liang ChenNo ratings yet

- HAZOP On RegeneratorDocument1 pageHAZOP On Regeneratorraiwasif100% (1)

- HAZOP FinalDocument2 pagesHAZOP Finalchiang95100% (3)

- Hazop StudyDocument8 pagesHazop StudyNavaganesh KannappenNo ratings yet

- HAZOPDocument18 pagesHAZOPMark GuevarraNo ratings yet

- HAZOPDocument29 pagesHAZOParmdsfNo ratings yet

- Example: HAZOP Analysis of A Fueling Terminal For A BargeDocument4 pagesExample: HAZOP Analysis of A Fueling Terminal For A BargeBharat LalNo ratings yet

- HAZOP Study (Part I)Document4 pagesHAZOP Study (Part I)Saad Ahmed100% (1)

- Lecture HAZOP ExampleDocument29 pagesLecture HAZOP ExampleIbtida SultanaNo ratings yet

- Hazop StudyDocument18 pagesHazop StudyChaudhary KashifNo ratings yet

- HAZOPDocument43 pagesHAZOPChemsys Mail100% (1)

- Annexure - 1 - Propane - Hazop WorksheetDocument25 pagesAnnexure - 1 - Propane - Hazop WorksheetsugandhajayaswalNo ratings yet

- Toxic Release and Dispersion ModelsDocument42 pagesToxic Release and Dispersion ModelsAdeel RazaNo ratings yet

- HAZOPDocument11 pagesHAZOPNathan Naelz Sandy100% (1)

- HAZOP StudyDocument7 pagesHAZOP StudySara KhanNo ratings yet

- Safety Inherent DesignDocument68 pagesSafety Inherent Designsubirme100% (1)

- Safety LOPADocument28 pagesSafety LOPAnandorg1113100% (1)

- HAZOP Study (Part II)Document18 pagesHAZOP Study (Part II)Saad Ahmed100% (14)

- F EI Calculation WorkbookDocument51 pagesF EI Calculation WorkbookWu DangNo ratings yet

- HAZOPDocument35 pagesHAZOPRiyadh Saleh100% (1)

- LOPA and Risk Graphs For SIL DeterminationDocument11 pagesLOPA and Risk Graphs For SIL DeterminationShweta181No ratings yet

- 3.2 HazopDocument66 pages3.2 Hazops sanjai100% (1)

- Hazard and Operability Study (Hazop) : Dr. M. Azam SaeedDocument39 pagesHazard and Operability Study (Hazop) : Dr. M. Azam SaeedMuhammad Bilal100% (2)

- Puff and Plume ModelsDocument3 pagesPuff and Plume ModelsFathi MawardiNo ratings yet

- (3 1) PhaDocument61 pages(3 1) Phajcv235100% (1)

- 10.1 HazopDocument15 pages10.1 HazopEdna TanNo ratings yet

- Fire and Explosion NoteDocument56 pagesFire and Explosion NoteLevine98100% (1)

- Hazop Record Form: Condensate Lines From The Condensers To The Holding TankDocument3 pagesHazop Record Form: Condensate Lines From The Condensers To The Holding Tanksajni123No ratings yet

- Appendix-1 (HAZOPWorksheets)Document37 pagesAppendix-1 (HAZOPWorksheets)zohaib_farooq100% (1)

- Acetone MSDSDocument9 pagesAcetone MSDSCeline TheeNo ratings yet

- Introduction To HAZOPDocument39 pagesIntroduction To HAZOPapi-19846338100% (1)

- HAZID PresentationDocument11 pagesHAZID PresentationAlvian FachrurroziNo ratings yet

- HAZOP Study On Heavy Water Research Reactor Cooling SystemDocument6 pagesHAZOP Study On Heavy Water Research Reactor Cooling SystemKristomiDerMarine-IngenieurNo ratings yet

- Orica Engineering HAZOP Training Courses Training InformationDocument2 pagesOrica Engineering HAZOP Training Courses Training InformationAbusaada2012No ratings yet

- 161che572 L115 HazopDocument24 pages161che572 L115 HazopMalak HindiNo ratings yet

- Hazop Basic ConceptsDocument14 pagesHazop Basic ConceptsClaudio Sobarzo100% (1)

- Toxic Release and Dispersion ModelsDocument57 pagesToxic Release and Dispersion ModelsRaushan KumarNo ratings yet

- Hazop Training GuideDocument9 pagesHazop Training GuideAli RizviNo ratings yet

- Hazop-Pro 1.2 TutorialDocument34 pagesHazop-Pro 1.2 TutorialKishore SakhileNo ratings yet

- Guidelines for Integrating Process Safety into Engineering ProjectsFrom EverandGuidelines for Integrating Process Safety into Engineering ProjectsNo ratings yet

- Guidelines for Safe Automation of Chemical ProcessesFrom EverandGuidelines for Safe Automation of Chemical ProcessesNo ratings yet

- Quantitative Risk Assessment A Complete Guide - 2020 EditionFrom EverandQuantitative Risk Assessment A Complete Guide - 2020 EditionNo ratings yet

- AbsorptionStripping PDFDocument25 pagesAbsorptionStripping PDFJuan Camilo HenaoNo ratings yet

- 5 StereoisomersDocument37 pages5 StereoisomersAudrey Patrick KallaNo ratings yet

- Chemical Process DesignDocument93 pagesChemical Process DesignAudrey Patrick Kalla50% (2)

- Chapter 1 - Process DiagramsDocument36 pagesChapter 1 - Process Diagramsmrajim93No ratings yet

- Absorption ColumnsDocument55 pagesAbsorption ColumnsAudrey Patrick KallaNo ratings yet

- Safety and Security Emergency Plan For EVENTDocument11 pagesSafety and Security Emergency Plan For EVENTAudrey Patrick KallaNo ratings yet

- Ammonia StorageDocument6 pagesAmmonia Storagemsathishkm3911No ratings yet

- Ads or PtionDocument141 pagesAds or PtionAudrey Patrick KallaNo ratings yet

- Unit Operations and Processes in Environmental EngineeringDocument815 pagesUnit Operations and Processes in Environmental EngineeringAudrey Patrick Kalla89% (28)

- Chapter 10 - QDocument32 pagesChapter 10 - Qmohammedakbar88No ratings yet

- .Cost EstimationDocument15 pages.Cost EstimationAudrey Patrick KallaNo ratings yet

- EiaDocument16 pagesEiaAudrey Patrick KallaNo ratings yet

- Paint and Coating ProcessesDocument65 pagesPaint and Coating ProcessesAudrey Patrick Kalla100% (1)

- Heat ExchangerDocument16 pagesHeat ExchangerAudrey Patrick KallaNo ratings yet

- 84 enDocument6 pages84 enNomaan AsimNo ratings yet

- Magnetic Fields: PHYS102 Previous Exam ProblemsDocument11 pagesMagnetic Fields: PHYS102 Previous Exam ProblemsAudrey Patrick KallaNo ratings yet

- 09.electromagntic and Faraday Law - InductionDocument53 pages09.electromagntic and Faraday Law - InductionAudrey Patrick KallaNo ratings yet

- Paint Testing ChartDocument39 pagesPaint Testing ChartAudrey Patrick Kalla0% (1)

- Group 2 Main Control Valve: 1. StructureDocument26 pagesGroup 2 Main Control Valve: 1. StructurePower MobileNo ratings yet

- DYNA 70025 APECS Integrated Actuator: For Stanadyne "D" Series Injection PumpsDocument16 pagesDYNA 70025 APECS Integrated Actuator: For Stanadyne "D" Series Injection PumpsmichaeltibocheNo ratings yet

- Effect of J-Groove On The Suppression of Swirl Flow in A Conical DiffuserDocument8 pagesEffect of J-Groove On The Suppression of Swirl Flow in A Conical DiffuserYoung Do ChoiNo ratings yet

- ASCE 7-22 CH 13 - For PC - SouDocument57 pagesASCE 7-22 CH 13 - For PC - SousharethefilesNo ratings yet

- Design and Fabrication of Steering and Bracking System For All Terrain VehicleDocument12 pagesDesign and Fabrication of Steering and Bracking System For All Terrain Vehiclemikael bezerra cotias dos santosNo ratings yet

- Static Equipment EngineerDocument5 pagesStatic Equipment EngineerSakthikumar ChandrasekaranNo ratings yet

- AHU 3 PsychrometricDocument1 pageAHU 3 PsychrometricIzaaz AhamedNo ratings yet

- Stability and Control Iit KanpurDocument844 pagesStability and Control Iit KanpursankalpNo ratings yet

- Technical Service Information: Ford 4F27EDocument3 pagesTechnical Service Information: Ford 4F27EAranza SuNo ratings yet

- Kavalani Hvac R Catalogue 2015Document32 pagesKavalani Hvac R Catalogue 2015Anoop Jacob KunnappuzhaNo ratings yet

- (PDF) Jaquar Bathroom Fittings Price List 2021 PDF DownloadDocument1 page(PDF) Jaquar Bathroom Fittings Price List 2021 PDF DownloadNikhilesh ChakarwartiNo ratings yet

- Car Parts BasicsDocument24 pagesCar Parts Basicstoyota952No ratings yet

- Aerodynamic Analysis of NANO CarDocument4 pagesAerodynamic Analysis of NANO Carmanikandan_murugaiahNo ratings yet

- Schaeffler Diagram PDFDocument16 pagesSchaeffler Diagram PDFrajesh_14No ratings yet

- Clif Mock CompletoDocument4 pagesClif Mock CompletoJosé Luis CoronadoNo ratings yet

- Materials System SpecificationDocument9 pagesMaterials System SpecificationFAPM1285No ratings yet

- Duct CatalogDocument1 pageDuct CatalogRajendraPrajapatNo ratings yet

- Actuador Abb Up D-AAP-UP - EDocument36 pagesActuador Abb Up D-AAP-UP - EHumberto SerratoNo ratings yet

- Autoconer Automatic Winding MachineDocument8 pagesAutoconer Automatic Winding MachineAbhay KumarNo ratings yet

- Series Gu Control Valves Globe-Single Seated, Top Guided: ConstructionDocument16 pagesSeries Gu Control Valves Globe-Single Seated, Top Guided: ConstructionMichael H. PrevooNo ratings yet

- Estimation of Rock Engineering Properties Using Hardness TestsDocument10 pagesEstimation of Rock Engineering Properties Using Hardness TestsAbdul Bari ZiaNo ratings yet

- Parker Flow Meter PDFDocument2 pagesParker Flow Meter PDFDaniel MarNo ratings yet

- Powerplant QPDocument3 pagesPowerplant QPsrimuthu_22100% (1)

- TedDocument94 pagesTednethajiratnaNo ratings yet

- Water Tube Package BoilerDocument12 pagesWater Tube Package Boilerravish ravindran67% (3)

- SSP 211 New BeetleDocument48 pagesSSP 211 New BeetleAlexandru CraiovanNo ratings yet

- Service Manual: Tennant A80Document33 pagesService Manual: Tennant A80Павел КорчагинNo ratings yet

Hazop.1092475 Appendix 30.hazop

Hazop.1092475 Appendix 30.hazop

Uploaded by

Audrey Patrick KallaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazop.1092475 Appendix 30.hazop

Hazop.1092475 Appendix 30.hazop

Uploaded by

Audrey Patrick KallaCopyright:

Available Formats

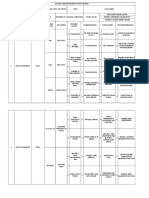

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 1. PGC Fill phase No. Deviation Cause

Ascot Environmental

Site

Page 1 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow (waste)

1 2

NO WASTE TOP DOOR FAILED

Plant shut down. Economic consequence

Storage on site surge piles

Hydraulic system has duty/stand-by Unable to load waste. Economic consequence from shut down of a single pump chamber. (refer to hydraulic system)

Two units on site. Service contract. 3 TELLY HANDLER FAILED Unable to load waste. Economic consequence from shut down of a single chamber. B More flow 1 TOO MUCH WASTE LOADED Waste could be drawn into the secondary Waste would burn off in secondary chamber. chamber. Waste material could block cross over duct. Visual check after loading to ensure ducts are clear. Depending on stage of rest of system. Too much air in secondary system and burners would ignite to maintain temperature. Emergency operation would be initiated by pressure differential. All fans in primary chambers and ID fans would shut down Interlock to prevent door opening with crossover valve open. 3 BURNERS START Health and safety issue. Waste would start to burn in open chamber. PLC interlock. Secondary hard wired switch for burner power to be considered. OSL to advise action on EEL PLC interlock. PLC interlock. Valve should be closed via PLC interlocks Interlock to prevent door opening with crossover valve open. EEL EEL/OSL EEL

EEL (SOP)

CROSS OVER VALVE OPEN

4 5 C Reverse flow 1

UNDER FANS START OVER FANS START GAS BACK THROUGH CROSS OVER

Odour issue but low volume. Odour issue but low volume. Flammable gases into open PGC. Health and safety issue.

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 1. PGC Fill phase No. Deviation Cause

Ascot Environmental

Site

Page 2 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

Also Flow

HAZARDOUS WASTE Explosion during burning sequence may Material is segregated during presupply stage. ITEMS (E.G. PROPANE cause damage to plant. GAS CYLINDER) ADDED Operators to be vigilant during TO CHAMBER loading. Waste may ignite when chamber is still CHAMBER NOT SUFFICIENTLY COOLED open PRIOR TO FILL (>100) Chamber to be emptied before loading High temperature interlock Chamber to be visually checked prior to fill. Chambers are only filled prior to operation.

EEL (SOP)

High Temperature

EEL (SOP)

Personnel Protection

1 Hand railing and or access for visual inspection and cleaning design to be risk assessed with respect to operation. Inadequate ventilation in building environment may lead to noxious/explosive gas build up (see also gasification phase below). Building design and ventilation to be reviewed. AEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 2. PGC Ignition phase No. Deviation Cause

Ascot Environmental

Site

Page 3 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow

ONE OR MORE DOORS Unable to start ignition. PLC will attempt Operator observation prior to closure NOT FULLY CLOSED to close doors hydraulically. Doors opened and fault rectified. CROSS OVER VALVE DOESNT OPEN (AUTOMATIC INITIATION) Unable to start ignition. Valve fault rectified. Non applicable

B C

Less Flow More flow

1 NO WASTE IN CHAMBER PGC wouldnt reach temperature inefficient operation. 1 POOR MIXING/ COMPOSITION OF WASTE

Operator training (note shift changeover)

Adverse pressure difference would Temperature may increase too rapidly and/or too high. Pressure difference may initiate emergency sequence. become adverse. High temperatures would cause under/over air shut down. Regular cleaning and maintenance EEL (SOP)

2 D No flow (under air) 1

LEAK THROUGH DOOR Leak wouldnt be high enough to cause OR OTHER SEAL any significant consequence FAN FAILURE

Reduced gasification rate. Burner would Alarm would sound and operator attempt to maintain/achieve temperature. would need to attend fault. Spare fan unit on site. Interlock to prevent burner from starting if fan is not available EEL EEL EEL (SOP)

BLOCKAGE IN DUCTING Total blockage is highly unlikely. More likely that a proportion of ducting would be blocked causing localised poor carbonisation. AUTO VALVE FAILED CLOSED Total blockage of duct.

Operator observation to spot poor carbonisation and blockages during de-ashing. Regular duct cleaning. Actuation method to be considered (pneumatic can fail in one direction) Closed limit switch to be included

EEL (SOP) EEL EEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 2. PGC Ignition phase No. Deviation Cause

Ascot Environmental

Site

Page 4 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

E F G H I 2 A

More flow (under air) Reverse flow (under air) More flow (over air)

1 OPERATOR STARTS AIR Airflow is initially too high. FLOW TOO HIGH 1 1 HIGHER PRESSURE IN Gas forced back down over air duct. PGC OVER AIR OUT OF SEQUENCE Waste would incinerate in PGC.

Maximum value cannot be exceeded during ignition. Non-return valve to be included in over air duct PLC prevents Over air running at this stage. Non-return valve to be included in over air duct EEL EEL

Reverse flow (over air) 1 Burner Flow Low temperature

HIGHER PRESSURE IN Gas forced back down over air duct. PGC

1 NOT ANALYSED, AS THIS IS A PROPRIETARY ITEM AND THERE ARE DUTY/STANDBY BURNERS. PLC WOULD ALARM IF BURNER DID NOT IGNITE. 1 BURNER FAILURE See above

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 3. PGC Gasification phase No. Deviation Cause

Ascot Environmental

Site

Page 5 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow

CROSS OVER VALVE CLOSED

PLC interlock on cross over valve ID fan would feedback to increase the under air fan flow, causing over pressure would shut fans/system down. in PGC. Obnoxious gas would leak SIL to be carried out and additional through doors etc. hard wired interlocks to fans to be included. Gas build up could be extremely explosive and dangerous. Economic consequence. Alarm would sound and operator would need to attend fault. Spare fan unit on site.

EEL/OSL

Less flow

UNDER AIR FAILURE

EEL

More flow

1 2

OVER AIR FAN STARTS Temperature would rise to incineration levels leading to poor gasification. TOO MUCH AIR DRAWN High temperature may trigger the next IN THROUGH OVER AIR stage FAN EXCESSIVE DRAFTS High temperature may trigger the next THROUGH DOOR LEAKS stage Gas generated and vented into building EMERGENCY VENT FAILS TO OPEN ON ID risking health hazard etc. FAN FAILURE

PLC interlock prevents Over air starting during this phase. Non-return valve will provide some resistance to minimise this. Shut off valve to be considered Maintenance and cleaning of doors. Emergency vent to be regularly maintained and inspected. SIL assessment to be carried out. Zoned study required for flammable gases. EEL

3 D Reverse flow 1

EEL(SOP) EEL (SOP) EEL/OSL OSL AEL

Also Flow

QUENCHING WATER INADVERTENTLY ADDED

Water added to assist rapid cool down if Quench water via a flexible hose temp is under 450C. Steam would drive (normally disconnected). Regulations to be checked up cross over duct. Door safety to be considered

DOOR ACCIDENTALLY Smoke/gas released into building OPENING

EEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 3. PGC Gasification phase No. Deviation Cause

Ascot Environmental

Site

Page 6 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

High Temperature

CONTROL SYSTEM FAILURE

Temperature rises, potentially up to 1300C.

Two temperature probes (duty/backup). Refractory lining capable of 1400C Note type and method to be reviewed EEL/OSL

B 3 A

Low temperature High pressure

1 1

UNDER AIR FAN FAILURE

Possible reduced temperature.

None required Spare fan available Top door lifts to relieve pressure, Limit switches would indicate opening event. Electrical equipment local to door to be designed to consider zoning. EEL EEL EEL

Spike increase in pressure in the PGC SMALL LOCALISED EXPLOSION FROM WASTE ITEM (E.G. GAS CANISTER)

Pressure fluctuation

CONTROL FAILURE

Pressure too high gives risk of explosion. Ensure adequate pressure control is Low pressure increases burner demand provided. on Secondary chamber Fine tuning during commissioning Fluctuating will cause release of smoke and gas through doors. Pressure too high gives risk of explosion. Ensure adequate pressure control is Low pressure increases burner demand provided. on Secondary chamber Fine tuning during commissioning Fluctuating will cause release of smoke and gas through doors.

POOR WASTE CONSISTENCY

EEL EEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 4. PGC Burn down phase No. Deviation Cause

Ascot Environmental

Site

Page 7 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow

CROSS OVER VALVE CLOSED

Temperature would feedback to increase PLC interlock on cross over valve would shut fans/system down. the under air fan flow, causing over pressure in PGC. Obnoxious gas would SIL to be carried out and additional leak through doors etc. hard wired interlocks to fans to be included. Gas build up could be extremely explosive and dangerous. Economic consequence. Alarm would sound and operator would need to attend fault. Spare fan unit on site.

EEL/OSL

Less flow

UNDER AIR FAILURE

EEL

OVER AIR FAILURE

Economic consequence (fails to speed up burn down phase).

Alarm would sound and operator would need to attend fault. Spare fan unit on site. EEL None required. Emergency vent to be regularly maintained and inspected. SIL assessment to be carried out. Zoned study required for flammable gases. EEL (SOP) EEL/OSL

C D

More flow Reverse flow

1 1

OVER AIR FAN TO FAST Temperature would reduce and trigger cool down too early. Gas generated and vented into building EMERGENCY VENT FAILS TO OPEN ON ID risking health hazard etc. FAN FAILURE

Also Flow

QUENCHING WATER INADVERTENTLY ADDED

Water added to assist rapid cool down if Quench water via a flexible hose temp is under 450C. Steam would drive (normally disconnected). Regulations to be checked up cross over duct. Door safety to be considered Two temperature probes (duty/backup). Refractory lining capable of 1400C

AEL

2 2 A High Temperature 1

DOOR ACCIDENTALLY Smoke/gas released into building OPENING CONTROL SYSTEM FAILURE Temperature rises, potentially up to 1300C.

EEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 4. PGC Burn down phase No. Deviation Cause

Ascot Environmental

Site

Page 8 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

B C

Low temperature Pressure fluctuation

1 1

UNDER AIR FAN FAILURE CONTROL FAILURE

Possible reduced temperature.

None required Spare fan available EEL EEL

Pressure too high gives risk of explosion. Ensure adequate pressure control is Low pressure increases burner demand provided. on Secondary chamber Fine tuning during commissioning Fluctuating will cause release of smoke and gas through doors.

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 5. PGC Cool down phase No. Deviation Cause

Ascot Environmental

Site

Page 9 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow

CROSS OVER VALVE CLOSED UNDER AIR FAILURE

Obnoxious gas would leak through doors PLC interlock on cross over valve would shut fans/system down. etc. Economic consequence. Cool down taking too long Economic consequence Cool down taking too long Alarm would sound and operator would need to attend fault. Spare fan unit on site. EEL Alarm would sound and operator would need to attend fault. Spare fan unit on site. EEL EEL

Less flow

OVER AIR FAILURE

More flow

OVER AIR TOO FAST DUE TO CONTROL FAILURE

Economic consequence Overall system Limiting factors for fans to be added flow imbalance after commissioning Emergency vent to be regularly maintained and inspected. SIL assessment to be carried out. Zoned study required for flammable gases.

Reverse flow

Gas generated and vented into building EMERGENCY VENT FAILS TO OPEN ON ID risking health hazard etc. FAN FAILURE

EEL (SOP) EEL/OSL

Also Flow

QUENCHING WATER INADVERTENTLY ADDED

Water added to assist rapid cool down if Quench water via a flexible hose temp is under 450C. Steam would drive (normally disconnected). Regulations to be checked up cross over duct. Door safety to be considered

AEL

DOOR ACCIDENTALLY Smoke/gas released into building OPENING

EEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 6. PGC Off phase (ash removal) No. Deviation Cause

Ascot Environmental

Site

Page 10 of 67 pages

Data sheet Ref: Check Sheet Ref Consequence

Facilitated By Reviewed By Safeguards

DATE: DATE: Action By

No Flow (ash)

1 2 3

DOOR FAILURE

Economic consequence. Unable to remove ash.

None required Regular maintenance/inspection More than one plough available Service contract Ash to be removed from front of chamber. Duct routing to be optimised to reduce risk of blockage. Duct size/flow to be optimised to reduce risk of blockage. EEL

PLOUGH BREAKDOWN Economic consequence. Unable to remove ash. CHAIN CONVEYOR FAILURE LINE BLOCKED Economic consequence. Unable to remove ash. Ash blocks suction line and ash dust is released from the ash conveyor.

No flow (ash suction line)

2 C Also Flow (ash) 1

MANUAL RESTRICTION No dust extraction VALVE CLOSED PLOUGH MOVES TOO Conveyor shroud damaged FAR AND DAMAGES CONVEYOR SHROUD WATER DAMPING FAILURE RESULTS IN ASH DUST RELEASE See water system.

Possible local dust extraction to be considered Plough access design to be reviewed to prevent plough from extending too far.

EEL EEL

High Temperature

DOORS OPENED TOO Ash >200C with risk to personnel and EARLY machinery

Interlock to door

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 7. SCC Cross over ducts (all) No. Deviation Cause

Ascot Environmental

Site

Page 11 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

A B

No Flow Less Flow

1 1

NOT CONSIDERED POSSIBLE LOCALISED POWER FAILURE ONE PGC (SAY) PGC Alarms Secondary air fans will reduce flow & burners will maintain temperature some steam generated economic consequences

Operator training & SOPs POOR SEQUENCING OF Secondary air fans will reduce flow & PGCS burners will maintain temperature some steam generated economic consequences POOR SEQUENCING OF PGCs out of sequence with too much PGCS gas being produced. High flow may cause high temperature. Feedback from ID fan to reduce the air flow through PGCs. High pressure will trip emergency vent. High temperature to bag house will trip emergency vent.

More flow

D 2 A B

Reverse Flow High Temperature Low temperature

1 SEE PGC NODES ABOVE 1 1 2 CONTROL SYSTEM FAILURE No consequence. Fans would maintain temperature Burners will maintain temperature Alarms on PGCs Burners will maintain temperature Alarms on PGCs Non required

POOR SEQUENCING OF Economic consequence. No PGCS consequence. LOW CV OF WASTE EXPLOSION IN PGC Economic consequence. No consequence. Volume of SCC will absorb pressure waves from PGCs

High Pressure

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 7. SCC Cross over ducts (all) No. Deviation Cause

Ascot Environmental

Site

Page 12 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

VENT FAILS TO OPEN

Damper on ID fan closes only when vent Consider manual operation of damper. feedback = open. PGC fans will stop. Gas will leak out of PGCs. Independent safety related, pressure triggered emergency fan shut down Consider gas monitoring for personnel protection to be considered Evacuation procedures to be developed

EEL OSL/AEL OSL/AEL OSL/AEL

Composition (gas)

OUT OF SPEC WASTE No consequence on secondary chamber GAS refer to down stream nodes.

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 8. SCC secondary Air No. Deviation Cause

Ascot Environmental

Site

Page 13 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow

BOTH FANS FAILURE

Temperature too high.

Fan failure alarm would sound Fans in PGC tripped If temperature continued to rise, the emergency vent would open. (Temperature/timings to be agreed & set during commissioning) EEL/OSL/ AEL EEL AEL/OSL/ EEL

Less Flow

ONE FAN FAILS

Temperature will rise as for no flow. Capacity can be reduced to 75% until new fan is installed.

Auto capacity reduction in all PGCs to be included. Note accessibility & lifting requirements for fans to be reviewed. Locking check valve to enable on-line maintenance/replacement?

More flow

FANS OVER SPEED

Alarm would sound. Pressure rises and temperature would drop. PGC will drop back on feed back Manual intervention to switch one fan from ID fan. Burners will start up on low off whilst fault is investigated. temperature. Economic consequence High pressure might force flammable gas Duct to ensure gas would be directed back through the fan. away from plant/electrics. Fan zoning to be reviewed. EEL OSL/EEL

Reverse flow

NRV FORCED OPEN

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 9. SCC Flue gas recirculation No. Deviation Cause

Ascot Environmental

Site

Page 14 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow

FAN FAILURE

Economical & environmental consequence. Air increases from fans to cool chamber resulting in more NOx, reduced throughput and higher flue gas to main stack. This will place higher demand on urea input.

Fan will alarm. Spare & replacement method to be reviewed Flue gas recirc to be sized similar to other demands to commonise spare parts. Isolation valves to be included for maintenance EEL/OSL/ AEL EEL

EEL EEL

BLOCKAGE

Economical & environmental consequence. Air increases from fans to cool chamber resulting in more NOx, reduced throughput and higher flue gas to main stack. This will place higher demand on urea input. Economical & environmental consequence. Air increases from fans to cool chamber resulting in more NOx, reduced throughput and higher flue gas to main stack. This will place higher demand on urea input. As above but less severe As above but less severe Reduced combustion due to lack of oxygen. Temperature would increase and NOx would reduce. Reduced combustion due to lack of oxygen. Temperature would increase and NOx would reduce.

Layout to be optimised to minimise the opportunity for blockage Secondary air fans would show high demand

NON-RETURN VALVE STUCK

Secondary air fans would show high demand Visual indication on NRV would indicate failure

Less flow

1 2

AS NO FLOW BUT PARTIAL FAILURES INVERTER FAILURE INVERTER FAILURE

As above. Feedback signal would indicate failure O2 Alarm from the CEM in stack Fan sized to prevent excessive recirculation. O2 Alarm from the CEM in stack Fan sized to prevent excessive recirculation.

More flow

OPERATOR ERROR

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 9. SCC Flue gas recirculation No. Deviation Cause

Ascot Environmental

Site

Page 15 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

Reverse flow

Safety arrangement to be included to NON RETURN VALVE Hot gas pushed back down to boiler FAILURE DURING HIGH exhaust. Safety issue as re-circ line and stop reverse flow on fan failure, and fan is not rated for higher temperatures consider route of FGR into secondary PRESSURE IN SCC air channel. Implication on secondary air fans to be considered if recirculation is taken back to that intake.

EEL

High Temperature

BOILER FOULED

This will gradually happen over time. FGR gas temp would rise

At 240C the emergency vent would open. FGR line designed to cope with 240C for a short period. EEL

BOILER CAPACITY EXCEEDED

FGR gas temp would rise

At 240C the emergency vent would open. FGR line designed to cope with 240C for a short period

Lower temperature

START UP & SHUT DOWN

Gas might corrode plant items

Cross over valves closed on start up.

EEL (SOP)

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 10 SCC De-NOx system No. Deviation Cause

Ascot Environmental

Site

Page 16 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow

FAILURE OF DE-NOX SYSTEM See separate HAZOP

Higher NOx emissions. The system can CEM would alarm run on 400mg/Nm3 for hour or daily De-NOx system would alarm. average of 200mg/Nm3 . Changeover valve to enable stream Batch would be completed and plant shut cross over if required. down. Mixing system to include buffer facilty Higher NOx emissions. The system can CEM would alarm run on 400mg/Nm3 for hour or daily Consider leaving air on to keep nozzle average of 200mg/Nm3 . clear. Batch would be completed and plant shut Nozzle location design to minimise down. risk of blockage. Urea solution boils off leaving residue which, builds up. Consider leaving air on to keep nozzle clear.

EEL EEL EEL

NOZZLE BLOCKAGE

3 B Less flow 1

HIGH TEMPERATURE NEAR NOZZLE AIR FAILURE

EEL

Atomisation would not occur reducing the Air alarm if total failure effective mixing. This might result in an NOx reduction might fail. increase in urea usage. CEMs are calibrated on 6 month minimum intervals.

Too much flow

CONTROL FAILURE OR Economic due to excessive urea use. FAULTY NOX READING SEPA limit on ammonia emission at 10mg/Nm3 for daily average, 20mg/Nm3 for hr average

2 UREA FLOWING DURING Urea may be wasted in secondary SHUT DOWN chamber. SEPA limit on ammonia emission at 10mg/Nm3 for daily average, 20mg/Nm3 for hr average

Ensure interlock to prevent urea addition below required temperature

EEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 10 SCC De-NOx system No. Deviation Cause

Ascot Environmental

Site

Page 17 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

Corrosion

LOW TEMPERATURE Corrosion of pipe work and possible leak. AROUND INLET CAUSING CONDENSATION FROM ACID GAS INCORRECT MAKEUP Ineffective or excessive use of urea.

Consider leaving air on to keep nozzle clear. Nozzle location design to minimise risk of gas condensate accumulation. Ensure make up system can be monitored.

EEL

Composition

EEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 11 SCC emergency vent No. Deviation Cause

Ascot Environmental

Site

Page 18 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow

VALVE FAILED CLOSED Massive gas leakages throughout system. Health & safety risk.

Manual override to force valve open. Valve is set to fail open. Ensure hydraulic accumulator is sized for two streams minimum. Duty/standby hydraulic motors. Additional independent system to be included. Independent direct hydraulic hand pump to be consider

EEL EEL EEL EEL OSL/AEL EEL

Reverse flow

VALVE FAILS OPEN

Air drawn into SCC causing temperature Limit switch on valve will prompt fans to drop and burners to come on in PGC and ID fan to shut down.

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 12 SCC gas through SCC No. Deviation Cause

Ascot Environmental

Site

Page 19 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

Thermal shock

E.G. COLD AIR DRAWN Damage to refractory if repeated DOWN HOT BY-PASS

Limit switch on stack will shut ID fan if open. Parameters fixed during operation to minimise risk

EEL EEL OSL/AEL

Composition

OUT OF SPEC O2 LEVELS

Incomplete combustion.

Investigate regulatory requirements. Provide measurement if required

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 13 Hydraulic pack for doors and valves No. Deviation Cause

Ascot Environmental

Site

Page 20 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow

NO OIL IN RESERVOIR Unable to operate hydraulic plant DUE TO LEAK including vents and doors.

Reservoir has level switches to indicate low level. Pressure switches in system will cause alarm to sound Unit located under secondary chamber and protected from mechanical damage Biodegradable oil to be used in case of spillage. Independent circuit and pipe route to emergency damper system required Emergency isolation valves to be included to isolate circuits. EEL/AEL/ OSL EEL/AEL EEL

COMMON SWITCH FAILURE

Pressure switches in system will Unable to operate hydraulic plant including vents and doors. Loss of level cause alarm to sound switches would prevent low level warning Ensure design of pack enables vent to open even on pack failure. Critical spares and oil to be kept on site. Contract with specialist for maintenance to be considered.

EEL

SYSTEM OFF FOR MAINTENANCE

Maximise independence of systems Common maintenance on some filters may require careful management of plant and ensure valves are included to allow on-line removal. outages. Dual/duplex filters to be provided Plant damage and blockage. Contract with specialist for maintenance to be considered.

EEL

EEL

Low flow

CONTAMINATED OIL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 13 Hydraulic pack for doors and valves No. Deviation Cause

Ascot Environmental

Site

Page 21 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

AMBIENT TEMPERATURE TOO LOW FILTER BLOCKED LOSS OF OIL

Viscosity to high.

Problem will be determined (if applicable) during commissioning, and heaters connected if required.

3 2 A Low level 1

Ineffective operation. Possible trip out on Contract with specialist for high pressure maintenance to be considered. Oil leaking on floor risking hazard and pollution. Bund system to be checked/ considered. EEL/AEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 14 Fuel system No. Deviation Cause

Ascot Environmental

Site

Page 22 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow

NO FUEL IN TANK

No operation economic consequence. Risk of compliance failure for temperature limit. If flame goes out in secondary there is a build up of residual gas.

Low-level and ultra low alarms in tank. Open vent interlock on low temperature on secondary chamber to reduce probability of explosion. Ensure plant is not started if fuel level is below minimal level. Ensure pumps dont trip on low level Pumps can run dry for a short period. EEL

EEL (SOP) OSL EEL EEL (SOP)

LINE BLOCKED DUE TO No operation economic consequence. NO STRAINER ON PUMP Risk of compliance failure for temperature limit. If flame goes out in INLET secondary there is a build up of residual gas. PUMP FAILURE No operation economic consequence. Risk of compliance failure for temperature limit. If flame goes out in secondary there is a build up of residual gas. No operation economic consequence. Risk of compliance failure for temperature limit. If flame goes out in secondary there is a build up of residual gas. Failure of this valve would result in No operation economic consequence. Risk of compliance failure for temperature limit. If flame goes out in secondary there is a build up of residual gas.

Add dual strainer between fuel tank and pumps Ensure strainers/filters are inspected and maintained on a regular basis. Duty standby pumps on auto changeover. Pumps started on alternate basis

EEL (SOP)

MANUAL VALVES CLOSED

Management of manual valves (locking etc) to be reviewed.

EEL (SOP)

AUTO VALVE

Remove actuator and replace with manual valve

EEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 14 Fuel system No. Deviation Cause

Ascot Environmental

Site

Page 23 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

6 PRESSURE REGULATOR Failure of this valve would result in No FAILS operation economic consequence. Risk of compliance failure for temperature limit. If flame goes out in secondary there is a build up of residual gas. 7 PIPE WORK LEAK No operation economic consequence. Risk of compliance failure for temperature limit. If flame goes out in secondary there is a build up of residual gas. Risk of oil spillage leading to health & safety issues B Less flow 1 No operation economic consequence. PUMPS RECIRCULATING IN PUMP Risk of compliance failure for temperature limit. If flame goes out in LOOP secondary there is a build up of residual gas. RETURN NRV STICKS No operation economic consequence. Risk of compliance failure for temperature limit. If flame goes out in secondary there is a build up of residual gas.

Provide manual isolating valves for maintenance. Provide manual bypass branch.

EEL EEL

Regulatory requirements and standards to be reviewed, with flanges/joints minimised if possible. Generally this is a low pressure system (1.5 bar)

EEL/OSL

Fit NRVs on pump outlets.

EEL

Delete NRV from return line and fit return with anti-siphon to tank.

Also Flow

CONTAMINATION FROM No operation economic consequence. WATER Risk of compliance failure for temperature limit. If flame goes out in secondary there is a build up of residual gas.

Filters have a water separation capability. Drain on tank below outlet with separate collection facility.

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 14 Fuel system No. Deviation Cause

Ascot Environmental

Site

Page 24 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

AIR LOCKS

No operation economic consequence. Risk of compliance failure for temperature limit. If flame goes out in secondary there is a build up of residual gas. No operation economic consequence. Risk of compliance failure for temperature limit. If flame goes out in secondary there is a build up of residual gas.

Design to be prepared to minimise the risk of air-locks.

Low temperature

WRONG FUEL STANDARD

Ensure correct standard of fuel is delivered according to season. This has implications on design of tank size. Local level indicator for delivery purposes. High level probe will cause actuated inlet valve to close and alarm Overflow will run to floor. Final location (outside) and method to be agreed. Local bund and rain cover required Dispense point to have a trigger action and manual override for fuel pumps. NOTE Standards regarding earth connections relevant to materials used to be reviewed and included

AEL/OSL

High level

1 OVERFILLING TANK DUE Fuel spilled on floor. TO FAULTY LEVEL INDICATOR

2 OVERFILLING VEHICLES Vehicle tank overfilled resulting in oil FROM FUEL TANK spillage

OSL/AEL OSL/AEL OSL/AEL OSL/AEL

Low level

OFFICE BOILER OIL SUPPLY

Office heating system runs off fuel oil and Storage method and location to be low level would result in heating failure investigated

OSL/AEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 15 Boiler system Super heaters No. Deviation Cause

Ascot Environmental

Site

Page 25 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow (gas)

EMERGENCY VENT OPENED

Reduced operation. Economic consequence. Cold start could take 3-4 hours Hot start would take 20-30 mins.

None required.

Low flow (gas)

Water spray unit will control to a point START UP/ABNORMAL Super heater temperature will rise and CONDITIONS cause possible damage to super heaters. (to be advised). This will happen on start up for up to UHTemp will alarm and steam vented 2-3 hrs. via high temperature vent valve. Route and termination of vent to be decided. TOO MUCH GAS Economical consequences. Emergency Vent will be opened by either high exhaust temp or low gas pressure ID fans will trip if vent is opened.

TIBS AEL/TIBS

More Flow (gas)

Low temperature (gas) High temperature (gas)

EMERGENCY VENT OPEN AND COLD AIR DRAWN IN

Reduced operation. Economic consequence. Reduce plant life from thermal shocks.

ABNORMAL UPSTREAM 1400C is the limit of refractory material in ducting. CONDITION (SEE ABOVE) Super heater would cope with temperatures up to 1200C for a short period but with a reduced life. RAPID TEMP RISE DURING WARM UP ID FAN PULLING AGAINST DEAD END Damage to plant from thermal shock Possible plant damage.

UHTemp will alarm and steam vented via high temperature vent valve. Route and termination of vent to be decided. Thermal loadings between SCC and boiler to be matched through dialogue Ensure ID fan doesnt exceed design pressures (+/- 100mBarg)

AEL/TIBS

2 3 A Low Pressure (gas) 1

EEL/TIBS EEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 15 Boiler system Super heaters No. Deviation Cause

Ascot Environmental

Site

Page 26 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

Poor composition (gas)

EXCESSIVE PARTICULATES,

Sticky deposits caused by sodium and potassium elements blockage and erosion of plant. Stickiness is also affected by temperature Loss of performance

Gasification design to minimise the particulate. Retrofit of soot blower to be provisioned for. Note design spec is 25mg/m3 of soot, which is considered low. Ash analysis facility will be available on site. Design parameters are set to ensure levels are correct. Mixing waste prior to processing will assist levels are optimised. TIBS AEL TIBS

2 EXCESSIVE CORROSIVE Chlorine & fluorides etc can reduce the PRODUCTS life of the plant.

A B C

No Flow (steam) Less flow (steam) More flow (steam)

VALVE CLOSED

Super heaters over heating and destroyed.

Pressure relief valves open.

1 SEE ABOVE 1 TURBINE, VENT OR Economic consequence if steam goes to Flow and temperature measurement CONDENSER OPENING waste designed to balance. Turbine trips on low steam pressure. FLOW BACK FROM SECOND BOILER. Economic consequence Steam drum overflows NRV on header.

D 6 7 A A

Reverse flow High & low temperature High Pressure

1 SEE ABOVE 1 2 VALVE CLOSED TURBINE TRIP VALVE Pressure would be exceeded and the plant damaged. Health & safety risk Pressure would be exceeded and the plant damaged. Health & safety risk Relief valves on drum & line. Relief valves on drum & line.

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 16 Boiler System boiler & drum No. Deviation Cause

Ascot Environmental

Site

Page 27 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

1 2

A A

More Flow (gas) Poor composition (gas)

1 EXCESS GAS THROUGH Possible plant damage SYSTEM 1 EXCESSIVE PARTICULATES, Sticky deposits caused by sodium and potassium elements blockage and erosion of plant. Stickiness is also affected by temperature Loss of performance

Flow limited by design of ID fan. Gasification design to minimise the particulate. Retrofit of soot blower to be provisioned for. Note design spec is 25mg/m3 of soot, which is considered low. Ash analysis facility will be available on site. TIBS

No Flow (water from economiser)

SUPPLY VIA ECONOMISER LOST (SEE BELOW)

Level in drum falls, high risk of explosion Low level alarm sounds in boiler. Health & safety consequences. Low low level trips system. High integrity safety trip required to trip ID fan & vent valve. Flow alarm to be considered on water supply to economiser EEL/TIBS/ OSL OSL/TIBS

More flow (water from economiser)

BLOW DOWN FAILURE Water level in boiler increases. Water carried through to super heater and turbine plant damage. (Note turbine has its own protection against water carry over)

Level control system with high level alarm and high high level dump valve opens if alarm for a period of time. Consider steam trap in dump line as alternative option. Consider steam trap in dump line as alternative option. TIBS

LEVEL CONTROL FAILURE

Water level in boiler increases. Water carried through to super heater and turbine plant damage. (Note turbine has its own protection against water carry over)

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 16 Boiler System boiler & drum No. Deviation Cause

Ascot Environmental

Site

Page 28 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

TUN DISH MANUAL VALVE CLOSED

Water level in boiler increases. Water carried through to super heater and turbine plant damage. (Note turbine has its own protection against water carry over)

Consider removing or repositioning valve and ensuring valves suitable for on-line maintenance..

Reverse flow (water from economiser) No Flow (to blow down

Steam/water leaking from economiser or NRV on water inlet to drum. BREAK IN LINE TO ECONOMISER OR PUMP pipe. Pumps have inbuilt NRVs. FAILURE VALVES CLOSED Concentration of solids in boiler increases causing carry over to super heater Water sampled every day. Conductivity meter required with alarm to control blow down Water supply is from RO plant and therefore low in solids. TIBS

More flow (to blow down) Excess cooling water flow (to blow down) Low cooling water flow (to blow down)

1 2 3 1

VALVE STUCK OPEN. CONTROL FAILURE COOLING WATER SUPPLY FAILS AS SUPER HEATER ABOVE RO PLANT FAILURE

Water waste economic consequence Economic consequence due to water tanking costs.

High integrity valves used. Thermostatic valve. TIBS TIBS/OSL

Blow down vessel would become hot with Temperature probe to alarm and trip excessive steam released. ash water pumps Plant rupture Health & safety risk Two PRVs on drum and one on super heater. High pressure alarm

High pressure

TIBS TIBS

Composition (feed water)

Concentration of solids in boiler increases causing carry over to super heater

Water sampled every day. Conductivity meter required with alarm to control blow down

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 16 Boiler System boiler & drum No. Deviation Cause

Ascot Environmental

Site

Page 29 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

Corrosion (water side) 1

FEED WATER DOSING Low pH, high hardness or excessive FAILURE oxygen causes internal (water side) corrosion.

Daily water checks

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 17 Boiler System Economiser No. Deviation Cause

Ascot Environmental

Site

Page 30 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

More flow (gas)

1 EXCESS GAS THROUGH Steaming in economiser causing water SYSTEM hammer and mechanical damage. Outlet gas temperature too high for bagging stage. (bags can cope with 220C for short period)

Gasifier system design to limit throughput on high temperature.

EEL

High temperature (gas)

DIRT INSIDE ECONOMISER

Gasifier system design to limit Outlet gas temperature too high for bagging stage. (bags can cope with 220C throughput on high temperature. for short period) See poor composition below. Sticky deposits caused by sodium and potassium elements blockage and erosion of plant. Stickiness is also affected by temperature Loss of performance Gasification design to minimise the particulate. Retrofit of soot blower to be provisioned for. Note design spec is 25mg/m3 of soot, which is considered low. Ash analysis facility will be available on site.

EEL

Poor composition (gas)

EXCESSIVE PARTICULATES,

TIBS

2 EXCESSIVE CORROSIVE Sulphur oxides etc can reduce the life of Design parameters are set to ensure PRODUCTS the plant. levels are correct. Mixing waste prior to processing will assist levels are optimised. Boiler feed water pre-heated to reduce the risk of condensing acidic deposits.

TIBS AEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 17 Boiler System Economiser No. Deviation Cause

Ascot Environmental

Site

Page 31 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No flow (water)

BOILER WATER FEED FAILED

Steaming in economiser causing water hammer and mechanical damage. Possible damage to recirc pump and system.

At high temperature, the emergency vent would trip Consider means of tripping on loss of water flow prior to high temperature and include trip of recirc pump

EEL TIBS/OSL

Outlet gas temperature too high for bagging stage. (bags can cope with 220C Boiler water feed pumps are duty/stand-by. (See water feed node) for short period)

Flow alarm to be considered on water supply to economiser 2 CONTROL VALVE FAILS Steaming in economiser causing water CLOSED hammer and mechanical damage. Possible damage to recirc pump and system. At high temperature, the emergency vent would trip Boiler water feed pumps are duty/stand-by. (See water feed node)

TIBS/OSL EEL

Flow alarm to be considered on water Outlet gas temperature too high for bagging stage. (bags can cope with 220C supply to economiser for short period) 5 A High temperature (water from economiser) Low temperature (water from economiser) 1 LOW WATER FLOW FROM CONTROL SYSTEM FAILURE Pulse steam/water causing vibration and Temperature control method on possible mechanical damage. recirculation loop.

TIBS/OSL

TIBS

RECIRC PUMP TRIPPED Outlet gas temperature rises too high for Spare pump to be available. bagging stage. (bags can cope with 220C Pump stop alarm for short period) Cold water through economiser may cause acid deposit condensation

TIBS/AEL TIBS

High water pressure

1 INLET VALVE TO BOILER Pumps can develop up to 60bar with risk PRV fitted to economiser header CLOSED of economiser damage

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 18 Boiler to bag filter No. Deviation Cause

Ascot Environmental

Site

Page 32 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

A B

No Flow (gas) Reverse flow (gas) High temperature (gas)

1 1 1

SEE ABOVE SEE ABOVE SEE ABOVE

Bi-carb & carbon build up in line Bi-carb & carbon drawn back into boiler causing sticky deposits. Bag filter damage.

ID fan stop causes dosing & recirc stop. ID fan has damper, which will close. High temperature trip to emergency vent. Generally as described above. See SCC Node

2 HOT GAS PULLED FROM Bag filter damage SECONDARY CHAMBER DOWN RECIRC LINE B Low temperature (gas) Composition 1 SEE ABOVE Potential corrosion due to acidic condensate No reaction in tower and breach of regulations for emissions Economic consequence

Bag house is coated for protection. Shutdown on low temperature at end of batch CEM feedback would alarm and system would need to be shut down if problem not promptly resolved. System design prevents excessive use of material. Operator training EEL (SOP) EEL (SOP)

NO BI-CARB AND/OR CARBON FLOW TOO MUCH BI-CARB AND/OR CARBON

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 19 Bicarbonate storage to line hopper No. Deviation Cause

Ascot Environmental

Site

Page 33 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow

NO BI-CARB IN SILO

No reaction in tower and breach of regulations for emissions

Silo level alarms and daily supply contract. 3-4 days storage capacity. CEM feedback would alarm and system would need to be shut down if problem not promptly resolved. Consider standby bagged material of pre-mix bicarb/carb AEL

NO CONVEYING AIR

No reaction in tower and breach of regulations for emissions

3-4 hours capacity in line silos Cross over facility in lines. Consider standby bagged material of pre-mix bicarb/carb

CROSS OVER IN WRONG POSITION

No reaction in tower and breach of regulations for emissions

Line hopper alarms on low level. Consider standby bagged material of pre-mix bicarb/carb CEM feedback would alarm and system would need to be shut down if problem not promptly resolved

BLOCKAGE

No reaction in tower and breach of regulations for emissions

Line hopper alarms on low level. Consider standby bagged material of pre-mix bicarb/carb CEM feedback would alarm and system would need to be shut down if problem not promptly resolved

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 19 Bicarbonate storage to line hopper No. Deviation Cause

Ascot Environmental

Site

Page 34 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

SILO DISCHARGE FAILURE

No reaction in tower and breach of regulations for emissions

Line hopper alarms on low level. Consider standby bagged material of pre-mix bicarb/carb CEM feedback would alarm and system would need to be shut down if problem not promptly resolved Consider manual facility for feeding bicarb directly into bag house/gas duct EEL/AEL

More flow

1 LEVEL SWITCH FAILURE Line silo would over fill and block line. IN LINE HOPPER 1 AIR FLOW BACK INTO Dust in atmosphere STORAGE METERING HOPPER BLOCKED MAIN SILO FILTER Relief valve would cause dust in atmosphere

Blower flow switch would cut out Consider Hi-Hi level alarm on line hopper. Metering rotary valve and/or other prevention system in metering hopper discharge Ensure filter has alarm. Ensure clean up facility available (minimal water usage) Consider CCTV for silo top Consider ways of disposing of waste water OSL OSL AEL AEL/EEL OSL OSL AEL/EEL OSL

Reverse flow

High Pressure

BLOCKED LINE SILO FILTER

Relief valve would cause dust in atmosphere

Ensure filter has alarm. Ensure clean up facility available (minimal water usage) Consider ways of disposing of waste water

Low Pressure

BLOCKED FILTER

Possibility of pulling vacuum and damaging silo

Consider vac relief on silo

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 19 Bicarbonate storage to line hopper No. Deviation Cause

Ascot Environmental

Site

Page 35 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

3 4

A A

High Level Composition

1 1 2

OVERFILL DURING LOADING

Damage filter and dust to atmosphere through relief valve

Local alarms and standards

INCORRECT MATERIAL Ineffective reactions leading to regulation Quality and purchasing control. SUPPLIED breach. LIME/BICARB MIX Bicarb or lime not cleaned out on changeover. Mix would tend to clump causing ineffective reactions. Quality control and operator training.

3 5 A Erosion 1

CAKED MATERIAL ABRASION BY MATERIAL

Prolonged storage may cause material to Check availability of silo emptying cake and block silos/lines (see above) contractors. Wear of plant & pipe work Unlikely due to fine nature of material and experience indicates this is not an issue.

AEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 20 Bicarbonate line hopper to gas line No. Deviation Cause

Ascot Environmental

Site

Page 36 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

Reverse flow

HOT GAS BACK UP THROUGH ROTARY VALVES

Damage to line silos

Rotary valve prevents reverse flow.

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 21 Cooling Tower Water make up No. Deviation Cause

Ascot Environmental

Site

Page 37 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow to CT

PUMP FAILURE

Cooling tower failure would result in condenser failure and turbine boiler shutdown Returning hot water would damage cooling tower.

Pond holds water sufficient for 4-6hrs operations. Relief valve on condenser Blow down from cooling tower will stop. Consider tripping emergency vent valves on low-low CT pond level and tripping level. Consider manual emergency water supply to CT pond. Boxed spare pump available. Level alarms in CT pond will sound. AEL/OSL

AEL/OSL

BALL VALVE FAILS CLOSED

Cooling tower failure would result in condenser failure and turbine boiler shutdown Returning hot water would damage cooling tower.

Pond holds water sufficient for 4-6hrs operations. Relief valve on condenser Blow down from cooling tower will stop. Consider tripping emergency vent valves on low-low CT pond level and tripping level. Consider manual emergency water supply to CT pond. Boxed spare pump available. Consider dual ball valves Level alarms in CT pond will sound. SPX AEL/OSL

AEL/OSL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 21 Cooling Tower Water make up No. Deviation Cause

Ascot Environmental

Site

Page 38 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

BORE HOLE PUMP FAILURE

Cooling tower failure would result in condenser failure and turbine boiler shutdown Returning hot water would damage cooling tower.

Pond holds water sufficient for 4-6hrs operations. Relief valve on condenser Blow down from cooling tower will stop. Consider tripping emergency vent valves on low-low CT pond level and tripping level. Consider manual emergency water supply to CT pond. Boxed spare pump available. Two bore holes available Level alarms in CT pond will sound. AEL/OSL

AEL/OSL

BORE HOLE FAILURE

Cooling tower failure would result in condenser failure and turbine boiler shutdown Returning hot water would damage cooling tower.

Pond holds water sufficient for 4-6hrs operations. Relief valve on condenser Blow down from cooling tower will stop. Consider tripping emergency vent valves on low-low CT pond level and tripping level. Consider manual emergency water supply to CT pond. Two bore holes available Level alarms in CT pond will sound. AEL/OSL

AEL/OSL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 21 Cooling Tower Water make up No. Deviation Cause

Ascot Environmental

Site

Page 39 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

VALVE CLOSED

Cooling tower failure would result in condenser failure and turbine boiler shutdown Returning hot water would damage cooling tower.

Pond holds water sufficient for 4-6hrs operations. Relief valve on condenser Blow down from cooling tower will stop. Consider tripping emergency vent valves on low-low CT pond level and tripping level. Consider manual emergency water supply to CT pond. Level alarms in CT pond will sound. AEL/OSL

AEL/OSL

PIPE BLOCKED/ BROKEN

Cooling tower failure would result in condenser failure and turbine boiler shutdown Returning hot water would damage cooling tower.

Pond holds water sufficient for 4-6hrs operations. Relief valve on condenser Blow down from cooling tower will stop. Consider tripping emergency vent valves on low-low CT pond level and tripping level. Consider manual emergency water supply to CT pond. Level alarms in CT pond will sound. AEL/OSL

AEL/OSL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 21 Cooling Tower Water make up No. Deviation Cause

Ascot Environmental

Site

Page 40 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

PIPE FROZEN

Cooling tower failure would result in condenser failure and turbine boiler shutdown Returning hot water would damage cooling tower. Only likely during winter shut downs resulting in start up problems. Condition of bore hole water and size of main reduce this possibility.

Pond holds water sufficient for 4-6hrs operations. Relief valve on condenser Blow down from cooling tower will stop. Consider tripping emergency vent valves on low-low CT pond level and tripping level. Consider manual emergency water supply to CT pond. Level alarms in CT pond will sound. Pipe work lagged and ability to drain down during shut down to be considered. AEL/OSL AEL/OSL

AEL/OSL

More flow

BALL VALVE FAILS OPEN ABNORMAL USE PUMPING AGAINST CLOSED VALVES

Excessive water usage and environmental contamination. Extraction license exceeded. Damage to pumps and pipe work

Over flow cut out to run towards surface drain and to lined pond. High-level alarm in CT pond. Flow meter(s) and alarm on both extraction systems. Investigate pump type. Ultimate low level will trigger towns water top up (manual or automatic). Consider option to blend towns water with high level shut off.

AEL/OSL

2 3 4 5

A A A A

More flow (bore hole water) High pressure Low level Composition

1 1 1 1 2

AEL/OSL AEL/OSL AEL/OSL AEL/OSL AEL/SOL

BORE HOLE HOLDING (See no flow above) TANK RUNNING LOW POOR BORE HOLE WATER CONDITION Poor mineral content of water will affect plant and operation

PARTICULATE CARRY Build up of debris on cooling towers and Consider in-line filter(s) water tanks OVER FROM BORE HOLES

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 22 Cooling Tower Chemical dosing No. Deviation Cause

Ascot Environmental

Site

Page 41 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No Flow

DOSING PACKAGE FAILURE

Potential Legionella Health & safety. Fouling of system.

Regular QC checks on CT water.

SPX/AEL

Global alarm on failure of package. Note plant would need to be failed for Towers to be shut down and cleaned a long period to cause problems on a regular basis (using one off line) Potential Legionella Health & safety. Fouling of system. Note plant would need to be failed for a long period to cause problems Purchasing and storage controls/ management. AEL

NO CHEMICALS

MEASUREMENT SYSTEM FAILURE

Potential Legionella Health & safety. Fouling of system. Note plant would need to be failed for a long period to cause problems

Manual dosing facility Global alarm on failure of package.

BLOCKAGE

Potential Legionella Health & safety. Fouling of system.

Regular QC checks on CT water.

SPX/AEL

Global alarm on failure of package. Note plant would need to be failed for Towers to be shut down and cleaned a long period to cause problems on a regular basis (using one off line) 5 PIPE RUPTURE Potential Legionella Health & safety. Fouling of system. Local bund protection for spillage. Regular QC checks on CT water. Global alarm on failure of package. SPX/AEL

Towers to be shut down and cleaned Note plant would need to be failed for on a regular basis (using one off line) a long period to cause problems B More flow 1 MEASUREMENT SYSTEM FAILURE OR EXCESSIVE PUMP RUNNING Chemical waste/cost Environmental impact Efficiency of plant would be reduced. Global alarm on failure of package. Regular QC checks on CT water. Water chemistry contractor required. AEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 22 Cooling Tower Chemical dosing No. Deviation Cause

Ascot Environmental

Site

Page 42 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

Also Flow

INCORRECT Mixing chemicals creates specific health Use specialist chemical contractor with appropriate in-house procedures. CHEMICALS TO TANKS hazards as well as give poor water treatment.

AEL

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 23 Cooling Tower RO plant No. Deviation Cause

Ascot Environmental

Site

Page 43 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No flow from RO plant 1 to CT pond 2

PUMPING FAILURE

Backwash tank overflow to pond without Check if conductivity probe will alarm. processing. Concentration of chemicals Regular QC checks on CT water and organic compounds increases. Concentration of chemicals and organic compounds increases. Check if conductivity probe will alarm or shut valve. Regular QC checks on CT water Check if conductivity probe will alarm. Regular QC checks on CT water Loss of blow down alarm required Control system alarm required Consider High temperature alarm and remedial action.

SPX

NO BLOW DOWN WATER DUE TO CONDUCTIVITY FAILURE.

SPX

Concentration of chemicals and organic NO BLOW DOWN WATER DUE TO VALVE compounds increases. FAIL CLOSED RO DRAIN/LEAK FAILED Higher demand on make up water OPEN CONTROL SYSTEM FAILURE WATER RETURN TOO HOT (>60C) FREEZING AMBIENT CONDITIONS Higher demand on make up water Economic consequence Consent limit exceeded. Possible damage to RO plant.

SPX

4 2 3 A A B High flow from RO plant High temperature Low temperature 1 1 1

SPX SPX SPX SPX/AEL

Water in line may freeze where exposed Pipe work to be lagged where required to external conditions. Processing unit located within building. Concentration of chemicals and organic compounds increases. Regular QC checks on CT water Regular backwash Consider a filter on bleed line to RO plant.

4 5

A A

High pressure Composition

1 COVERED WITHIN RO PACKAGE 1 RO ACTION FAILED AEL AEL SPX

HAZOP STUDY RESULT SHEET

Lorien Engineering Solutions Ltd

STUDY AREA Energy From Waste Facility SUB-SYSTEM OR NODE 24 Condenser/cooling tower Loop No. Deviation Cause

Ascot Environmental

Site

Page 44 of 67 pages

DATE: 29th Oct 2007 DATE: Action By

Data sheet Ref: 1188_ 93610 Check Sheet Ref 1188_93611 Consequence

Facilitated By A G Cooper Reviewed By Safeguards

No flow

PUMP FAILURE

No water to condenser and turbine resulting in plant damage

Stand by pump (+ 2 x duty) PRV on condenser Check turbine operating period without cooling water and fit rips accordingly. Ensure pump will auto changeover on failure Consider need for direct emergency vent operation on loss of flow/pumping facility. OSL

OSL OSL

WATER LOSS

No water to condenser and turbine resulting in plant damage

See previous node (water make-up) Ensure low level in pond doesnt trip all pumps OSL

VALVES CLOSED (PUMPS)